Oklahoma Soil Fertility Handbook

- Jump To:

- Chapter 1 - Soil and Soil Productivity

- Chapter 2 - Essential Plant Nutrient Functions, Soil Reactions and Availability

- Chapter 3 - Problem Soils

- Reclamation

- Reclamation

- Chapter 4 - Determining Fertilizer Needs

- Chapter 5 - Fertilizer Use in Oklahoma

- Chapter 6 - Use of Animal Manure as Fertilizer

- Chapter 7 - Environmental Concerns Associated with Fertilizer Use

- Chapter 8 - Land Application of Drilling Mud

- Chapter 9 - Long-term Fertility Research

- Chapter 11 - Nitrogen-Rich Strips, GreenSeeker Sensor and Sensor-Based Nitrogen Rate Calculator

- Chapter 12 - Laws and Acts Governing the Marketing of Fertilizer, Lime and Soil Amendments in Oklahoma

Chapter 1 - Soil and Soil Productivity

Jason Warren

Soil is perhaps the most important natural resource in Oklahoma. It is important to all, for without soil there would be no life on Earth. Our food and much of our clothing and shelter come from soil. Soil supports the gigantic agricultural system, which is the major contributor to the state’s development and continued prosperity.

Oklahoma has a land area of more than 44 million acres, part of which is covered by

water. The majority, about 41 million acres, is used for production of food and fiber.

This land has an average value of more than $400 per acre or a total value in excess

of $16.4 billion. It is an asset well worth protecting.

Many different kinds of soil occupy this land area. Some soils are extremely productive,

while others are not as productive. Each soil has a set of unique characteristics

that distinguishes it from other soils. These characteristics determine the potential

productivity of the soil.

Soil productivity is a result of how well the soil is able to receive and store moisture

and nutrients, as well as providing a desirable environment for all plant root functions.

What is Soil?

Soil is the unconsolidated mineral and organic material on the immediate surface of the Earth which provides nutrients, moisture and anchorage for land plants.

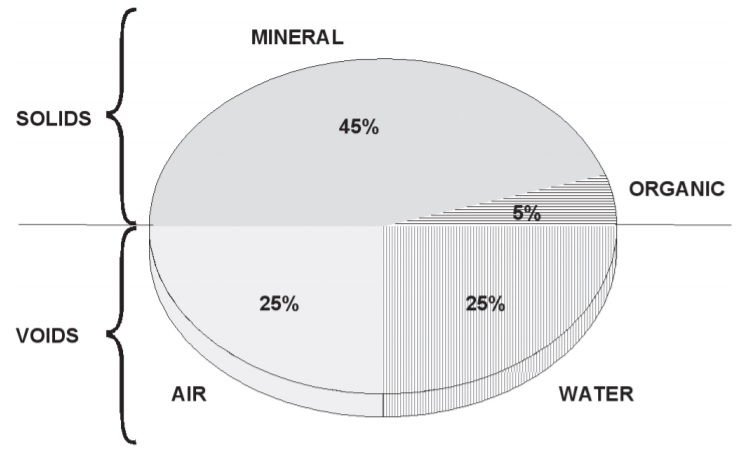

The principal components of soil are mineral material, organic matter, water and air.

These are combined in widely varying amounts in different soils. In a typical loam

soil, solid material and pore space are equally divided on a volume basis, with the

pore space containing nearly equal amounts of water and air. The approximate proportions

are illustrated in Figure 1.1.

How Soils are Formed

The development of soils from parent rock is a long-term process involving physical and chemical weathering along with biological activity. The wide variety of soils and their properties are a function of the soil forming factors including parent material, climate, living organisms, topography and time.

The initial action on the parent rock is largely mechanical-cracking and chipping

due to temperature changes. As the rock is broken, the total surface area exposed

to the atmosphere increases. Chemical action of water, oxygen, carbon dioxide and

various acids further reduce the size of rock fragments and change the chemical composition

of many resulting particles. Finally, the microorganism activity and higher plant

and animal life contribute organic matter to the weathered rock material, and a true

soil begins to form.

Figure 1.1: Volume composition of a desirable surface soil.

Since all of these soil-forming agents are in operation constantly, the process of soil formation is continual. Evidence indicates the soils we depend on today to produce our crops required hundreds or even thousands of years to develop. In this regard, consider soil as a nonrenewable resource measured in terms of man’s life span. Thus, it is very important to protect soils from destructive erosive forces and nutrient depletion, which can rapidly destroy the product of hundreds of years of nature’s work, as well as greatly reduce soil productivity.

Soil Profile

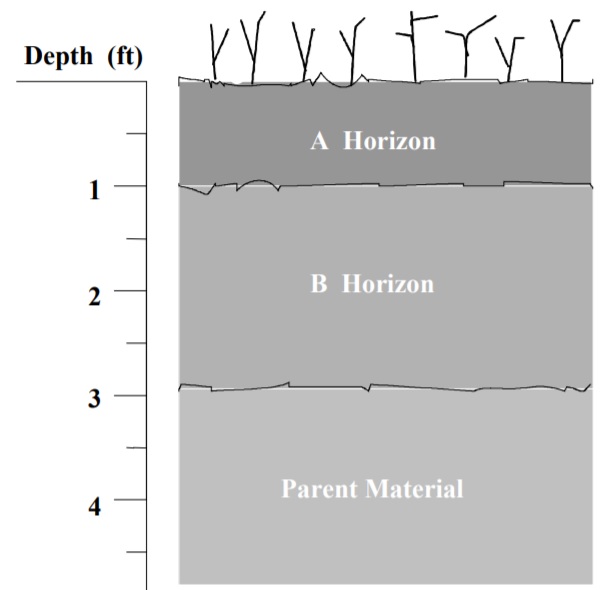

A vertical cross-section through a soil typically represents a layered pattern. This section is called a “profile” and the individual layers are called “horizons.” A typical soil profile is illustrated in Figure 1.2.

Figure 1.2: A typical soil profile.

The uppermost layer includes the surface soil or topsoil and is designated the ‘A’ horizon. This is the layer which is most subject to climatic and biological influence. It usually IS the layer of maximum organic accumulation, has a darker color, and has less clay than subsoil. The majority of plant roots and most of the soil’s fertility are contained in this horizon.

The next successive horizon is called the subsoil or ‘B’ horizon. It is a layer that

commonly accumulates materials that have migrated downward from the surface. Much

of the deposition is clay particles, iron and aluminum oxides, calcium carbonate,

calcium sulfate and possibly other salts. The accumulation of these materials creates

a layer that is normally more compact and has more clay than the surface. This often

leads to restricted movement of moisture and reduced crop yields.

The parent material, or ‘C’ horizon is the least affected by physical, chemical and

biological weathering agents. It is very similar in chemical composition to the original

has formed in its original position by weathering of bedrock is termed “residual;”

or transported if it has been moved to a new location by natural forces. This latter

type is further characterized on the basis of the kind of natural force responsible

for its transportation and deposition. When water is the transporting agent, the parent

materials are referred to as alluvial (stream deposited). This type is especially

important in Oklahoma. These are often the most productive soils for agricultural

crops. Wind-deposited materials are called aeolian.

Climate has a strong influence on soil profile development. Certain characteristics

of soils formed in areas of different climates can be described. For example, soils

in western Oklahoma are drier and tend to be coarser textured, less well developed

and contain more calcium, phosphorus, potassium and other nutrients than do soils

in the humid eastern part of the state.

The soil profile is an important consideration in terms of plant growth. The depth

of the soil, its texture and structure, its chemical nature as well as the soil position

on the landscape and slope of the land largely determine crop production potential.

The potential productivity is vitally important in determining the level of fertilization.

Soil Texture

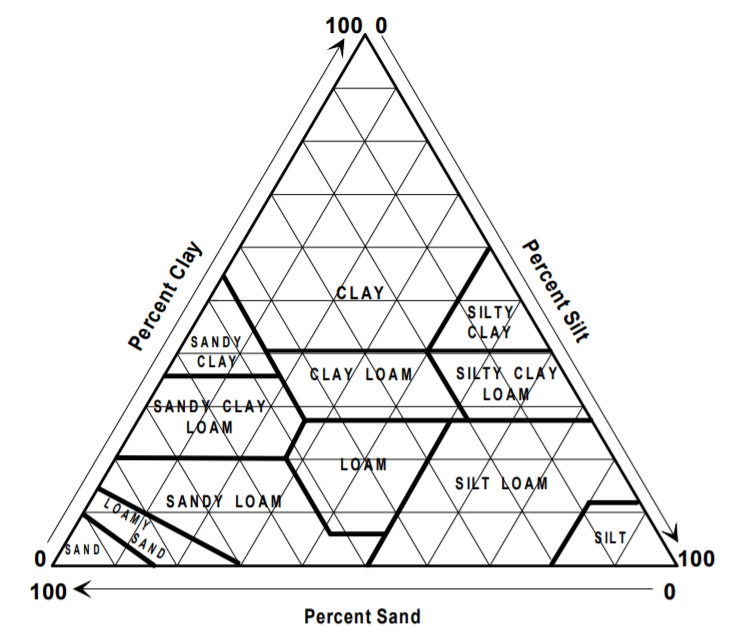

Soils are composed of particles with an infinite variety of sizes. The individual particles are divided by size into the categories of sand, silt and clay. Soil texture refers to the relative proportion of sand, silt and clay in the soil. Textural class is the name given to soil, based on the relative amounts of sand, silt and clay present, as indicated by the textural triangle shown in Figure 1.3. Such divisions are very meaningful in terms of relative plant growth. Many of the important chemical and physical reactions are associated with the surface of the particles, and hence are more active in fine than coarse-texture soils.

A textural class description of soils can tell a lot about soil-plant interactions,

since the physical and chemical properties of soils are determined largely by texture.

In mineral soils, exchange capacity (ability to hold plant nutrient elements) is related

closely to the amount and kind of clay in soils. Texture is a major determining factor

for water-holding capacity. Fine-textured soils (high percentage of silt and clay)

hold more water than coarse-textured soils (sandy). Water and air movement through

the finer-textured soils is reduced, making it more difficult to work.

Figure 1.3 Triangle for determining soil textural classes.

From the standpoint of plant growth, medium-textured soils, such as loams, sandy loams

and silt loams, are the most ideal. Nevertheless, the relationships between soil textural

class and soil productivity cannot be generally applied to all soils, since texture

is one of the many factors that influence crop production.

Check the texture of the surface and subsoil. Normally, the surface includes the top

foot of soil, but it may be shallower or deeper in certain situations. Soil below

the tillage zone is called subsoil. It is also necessary to consider the subsoil texture

when determining productivity potentials.

Soil Structure

Soil structure refers to the presence of aggregates of soil particles that have been bound together to form distinct shapes. Sometimes the binding or cementing is weak, however the aggregates are much larger than individual soil particles. Soil organic matter contributes significantly as a cementing agent. Air and water movement and root penetration in the soil is related to the soil structure. The better the structure, the higher the productivity of the soil.

Size and shape of the structure units is important. When height of the structure unit

is approximately equal to its width (blocky structure) we expect good air and water

movement. Structure units that have greater height than width (prismatic structure)

often are associated with subsoils that swell when wet and shrink when dry, resulting

in poor air and water movement. When particles have greater width than height (platy

structure), water and air movement and root development in the soil is restricted,

compared to a soil with desirable structure.

Granular structure, particularly in fine-textured soils, is ideal for water penetration

and air movement. Water and air move more freely through subsoils that have blocky

structure than those with platy structure. Good air and water movement is conducive

to plant root development. Types of soil structure are illustrated in Figure 1.4.

The productivity of the soil is influenced by both surface and subsoil texture and

structure. An approximate rating for soils considering texture and structure is shown

in Table 1.1.

Raise or lower the rating 10 to 20 percent, according to whether the soil structure

is more, or less, favorable than the average. If gravel occurs in the soil, lower

the rating according to its effect on the productive capacity.

Figure 1.4 Types of soil structure.

The productivity of the soil is influenced by both surface and subsoil texture and structure. An approximate rating for soils considering texture and structure is shown in Table 1.1. Raise or lower the rating 10 to 20 percent, according to whether the soil structure is more, or less, favorable than the average. If gravel occurs in the soil, lower the rating according to its effect on the productive capacity.

Table 1.1: Soil productivity rating as affected by texture.*

| Subsoil Texture |

Sand | Sandy Loam |

Loam | Clay Loam |

Clay; Silty Clay |

|---|---|---|---|---|---|

| ---Percent of Maximum Productivity--- | |||||

| Sandy | 50% | 55% | 65% | 60% | 55% |

| Sandy Loam | 60% | 70% | 80% | 75% | 65% |

| Loam | 70% | 80% | 95% | 90% | 75% |

| Clay Loam | 70% | 80% | 90% | 90% | 75% |

| Clay; Silty Clay | 65% | 70% | 80% | 80% | 70% |

* Numbers represent average soil conditions.

Soil Depth

Soil depth generally is used to describe how deep roots can favorably penetrate. Soils that are deep, well drained and have desirable texture and structure are suitable for production of most crops. For satisfactory production, most plants require considerable soil depth for root development to secure nutrients and water. Plants growing on shallow soils have little soil volume from which to secure water and nutrients. Depth of soil and its capacity to hold nutrients and water frequently determines crop yield, particularly for summer crops.

Roots of most crops extend 3 feet or more into favorable soil. Soils should be at least six feet deep to give maximum production. Look for materials or conditions that limit soil depth, such as hardpans, shale, coarse gravelly layers and tight impervious layers. These are almost impossible to change. A high water table may limit root growth, but it usually can be corrected by drainage. Soil productivity estimates on the basis of soil depth can be made using Table 1.2.

Table 1.2. Soil productivity rating as affected by depth.

| Soil Depth Usable by Crop (Feet) |

Roots Relative Productivity (Percent) |

|---|---|

| 1 | 35 |

| 2 | 60 |

| 3 | 75 |

| 4 | 85 |

| 5 | 95 |

| 6 | 100 |

Soil Slope

Topography of the land largely determines potential for runoff and erosion, method of irrigation and management practices needed to conserve soil and water. Higher-sloping land requires more management, labor and equipment expenditures.

Table 1.3 can be used to rate land productivity based on slope. If slope varies, use steeper slopes for the rating.

Erosion

Principal reasons for soil erosion in Oklahoma are 1) insufficient vegetative cover, which usually is a result of inadequate fertility to support a good plant cover, 2) growing cultivated crops on soils not suited to cultivation and 3) improper tillage of the soil. Soil erosion can be held to a minimum by 1) using the soil to produce crops for which it is suitable, 2) using adequate fertilizer and lime to promote vigorous plant growth and 3) using proven soil preparation and tillage methods.

Soils that have lost part or all their surfaces are usually harder to till and have lower productivity than non-eroded soils. To compensate for surface soil loss, more fertilization, liming and other management practices should be used.

Table 1.3. Soil productivity ratings as affected by slope.

| Slope ( % ) |

Relative Productivity Stable Soil ( % ) |

Relative Productivity Unstable, Easily Eroded soil ( % ) |

|---|---|---|

| 0-1 | 100 | 95 |

| 1-3 | 90 | 75 |

| 3-5 | 80 | 50 |

| 5-8 | 60 | 30 |

| 8-12 | 40 | 10 |

Soil and Available Water

Plants are totally dependent on water for growth and production. Even with well-fertilized soils, limited water can greatly reduce yields. Rainfall is not always dependable in Oklahoma. Therefore, crops are dependent on the moisture stored in the soil profile for growth and production.

Soils differ in their ability to supply water to plants. Limited root zones caused by shallow soils, high water table or claypans or extremely porous subsoils cause drought stress in plants faster than more desirable soils. Table 1.4 illustrates the differences in available water in selected soil profiles. Soils with silt loam or fine sandy loam surface textures have high available water-holding capacities. Differences in available water-holding capacity between the soils caused by widely varying textures of the subsoil and soil depth point out the need for knowing what is below the surface. (This kind of information is available in county soil survey manuals). During a drought, differences of 2 inches of available water can keep plants growing for an extra 10 days during peak plant use and could be the difference between success and crop failure.

Soil Fertility

Soil fertility is the soil’s ability to provide essential plant nutrients in adequate amounts and proper proportions to sustain plant growth. These nutrients and their functions are covered in details in the next chapter. Soil fertility is a component of soil productivity that is quite variable and strongly influenced by management. Other components of soil productivity, especially soil slope and soil depth, will be the same year after year. Together with climate, these components set the soil productivity limits, above which yields cannot be obtained even with ideal use of fertilizer. It is important to understand added fertilizer cannot compensate for an unproductive soil due to it being excessively stony or has a subsoil layer that restricts normal root growth and development. This point is illustrated in Figure 1.5.

Table 1.4. Effect of depth and texture on available water for crop use.

| Soil Name | Texture | Depth (inches) |

Available Water (inches) |

|---|---|---|---|

| Dennis | Silt loam Silty clay loam Clay |

0-11 11-23 23-60 |

1.98 2.52 5.55 |

| TOTAL | 60 | 10.05 | |

| Sallisaw | Silt loam Silt loam Gravelly clay loam Very gravelly clay loam |

0-10 10-20 20-40 40-60 |

1.8 1.8 2.8 1.6 |

| TOTAL | 60 | 8 | |

| Shellabarger | Fine sandy loam Sandy clay loam Fine sandy loam |

0-16 16-52 52-60 |

1.92 5.86 0.88 |

| TOTAL | 60 | 8.66 | |

| Stephenville | Fine sandy loam Sandy clay loam Sandstone |

0-14 14-38 38+ |

1.82 3.84 - |

| TOTAL | 38+ | 5.66 |

Figure 1.5: Influence of soil productivity on yield response to fertility.

Soil Management

There are numerous other soil characteristics that can be important to soil productivity in specific areas. These include: soil drainage, soli salinity, presence of stone and/or rocks and organic matter content. They are not major limiting factors over wide areas and will not be discussed here.

One additional factor on which soil productivity is highly dependent is soil management. This implies using the best available knowledge, techniques, materials and equipment in crop production. The use of minimum tillage is an important management practice used to reduce the potential damage to soil structure from overworking, and for economic and fuel conservation purposes, as well as to allow farming of more acres per unit of labor.

Soil conservation is a concept integrating important management practices that deserves close attention. In the U.S., it is estimated that four billion tons of sediment are lost annually from the land in runoff waters, and with it much of the natural and applied fertility. That is equivalent to the total loss of topsoil (6 inches deep) from four million acres. Wind erosion is also a problem in certain areas. Management practices such as contouring, strip planting, cover cropping, reduced tillage, terracing and crop residue management help eliminate or minimize the loss of soil from water and wind erosion.

Proper utilization of crop residues can be a key management practice. Crop residues returned to the soil improve soil productivity through the addition of organic matter and plant nutrients. The organic matter also contributes to an improved physical condition of the soil, which increases water infiltration and storage and aids aeration. This is vital to crop growth.

Summary

Limitations of soil, water or climate reduce the soil’s ability to produce. These limitations increase the need for better management practices. Poor management, or the presence of weeds, compact soils, soil erosion, etc., will result in low yields even on the most productive soils. On the other hand, good management on moderately productive soils can give high yields. By considering the factors discussed in this chapter, one can make a better determination of the soil’s overall crop productivity and make better decisions about nutrient management including use of fertilizers.

Chapter 2 - Essential Plant Nutrient Functions, Soil Reactions and Availability

Bill Raun

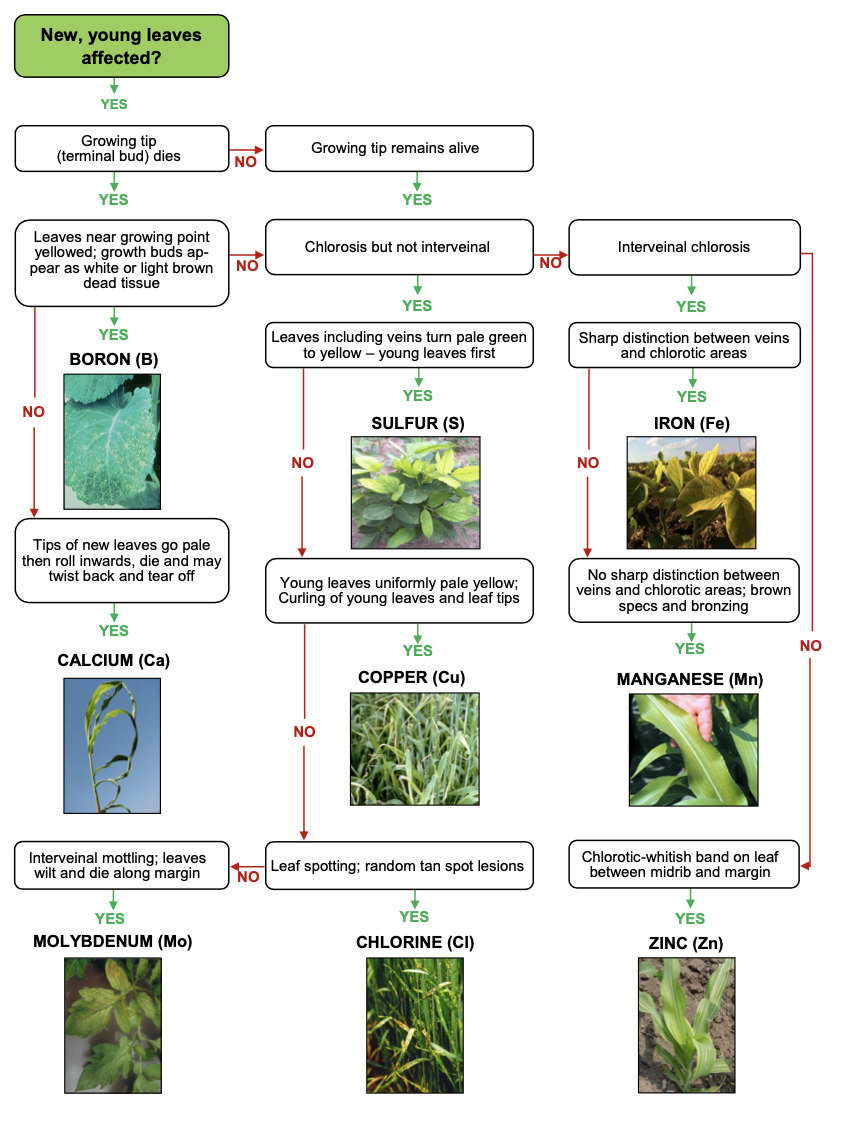

More than 100 chemical elements are known to man today. However, only 16 have been proven to be essential for plant growth. For a nutrient to be classified as essential, certain rigid criteria must be met. The criteria are as follows:

- The element is essential if a deficiency prevents the plant from completing its vegetative or reproductive cycle.

- The element is essential if the deficiency in question can be prevented or corrected only by supplying the element.

- The element is essential if it is directly involved in the nutrition of the plant and is not a result of correcting some microbiological or chemical condition in the soil or culture media.

The essential elements and their chemical symbols are listed in Table 2.1. Three of the 16 essential elements – carbon, hydrogen and oxygen – are supplied mostly by air and water. These elements are used in relatively large amounts by plants and are considered to be non-mineral, since they are supplied to plants by carbon dioxide and water. The non-mineral elements are not considered fertilizer elements. The other 13 essential elements are mineral elements and must be supplied by the soil and/or fertilizers.

Table 2.1. Essential plant nutrients, chemical symbols and sources.

| Mostly from air and water (non-mineral) | Mostly from air and water (non-mineral) | From soil and/or fertilizers (mineral) | From soil and/or fertilizers (mineral) | From soil and/or fertilizers (mineral) | From soil and/or fertilizers (mineral) |

|---|---|---|---|---|---|

| Element | Symbol | Element | Symbol | Element | Symbol |

|

Carbon |

C |

Nitrogen |

N |

Iron |

Fe |

|

Hydrogen |

H |

Phosphorus |

P |

Manganese |

Mn |

|

Oxygen |

O |

Potassium |

K |

Zink |

Zn |

|

|

|

Calcium |

Ca |

Copper |

Cu |

|

|

|

Magnesium Mg |

Mg |

Boron |

B |

|

Sulfur |

S |

Molybdenium |

Mo |

||

|

Chlorine |

Cl |

The essential plant nutrients may be grouped into three categories. They are as follows:

- Primary nutrients - nitrogen, phosphorus and potassium

- Secondary nutrients - calcium, magnesium and sulfur

- Micronutrients - iron, manganese, zinc, copper, boron, molybdenum and chlorine

This grouping separates the elements based on relative amounts required for plant growth, and is not meant to imply any element is more essential than another.

Primary Non-Mineral Nutrients

Carbon, Hydrogen and Oxygen

Carbon is the backbone of all organic molecules in the plant and is the basic building block for growth. After absorption of carbon dioxide (CO2) by the leaves of the plant, carbon is transformed into carbohydrates by combining with hydrogen and oxygen through the process of photosynthesis.

Metabolic processes within the plant transform carbohydrates into amino acids and proteins and other essential components.

Primary Mineral Nutrients

Nitrogen

Nitrogen is an integral component of amino acids, which are the building blocks for proteins. Proteins are present in the plant as enzymes that are responsible for metabolic reactions in the plant. Because nitrogen is so important, plants often respond dramatically to available nitrogen.

Soil Nitrogen Reactions and Availability

Most of the nitrogen in Oklahoma soil is present as organic nitrogen in the soil organic matter. There are about 1,000 pounds per acre of nitrogen in this form for every one percent organic matter in the soil. However, since the soil organic matter is resistant to further decay, most of this nitrogen is unavailable during any given growing season. Normally, about two percent of the nitrogen from soil organic matter will be released each year to mineral forms when soils are cultivated. This 20 to 40 pounds per acre of nitrogen is typical of the amount present in unfertilized soils after cultivation and seed bed preparation.

Nitrogen Mineralization and Immobilization

Because nitrogen release from organic matter is dependent upon decay by microorganisms, which themselves require nitrogen, the amount of nitrogen available for a crop is in constant flux. Unlike crops, which get their carbon as carbon dioxide from the air, many microorganisms get their carbon by decaying organic matter. Nitrogen availability depends upon the relative amount of carbon and nitrogen in the organic matter, its resistance to decay, and environmental conditions to support microbial activity. Figure 2.1 illustrates how nitrogen becomes more concentrated as soil organic matter decays.

Figure 2.1: Narrowing of carbon to nitrogen ratio as residue decay until mineral nitrogen finally becomes available.

Note that nitrogen is not released during the first stages of decay. This is because nitrogen that is released is immediately consumed by active microorganisms. With time, remaining organic material becomes more resistant to decay, microorganisms die off, and there is more mineral nitrogen present than can be consumed by the few active microorganisms. This results in a final release of measurable mineral nitrogen in the form of ammonia (NH3). The ammonia readily reacts with soil moisture to form ammonium (NH4+). These two reactions can be stated simply as:

organic nitrogen → NH3 (gas) [1]

NH3 + H2 O → NH4+ + OH- [2]

ammonia + water ammonium + hydroxide

The process of converting or transforming nitrogen from organic compounds to inorganic compounds is called mineralization. This results in increasing nitrogen available for crops. When the reverse happens, and available nitrogen is absorbed by crops or microorganisms, the process is called immobilization and results in a decrease in the amount of nitrogen immediately available for crops. These processes and their interacting nature with soil nitrogen for a typical field situation are illustrated in Figure 2.2.

Approximately 98 percent of the soil nitrogen is unavailable for plant uptake. This large reservoir of organic nitrogen provides an important buffer against rapid changes in available nitrogen and plant stress. The small reservoir of mineral nitrogen can often be slowly replenished by mineralization (Figure 2.2) when crops need additional nitrogen.

Figure 2.2: Interacting pools of soil nitrogen.

Supplemental nitrogen as fertilizer usually must be added to support high, economic production levels. Immediately following fertilization with 120 pounds nitrogen, the system may be illustrated by Figure 2.3a. Addition of fertilizer nitrogen will stimulate microorganism activity, resulting in consumption of nitrogen and breakdown of some crop residues (immobilization) as illustrated in Figure 2.3b. The immobilized nitrogen will be present as microbial tissue and other new material in the organic pool. As indicated by the two arrows pointing in opposite pathways, mineralization and immobilization are both taking place simultaneously. Immobilized fertilizer nitrogen will again become available in a few weeks if conditions favor crop uptake.

Figure 2.3: Relative amounts of organic and mineral nitrogen in soil immediately after fertilizing (a) and several days after active immobilization (b).

Nitrification

In addition to the general mineralization and immobilization reactions, other reactions also are responsible for nitrogen changes (transformations) in the soil. Nitrification is one of the first reactions to occur after organic nitrogen has been converted to ammonium-N. This change is also a result of aerobic microorganism activity as depicted in the following reaction.

2NH4+ + 3O2 → 2NO2- + 2H2O + 4H+ [3]

ammonium oxygen nitrite water hydrogen ion

This reaction produces nitrite-N and hydrogen ions. Since hydrogen ions are generated, it is easy to see this step will at least temporarily contribute to soil acidity. However, this production of acidity is partially compensated for by the hydroxide (OH-) produced from reaction [2]. The hydrogen and hydroxide will combine to form water, so the net effect on acidity when organic nitrogen is mineralized will be 1 pound of hydrogen produced for every 14 pounds of nitrogen mineralized. The same reactions and acidity will occur when fertilizer nitrogen is added in the ammonia form (anhydrous ammonia or urea). Ammonium sulfate will be twice as acidifying because equation [2] will be avoided by adding the ammonium (NH4+) form of nitrogen.

Almost immediately after nitrite (NO2-) nitrogen is produced (reaction [3]), a companion reaction occurs that is also carried out by soil microorganisms resulting in nitrate-N (NO3 - N) being produced from nitrite.

2NO2- + O2 → 2NO3- [4]

Because this change is quite rapid compared to the change from ammonium to nitrite [3] there is seldom any nitrite (NO2-) present in soils. Ammonium and nitrate are common and will increase or decrease depending on microbial activity that will both generate and consume ammonium and nitrate. This cyclic interaction of nitrogen transformations is shown in Figure 2.4.

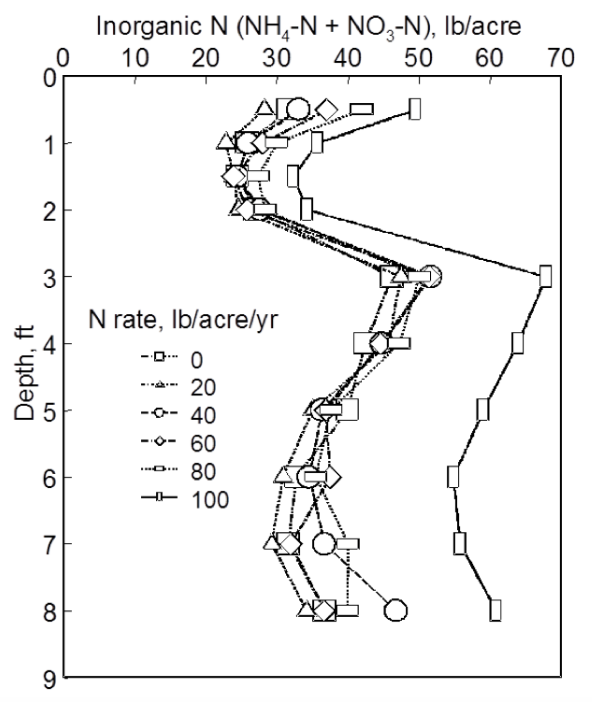

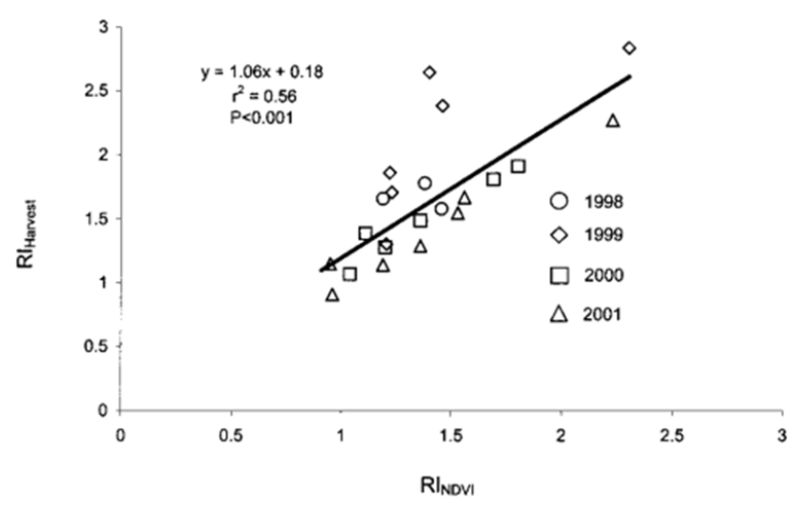

Whenever nitrate and/or ammonium nitrogen are measured in the soil, these measurements provide a view of two components of the nitrogen cycle at a single point in time. If the measurement is made when the system is likely to be in balance, or equilibrium, such as when wheatland soils are tested for nitrate in July or August, the value can be a useful guide for determining nitrogen fertilizer needs. Figure 2.5 illustrates the changes that took place for ammonium and nitrate nitrogen in soil during wheat production under different rates of fertilizer use. Because ammonium and nitrate nitrogen are the two forms of nitrogen that higher plants utilize, these two forms have received the greatest attention.

Figure 2.4: Primary forms of nitrogen in soils and the transformations among them. (1) Decay of soil organic matter releasing ammonia; (2) reaction of ammonia with water to form ammonium; (3) transformation of ammonium to nitrate by microorganisms; (4) uptake of ammonium and/ or nitrate by plants and microorganisms; (5) plants eaten by animals; (6) animal manures, nitrogen fixation and plant residue return to soil; (7) residues decay to resistant organic matter, ammonia produced from nitrogen rich materials; (8) soil organic matter produced as decay continues.

Soil fertility research at OSU has documented the change of ammonium and nitrate nitrogen following fertilization (Figure 2.5). Only about 60 percent of the fertilizer nitrogen could be accounted for at the first sampling after fertilization. This was mostly present as nitrate although the fertilizer (ammonium nitrate) was an equal mixture of the two nitrogen forms measured. In the short period after application, some transformations had taken place. These continued, resulting in a gradual increase in ammonium nitrogen (probably from some mineralization) and a rapid decline in nitrate, likely from immobilization caused by microbial activity and uptake by the wheat crop.

Figure 2.5. Surface soil (0-6”) ammonium and nitrate nitrogen following fertilization at different rates from OSU Soil Fertility Research.

When crop production is added to the cycle in Figure 2.4, it becomes obvious that the cycle is not self sustaining. Harvesting removes significant amounts of nitrogen each year and eventually the system becomes depleted in organic matter and available nitrogen to support normal crop yields. A common response is to add nitrogen back using legumes and commercial fertilizers. When additions are balanced with removals, soil organic matter and productivity can potentially be sustained. However, excessive tillage, residue removal (straw and chaff in wheat production) and residue burning often result in continued soil organic matter decline. This loss in soil organic matter can lead to more pronounced surface crusting following rain.

Nitrogen Fixation

Additions to soil nitrogen are made as a result of either atmospheric, biological or industrial fixation of atmospheric nitrogen (N2). These processes are responsible for transforming nitrogen from the atmosphere to either ammonium or nitrate nitrogen that can be used by plants. The atmosphere contains an inexhaustible amount (78 percent) of nitrogen. Approximately 35,000 tons of nitrogen are present in the atmosphere above each acre of the earth’s surface.

Atmospheric nitrogen fixation occurs when there is electrical discharge or lightning

during thunderstorms. This causes elemental nitrogen (N2) to combine with elemental oxygen (O2) to form nitrate (NO3-). The nitrate is added to the soil with rainwater and accounts for about 3 to 5

pounds of nitrogen per acre per year.

Biological nitrogen fixation can be either symbiotic or non-symbiotic. Symbiotic nitrogen

fixation occurs within legumes. Bacteria (rhizobium sp.) infect the root of the legume

and cause a nodule to form. The rhizobium obtain their energy from the legume and

convert free nitrogen to ammonia (NH3), which the host plant utilizes to make amino acids and proteins. Legumes may fix

as much as 500 pounds of nitrogen per acre per year (alfalfa) by this process. However,

only a small fraction of the nitrogen fixed by legumes will be available for subsequent

crops unless the legume is “plowed down” when a significant amount of top growth is

present. Normally, most of the fixed nitrogen is removed in the harvest. Typical amounts

of nitrogen added from legumes are shown in Table 2.2.

Biological nitrogen fixation is an extremely important source of adding nitrogen to

soils when fertilizer nitrogen is unavailable. In Oklahoma, the addition of nitrogen

to soils as a result of growing legumes is significant and should always be accounted

for when determining nitrogen needs for non-legume crops in the subsequent season.

However, the cost of establishing and growing legumes for this purpose alone, precludes

their use as a sole substitute for nitrogen fertilizers.

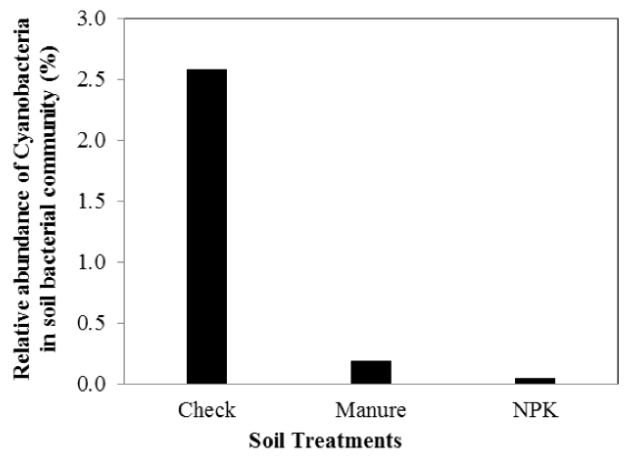

Non-symbiotic nitrogen fixation is accomplished by certain “free-living” microorganisms

(cyanobacteria or blue-green algae), which live independently of other living tissue.

The total contribution of nitrogen from these microorganisms can actually be significant.

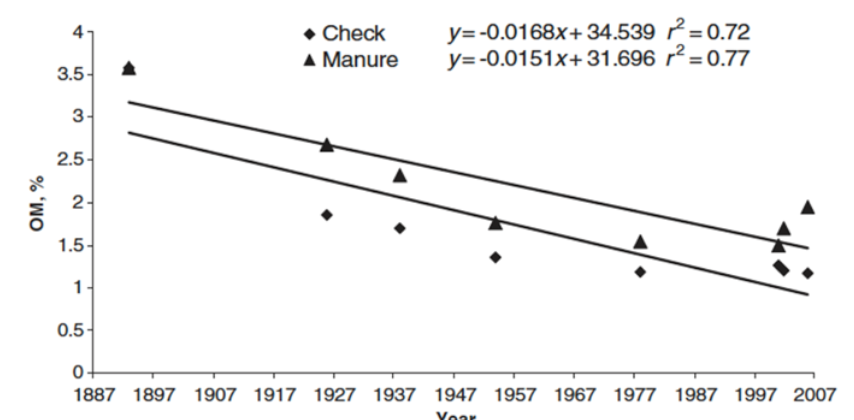

Recent studies from the Magruder Plots started in 1892 found cyanobacteria in the

check plot where no nitrogen has ever been applied. This helps to explain why wheat

yields in these plots continue to be around 20 bushels per acre, more than 120 years

later with no nitrogen additions.

Table 2.2 Average nitrogen remaining (N-credit) in the soil after legume crops.

| Legume | N-credit (lb N/acre) | Legume | N-credit (lb N/acre) |

|---|---|---|---|

| Alfalfa | 80 | Cowpeas | 30 |

| Ladino clover | 60 | Lespedeza (annual) | 20 |

| Sweet clover | 60 | Vetch | 40 |

| Red clover | 40 | Peas | 40 |

| Kudzu | 40 | Winter peas | 40 |

| White clover | 20 | Peanuts | 20 |

| Soybeans | 20 | Beans | 20 |

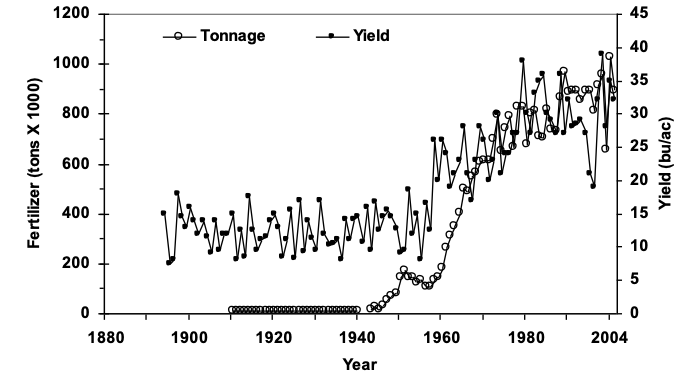

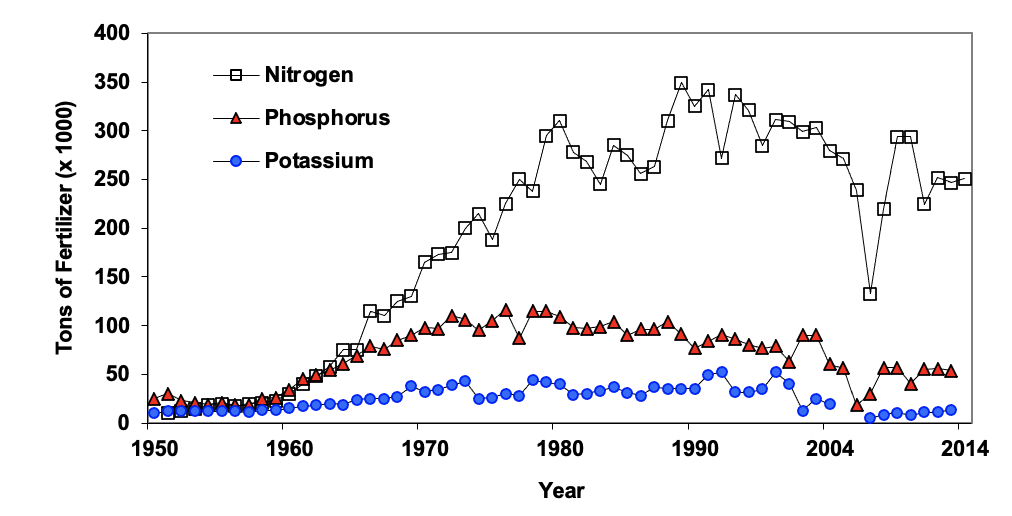

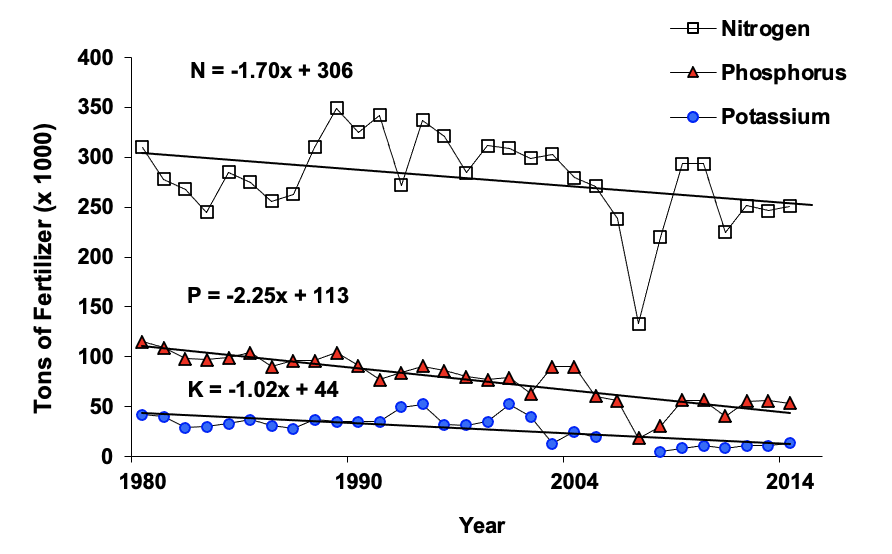

Industrial fixation of nitrogen involves reacting atmospheric nitrogen (N2) with hydrogen (H), usually in the form of natural gas, under high temperature and pressure to form ammonia (NH3 ). The ammonia may be used directly as anhydrous ammonia gas or converted to other nitrogen fertilizers such as urea, ammonium nitrate, urea-ammonium nitrate solution, ammonium sulfate or ammonium phosphates. Industrial fixation in Oklahoma is responsible for additions of about 300,000 tons of nitrogen per year. This amount of nitrogen is roughly equal to nitrogen removed in harvested crops.

Nitrogen fixation results in addition of nitrogen to the soil through utilization by plants and their residues subsequently added back to the soil (Figure 2.6). In order for soil organic matter to be maintained it is necessary for these additions to be at least equal to the amount of nitrogen removed from the field by harvest. Figure 2.6 illustrates how nitrogen fixation interacts with other forms of nitrogen and their transformations.

Figure 2.6: Addition of nitrogen to the nitrogen cycle from fixation of atmospheric nitrogen by: (9) lightning; (10) symbiosis with legumes; (11) industrial fertilizer plants.

Nitrogen Losses

The major nitrogen loss from soils is the removal of nitrogen by harvest of non-legume crops. Other significant nitrogen losses include:

- Volatilization of ammonia.

- Volatilization of nitrous oxide (N2O) and nitric oxide (NO) from nitrate in poorly aerated soils (denitrification).

- Leaching of nitrate out of the root zone in permeable soils receiving heavy rainfall or irrigation.

- Plant nitrogen loss as ammonia from plants containing nitrogen in excess of what the plant can use in seed production, just after flowering.

Each of these processes is responsible only for very small amounts of nitrogen loss over the course of a crop growing season. However, when considered over a generation of farming, or even just a few years, the amount of nitrogen lost can be significant. Nitrogen losses by these processes are responsible for the fact only 30 to 40 percent of fertilizer nitrogen applied can be found in the crop at harvest. Research at OSU and other institutions continues to examine practices that will improve fertilizer-nitrogen-use efficiency. Figure 2.7 illustrates the interaction of these nitrogen losses with other forms of nitrogen and their transformations.

Phosphorus

Most of the total phosphorus in soils is tied up chemically in compounds with low solubility. In neutral- to alkaline-pH soils, calcium phosphates are formed, while in acid soils, iron and aluminum phosphates are produced.

Soil Phosphorus Reactions and Availability

Available soil phosphorus, or that fraction which the plant can use, makes up about

one percent or less of the total phosphorus in soils. The availability of inorganic

phosphorus in soils is related to the solubility of specific phosphorus compounds

present. Phosphorus solubility in particular is controlled by a number of factors

– most importantly soil pH.

The amount of precipitated phosphorus is one factor. The greater the total amount

present in soil, the greater the chance to have more phosphorus in solution. Another

important factor is the extent of contact between precipitated phosphorus forms and

the soil solution. Greater exposure of phosphate to soil solution and plant roots

increases its ability to maintain replacement supplies. During periods of rapid growth,

phosphorus in the soil solution may be replaced 10 times or more per day from the

precipitated or solid phase. The rate of dissolution and diffusion of soluble phosphorus

determines soil phosphate availability. As phosphate ions (mainly H2PO4- and HPO42-) are taken up by the plant, more must come from the solid phase.

Soil pH can be a controlling factor that determines phosphorus solubility. Maximum

phosphorus availability occurs in a pH range of 5.5 to 7.2. At soil pH levels below

5.5, iron (Fe), aluminum (Al) and manganese (Mn) react with phosphorus to form insoluble

compounds. When soil pH exceeds 7.2, phosphorus will complex with calcium (Ca) to

form plant-unavailable phosphorus forms. However, it should be noted the solubility

of calcium phosphates is much greater than aluminum and iron phosphates.

Figure 2.7: Losses of nitrogen from the nitrogen cycle as a result of: (12) ammonia volatilization; (13) transformation of nitrate to gaseous oxides (denitrification); (14) leaching below the root zone; (15) volatilization from crops; and (16) harvest removal.

The proportion of total soil phosphorus relatively available is dependent upon time of reaction, type of clay present in the soil, organic matter content and temperature. The solubility of phosphate compounds formed from added phosphorus due to time of reaction can be broken down in three major groups (Figure 2.8). Fertilizer phosphates are generally in the readily available phosphate group but are quickly converted to slowly available forms. These can be utilized by plants at first, but upon aging are rendered less available and are then classified as being very slowly available. At any one time, 80 to 90 percent of the soil phosphorus is in very slowly available forms. Most of the remainder is in the slowly available form since less than 1 percent would be expected to be readily available.

The formation of insoluble phosphorus containing compounds in soils that renders phosphorus unavailable for plant use is called phosphorus fixation. Each soil has an inherent fixation capacity that must be satisfied in order to build available phosphorus levels. In Oklahoma, a large portion of the clays have a lower fixation capacity than the highly weathered soils found in high rainfall areas. It is important to understand the actual amount of phosphorus in the soil and the amount available to crops will not necessarily be reflected in a soil test. These soil tests simply provide an index of sufficiency and not an index of build-up or accumulation. Because different soils will have differing fixation capacities, the importance of annual soil testing becomes clear, since this practice is the only method used to estimate future crop fertilizer needs. In addition, these tests should reflect past management (farmers applying more than enough or not enough on an annual basis), and farmers thus can compensate accordingly.

Very slowly available phosphates

Apatites, aged Fe, Mn and Al phosphates,

stable organic phosphates

⇑ ⇓

Slowly available phosphates

Ca3 (PO4)2 , freshly formed Fe, Al, Mn phosphates

(small crystals) and mineralized organic phosphates

⇑ ⇓

Readily available phosphates

Water-soluble

ammonium phosphates

NH4 H2 PO4 (MAP 11-52-0)

(NH4 )2 HPO4 (DAP 18-46-0)

monocalcium phosphate

Ca(H2 PO4 )2 (0-46-0)

Water-insoluble

dicalcium phosphate

CaHPO4

Figure 2.8: Relative availability of different phosphate forms and their transformations.

Organic matter and microbial activity affect available soil phosphorus levels. As was the case with nitrogen, the rapid decomposition of organic matter and consequent high microbial population results in temporary tying up of inorganic phosphorus (immobilization) in microbial tissue, which later is rendered available through release (mineralization) processes. This is one of the reasons why broadcasting phosphorus in zero/minimum tillage systems can be beneficial, especially where soil phosphorus fixation capacities are high.

Less than 30 percent of phosphorus fertilizers applied is recovered in plants. Therefore, due to fixation reactions, more phosphorus must be added than is actually removed by crops. Legumes, in general, require much larger amounts of phosphorus than many of the common grain crops grown in Oklahoma.

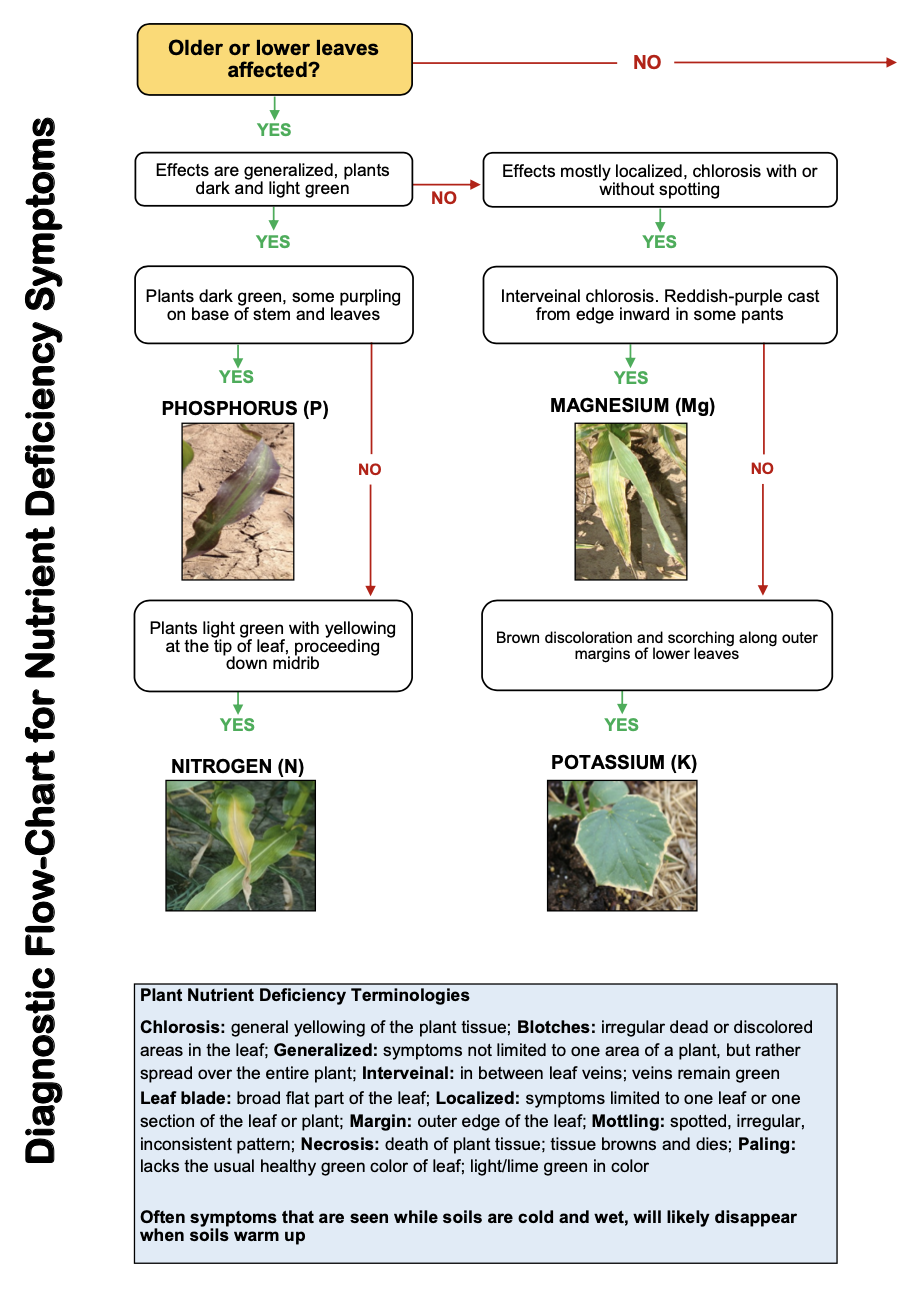

Because phosphorus is immobile in the soil, roots must come in direct contact with this element before the plant can take it up. However, phosphorus is mobile within the plant and if deficient, lower leaves generally will demonstrate purple coloration on the outer edge of the leaf and/or the leaf margins.

Over a wide range of soils and cropping conditions, phosphorus has proven to be one of the more deficient elements in Oklahoma production agriculture. Soil testing on an annual basis should assist in determining crop needs.

Potassium

Plants take up potassium as the potassium ion (K+). Potassium within plants is not synthesized into compounds and tends to remain in ionic form in cells and plant tissue. Potassium is essential for photosynthesis, starch formation and translocation of sugars within plants. It is necessary for the development of chlorophyll, although it is not part of its molecular structure.

The main functions of potassium in plants are in the translocation of sugars and its involvement in photosynthesis.

Soil Potassium Reactions and Availability

In most soils (except extremely sandy soils in high rainfall regions), total potassium contents are high. Similar to nitrogen and phosphorus, not all of the total potassium is available for plant growth. The relationship of unavailable, slowly available and readily available forms of potassium is illustrated in Figure 2.9. Only 1 to 2 percent of the total potassium in soils is readily available. Of this, approximately 90 percent is exchangeable or attached to the outside edge of clays, and the remaining 10 percent is in the soil solution. Equilibrium exists between the nonexchangeable, exchangeable and water soluble forms. When the plant removes potassium from the water soluble form, the concentration is readjusted by the exchangeable and nonexchangeable forms. In the case of added potassium, some of the available forms will move toward nonexchangeable forms. The nonexchangeable form also may be referred to as fixed. Certain 2:1 type clay minerals have pore space large enough for the potassium ions (K+) to become trapped, rendering the ions unavailable for immediate plant use. Potassium is positively charged and clays are negatively charged and this makes the potassium ion relatively immobile in the soil. Except in extremely sandy soils, leaching losses under normal Oklahoma conditions are minimal. The largest loss comes from crop removal, particularly where hay crops are produced. Most of western Oklahoma soils have adequate plant available potassium, however, this can best be determined for individual fields by soil testing.

Relatively Unavailable Potassium (Feldspars, Micas, etc.) 90 to 98% of total potassium

⇒ Slowly Available Potassium (Nonexchangeable (fixed)) 1 to 10% of total potassium

⇑ ⇓

⇒ Readily Available Potassium (Exchangeable and solution) 1 to 2% of total potassium

Figure 2.9: Relative amounts of soil potassium present in different levels of availability to plan

Secondary Mineral Elements

Nutrients that are used in relatively moderate amounts by most plants have been categorized as secondary nutrients. These nutrients are calcium (Ca), magnesium (Mg) and sulfur (S).

Calcium

Calcium is taken up by plants as the cation, Ca2+. Calcium functions in the plant in cell wall development and formation. Calcium is not translocated in plants and consequently, the deficiency of calcium will be observed first in the new, developing plant tissue. Calcium deficient tissue fails to develop normal morphological features and will appear to be an undifferentiated gelatinous mass in the region of new leaf development.

The calcium ion is referred to as a basic ion because the element reacts with water to form the strong base calcium hydroxide, Ca(OH)2 . Calcium is held tightly on the negatively charged clay and organic particles in soils and is abundant in soils that have developed in arid and semi-arid climates. Because of this, it is primarily responsible for maintaining these soils at or near a neutral pH. In addition to unweathered primary and secondary minerals, soils often contain calcium in the form of impure lime (calcium carbonate, CaCO3 ) and gypsum (calcium sulfate, CaSO4 ). Except in the production of peanuts on sandy, acid soils, calcium deficiency in Oklahoma crops has not been substantiated by research. However, because calcium absorption by the developing peanut pod is not very effective from soils with a marginal supply of calcium, peanut producers often apply gypsum over the pegging zone just before the plant begins to peg to assure the crop will be adequately supplied with calcium. For most soils, before the available calcium level reaches a critically low point, the soil pH will become so low that soil acidity will be a major limitation to crop production. Since the common correction of acid soils is to add lime in amounts of tons per acre, this practice will incidentally maintain a high level of available calcium for crops.

Magnesium

Magnesium is absorbed as the divalent cation, Mg2+, and functions in many enzymatic reactions as a co-factor or in a co-enzyme. The most noteworthy function of magnesium in plants is as the central cation in the chlorophyll molecule. Without magnesium, plants cannot produce adequate chlorophyll and will lose their green color and ability to carry out photosynthesis, the process responsible for capturing energy from sunlight and converting it into chemical energy within the plant. Magnesium deficiency will result in yellow, stunted plants.

Magnesium reactions in soils are similar to calcium in many respects. Magnesium, like calcium, is a basic ion that generally is abundant in arid and semi-arid soils with near neutral pH. Deficiencies most often occur in deep sandy soils with a history of high forage production (8 to 10 tons per acre annually), where forage has been removed as hay. In Oklahoma, deficiencies have occasionally been noted under these conditions in the eastern half of the state. Like calcium, deficiencies are likely to occur on acid soils, and since most lime will contain a small amount (2 to 5 percent) of magnesium carbonate, liming acid soils on a regular basis usually will assure an abundant supply of plant available magnesium. If magnesium deficiency is a reoccurring problem, dolomitic lime (primarily magnesium carbonate) should be sought as a liming source.

Sulfur

Sulfur is absorbed by plants as the sulfate anion, SO42- . Sulfur is a component of three of the 21 essential amino acids and thus, is critical to the formation and function of proteins. Sulfur deficiency causes plants to become light green and stunted. Most crops require about 1/20 the amount of sulfur that they do of nitrogen. Bumper yields of most crops can be supported by 5 to 15 pounds per acre of sulfur.

Sulfur is found in soil in the form of soil organic matter (like nitrogen), dissolved in the soil solution as the sulfate ion and as a part of the solid mineral matter of soils. Sulfur compounds, such as gypsum, are slightly soluble in water. Like nitrate nitrogen, the negatively charged sulfate ion is not readily adsorbed to clay and humus particles and may be leached into the subsoil with a porous surface soil layer. Sulfur deficiencies most often occur in deep sandy soils, low in organic matter, with a history of high crop production and removal. Soils that have a well developed B horizon seldom will be deficient in sulfur because sulfur will not leach out of the root zone and the accumulated sulfur in the subsoil will adequately satisfy crop needs. This is one of the reasons why early sulpher deficiencies often disappear at late stages of growth, at which time roots have penetrated subsoil horizons rich in sulfur. Plant deficiencies in general show up on the younger leaves, with light yellow discoloration. Soils that contain normal amounts of organic matter will release sulfur by mineralization, much like nitrogen, and this will contribute significantly to meeting crop needs. Sulfur deficiencies in Oklahoma are very rare because on the average there is about 6 pounds per acre of sulfur added to soils annually in the form of rainfall. Sulfur is still added incidentally as a component of phosphate fertilizers and other agricultural chemicals which contribute significantly to the requirement of crops. Also, Oklahoma irrigation waters are usually high in sulfate, and add significant amounts each year (for every ppm of sulfate-S, 2.7 pounds per acre of sulfur is added for each acre-foot of irrigation).

Micronutrients

The micronutrients are grouped together because they are all required by plants in very small amounts. Some, like molybdenum (Mo), are required in such small amounts that deficiencies can be corrected by applying the element at only a fraction of a pound per acre. Similarly, chlorine is needed in such small quantities that when researchers at the University of California were attempting to document its necessity, they found that touching plant leaves with their fingers transferred enough chlorine from the perspiration on their skin to meet the plant’s requirements. These elements do not function in plants as a component of structural tissues like primary and secondary nutrients. Instead, micronutrients are mainly involved in metabolic reactions as a part of enzymes where they are used over and over without being consumed. Nevertheless, their functions are very specific and cannot be substituted for by some other element. Deficiencies of any of the elements can be corrected by foliar application of solutions containing the element.

Manganese, Chlorine, Copper and Molybdenum

Deficiencies of these nutrients have yet to be documented in Oklahoma, except for chlorine in wheat on a deep sandy soil near Perkins. Each of the elements is adsorbed by plants in the ionic form, manganese and copper as the divalent cations Mn2 + and Cu2 +, molybdenum as the oxyanion MoO42 -, and chlorine as the simple Cl- anion. Of these four nutrients, molybdenum and chlorine are probably the most likely to receive attention. Molybdenum functions in plants in the enzyme nitrate reductase, which is very important in nitrogen metabolism in legumes. Availability is reduced in acid soils and often if molybdenum availability is marginal it can be increased to adequate levels by simply liming the soil. Where large seeded legumes are grown, like soybeans or peanuts, obtaining seed that was grown with a good supply of molybdenum will avoid the deficiency because normal levels of molybdenum in the seed will be enough to meet the plant needs.

Soil fertility research in the Great Plains has occasionally shown small grain response to fertilizers containing chlorine. Often the response has been the result of disease suppression (take-all disease) rather than correction of an actual nutrient deficiency in the plant, and usually it has been in areas that do not commonly apply potassium fertilizers containing chloride (such as muriate of potash or potassium chloride, 0-0-62).

Boron

Boron is absorbed by plants as uncharged boric acid, B(OH)3 , the chemical form also present in soil solution. Boron is believed to function in plants in the translocation of sugars. Because B is uncharged in soil solution and it forms slightly soluble compounds, it also is relatively mobile in soils and can be leached out of the surface soil. This is sometimes critical in peanut production because of the very sandy, porous soils peanuts are produced in. As a result, boron deficiency has been reported in peanuts. The deficiency manifests itself as a condition known as “hollow heart” whereby the center of the nut is not completely filled and an inferior crop is harvested. Although alfalfa has an annual requirement twice that of peanuts, the deficiency of boron has never been documented in alfalfa. The reason for this is likely because alfalfa is usually grown in deep, medium textured soils and because alfalfa has an extensive root system even at lower depths in the soil profile. Whenever boron deficiencies are suspected, and if boron fertilizer is applied, care should be exercised as toxicities can be created by simply doubling the recommended rate.

Iron and Zinc

Iron and zinc deficiencies both occur in Oklahoma and are associated with unique soil and crop situations. Zinc is absorbed as the divalent cation Zn2+, while iron is absorbed as a “plant provided” chelated Fe3+ complex by grass type plants and as the “plant-reduced” divalent cation Fe2+ by broad-leaved plants.

Corn is sensitive to moderately low soil zinc levels and deficiencies may occur at DTPA soil test values below 0.8 parts per million. Winter wheat, on the other hand, has been grown in research experiments near Woodward, Oklahoma where the soil test zinc value was less than 0.15 parts per million without showing any deficiency or responding to zinc fertilizer. Obviously winter wheat is very effective in utilizing small amounts of soil zinc. Zinc deficiencies in corn are most common where fields have been leveled or for some other reason the topsoil has been removed and the surface soil has very little organic matter and where the subsoil pH is high. Deficiencies are easily corrected by broadcast application of about 4 to 6 pounds per acre of zinc preplant. An application of this rate should remove the deficiency for 3 to 4 years. The most sensitive plant to zinc deficiency in Oklahoma is pecans. Deficiencies may occur whenever DTPA soil test values are less than 2.0 parts per million. Foliar sprays are very effective in preventing and/or correcting the deficiency. A single application usually lasting the entire growing season.

Iron deficiency is most common in sorghum and sorghum-sudan crops in Oklahoma. The occurrence is limited to the western half of the state in soils that are slightly alkaline (pH above 7.5). All soils in Oklahoma contain large amounts of iron, usually in excess of 50,000 pounds per acre. However, almost all of this iron is in a form that is not available to crops, like rust. Iron availability is increased greatly in acid soils, consequently the deficiency is seldom observed in any crops in eastern and central Oklahoma, where soil pH is usually less than 7.0. Iron deficiency cannot be corrected by soil application of iron-containing fertilizers because the iron from the fertilizer is quickly converted to unavailable iron just like that already present in the soil. The exception to this general rule is the use of chelated iron. However, these fertilizer materials can be cost prohibitive for field scale use. Foliar application of iron sulfate solutions is effective for supplying iron to deficient plants. Unfortunately, iron is not translocated in the plant and subsequent new leaves will again exhibit the interveinal chlorosis (yellow between the veins) characteristic of iron deficiency. Repeated spraying will provide iron for normal growth but often will be cost prohibitive. The most effective long-term corrective measure for dealing with iron chlorosis is to increase soil organic matter since iron deficiency usually is limited to small areas of a field. Organic matter can be effectively increased by annual additions of animal manure or rotted hay. This results in additional chelating of iron and also has a tendency to acidify the soil. Broadleaf plants have what is called an “adaptive response mechanism” that allows them to make iron more available if they experience iron stress. The strength of this mechanism is a genetic trait and some varieties, such as ‘forest’ soybeans, do not possess this ability and will often become chlorotic if grown in neutral or alkaline soils.

The Mobility Concept

The nutrient mobility concept as it relates to soil fertility was first proposed in 1954 by Roger H. Bray at the University of Illinois. Much research since then has supported his mobility concept and it is now considered basic to the understanding of soil fertility. Bray simplified all the soil chemistry surrounding the essential nutrients to the fact that some are quite mobile in soils and others are relatively immobile.

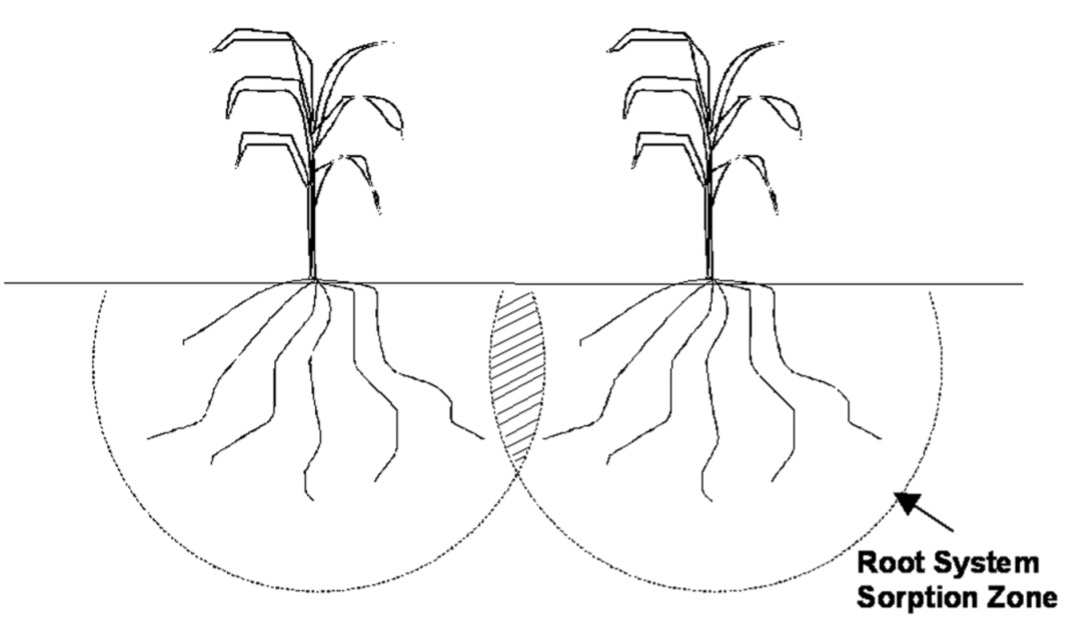

Mobile Nutrients

Plants are able to extract mobile nutrients from a large volume of soil, even soil beyond the furthest extension of their roots because as the plants extract water from around their roots, water from further away moves toward the root and carries the mobile nutrient with it. Figure 2.10 illustrates this point. Plants obtain mobile nutrients from a “root system sorption zone” and are capable of using nearly all of the mobile nutrient (or mobile form of the nutrient) if the supply is limited. According to Bray, the mobile nutrients are: nitrogen, sulfur, boron and chlorine.

Figure 2.10. The large volume of soil from which plants extract mobile nutrients (root system sorption zone).

In a field situation, where there is more than one plant, root system sorption zones overlap if plants are close enough together as illustrated in Figure 2.11. As a result there is a volume of soil between plants where the nutrient is in demand by both plants. As plants are placed closer and closer together (e.g. increasing plant population to increase potential yield) the competition for nutrients increases. Unless the competition among plants in a field for a mobile nutrient is satisfied by supplying more of the nutrient, the growth and yield of plants will be restricted. From this simple illustration we learn the supply of mobile nutrients like nitrogen must be provided in direct proportion to the number of plants, or potential yield of the crop. This “supply” can be easily determined by calculating the amount of nutrient that will be taken up by the crop. To do this, we only need to know the average concentration of the nutrient in the crop and what the crop yield will be. Average nutrient concentrations are commonly known, however yields vary from field to field and year to year. For this reason it is critical to have in mind a “yield goal” or expected yield in order to determine fertilizer needs for mobile nutrients like nitrogen. For example, in Oklahoma the rule “2 pounds nitrogen per acre for every bushel of wheat” is commonly used to estimate the nitrogen requirements of winter wheat. This rule takes into account that soil test and fertilizer nitrogen will only be about 70 percent utilized by the plant. Because mobile nutrients are almost completely extracted from the root system zone, soil test values like nitrate nitrogen will change drastically from one year to the next in relation to how much nitrogen was available and the crop yield.

Figure 2.11. Competition among plants brought about by increasing yield goal.

Immobile Nutrients

Nutrients that are immobile in the soil are: phosphorus, potassium, calcium, magnesium, iron, zinc, manganese, copper and molybdenum. These nutrients are not transported to plant roots as soil water moves to and is absorbed by the root. These nutrients are absorbed from the soil and soil water that is right next to the root surface. Because of this there is only a small volume of soil next to the root surface that is involved in supplying immobile nutrients to plants. Figure 2.12 identifies this soil volume as the root surface sorption zone. This figure illustrates that only a small fraction of the soil in the total rooting zone is actually involved in supplying immobile nutrients. The total amount of immobile nutrient in the whole soil volume is not as important as the concentration right next to the root surface. Because only the thin layer of soil surrounding the roots is involved in supplying immobile nutrients, when more plants are considered as in Figure 2.13, there is still little or no competition among the plants for immobile nutrients. Competition would occur only at points where roots from adjacent plants actually came in contact with one another. This illustration indicates that the supply of immobile nutrients like phosphorus does not have to be adjusted (increased) in relation to an increase in yield goal or yield potential. If soil availability is adequate for a 25-bushel wheat yield, then in the event that conditions are favorable (better moisture supply) for 50-plus-bushel yield, the more extensive root system that develops for the higher yield will explore new soil and extract the required phosphorus.

Figure 2.12. Small volume of soil from which plants extract immobile nutrients (root surface sorption zone).

Figure 2.13. Limited competition among plants for immobile nutrients.

The mobility concept and these simple illustrations can help one understand the basis for some common practices and observations. For example, immobile nutrient fertilizers usually are more effective if they can be incorporated, but especially should be placed where roots have a high probability of coming in contact with the fertilizer. This is why band applying phosphate fertilizers is generally more effective than the same rate broadcast and incorporated. Mobile nutrients like nitrogen can be broadcast during the growing season (topdressing wheat) because they are moved easily to the roots with rain or irrigation. The phosphorus soil test does not change much from year to year regardless of the previous year’s yield or fertilizer rate because much of the soil was not in contact with the roots or fertilizer and its available phosphorus status was therefore unchanged. Continued broadcast application of high rates of phosphorus will cause a build up and an increase in the soil test phosphorus because only a fraction (15 to 20 percent) of the fertilizer comes in contact with the roots (fertilizes the crop) and the rest reacts only with the soil (fertilizes the soil).

It sometimes is useful to compare mobile and immobile nutrients and their management to fuel and oil for a tractor or pickup. Fuel is required in relation to the amount of work expected from the tractor in much the same way nitrogen is required in relation to the amount of yield expected from the crop. Oil is required more in relation to the level in the crankcase identified by the dipstick than by what or how much work is expected from the tractor (oil burners excepted). Similarly, phosphorus and potassium requirements are determined from the soil test and the amount of fertilizer recommended does not depend on the yield goal. Like the dipstick that is calibrated with a mark showing full and 1-quart low, the soil test for phosphorus (and any immobile nutrient) must be calibrated by field research. Just as the dipstick is uniquely calibrated for each kind of tractor, soil test calibrations vary slightly for different crops and soils and may be somewhat unique for states and regions.

Figure 2.14. Nitrogen cycle.

Advanced Considerations

The students and faculty at OSU developed a nitrogen cycle (Figure 2.14) that includes various components interlinked with what has been presented here. In addition, this cycle includes the relationships of temperature, pH and oxygen with nitrogen dynamics in plant-soil systems. Note that this cycle is more complex than that illustrated in Figures 2.4, 2.6 or 2.7.

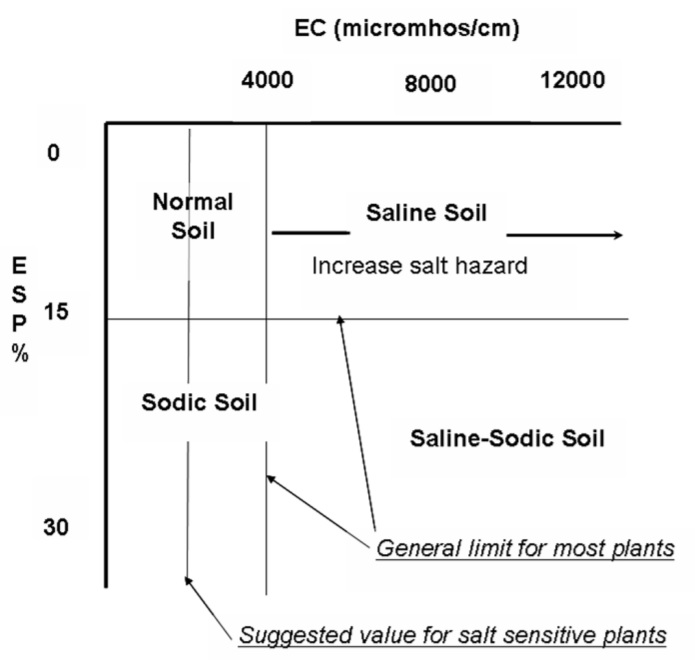

Chapter 3 - Problem Soils

Hailin Zhang

Most soils in Oklahoma have developed under conditions that have resulted in them being naturally productive. Because of how they have been managed for agricultural production and otherwise changed by man’s activities, some of these soils are now less productive. Two of the most common causes of productivity losses are the development of acidic and saline (including saline-alkali and alkali) conditions. They are often considered as problem soils because they do not respond to normal management. Therefore, their treatment and management should be different.

Acid Soils

Soil acidity is a crop production problem of increasing concern in central and western Oklahoma. Although acid soil conditions are more widespread in eastern Oklahoma, their more natural occurrence has resulted in farm operators being better able to manage soil acidity in that part of the state. However, in central and western Oklahoma this problem is increasing with time.

The median soil pH of all agricultural samples tested by the Soil, Water and Forage Analytical Laboratory from 2009 to 2013 was 6.1. This means 50 percent of the sample had a pH less than 6.1 and 50 percent higher than 6.1 statewide. Some counties had more than 35 percent of fields with pH lower than 5.5, which is critically low for most field crops. The median soil pH for all counties is shown in Figure 3.1. More acidic soils frequently are found in the central part of the state, which likely is due to intensive crop production.

Figure 3.1: Median soil pH for all Oklahoma counties tested between 2009 and 2013.

Why Soils are Acidic

The four major causes for soils to become acidic are listed below:

- Rainfall and leaching

- Acidic parent material

- Organic matter decay

- Harvest of high yielding crops

- Nitrification of ammonium

The above causes of soil acidity are most easily understood when we consider a soil is acidic when there is an abundance of acidic cations, like hydrogen (H+) and aluminum (Al3+) present compared to the alkaline cations like calcium (Ca2+), magnesium (Mg2+), potassium (K+), and sodium (Na+).

Rainfall and Leaching

Excessive rainfall is an effective agent for removing basic cations. In Oklahoma, for example, we generally can conclude soils are naturally acidic if the rainfall is above about 30 inches per year. Therefore, soils east of I-35 tend to be acidic and those west of I-35, alkaline. There are many exceptions to this rule though, mostly as a result of item 4, intensive crop production and application of nitrogen fertilizers. Rainfall is most effective in causing soils to become acidic if a lot of water moves through the soil rapidly. Sandy soils are often the first to become acidic because water percolates rapidly, and sandy soils contain only a small reservoir (buffer capacity) of bases due to low clay and organic matter contents. Since the effect of rainfall on acid soil development is very slow, it may take hundreds of years for new parent material to become acidic even under high rainfall.

Parent Material

Due to differences in chemical composition of parent materials, soils will become acidic after different lengths of time. Thus, soils that developed from granite material are likely to be more acidic than soils developed from calcareous shale or limestone.

Crop Production

Harvesting of crops has its effect on soil acidity development because crops absorb lime-like elements, as cations, for their nutrition. When these crops are harvested and the yield is removed from the field, some of the basic material responsible for counteracting the acidity developed by other processes is lost, and the net effect is increased soil acidity. Increasing crop yields will cause greater amounts of basic material to be removed. Grain contains less basic materials than leaves or stems. For this reason, soil acidity will develop faster under continuous wheat pasture than when only grain is harvested. High yielding forages, such as Bermudagrass or alfalfa, can cause soil acidity to develop faster than with other crops.

Table 3.1 identifies the approximate amount of lime-like elements removed from the soil by a 30-bushel wheat crop. Note there is almost four times as much lime material removed in the forage as the grain. This explains why wheat pasture that is grazed will become acidic much faster than when grain alone is produced. Using 50 percent Effective calcium carbonate equivalent lime, it would take about one ton every 10 years to maintain soil pH when straw (or forage) and grain are harvested annually at the 30-bushels-per-acre level.

Nitrification

The use of fertilizers, especially those supplying nitrogen, often is a cause of soil acidity. Acidity is produced when ammonium containing materials are transformed to nitrate in the soil. The more ammoniacal nitrogen fertilizer is applied, the more acidic the soil gets.

Table 3.1: Bases removed by a 30-bushel wheat crop.

(CALCIUM CARBONATE EQUIVALENTS)

|

|

Calcium |

Potassium |

Magnesium |

Sodium |

Total |

|---|---|---|---|---|---|

|

Grain |

2 |

10 |

10 |

2 |

24 |

|

Straw* |

11 |

45 |

14 |

9 |

79 |

|

Total |

13 |

55 |

24 |

11 |

103** |

*Straw/forage

**One ton of alfalfa will remove slightly more than this amount.

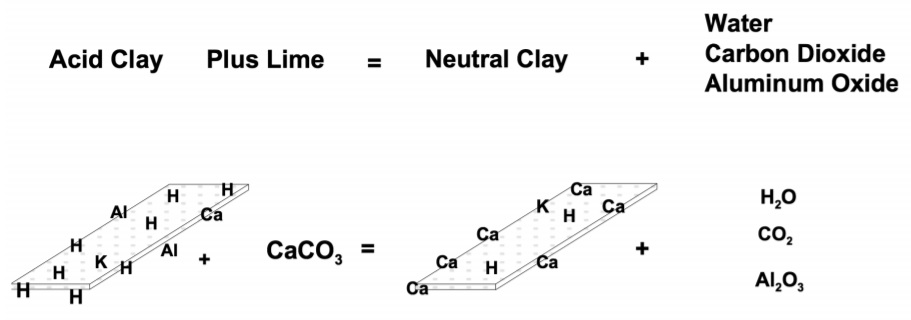

What Happens in Acid Soils

Knowing the soil pH helps identify the kinds of chemical reactions likely to occur in soils. Generally, the most important reactions, from the standpoint of crop production are those dealing with solubilities of compounds or materials in soils. In this regard, we are most concerned with the effects of pH on the availability of toxic elements and nutrient elements.

Toxic elements like aluminum (Al) and manganese (Mn) are the major causes for crop failure in acid soils. These elements are a problem in acid soils because they are more soluble (available for plant uptake) at low pH. In other words, more of the solid form of these elements will dissolve in water when the pH is very low. There is always a lot of solid aluminum present in soils because it is a part of most clay particles.

Element Toxicities

When soil pH is above 5.5, aluminum in soils remains in a solid combination with other elements and is not harmful to plants. As pH drops below 5.5, aluminum containing materials begin to dissolve. Because of its nature as a trivalent cation (Al3+), the amount of dissolved aluminum is 1,000 times greater at pH 4.5 than at 5.5 and 1,000 times greater at 3.5 than at 4.5. For this reason, some crops may seem to do very well, but then fail completely with just a small change in soil pH. Wheat, for example, may do well even at pH 5.0, but usually will fail completely at a pH of 4.0.

The relationship between pH and dissolved manganese in the soil is similar to that

described for aluminum, except that manganese (Mn2+) only increases 100 fold when the pH drops from 5.0 to 4.0.

Toxic levels of aluminum harm the crop by root pruning. That is, a small amount of aluminum in the soil solution in excess of what is normal causes the roots of most plants to either deteriorate or stop growing. As a result, the plants are unable to normally absorb water and nutrients, appear stunted and exhibit nutrient deficiency symptoms, especially those for phosphorus. The final effect is either complete crop failure or significant yield loss. Often, the field will appear to be under greater stress from pests, such as weeds, because of the poor crop conditions.

Toxic levels of manganese interfere with normal growth processes in above ground plant parts. This usually results in stunted, discolored growth and poor yields.

Desirable pH

The adverse effect of these toxic elements is most easily (and economically) eliminated by liming the soil. Liming raises soil pH and causes aluminum and manganese to go from the soil solution back into solid (non-toxic) chemical forms. For grasses, raising soil pH to 5.5 will generally restore normal yields. Legumes, on the other hand, do best in a calcium-rich environment and often need a soil pH between 6.5 and 7.0 for maximum yields.

Soil pH in the range of 6.0 to 7.0 also is desirable from the stand point of optimum nutrient availability. However, the most common nutrient deficiencies in Oklahoma are for nitrogen, potassium and phosphorus, and availability of these elements will not be greatly changed by liming. Nutrients most affected by soil pH are iron and molybdenum. Iron deficiency is more likely to occur in non-acid (high pH) soils. Molybdenum deficiency is not common in Oklahoma, but would be most apt to occur in acid soils and could be corrected by liming.

Soil Buffer Capacity and Buffer Index

Although crops remove large quantities of lime-like materials that are harvested each year, the soil pH usually does not change noticeably from one season to the next. Because soil pH does not change quickly, it is said to be buffered. Buffer means the resistance to the change of pH.

There are several reasons why soils have this buffer ability or capacity. For example, in the Oklahoma Panhandle, soils commonly contain free calcium carbonate (lime). The term caliche is used to describe layers of soil material cemented by accumulated calcium carbonate. These accumulations provide a huge reserve of lime that will maintain soil pH in the alkaline range (above pH 7.0) for generations, perhaps centuries, even with the most productive agricultural systems.

A second contribution to the buffering capacity of soils is the release of basic chemical elements from normal chemical weathering of soil minerals. This is a very slow process that occurs whenever water is added to soil. The effect is influenced by the type of minerals in the soil, the amount and frequency of water addition, and soil temperature.

The most important source of buffer capacity in acid soils (no free lime present) is exchangeable cations. These are the lime-like chemical elements (mostly calcium) that are adsorbed on the surface of soil particles. These adsorbed basic materials act like a large reservoir that continually replenishes basic materials in the soil solution when they are removed by a crop or neutralized by acid. Figure 3.2 illustrates this and the relationship between soil pH and buffer capacity.

As crops remove bases from soil water in the reservoir on the right (Figure 3.2), bases from the large reservoir of soil solids (clay and humus) on the left move to the soil solution and replenish the supply. Because of this relationship and the large reserve of bases from soil solids, the pH does not change much from month to month or even year to year. Also since the large reservoir on the left is shaped like a pyramid, pH can often be changed more easily by liming at pH near 6 than in the very acid pH 4.5 to 5.5 range.

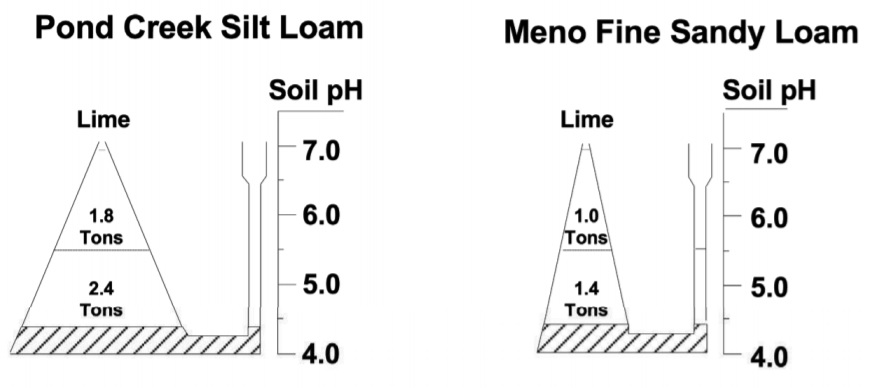

Figure 3.3 shows the influence of soil organic matter and texture on buffer capacity. Both soils have a pH of 4.3, and are too acidic for efficient crop production. In order to provide a more favorable pH, the soils must each be limed. The amount of lime required will depend on the size of the large reservoirs and how base depleted they may be.

From these diagrams it is easy to understand why it takes much more lime to raise the pH of a clay soil with its large reservoir than it does for a sandy soil and its small reservoir. Also, because the reservoir of sandy soil is small, if acidifying conditions are equal, sandy soil will tend to become acidic more rapidly and need to be limed more frequently than a clayey soil.

Figure 3.2: The relationship of basic materials in soil solids to pH of the soil solution.

Figure 3.3: Reservoirs of soil solids in clayey vs. sandy soil.

The Soil Test

Buffer Index, measured in the laboratory as a part of the OSU routine soil test, is an indirect estimate of the soil reservoir size for storing basic material. Because the test involves adding basic (lime-like) material to soils of pH less than 6.3 and then measuring pH again, the BI pH is larger when the reservoir is small. The two soils illustrated in Figure 3.3 need to be limed. The Pond Creek Silt Loam soil would have a Buffer Index value of about 6.2. About 4.2 tons of effective calcium carbonate equivalent lime would be required to raise the soil pH to 6.5. The sandy soil, having the same soil pH, would have a BI value of about 6.5 and require only 2.5 tons of effective calcium carbonate equivalent lime to reach the same pH. The field calibration for BI and lime requirement is provided in Table 3.2.

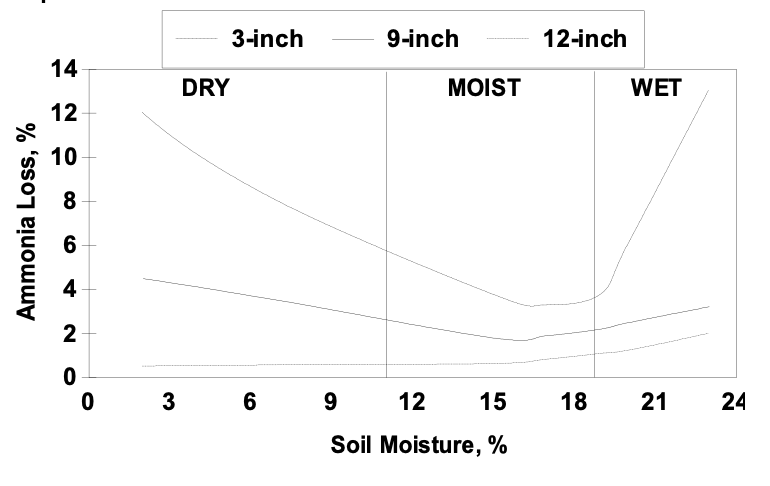

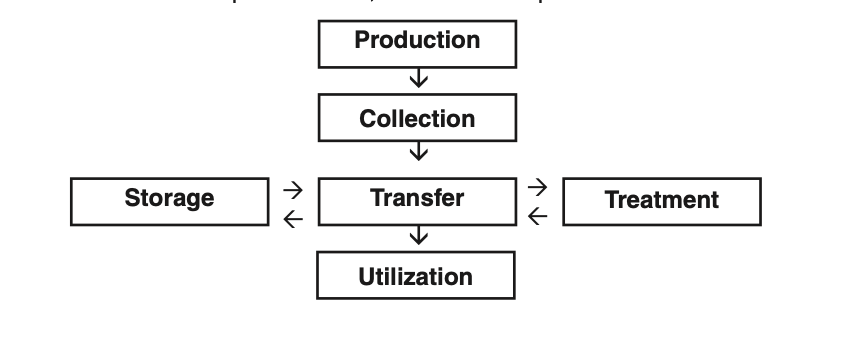

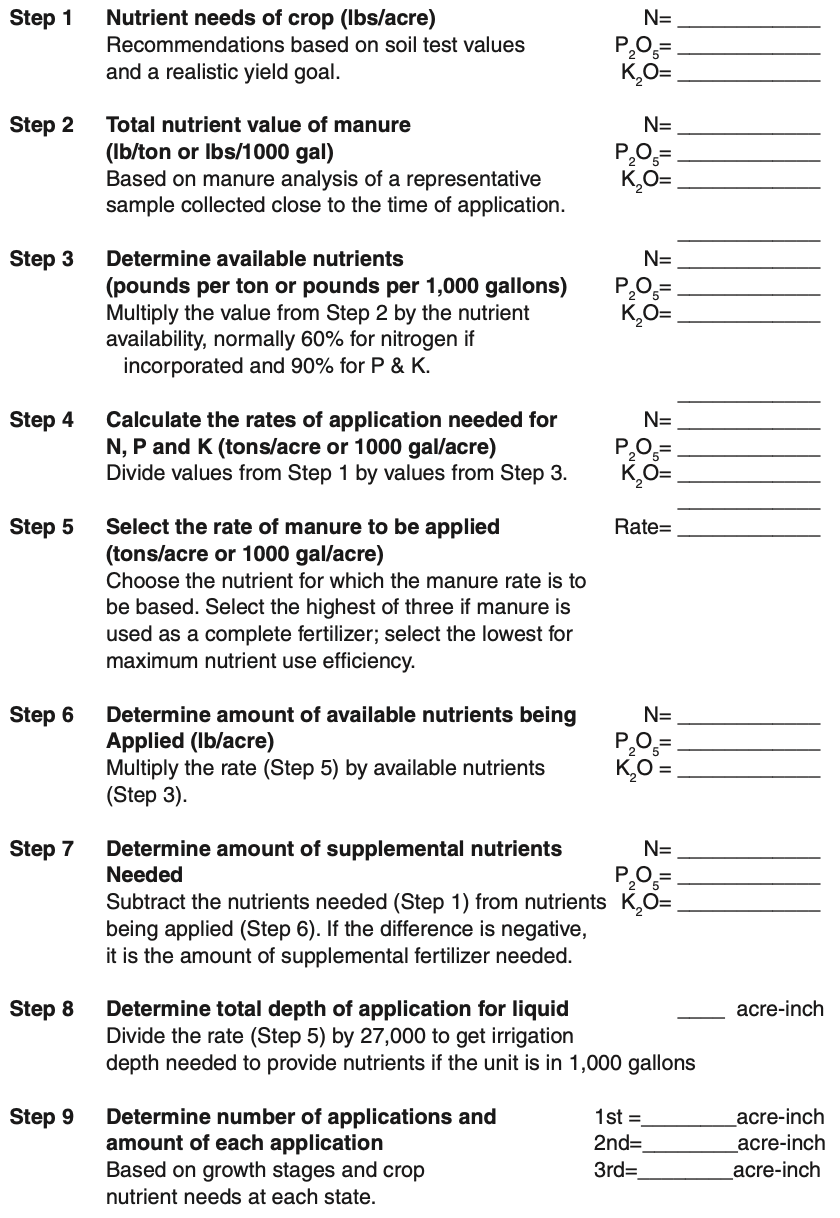

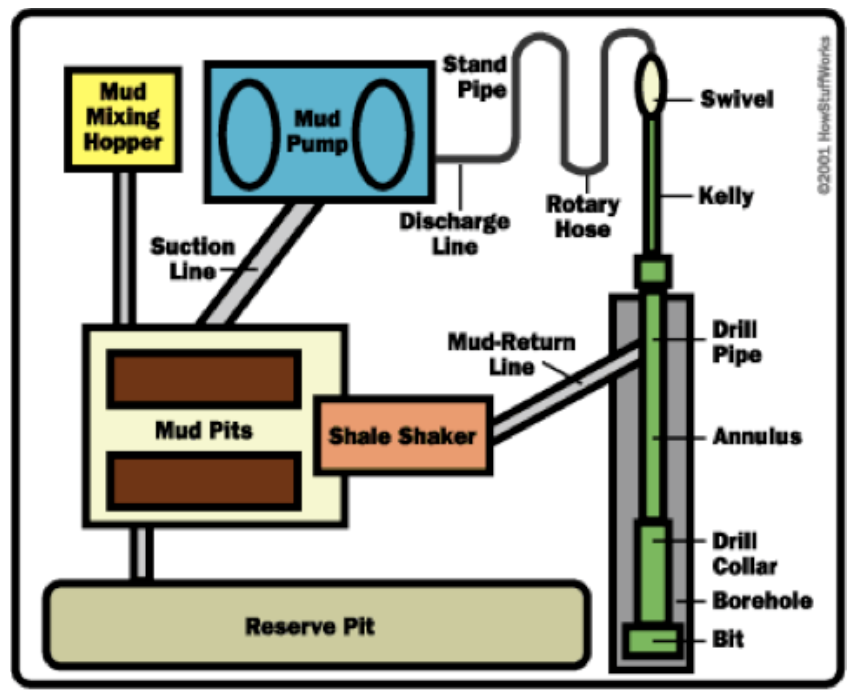

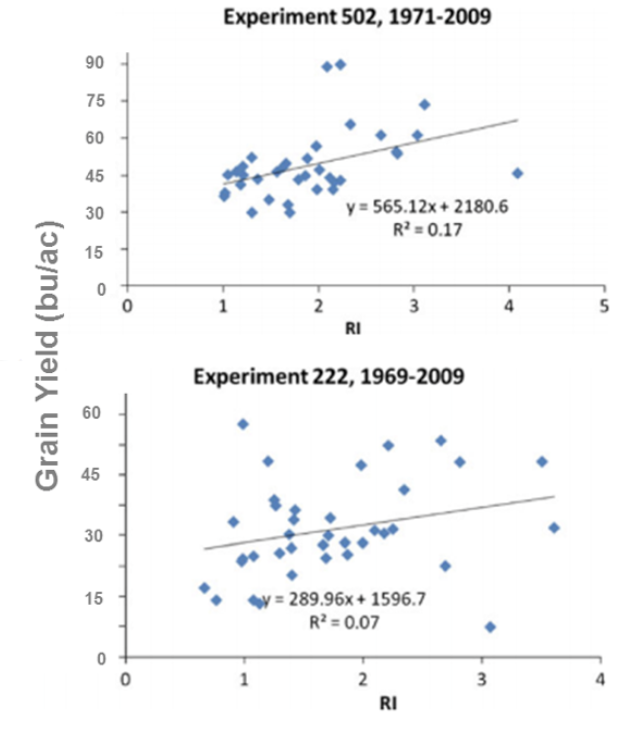

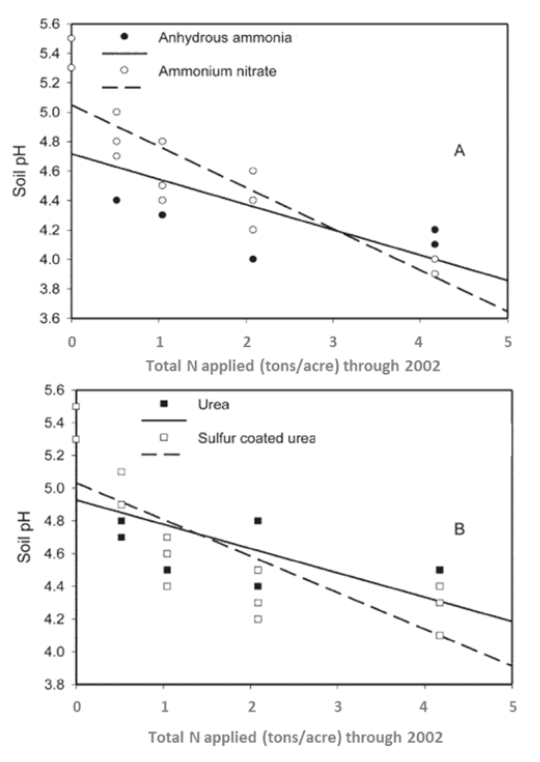

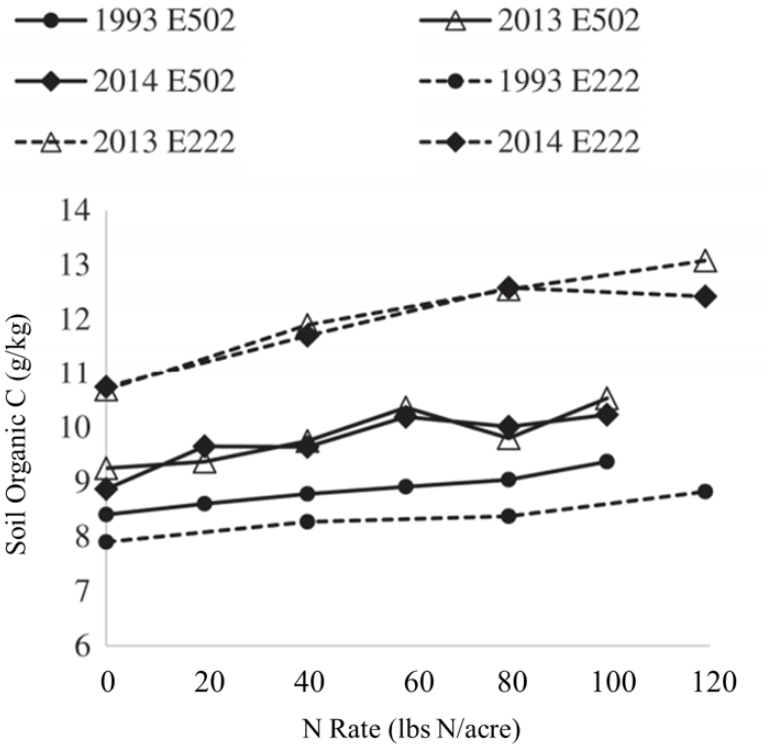

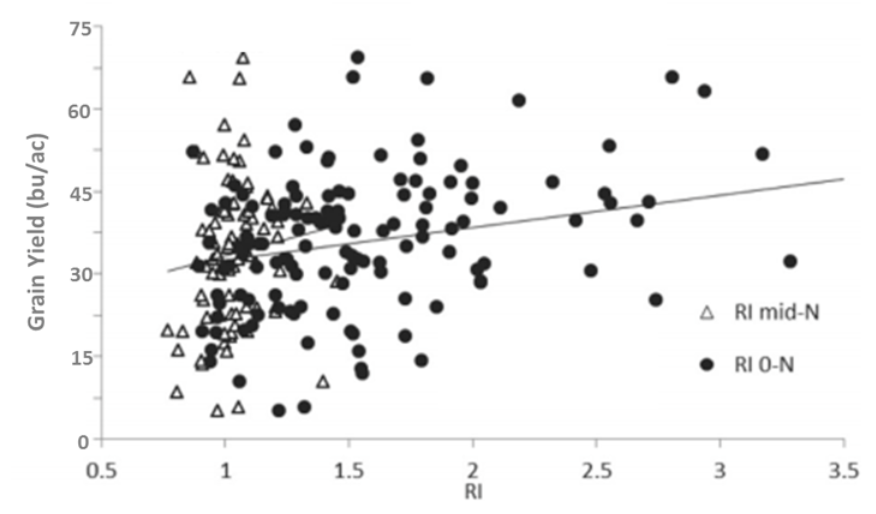

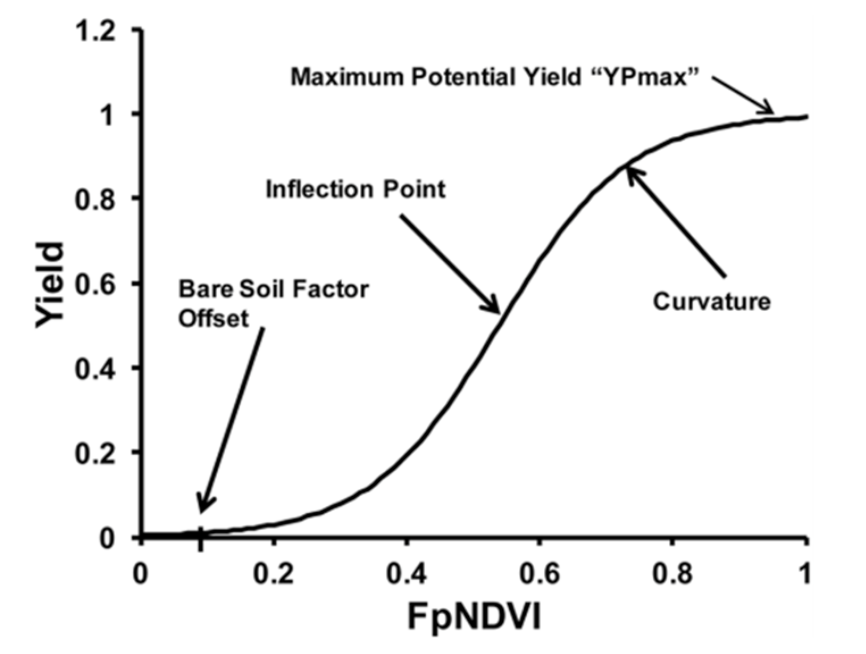

How to Interpret pH and Buffer Index