Can Urban Horizontal Directional Drilling Mud be Land Applied?

What is Urban Horizontal Directional Drilling Mud?

Urban horizontal directional drilling (HDD) mud is mixed material generated during horizontal directional drilling process. Other common names used for this by-product are urban subsurface residuals, spent drilling fluids and spent drilling mud. This growing industry is a non-invasive alternative to trenching and is commonly used for boring holes for the installation of fiber optic cable, sewer lines, gas lines and many other common utilities (Figure 1). As the HDD industry continues to grow, so does the amount of drilling mud needing disposal. Currently, the most common method of disposal is by landfills. This is both costly and time-consuming for the contractor doing the drilling, and this cost is ultimately passed on to the municipality or customer that the contractor is doing the work for.

A typical HDD mud consists of water and cuttings (i.e. soil or rock) from the borehole. However, additives are sometimes used in the drilling fluid to aid in the drilling process depending on the geologic formation or substrate being drilled through. Possible constituents that may be added to the initial drilling fluid include:

- Bentonite clay (soil mineral), which is used for sealing the bore wall (prevent seepage of drilling fluid). Bentonite is also used for increasing fluid viscosity in order to make the fluid more “flowable” with regard to carrying the suspended cuttings back out of the hole to the surface. Bentonite is a clay mineral with a high cation exchange capacity, which can improve the ability of a soil to retain nutrients after land application.

- Polymers such as polyacrylamide (PAM) may be used as a substitute or in addition to bentonite for the same purpose. Polyacrylamide is a common soil conditioner used to stabilize soil on road construction sites and also to prevent erosion on furrow irrigated soils.

- Soda ash (sodium carbonate) is used for pH control. Soda ash is used in the production of certain foods, toothpaste, and as a water softening agent in laundry and boilers.

- Surfactants (a.k.a. wetting agents), are used to disperse clay particles during the drilling process. This prevents heavy clays from “balling up” at the drill bit, and allows clay particles to flow back toward the surface. Surfactants reduce the surface tension between two liquids or between a liquid and a solid. While some surfactants are synthesized naturally by living cells, manufactured surfactants are commonly used in shampoos, soaps, pharmaceuticals and foods.

The Oklahoma Corporation Commission (OCC) has the jurisdiction in regulating the land application of spent HDD mud, but there are no such regulations or recommendations currently available. This is likely due to the lack of research addressing the environmental impacts of spent drilling mud.

Figure 1a. Picture of a HDD rig

Figure 1b. Schematic showing the non-invasive, trenchless technology that HDD rigs provide

What is in HDD mud?

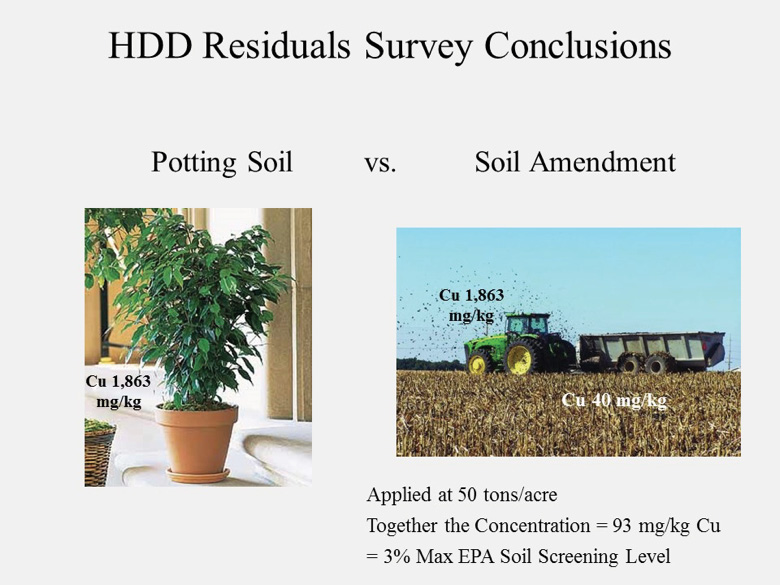

Oklahoma State University has recently performed an in-depth chemical and physical characterization of spent HDD fluids. A total of 56 samples from 28 different states were received and analyzed for total solids, pH, total salts, sodium, plant available nutrients and heavy metals. Fifteen of the samples had metal concentrations above the typical levels found in Oklahoma soils (Table 1); however there were no metal concentrations above the limits for EPA 503 Criteria for Heavy Metals for Exceptional Quality Biosolids or the EPA Soil Screening Levels for Residential Soils. This means that if the drilling mud samples were biosolids, no permit would be required for land application. As far as we know, there is no chemical present beyond allowable concentrations that can limit the land application of spent HDD mud as a means of disposal. However, not every single HDD mud, like exceptional quality biosolids, is suitable for use as a pure media for plant growth, such as a potting/container soil (Figure 2).

Table 1. Number of HDD residual samples that exceeded typical soil metals concentrations found in typical Oklahoma soils. Typical soil metals concentrations in Oklahoma are reported by Zhang and Schroder.

| Metal | Typical Levels in Oklahoma Soils (mg/Kg) | Numbers of Samples Above Range | Median (mg/Kg) | Min (mg/Kg) | Max (Mg/Kg) |

|---|---|---|---|---|---|

| Copper | 1.94-32.7 | 12 | 12.6 | 0 | 1863.4 |

| Manganese | 27.4-2165 | 0 | 230.6 | 0 | 1606.1 |

| Zinc | 15.3-142 | 1 | 30.1 | 0 | 341.4 |

| Nickel | 2.41-57.3 | 0 | 8.6 | 0.6 | 43.3 |

| Arsenic | 0.75-33.6 | 0 | 0 | 0 | 1.6 |

| Chromium | 4.3-69.7 | 1 | 14.6 | 4.2 | 100.1 |

| Cadmium | 0.13-0.80 | 0 | 0 | 0 | 0 |

| Lead | 2.60-31.7 | 1 | 0 | 0 | 58.4 |

Figure 2. A spent HDD mud with a copper concentration of 1,863 mg/kg may not be safe for a potted plant or the human consumption of that potted plant. However, land application and incorporation of the same spent HDD mud at a rate of 50 tons solids/acre to a soil containing a normal level of copper (40 mg/kg) results in a soil concentration of only 93 mg/kg. This is only 3 percent of maximum EPA Soil Screening Level for Residential Soils (3100 mg/kg). Note that a copper concentration of 1,863 mg/kg was the highest copper level observed in the HDD residuals survey.

Many HDD residuals contained plant available (as assessed by Mehlich-3 extraction) nutrients such as phosphorus, potassium, calcium and magnesium in appreciable amounts. Solids content ranged from 4 percent to 45 percent. Thus, application of the material is most easily achieved by spraying as a slurry onto soils.

Based on the results of the survey, it is highly unlikely that excessive trace metals will be applied to soils through land application of the residuals. However, if a contractor is drilling through an area that was historically contaminated, perhaps by previous industries such as mining, refining or smelting, then the residuals will take on the same characteristics of that contaminated soil. If this situation occurs, then the HDD residuals must be tested to determine if the material is suitable for land application, or if a limited application rate is necessary. Although there are no existing guidelines for land application of HDD residuals contaminated with trace metals, a suitable substitute is the EPA 503 guidelines for land application of biosolids.

Land Application of HDD Residuals to Established Forages and Bare Soil

Application of HDD Residuals to Established Hay/Pasture

Two field studies were conducted to examine any potential agronomic or environmental impact resulting from the land application of spent HDD mud. Because there was nothing chemically limiting in the material, application rates were based on total solids. Application rates were 0, 10, 20, 30, 40 and 50 tons of solid per acre. The mud was sprayed onto the surface in a slurry. The first study involved surface application of HDD mud to a typical Bermudagrass hay (Figure 3) followed by measurements of soil chemical properties and resulting biomass production. Biomass measurements at 120 days after application revealed no statistical difference between any of the rates applied and the control (no amendment). Soil samples also revealed no effect of land application of mud on soil chemical analysis.

Figure 3. Picture of several established Bermudagrass plots immediately after application of HDD mud (left) and seven days after application and nearly three inches of rainfall (right).

Application of HDD Residuals to Bare Soils

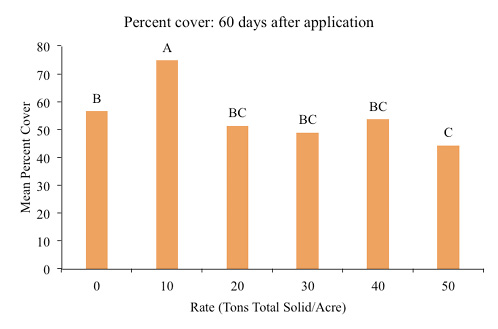

The second field study involved the application of HDD mud to a bare ground, which was meant to represent a highly disturbed construction site (Figure 4). Prior to surface application, the topsoil was scraped from the surface to expose subsoil. Bermudagrass seed was then spread at the suggested rate for establishing a new yard, followed by application of HDD mud at the same solids loading rates previously described. Percent cover was calculated on day 60 by digital image analysis. Percent cover for the plots that received 10 tons of solids per acre was significantly higher than the control (no amendment) and all other rates applied. Percent cover for plots that received mud at the rate of 50 tons of solid per acre was significantly lower than the control (Figure 5).

Figure 4. Scraped/bare soil plots pictured immediately after surface application (upper) and approximately 120 days after application (lower).

Figure 5. Mean percent cover at 60 days after application of HDD residuals to bare-disturbed soil plots. HDD mud applied at rates of 0, 10, 20, 30, 40 and 50 tons solid per acre. Treatments sharing the same letter indicate no significant difference. The rate of 10 tons solid/acre was significantly higher than the control and other treatments, while the rate of 50 tons solid/acre was significantly lower than the control.

Summary

Some level of compaction is apparent in much of Oklahoma’s cropland. However, impact on crop productivity is dependent of its severity, soil type, crop type and the weather. The best cure for compaction is prevention. Utilize proper tire sizes and inflation pressures, or consider tracks to prevent surface compaction, which is most detrimental in no-till systems due to its impact on crop establishment. Minimize the traffic of heavy loads across the field, especially in moist soil conditions to prevent deep compaction. Lastly, avoid overgrazing cropland under no-till management, which can cause severe compaction in the near surface soil.

Josh Daniel

Graduate Research Assistant

Chad Penn

Associate Professor