MCi-Kicker® Dockage Machine Wheat, Grain Sorghum, Corn, & Soybean

Mechanical dockage testers are used in the grain grading process to remove dockage from wheat, corn, grain sorghum, rye, barley, flax, and other grains. In wheat, the Kicker® also separates the shrunken and broken kernels (SBK). Dockage machines produce more accurate and consistent results and save time compared to hand sieving. As the machine removes the dockage, the grader may complete other grading tasks.

To officially grade grain, the Federal Grain Inspection Service (FGIS) removes dockage from grain mechanically. Country elevator graders may determine grades that more closely match official grades by using mechanical dockage machines.

The purpose of this fact sheet is to describe the set-up procedures for the MCi-Kicker® 3-screen and 4-screen machines for use in grading wheat, grain sorghum, soybeans, and corn.

Dockage

Dockage is seeds, weed stems, chaff, straw, sand, dirt, and any material other than the predominant grain which can be removed readily from the grain by use of sieves and cleaning devices. Elevators that do not accurately measure dockage lose money by paying grain price for non-grain material. In addition, the grading procedures for many grains, including wheat, triticale, sunflower seed, rye, flaxseed, and barley, specify that dockage must be removed before determining test weight. Elevator operators handling these grains that do not effectively remove dockage underestimate test weight and may assign incorrect grades.

Test weights for grain sorghum, corn, and soybeans are determined before removing dockage and foreign material (FM). Additional information about grading wheat, grain sorghum, soybeans, and corn may be found in OSU Extension Facts AGEC-224 and AGEC-227.

The net effect of failing to correctly remove dockage depends on the grain price, grade premiums and discounts, and dockage discounts. In most cases, elevators that underestimate dockage are losing money even if the numerical grade is lowered due to test weight. Research indicates a dockage machine will pay for itself with 25 loads of 15 percent or higher dockage. The same research indicates that producers delivering high dockage grain are overpaid and producers delivering clean grain are underpaid.

Material other than corn in corn and sorghum in sorghum is classified as FM. FM is counted in both the broken corn and foreign material (BC (BN) & FM) category and the FM categories.

There is no dockage category in soybeans. Material other than soybeans is counted as FM. The MCi-Kicker® may be used to assist in the determination of FM in sorghum, soybeans, and corn.

Setup Procedure - MCi-Kicker®

The following discussion presents the setup procedure for wheat, grain sorghum, soybeans, and corn. Country elevators use one of two models of the MCi-Kicker®: the 3-screen or the 4-screen model. The 3-screen Kicker® has three slots for screens and the 4-screen Kicker® has four slots for screens.

Wheat Set-up

For wheat, the 3-screen and 4-screen Kickers® are set-up using the same riddle and screens. On the 4-screen Kicker®, the #2 slot is blank.

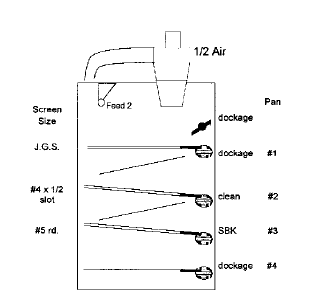

The Kicker® uses an aspirator, a riddle, and two screens to separate the wheat from the dockage and SBK (Figure 1).

Figure 1. Screen MCi-Kicker® with suggested wheat screens.

The Standard setup for wheat is:

- Air at 1/2 for 3-screen & 1/4 for 4-screen

- Feed control at 2

- J.G.S. riddle in top slot

- # 2 slot blank on 4-screen

- #4 slotted sieve in next slot

- # 5 round-hole sieve in last (bottom) slot

To help keep the screens clean, rubber balls have been placed under the screens. Machine movement causes the balls to bounce against the screens to keep them relatively clean.

Before pouring wheat into the feed, check the feed speed, air setting, and screens. Periodically, graders may experiment with the air setting. The aspirator removes small, light non-wheat materials. Good, clean wheat works best at the recommended setting. Wheat that contains relatively high dockage may require air settings slightly above the recommended setting.

If the air setting is too high, more wheat (shrunken & broken kernels) will be removed than necessary. If the air is set too low, insufficient amounts of dockage will be removed.

The J.G.S. riddle is used to remove large stems and other none wheat material. Additional dockage and the SBK are removed with the #4 slotted and #5 round-hole sieves.

Both the 4-screen and 3-screen Kicker® have 4 catch pans (Figure 1). The top pan contains dockage. The next pan contains clean wheat, the third pan contains SBK (or dockage) and the bottom pan contains dockage. If the wheat contains large amounts of cheat (chess); the third pan may contain more dockage than wheat and would be added to the dockage.

Steps for Grading Wheat

The following are the steps for grading a wheat sample using the MCi-Kicker®:

- If using a quart cup to determine test weight, collect about a 1,000-gram sample.

- If using a pint cup to determine test weight, collect about a 500-gram sample.

- Weigh the sample and write down the weight.

- Check Kicker® settings and screens.

- TURN THE MACHINE ON.

- Pour sample into feed.

- After sample clears the screens, TURN THE MACHINE OFF then dump dockage from aspirator into pan # 1.

- Pour dockage from bottom pan into first pan.

- Weigh and note the SBK in pan #3.

- Pour the SBK into pan #2 (good wheat) and mix.

- Weigh, note, and discard the dockage in the #1 (top) pan.

The most common mistake is forgetting to dump the dockage removed by the aspirator into the top pan (#1). Turn off the machine before emptying the aspirator.

The next step most often missed is not pouring the SBK from pan #3 into the good wheat pan (#2). If the SBK is not added to and mixed with the good wheat, test weight will be overestimated.

Special Settings

There are no special settings for the MCi-Kicker®. However, if the sample contains excessive amounts of cheat (dockage) there may be more dockage in the SBK pan than wheat. In this case, the contents may be poured into the dockage pan (#1) rather than the good wheat (pan #2).

If the sample contains an excessive amount of dockage (cheat), the air setting may need to be increased.

The Federal Grain Inspection Service has only approved the Carter-Day® Dockage machine for use in determining “official” grades. Experiments with the MCi-Kicker® indicate that the dockage and SBK levels determined with both machines are comparable. Commercial elevators may use any mechanical dockage tester that produces comparable results with “official” grades.

Grain Sorghum Set-up

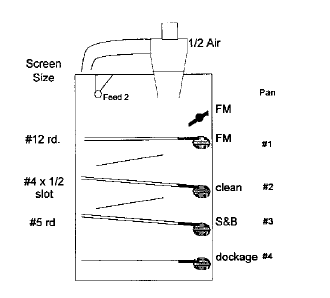

The Kicker® set-up for grain sorghum is nearly identical to wheat (Figure 2). Some elevators use the same screens. But to get grades that will come closer to official, the JGS riddle is replaced with a # 12 round-hole sieve.

Figure 2. 3-Screen MCi-Kicker® with suggested sorghum screens.

The Standard setup for grain sorghum wheat is:

- Air at 1/2 for 3-screen & 1/4 for 4-screen

- Feed control at 2

- # 12 round-hole sieve top slot

- # 2 slot blank on 4-screen

- # 4 x 1/2 slotted sieve in next slot

- # 5 round-hole sieve in last (bottom) slot

Steps for Grading Grain Sorghum

The steps for grading a sorghum sample using the MCi-Kicker® are:

- If using a quart cup to determine test weight, collect about a 1,000-gram sample. If using a pint cup to determine test weight, collect about a 500-gram sample.

- Inspect sample for objectionable odor, insects, and harmful conditions

- Determine the test weight.

- Also note the gram weight of the test weight sample.

- Pour sample into Kicker® feed.

- After sample clears the screens, empty aspirator into pan #1 (FM).

- Weigh, note the percentage and discard FM in the top pan (#1).

- Weigh, note the percentage and discard the SBK in pan #3.

- Weigh, note the percentage and discard the dockage in the bottom pan #4.

- Weigh out approximately 30 grams of sorghum from pan #2 (clean grain) and hand pick the FM. Calculate the percentage and add to the percentage FM determined in step 7.

- Determine damage and class from 15-gram sample taken from pan #2 (clean grain).

Note that the four pans for wheat contain (in order from top to bottom) dockage, clean grain, SBK, and dockage. With sorghum the pans contain FM, clean grain, SBK, and dockage (Figure 2). Also with sorghum, test weight is determined before removing FM and dockage.

Special Settings

There are no special settings. If the sorghum has excessive amounts of FM, the air may be increased to remove more via aspiration. Care must be taken that whole kernels of sorghum are not removed.

Dockage in sorghum is always rounded down (i.e. 0 to .99 = 0, 1.0 to 1.99 = 1, etc.). If a # 5 round-hole sieve is used as the bottom screen, there is a possibility that dockage will be overestimated. If dockage is being overestimated, a smaller sieve may be placed in the bottom slot (#4).

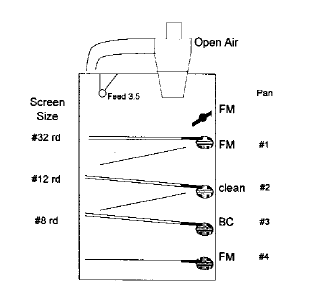

Figure 3. 3-Screen MCi-Kicker® with suggested corn screens.

The standard setup for corn is:

- Air open for 3-screen & 4-screen models

- Feed control at 3.5

- # 32 round-hole sieve top slot

- # 2 slot blank on 4-screen

- # 12 round-hole sieve in next slot

- # 8 round-hole sieve in bottom slot

Note that the # 12 round-hole sieve used for corn is a fine (short) sieve and is different from the # 12 used with sorghum. As with the wheat and sorghum MCi_Kicker® screen placement, the #2 slot is blank.

The top pan (#1) contains FM (empty aspirator), pan #2; clean corn, pan #3; broken kernels, and the bottom pan (#4) contains FM. Note that there is no dockage classification with corn.

Steps for Grading Corn

Test weight is determined before removing FM and dockage.

The steps are:

- Obtain a representative sample, about 1,000 grams (500 grams for pint cup).

- Inspect for objectionable odor, insects, and harmful conditions.

- Determine the moisture.

- Determine the test weight.

- Determine the percentage of broken corn and foreign material (BCFM).

- Divide out a representative portion of corn (approximately 250 grams). Record the weight of sample used.

- Pour the sample into the Kicker® feed.

- Empty aspirator into the top pan and add bottom two pans to top pan.

- Add FM from bottom pan to top pan.

- Hand pick FM from the corn in the clean grain pan (Figure 3), and add to BC & FM in the top pan, calculate the percentage BC & FM.

- Determine percent damage.

- Determine the class.

- Determine the grade (Flint, Flint and Dent, or Waxy).

Soybean Setup

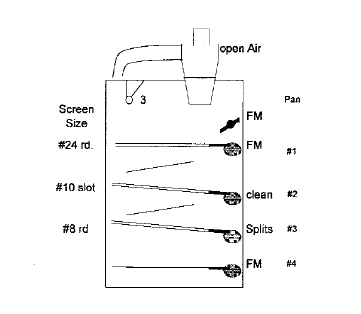

The MCi-Kicker® screen setup for wheat, corn, and grain sorghum is the same for both the 3-screen and 4-screen models. The # 2 slot (second from top) is left blank. With soybeans, the # 2 slot (second from top) on the 4-screen model contains a # 8 round-hole screen. Only the 3-screen model is shown in the Figure 4.

Figure 4. Three Screen MCi-Kicker® with suggested soybean screens.

The suggested screens and settings for the MCi-Kicker® and soybeans are:

- Air open for both 3- and 4-screen models

- Feed control at 3

- # 24 round hold sieve top slot

- # 8 round-hole sieve on 4-screen model

- # 10 slotted sieve in next to bottom slot

- # 8 round-hole sieve in bottom slot

Both the 3-screen and 4-screen models have four pans. From the top, the pans contain FM (empty aspirator), clean beans, splits, and FM.

Steps for Grading Soybeans

- Get 1,000 to 1,025 gram sample (500 grams for pint cup).

- Examine sample for sample grade factors. Odor heating, unknown foreign substances, and any other unusual conditions.

- Determine the test-weight per bushel before the removal of foreign material.

- Divide out a representative portion from the sample and determine moisture content (250 grams).

- Examine the sample for garlicky, infested, purple mottled, or stained soybeans.

- Handpick the sample for course foreign material. Remove large FM. Calculate percent course FM.

- Cut out approximately 125 grams and pour into the Kicker® feed.

- Combine the fine FM in pan #4 with the fine FM in pan #1.

- Handpick the FM in pan #2 (clean soybeans) and add to the fine FM in pan # 1.

- Subtract the weight of the fine FM (pan #1) from the 125-gram portion.

- Pick damage and splits on the remaining sample.

1999 Air Setting Modifications

MCi-Industries modified the air setting control in 1999. Kickers manufactured after 1998 have the air control setting at the back of the airflow tube. The settings are from 1 to 10. Open air is 1 and closed air is 10. Refer to the owners or operators manual for air settings.

Kim Anderson

Extension Economist

MCi-Industries

Newton, Kansas