Practical Soybean Sampling and Hand Sieving Procedures

This publication provides practical procedures which can be used by producers, warehouse managers, and elevator managers for sampling and grading soybeans. The procedures and portion sizes are based on the USDA Practical Procedures for Grain Handlers. The portions and hand-sieving methods presented in this Current Report are not used by official grain inspectors licensed by the Federal Grain Inspection Service. Licensed graders should use larger portions and precision mechanical equipment that will provide the most accurate and most uniform results.

Representative Sample

Obtaining a representative grain sample is an essential part of grain inspection. Without a representative sample, the final grade will not reflect the true grade or value of the grain. In order for a sample to be considered representative, it should:

- be obtained in accordance with recommended procedures

- be of the prescribed size (at least 1,000 gram or approximately 1 1/4 quart)

- be handled securely, protected from manipulation, substitution, and careless handling.

The following pages explain the proper way to do probe sampling. Some of this information was taken from: Inspecting Grain-Practical Procedures for Grain Handlers, Sec. 1, Sampling Grain.

Probe Sampling

A large percentage of grain, as it travels from the farm to the final consumer, is at one time or another sampled with a grain probe. Probe sampling is the only approved method for obtaining samples from stationary lots. If probe sampling is performed correctly, the samples drawn will consistently be representative.

The Equipment

Before learning the sampling procedure, the sampler should be familiar with the equipment used.

Hand Probe: This standard piece of equipment, sometimes referred to as a trier, is constructed of brass or aluminum. Probes come in various sizes with standard lengths of 5, 6, 8, 10, and 12 feet. The type of carrier dictates which probe length shall be used. There are two types of hand probes: compartmented probes in which slots in the outer tube match compartments in the inner tube and open throat probes in which the inner tube is open. Open-throat probes tend to draw more of their sample from the top portion of the grain while compartmented probes draw a representative sample from each layer. All official grain probes are compartmented probes with a 1-3/8 inches in diameter (outer tube). Make sure the probe reaches the bottom of the carrier. A 5 or 6 feet probe will be sufficient for most farm trucks while hopper-bottom carriers may require a longer (6, 8, or 10 feet) probe.

Mechanical probe:

There are two types of mechanical probes which are recommended for sampling stationary lots of grain in trucks, railcars, or other open-top carriers. The gravity-fill probe function is similar to compartmented hand probes except that after the compartment is filled it rotates to an inner tube where it is forced up by air. The core probe functions by forcing the sample up into the core as the probe is pushed down and then using air to transport the sample to the output point. A third type, the in-load suction probe which uses negative air pressure to suck the sample into the bottom of the probe, is not recommended since it tends to overestimate foreign material.

Sampling Canvas:

Heavy canvas cloth or similar material can be used to display the sample from the compartmented probe. Another alternative is a short section of rain gutter, half section of pipe. The sampling canvas or other material should be at least 6 inches longer than the probe used to draw the sample. This size is necessary so that the grain from the entire length of each probe will not spill off the ends of the canvas. Sampling canvases must always be kept clean, dry, and free of holes.

Sampling Containers such as heavy cloth or canvas bags and metal buckets or plastic cans may be used to transport the sample to the inspection station. Sample containers should be free of all old grain, insects, and other waste material prior to use. Air-tight containers or bags lined with a polyethylene liner should be used to store grain to prevent loss of moisture and to protect the sample from adverse environmental conditions such as rain or humid weather.

General Procedures

Before sampling any carrier, record on your sample ticket the carrier’s identification number. Visually examine the whole lot of grain. Take a handful of grain from several locations and check it for odor. Record any unusual conditions on your sample ticket. Next, spread your canvas and check to see that the probe and canvas are clean and dry. You are now ready to start sampling.

There are several ways to insert the probe into the grain. Regardless of which technique

you use, the general rules are:

- Insert the probe at a 10-degree angle from the vertical with the slots facing upward and completely closed. The 10-degree angle eases the resistance of the compacted grain against the probe while still allowing the probe to reach the bottom of the container. The slots must be kept closed until the probe is inserted as far as it will go. Otherwise, a disproportionate amount of grain from the top of the load will fall into the probe compartments as it is being inserted. When sampling grain which contains sand or grit, insert the probe with the slots downward to avoid jamming it. After the probe is inserted, turn the slots upward before opening.

- After the probe is fully inserted (with the slots facing upward), open the slots and move the probe up and down quickly in two short motions. Close the slots completely, grasp the probe by the outer tube, and withdraw it from the grain. Do not pull the probe by the wooden handle. This can result in the inner tube being pulled out of the outer tube. When this occurs, the probe must be emptied, reassembled, cleaned, and the area probed again.

- Empty the probe onto the canvas and compare the grain from each depth of the probe for uniformity of kind, condition, and infestation. Also, compare the probe to others drawn from the same lot. If all probes and portions of probes are uniform with one another, they shall be composited and placed in a sample bag along with a completed sample ticket. If the examination of the probes indicates that the lot of grain is made up of distinctly different parts in regard to condition (such as musty, sour, commercially objectionable foreign odor, or heating grain), the sampler must then draw a sample from each of the different parts, in addition to the sample that represents the carrier as a whole.

- When transferring the grain from the canvas to the sampling bag, take care not to allow fine material to be blown from the canvas.

Where to Probe

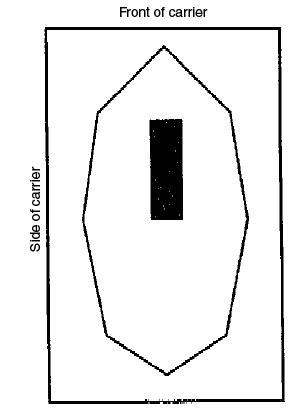

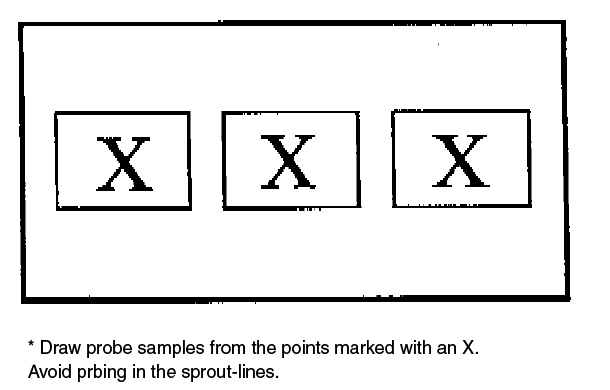

Draw at least two samples from any truck or trailer that are 600 bushels or less. Larger lots of grain should be probed in 3 to 5 places. Recommended probe sites, which are shown in Figure 1, are anywhere in the carrier except the corners and the center of the load (which was directly underneath the loading spout). The probe sites should be varied between loads in a random manner. Elevators which routinely sample in the same location have found that bad grain seems to migrate to the areas in the load which are not sampled. Hopper-bottomed carriers should be probed in the center of each hopper (Figure 2).

* Draw at least two probe samples form any point in the shaded area.

Figure 1. Sampling Sites-Truck or Trailer.

Figure 2. Sampling Sites-Hopper Bottomed Carriers.

Inspection Procedures

The process of inspecting soybeans begins when the sample is drawn and follows a prescribed path:

- Obtain a representative sample of approximately 1,000 grams.

- Examine the sample for objectionable odors, insect infestation, heating, or other harmful conditions.

- Divide out a 250-gram portion (or the amount recommended by the moisture meter’s manufacturer) and determine the moisture content.

- Determine the test weight.

- Divide the sample into a 125-gram portion for examination of foreign material.

- When deemed necessary, divide the sample into 125-gram portions and determine the percentage of class, heat-damaged, damaged kernels foreign material, oil, protein, soybeans of other colors, purple mottled and stained soybeans and splits.

Step 1 – Obtain a Representative Sample

Use the probing procedures described above, or a tailgate sampler or other method, to obtain a representative sample of approximately 1,000 grams.

Step 2 – Odors, Insects, and Harmful Conditions

Except for smut or garlic odors, soybeans which have a musty sour or commercially objectionable foreign odor (COFO) is “U.S. Sample grade.” Use the entire sample to determine odor. Fumigant or insecticide odors are not considered COFO if they dissipate after aerating the sample for up to 4 hours. The presence of two or more live insects injurious to stored grain causes the grain to be designated “infested,” but does not affect the numerical grade. Heating is a condition common to grain which is spoiling and also causes the grain to be designated “U.S. Sample grade.” Be careful not to confuse heating with sound grain which is warm due to storage in bins, railcars or other containers during hot weather. Other harmful substances which can cause the grain to be considered U.S. Sample grade include: rodent pellets, castor beans, crotalaria seeds, glass, stones, and unknown foreign substances such as rock salt, or fertilizer.

Step 3 – Moisture

Moisture is an essential measure of soybean storability and value and should be determined prior to removing dockage. Moisture can be determined with any device which has been tested and approved by the Oklahoma Department of Agriculture. Moisture meters should be certified once a season and maintained in adherence with the manufacturer’s recommendation. Many moisture meters (such as the Montomco) require that a specific weight sample be used. The use of an inexact sample weight will result in an inaccurate measure of moisture content. Additionally, some of the newer moisture meters also display an estimate of test weight. This test weight estimate cannot be legally used in determining grade since it is based on a small sample size (often 100 grams or less).

Step 4 – Test Weight

Test weight is a measure of the weight of grain required to fill a specific volume (pint, quart, or bushel). To determine test weight, pour the entire dockage free sample through a funnel into a kettle until the grain overflows the kettle. Level off the kettle making three, full-length, zigzag motions with a stroker. The test weight is determined by weighing the filled kettle on either a special beam scale, an electronic scale programmed to convert gram weight to test weight, or a standard laboratory scale. If a standard scale is used, the gram weight must be converted to test weight per bushel (multiple the grams in a one quart kettle by .0705 to obtain the test weight in pounds per bushel).

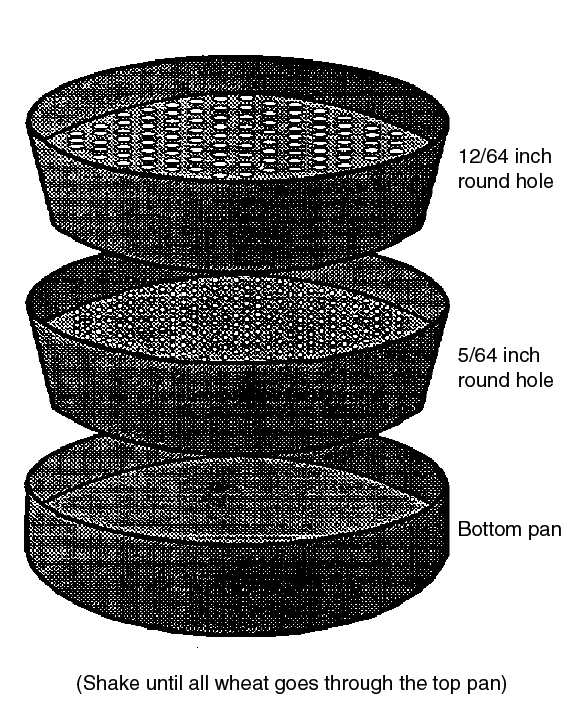

Step 5 – Determination of Foreign Material in Soybeans by Hand Sieves

Percent foreign material (FM) in soybeans affects the USDA grade. The maximum percent FM is 1%, 2%, 3%, and 5% for USDA #1, #2, #3, and #4 soybeans, respectively. To determine the percentage of FM:

- Divide out a representative portion of soybeans (approximately 125 grams). Record the weight of the sample used.

- Assemble the hand sieves by placing an 8/64 inch round-hole sieve on a bottom pan and then placing a 10/64 x 3/4 inch slotted sieve on top of the 8/64 inch round-hole sieve (Figure 3). The top slotted sieve shall be placed so that the perforations will be parallel to the motion of the sieve as it is shaken. Hold the sieve in both hands directly in front of the body with elbows close to the sides. The sieves should be held level so the soybeans move lengthwise of the top sieve perforations. In a gently, steady, side-sieving motion move the sieves right to left approximately 10 inches and return from left to right.

Repeat the operation five times. The foreign material will consist of:

* All coarse material that remains on top of the 10/64 by 3/4 inch top sieve

* Plus, all material, including soybeans and pieces of soybeans which readily passed

through the 8/64 inch round-hole sieve and fall in the bottom pan

* Plus, all matter other than soybeans which are hand-picked from the material remaining

on top of the 8/64 sieve (middle sieve) after sieving.

Figure 3. Determining Foreign Material in Soybeans with Hand Sieves.

Sieve for 20 strokes.

FM is all the material in the bottom pan plus, the hand picked foreign material from

the top of the 8/64 round hole sieve plus, the coarse foreign material remaining on

top of the 10/64 by 3/4 inch slotted sieve.

Step 6 – Determination of Splits in Soybeans Using Hand Sieves

The percentage of split soybeans also affect the USDA grade; thus, the value of the beans. The maximum percentage splits for determining grade are 10% for #1, 20% for #2, 30% for #4 and 40% for #5. A split is any sound soybean that has more than one-fourth broken off.

- The determination of split is based on the same portion (approximately 125 grams) that was previously used in the determination of fine foreign material.

- Weigh the fine material which passed through the 8/64 round hole sieve and fell into the bottom pan and then add in the material remaining on top of the 8/64 role hole sieve.

- Separate the splits from the whole beans by hand-picking.

- Subtract the weight of the fine material subtracted from the total sample weight to get the sample weight used for calculating the percentage of splits.

- The percentage of splits is determined, by dividing the weight of the splits by the adjusted sample weight (total sample weight minus weight of FM).

Step 6 – Determination of Damage

The most common types of kernel damage are drier damage, germ, frost, heat, mold, scab, sprout, and insect damage. The percentage of damaged kernels is determined by handpicking a 125-gram sample. Stinkbug stung damaged kernels are kernels which, when cross sectioned, show damage caused by stinkbugs. Consider stinkbug stung-damaged kernels at the rate of one-fourth of the actual percentage.

Step 6 – Purple-mottled and Stained Soybeans

Soybeans that are discolored by the growth of a fungus, dirt, dirt like substances including nontoxic inoculants or other substances are designated purple mottled and stained and can be graded no higher than U.S. No. 3. The percentage of purple-mottled and stained soybeans is determined by handpicking a 125-gram portion.

Step 6 – Soybeans of Other Colors

Soybeans with green, black, brown or bicolored seed coats are designated soybeans of other colors. The percentage of soybeans of other colors is determined by handpicking a 125-gram portion.

Step 6 – Class

Soybeans are divided into two classes based on color: yellow soybeans and mixed soybeans. There are no subclasses in soybeans. Class is determined by handpicking a 125-gram portion.

Summary

It is important that grain handlers concentrate on determining the correct grade. Profit margins are too small to lose money because of improper grade determination. The procedures presented in this Fact Sheet are not designed to produce official grades. The procedures should produce relatively accurate estimates of dockage, foreign material, damaged kernels, and other factors affecting grades and the value of the grain.

Kim Anderson

Extension Economist

Phil Kenkel

Extension Economist