Adjusting and Setting Up Mechanical Dockage Testers

Mechanical dockage testers can be used in the grain grading process to remove dockage from wheat, corn, grain sorghum, rye, barley, flax, and other grains. They provide more consistent results than hand sieving procedures. They also save time since the grader can be occupied with other steps of the grading process while the machine removes the dockage. Since the Federal Grain Inspection Service (FGIS) uses mechanical dockage testers in their official grading process, these machines can help the manager of the country elevator be assured that out-bound grain will meet a buyer’s requirements. However, many elevator operators who have invested in mechanical dockage testers are unfamiliar with how the machines should be set up and adjusted and are not accurately measuring the amount of dockage. The purpose of this fact sheet is to describe the adjustment and set-up procedures for the most common brand of mechanical dockage testers used in grading wheat, corn, and grain sorghum.

Dockage is weed seeds, weed stems, chaff, straw, grain other than the predominant grain, sand, dirt, and any other material other than the predominant grain which can be removed readily from the grain by use of appropriate sieves and cleaning devices. Elevators that do not accurately determine the amount of dockage are losing money by paying grain price for material which will have little or no value when the grain is resold. In addition, the grading procedures for many grains, including wheat, triticale, sunflower seed, rye, flaxseed, and barley, specify that dockage must be removed before determining test weight. Elevator operators handling these grains who do not effectively remove dockage are underestimating test weight and may be assigning incorrect grades. The net effect of failing to completely remove dockage in wheat depends on the price of wheat, grade premiums and discounts, and dockage discounts (if any). In most cases, elevators which underestimate dockage are losing money even if the numerical grade is lowered due to test weight.

Set-up Procedures—Carter Day Dockage Tester1

The Carter Day Dockage Tester has a small aspirator, a riddle carriage with interchangeable riddles for the removal of large material, and three sieve carriages with interchangeable sieves. It also has an air control and a control on the hopper feed opening that must be set for each type of grain. The speed of the machine is controlled by an adjustable pulley and should be checked once a season. Prior to grading a sample, the grader should set the air and feed control on the correct numerical setting and ensure that the appropriate riddle and sieves are installed in the appropriate carriages. The general procedure is:

Step 1. Check that the tester is clean.

Step 2. Turn on the tester and pour the sample into the hopper.

Step 3. After the sample has cleared the last sieve, turn the tester off.

Step 4. Collect and weigh the material from the appropriate pans.

Hard Red Winter Wheat—Standard Set-up and Adjustment

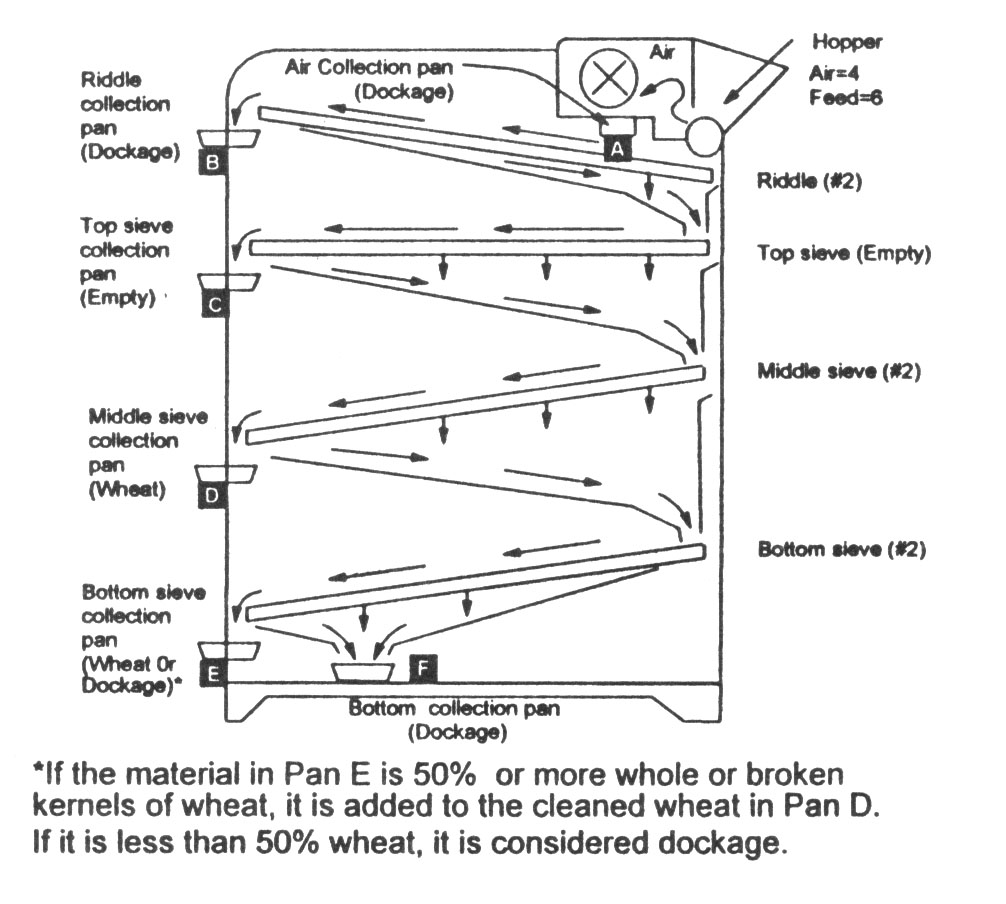

The standard set-up for wheat is depicted in Figure 1.

Set-up:

- Set air control at 4.

- Set feed control at 6.

- #2 riddle in the riddle carriage.

- No sieve in the top sieve carriage.

#2 sieve in the middle carriage.

#2 sieve in the bottom carriage.

Dockage will consist of the material that was removed by the aspirator (pan A in Figure 1), passed over the riddle (pan B in Figure 1), or passed through the bottom sieve (pan F in Figure 1). The material in the bottom sieve collection pan (pan E in Figure 1) is usually cleaned wheat. However, if pan E contains over 50% of material other than wheat, it should be added to dockage). The material in the middle collection pan (pan D in Figure 1) is always cleaned wheat.

Figure 1. Set-up Procedure for Carter Day Dockage Tester Standard Procedure for Hard Red Wheat.

Hard Red Winter Wheat—Special Procedure for Wheat Containing Chess or Similar Seeds

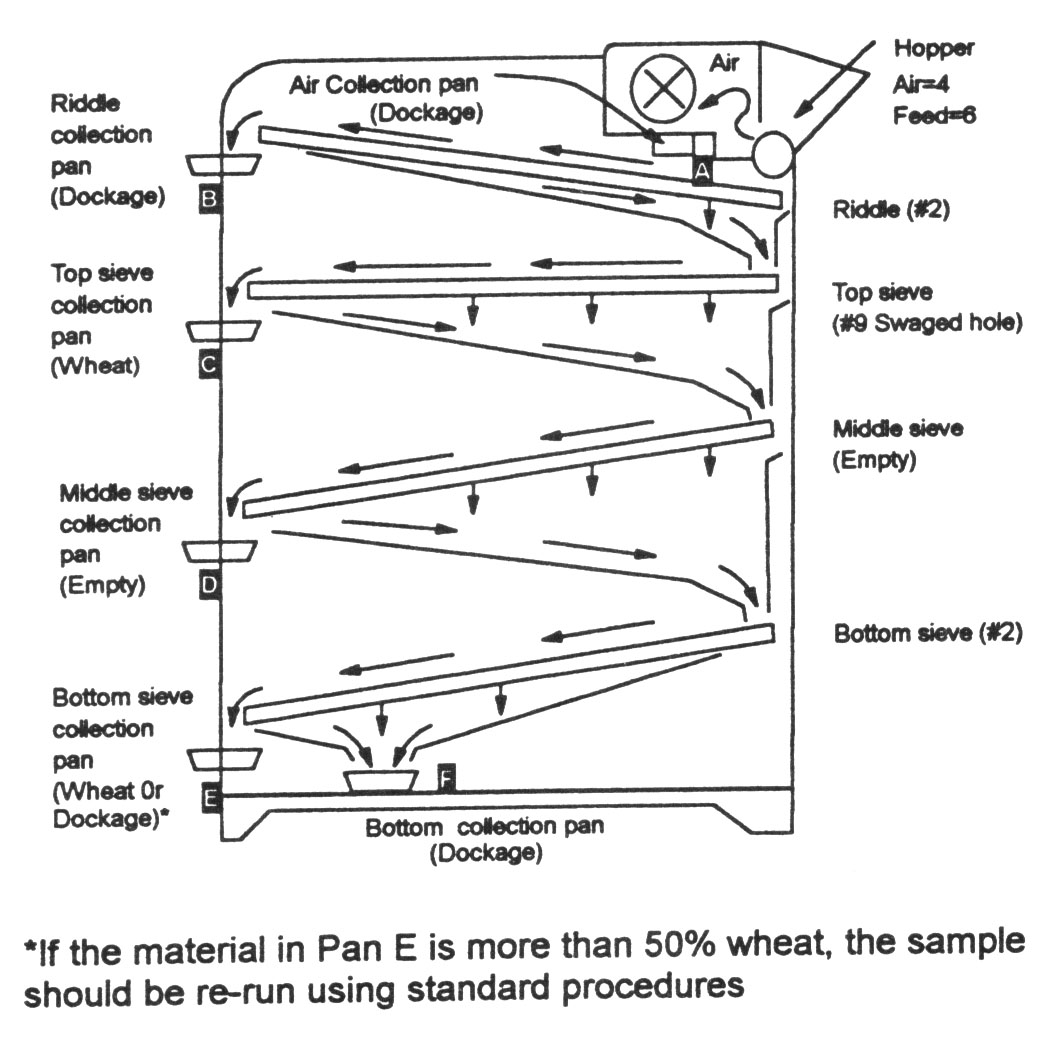

When a visual inspection indicates that chess is present in the sample, the inspector hand picks a 50-gram sample to determine the percentage of chess by weight. If more than 0.5% chess (by weight) is present, the sample is run on a mechanical dockage tester under special chess procedures. The special chess procedures for a Carter Day Dockage Tester are:

Set-up:

- Set air control at 4.

- Set feed control at 6.

- #2 riddle in the riddle carriage.

- #9 swaged-hole sieve in the top sieve carriage.

- No sieve in the middle sieve carriage.

- #2 sieve in the bottom sieve carriage.

Dockage will consist of the material that was removed by the aspirator in the air collection pan (pan A in Figure 2), the material going over the riddle and falling in the riddle collection pan (pan B in Figure 2), and the material passing through the #9 swag-holed sieve and passing over the top of the #2 sieve that falls in the bottom collection pan (pan E in Figure 2) (provided that this material is at least 50% chess), and the material that passed through the bottom #2 sieve, which falls in the bottom collection pan (pan F in Figure 2). Note that this procedure requires that all of the material passing through the #9 sieve and remaining on top of the #2 sieve (pan E in Figure 2) be hand picked to determine the percentage of chess by weight. When there is less than 50% chess in pan E, then the sample is rerun under standard procedures.

Figure 2. Set-up Procedure for Carter Day Dockage Tester Special Chess Procedure for Hard Red Wheat.

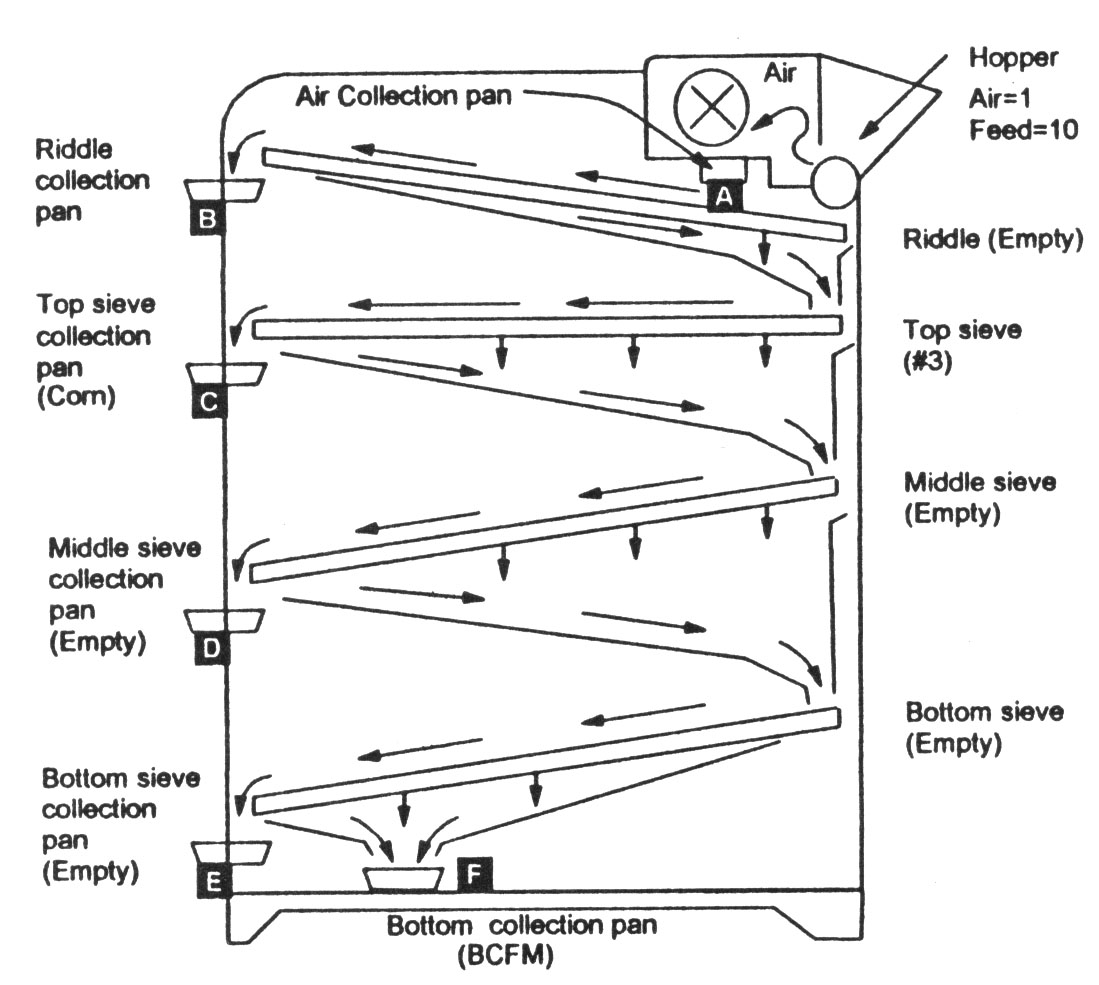

Corn—Standard Set-up and Adjustment

The amount of broken corn and foreign material (BCFM) can be determined by weighing the material removed by the Carter Day Dockage Tester and adding in the foreign material hand-picked from the mechanically cleaned sample.

- Set-up:

- Set air control at 1.

- Set feed control at 10.

- No riddle in the riddle carriage.

- #3 combination 12/64 and 6/64 sieve in the top sieve carriage.

- No sieve in the middle sieve carriage.

- No sieve in the bottom sieve carriage.

The BCFM will consist of all material that passed through the #3 combination screen (pan F in Figure 3), along with the hand-picked foreign material that was obtained from the mechanically cleaned sample.

Figure 3. Set-up Procedure for Carter Day Dockage Tester Standard Set-up for Corn.

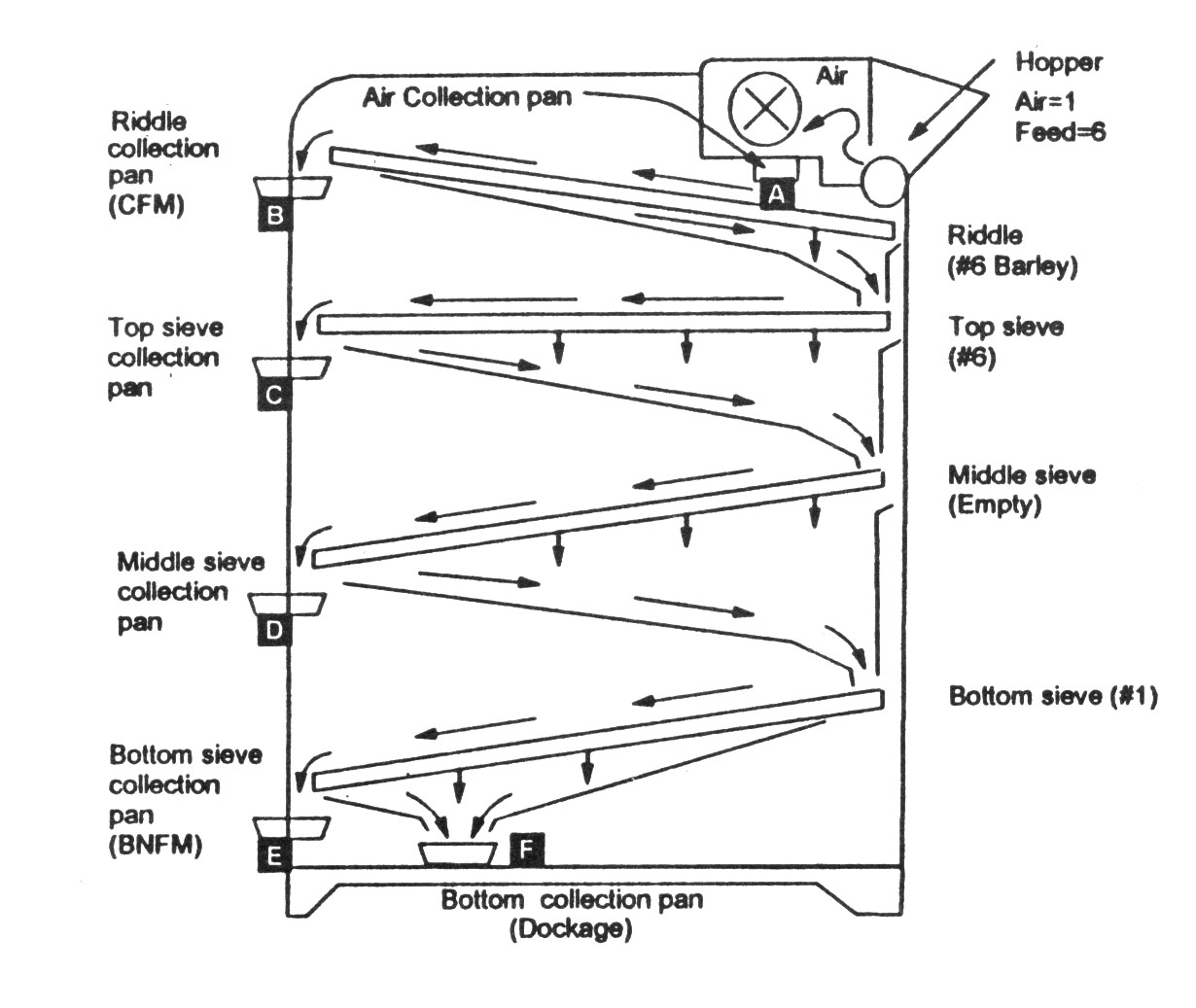

Grain Sorghum—Standard Set-up and Adjustment

Set-up:

- Set air control at 1.

- Set feed control at 6.

- #6 barley riddle in the riddle carriage.

- #6 sieve in the top sieve carriage.

- No sieve in the middle sieve carriage.

- #1 sieve in the bottom sieve carriage.

The dockage is considered to be all material that passes through the bottom #1 sieve (pan F in Figure 4).

The foreign material is all coarse material that passes over the riddle (Pan B in Figure 4) along with all material other than sorghum that is hand-picked from the mechanically cleaned sample.

The broken kernels, foreign material, and other grains (BNFM) that is all material that passes through the #6 top sieve, but stays on top of the #1 bottom sieve (Pan E in Figure 4).

Figure 4. Set-up Procedure for Carter Day Dockage Tester Standard Set-up for Sorghum.

1 The Carter Day Dockage Tester is the only machine currently approved to be used by FGIS in official inspections. However, several brands of mechanical dockage testers provide similar results. References to the Carter Day Dockage Tester are provided for illustration purposes only and should not be interpreted as any form of endorsement.