Aeration System Design for Cone-Bottom Round Bins

Before attempting to select, design or manage an aeration system, you should study the following publication: BAE-1101 “Aeration and Cooling of Stored Grain.”

Fact Sheet BAE-1101 discusses the importance of choosing the right airflow rate to obtain the desired aeration system capabilities. Power requirements, fan selection, control systems, and management suggestions are also explained.

This fact sheet presents information for the design or selection of aeration system components for cone-bottom round grain bins.

Cone-bottom bins have the advantage of complete and easy unloading. The cone also provides additional storage capacity in the bin.

Below-grade cone-shaped foundations can only be used in areas of low water tables. If the water table rises to the level of the cone, water may enter the cone and cause grain spoilage.

When only dry grain will enter the bin, a cone slope of 37° or 3 feet fall in a 4 foot run will allow complete unloading. When wet grain will be handled through the bin, the cone slope should be 45° or 1 foot fall in a run of 1 foot.

Aeration Systems

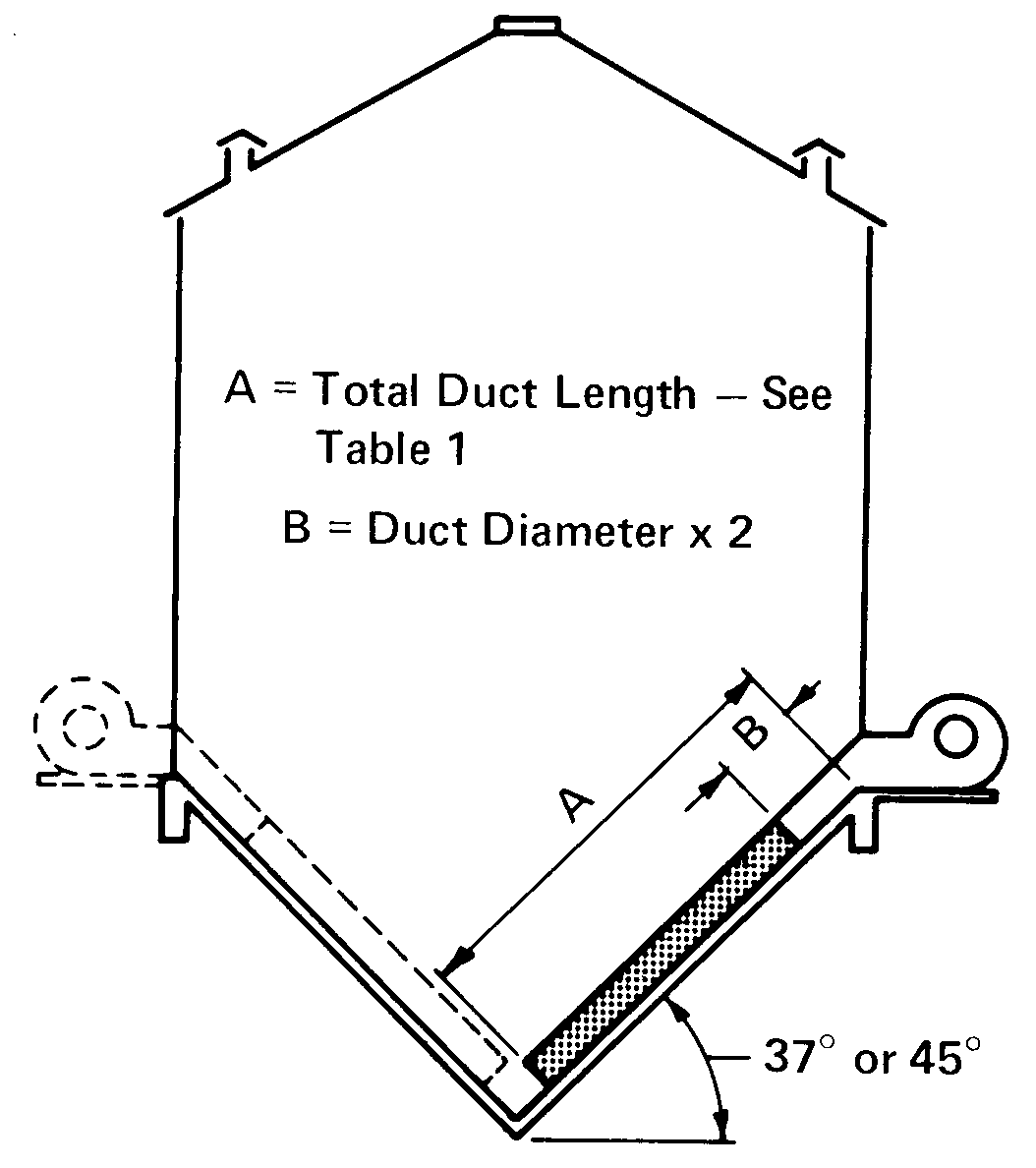

A typical aeration system for a cone-bottom round grain bin is shown in Figure 1. Round metal ducts are used to distribute air in cone-bottom bins. The upper section of the duct is non-perforated with lower sections perforated. The bottom of the duct is usually open.

If a single duct does not have sufficient surface area to avoid excessive operating pressures, a second fan and duct are added as shown in Figure 1, with the air volume divided between the two fans. In large bins, three or more fans and ducts are sometimes required to deliver high airflow rates. In general, centrifugal fans with backward-inclined blades are required to deliver efficient air volumes when operating against the higher static pressures encountered in cone-bottom bins.

Figure 1. Aeration system for a cone-bottom round grain bin.

Description of Terms

The following terms are used in the design procedure:

fpm = feet per minute, air velocity;

CFM = cubic feet of air per minute, air volume;

CFM/bu = cubic feet of air per minute per bushel, airflow rate

Static pressure is the pressure against which the fan must operate, expressed as inches of water.

Design Procedure

The design procedure for aeration systems involves:

- Determining bin capacity, selecting air-flow rate, and determining total air volume to be delivered;

- Selecting ducts on the basis of surface area;

- Determining operating static pressure; and

- Selecting fans to deliver the required air volume when operating against the expected static pressure.

Determining Bin Capacity and Air-Flow Volume

Bin capacity is the number of bushels which can be stored in the bin plus the number which can be stored in the cone. The capacity of the bin with and without the cone can be determined from Table 1. Bin capacity does not include storage in the roof section.

Example: Consider a 30 feet diameter bin with 19 foot sidewalls and a 45° concrete cone shaped foundation. The bin capacity with and without the cone can be found using Table 1. In addition to individual capacities, Table 1 gives the total capacity, bin plus cone. From Table 1, bin capacity without cone is 10,775 bu. The capacity of a 30-foot diameter, 45° cone is 2,820 bu. Therefore total capacity, bin plus cone, is 13,595 bu. Table 1 can be used for bins with concrete cone shaped foundations and for steel hopper bottom bins.

It is best to aerate the grain with 1/5 cfm/bu (0.2 cfm/bu). The total airflow requirement would be 0.2 cfm/bu multiplied by the total bushels in the bin.

0.2 cfm/bu x 13,595 bu = 2719 cfm

Table 1. Bin Capacity with/without cone.

| Diameter (ft.) | Height (ft.) | Bin Capacity (bu) | Capacity due to Cone (bu) 45o cones |

Capacity due to Cone (bu) 37o cones |

Total Capacity (Bin+Cone),bu 45o cones |

Total Capacity (Bin+Cone),bu 37o cones |

|---|---|---|---|---|---|---|

| 15 | 8 | 1125 | 363 | 270 | 1488 | 1395 |

| 13 | 1850 | 363 | 270 | 2213 | 2120 | |

| 16 | 2275 | 363 | 270 | 2638 | 2545 | |

| 18 | 11 | 2250 | 610 | 450 | 2860 | 2700 |

| 13 | 2650 | 610 | 450 | 3260 | 3100 | |

| 16 | 3275 | 610 | 450 | 3885 | 3725 | |

| 21 | 4300 | 610 | 450 | 4910 | 4750 | |

| 21 | 13 | 3625 | 960 | 720 | 4585 | 4345 |

| 16 | 4450 | 960 | 720 | 5410 | 5170 | |

| 24 | 6675 | 960 | 720 | 7635 | 7395 | |

| 24 | 16 | 5825 | 1440 | 1080 | 7265 | 6905 |

| 19 | 6900 | 1440 | 1080 | 8340 | 7980 | |

| 24 | 8725 | 1440 | 1080 | 10165 | 9805 | |

| 32 | 11625 | 1440 | 1080 | 13065 | 12705 | |

| 27 | 19 | 8750 | 2060 | 1540 | 10810 | 10290 |

| 24 | 11025 | 2060 | 1540 | 13085 | 12565 | |

| 32 | 14725 | 2060 | 1540 | 16785 | 16265 | |

| 30 | 19 | 10775 | 2820 | 2120 | 13595 | 12895 |

| 24 | 13625 | 2820 | 2120 | 16445 | 15745 | |

| 32 | 18175 | 2820 | 2120 | 20995 | 20295 | |

| 33 | 24 | 16475 | 3850 | 2890 | 20325 | 19365 |

| 27 | 18550 | 3850 | 2890 | 22400 | 21440 | |

| 32 | 21975 | 3850 | 2890 | 25825 | 24865 | |

| 36 | 24 | 19625 | 4880 | 3660 | 24505 | 23285 |

| 27 | 22075 | 4880 | 3660 | 26955 | 25735 | |

| 32 | 26150 | 4880 | 3660 | 31030 | 29810 | |

| 40 | 32700 | 4880 | 3660 | 37580 | 36360 | |

| 42 | 27 | 30050 | 6315 | 4735 | 36365 | 34785 |

| 32 | 35600 | 6315 | 4735 | 41915 | 40335 | |

| 40 | 44500 | 6315 | 4735 | 50815 | 49235 | |

| 48 | 53425 | 6315 | 4735 | 59740 | 58160 | |

| 48 | 27 | 39250 | 7750 | 5810 | 47000 | 45060 |

| 32 | 46500 | 7750 | 5810 | 54250 | 52310 | |

| 40 | 58150 | 7750 | 5810 | 65900 | 63960 | |

| 48 | 69775 | 7750 | 5810 | 77525 | 75585 |

Table 2 gives the maximum length of duct which may be placed down one side of the cone foundation for various bin diameters and the two cone slopes.

Table 2. Duct Lengths for Cone-Shaped Foundations or Bottoms.

| Bin Diameter (ft.) |

45 o cones 1 in 1 slope Max. length of duct (ft.) |

37 o cones 3 in 4 slope Max. length of duct (ft.) |

|---|---|---|

| 14 | 9 | 8 |

| 15 | 9.75 | 9 |

| 18 | 12 | 10 |

| 21 | 14 | 12 |

| 24 | 16 | 14 |

| 27 | 18 | 16 |

| 30 | 20 | 18 |

| 36 | 24 | 21 |

| 42 | 28 | 25 |

Example: For a 30 ft. diameter bin with 45° cone shaped bottom, the maximum length of a duct is 20 feet (using Table 2).

As shown in Figure 1, the air makes a turn when it leaves the fan and transition and enters the duct. This air turbulence is accompanied by an increase in static pressure in the initial section of the duct. For this reason, the initial section of the duct should be non-perforated for a distance equal to twice the duct diameter.

Max. length of duct (Table 2) – (2 x the duct diameter) = max. length of perforated duct

Example: If a 12 inch diameter duct is to be used in our example bin (30 ft. diameter bin), the maximum length of perforated duct is 18 ft.

12 inches = 1 ft.

20 ft. (from Table 2) – (2 x 1 ft.) (1 ft. is the duct diameter) = 18 ft

If an 18 inch (1.5 ft.) diameter duct is to be used, the maximum length of perforated duct is 17 ft.:

20 ft. – (2 x 1.5 ft.) = 17 ft.

Determining Air Velocity through the Grain

Table 3 and Table 4 are used to determine total air volume and the air velocity through the grain when the desired airflow rate is known. Table 3 is for 45 degree cones and Table 4 is for 37 degree cones. The choice of airflow rate is an important decision. Higher aeration airflow rates give greater management flexibility and may allow the storage of grain with higher moisture content because the grain can be cooled and dried with natural air quicker. However, higher aeration airflow rates also require larger ducts, involve higher static pressures, and have greater power requirements. For a complete discussion of airflow rates, see BAE-1101.

Table 3 (Part A : Total Air Volume (cfm) ). Total air volume and air velocity through the grain for grain bins with 45 degree cones.

| Total Air Volume (cfm) | ||||||||

| Air Flow Rate (cfm/bu) | ||||||||

| Diameter (ft.) | Height (ft.) | Total Capacity (Bin+Cone), bu |

1/2 | 1/3 | 1/4 | 1/5 | 1/10 | 1/20 |

| 15 | 8 | 1488 | 744 | 496 | 372 | 298 | 149 | 74 |

| 13 | 2213 | 1107 | 738 | 553 | 443 | 221 | 111 | |

| 16 | 2638 | 1319 | 879 | 660 | 528 | 264 | 132 | |

| 18 | 11 | 2860 | 1430 | 953 | 715 | 572 | 286 | 143 |

| 13 | 3260 | 1630 | 1087 | 815 | 652 | 326 | 163 | |

| 16 | 3885 | 1943 | 1295 | 971 | 777 | 389 | 194 | |

| 21 | 4910 | 2455 | 1637 | 1228 | 982 | 491 | 246 | |

| 21 | 13 | 4585 | 2293 | 1528 | 1146 | 917 | 459 | 229 |

| 16 | 5410 | 2705 | 1803 | 1353 | 1082 | 541 | 271 | |

| 24 | 7635 | 3818 | 2545 | 1909 | 1527 | 764 | 382 | |

| 24 | 16 | 7265 | 3633 | 2422 | 1816 | 1453 | 727 | 363 |

| 19 | 8340 | 4170 | 2780 | 2085 | 1668 | 834 | 417 | |

| 24 | 10165 | 5083 | 3388 | 2541 | 2033 | 1017 | 508 | |

| 32 | 13065 | 6533 | 4355 | 3266 | 2613 | 1307 | 653 | |

| 27 | 19 | 10810 | 5405 | 3603 | 2703 | 2162 | 1081 | 541 |

| 24 | 13085 | 6543 | 4362 | 3271 | 2617 | 1309 | 654 | |

| 32 | 16785 | 8393 | 5595 | 4196 | 3357 | 1679 | 839 | |

| 30 | 19 | 13595 | 6798 | 4532 | 3399 | 2719 | 1360 | 680 |

| 24 | 16445 | 8223 | 5482 | 4111 | 3289 | 1645 | 822 | |

| 32 | 20995 | 10498 | 6998 | 5249 | 4199 | 2100 | 1050 | |

| 33 | 24 | 20325 | 10163 | 6775 | 5081 | 4065 | 2033 | 1016 |

| 27 | 22400 | 11200 | 7467 | 5600 | 4480 | 2240 | 1120 | |

| 32 | 25825 | 12913 | 8608 | 6456 | 5165 | 2583 | 1291 | |

| 36 | 24 | 24505 | 12253 | 8168 | 6126 | 4901 | 2451 | 1225 |

| 27 | 26955 | 13478 | 8985 | 6739 | 5391 | 2696 | 1348 | |

| 32 | 31030 | 15515 | 10343 | 7758 | 6206 | 3103 | 1552 | |

| 40 | 37580 | 18790 | 12527 | 9395 | 7516 | 3758 | 1879 | |

| 42 | 27 | 36365 | 18183 | 12122 | 9091 | 7273 | 3637 | 1818 |

| 32 | 41915 | 20958 | 13972 | 10479 | 8383 | 4192 | 2096 | |

| 40 | 50815 | 25408 | 16938 | 12704 | 10163 | 5082 | 2541 | |

| 48 | 59740 | 29870 | 19913 | 14935 | 11948 | 5974 | 2987 | |

| 48 | 27 | 47000 | 23500 | 15667 | 11750 | 9400 | 4700 | 2350 |

| 32 | 54250 | 27125 | 18083 | 13563 | 10850 | 5425 | 2713 | |

| 40 | 65900 | 32950 | 21967 | 16475 | 13180 | 6590 | 3295 | |

| 48 | 77525 | 38763 | 25842 | 19381 | 15505 | 7753 | 3876 | |

Table 3 (Part B : Air Velocity (fpm) ). Total air volume and air velocity through the grain for grain bins with 45 degree cones.

| Air Velocity (fpm) | ||||||||

| Air Flow Rate (cfm/bu) | ||||||||

| Diameter (ft.) | Height (ft.) | Total Capacity (Bin+Cone), bu |

1/2 | 1/3 | 1/4 | 1/5 | 1/10 | 1/20 |

| 15 | 8 | 1488 | 4.21 | 2.81 | 2.11 | 1.68 | 0.84 | 0.42 |

| 13 | 2213 | 6.26 | 4.18 | 3.13 | 2.51 | 1.25 | 0.63 | |

| 16 | 2638 | 7.47 | 4.98 | 3.73 | 2.99 | 1.49 | 0.75 | |

| 18 | 11 | 2860 | 5.62 | 3.75 | 2.81 | 2.25 | 1.12 | 0.56 |

| 13 | 3260 | 6.41 | 4.27 | 3.2 | 2.56 | 1.28 | 0.64 | |

| 16 | 3885 | 7.64 | 5.09 | 3.82 | 3.05 | 1.53 | 0.76 | |

| 21 | 4910 | 9.65 | 6.43 | 4.83 | 3.86 | 1.93 | 0.97 | |

| 21 | 13 | 4585 | 6.62 | 4.41 | 3.31 | 2.65 | 1.32 | 0.66 |

| 16 | 5410 | 7.81 | 5.21 | 3.91 | 3.13 | 1.56 | 0.78 | |

| 24 | 7635 | 11.03 | 7.35 | 5.51 | 4.41 | 2.21 | 1.1 | |

| 24 | 16 | 7265 | 8.03 | 5.36 | 4.02 | 3.21 | 1.61 | 0.8 |

| 19 | 8340 | 9.22 | 6.15 | 4.61 | 3.69 | 1.84 | 0.92 | |

| 24 | 10165 | 11.24 | 7.49 | 5.62 | 4.5 | 2.25 | 1.12 | |

| 32 | 13065 | 14.45 | 9.63 | 7.22 | 5.78 | 2.89 | 1.44 | |

| 27 | 19 | 10810 | 9.44 | 6.3 | 4.72 | 3.78 | 1.89 | 0.94 |

| 24 | 13085 | 11.43 | 7.62 | 5.72 | 4.57 | 2.29 | 1.14 | |

| 32 | 16785 | 14.67 | 9.78 | 7.33 | 5.87 | 2.93 | 1.47 | |

| 30 | 19 | 13595 | 9.62 | 6.41 | 4.81 | 3.85 | 1.92 | 0.96 |

| 24 | 16445 | 11.64 | 7.76 | 5.82 | 4.66 | 2.33 | 1.16 | |

| 32 | 20995 | 14.86 | 9.91 | 7.43 | 5.94 | 2.97 | 1.49 | |

| 33 | 24 | 20325 | 11.89 | 7.93 | 5.94 | 4.76 | 2.38 | 1.19 |

| 27 | 22400 | 13.1 | 8.73 | 6.55 | 5.24 | 2.62 | 1.31 | |

| 32 | 25825 | 15.1 | 10.07 | 7.55 | 6.04 | 3.02 | 1.51 | |

| 36 | 24 | 24505 | 12.04 | 8.03 | 6.02 | 4.82 | 2.41 | 1.2 |

| 27 | 26955 | 13.25 | 8.83 | 6.62 | 5.3 | 2.65 | 1.32 | |

| 32 | 31030 | 15.25 | 10.17 | 7.63 | 6.1 | 3.05 | 1.53 | |

| 40 | 37580 | 18.47 | 12.31 | 9.23 | 7.39 | 3.69 | 1.85 | |

| 42 | 27 | 36365 | 13.13 | 8.75 | 6.57 | 5.25 | 2.63 | 1.31 |

| 32 | 41915 | 15.13 | 10.09 | 7.57 | 6.05 | 3.03 | 1.51 | |

| 40 | 50815 | 18.35 | 12.23 | 9.17 | 7.34 | 3.67 | 1.83 | |

| 48 | 59740 | 21.57 | 14.38 | 10.79 | 8.63 | 4.31 | 2.16 | |

| 48 | 27 | 47000 | 12.99 | 8.66 | 6.5 | 5.2 | 2.6 | 1.3 |

| 32 | 54250 | 15 | 10 | 7.5 | 6 | 3 | 1.5 | |

| 40 | 65900 | 18.22 | 12.15 | 9.11 | 7.29 | 3.64 | 1.82 | |

| 48 | 77525 | 21.43 | 14.29 | 10.72 | 8.57 | 4.29 | 2.14 | |

Table 4 (Part A : Total Air Volume (cfm) ). Total air volume and air velocity through the grain for grain bins with 37 degree cones.

| Total Air Volume (cfm) | ||||||||

| Air Flow Rate (cfm/bu) | ||||||||

| Diameter (ft.) | Height (ft.) | Total Capacity (Bin+ Cone), bu |

1/2 | 1/3 | 1/4 | 1/5 | 1/10 | 1/20 |

| 15 | 8 | 1395 | 698 | 465 | 349 | 279 | 140 | 70 |

| 13 | 2120 | 1060 | 707 | 530 | 424 | 212 | 106 | |

| 16 | 2545 | 1273 | 848 | 636 | 509 | 255 | 127 | |

| 18 | 11 | 2700 | 1350 | 900 | 675 | 540 | 270 | 135 |

| 13 | 3100 | 1550 | 1033 | 775 | 620 | 310 | 155 | |

| 16 | 3725 | 1863 | 1242 | 931 | 745 | 373 | 186 | |

| 21 | 4750 | 2375 | 1583 | 1188 | 950 | 475 | 238 | |

| 21 | 13 | 4345 | 2173 | 1448 | 1086 | 869 | 435 | 217 |

| 16 | 5170 | 2585 | 1723 | 1293 | 1034 | 517 | 259 | |

| 24 | 7395 | 3698 | 2465 | 1849 | 1479 | 740 | 370 | |

| 24 | 16 | 6905 | 3453 | 2302 | 1726 | 1381 | 691 | 345 |

| 19 | 7980 | 3990 | 2660 | 1995 | 1596 | 798 | 399 | |

| 24 | 9805 | 4903 | 3268 | 2451 | 1961 | 981 | 490 | |

| 32 | 12705 | 6353 | 4235 | 3176 | 2541 | 1271 | 635 | |

| 27 | 19 | 10290 | 5145 | 3430 | 2573 | 2058 | 1029 | 515 |

| 24 | 12565 | 6283 | 4188 | 3141 | 2513 | 1257 | 628 | |

| 32 | 16265 | 8133 | 5422 | 4066 | 3253 | 1627 | 813 | |

| 30 | 19 | 12895 | 6448 | 4298 | 3224 | 2579 | 1290 | 645 |

| 24 | 15745 | 7873 | 5248 | 3936 | 3149 | 1575 | 787 | |

| 32 | 20295 | 10148 | 6765 | 5074 | 4059 | 2030 | 1015 | |

| 33 | 24 | 19365 | 9683 | 6455 | 4841 | 3873 | 1937 | 968 |

| 27 | 21440 | 10720 | 7147 | 5360 | 4288 | 2144 | 1072 | |

| 32 | 24865 | 12433 | 8288 | 6216 | 4973 | 2487 | 1243 | |

| 36 | 24 | 23285 | 11643 | 7762 | 5821 | 4657 | 2329 | 1164 |

| 27 | 25735 | 12868 | 8578 | 6434 | 5147 | 2574 | 1287 | |

| 32 | 29810 | 14905 | 9937 | 7453 | 5962 | 2981 | 1491 | |

| 40 | 36360 | 18180 | 12120 | 9090 | 7272 | 3636 | 1818 | |

| 42 | 27 | 34785 | 17393 | 11595 | 8696 | 6957 | 3479 | 1739 |

| 32 | 40335 | 20168 | 13445 | 10084 | 8067 | 4034 | 2017 | |

| 40 | 49235 | 24618 | 16412 | 12309 | 9847 | 4924 | 2462 | |

| 48 | 58160 | 29080 | 19387 | 14540 | 11632 | 5816 | 2908 | |

| 48 | 27 | 45060 | 22530 | 15020 | 11265 | 9012 | 4506 | 2253 |

| 32 | 52310 | 26155 | 17437 | 13078 | 10462 | 5231 | 2616 | |

| 40 | 63960 | 31980 | 21320 | 15990 | 12792 | 6396 | 3198 | |

| 48 | 75585 | 37793 | 25195 | 18896 | 15117 | 7559 | 3779 | |

Table 4( Part B : Air Velocity (fpm) ). Total air volume and air velocity through the grain for grain bins with 37 degree cones. (cont'd)

| Air Velocity (fpm) | ||||||||

| Air Flow Rate (cfm/bu) | ||||||||

| Diameter (ft.) | Height (ft.) | Total Capacity (Bin+Cone), bu |

2-Jan | 3-Jan | 4-Jan | 5-Jan | 10-Jan | 20-Jan |

| 15 | 8 | 1395 | 3.95 | 2.63 | 1.97 | 1.58 | 0.79 | 0.39 |

| 13 | 2120 | 6 | 4 | 3 | 2.4 | 1.2 | 0.6 | |

| 16 | 2545 | 7.2 | 4.8 | 3.6 | 2.88 | 1.44 | 0.72 | |

| 18 | 11 | 2700 | 5.31 | 3.54 | 2.65 | 2.12 | 1.06 | 0.53 |

| 13 | 3100 | 6.09 | 4.06 | 3.05 | 2.44 | 1.22 | 0.61 | |

| 16 | 3725 | 7.32 | 4.88 | 3.66 | 2.93 | 1.46 | 0.73 | |

| 21 | 4750 | 9.34 | 6.23 | 4.67 | 3.74 | 1.87 | 0.93 | |

| 21 | 13 | 4345 | 6.28 | 4.18 | 3.14 | 2.51 | 1.26 | 0.63 |

| 16 | 5170 | 7.47 | 4.98 | 3.73 | 2.99 | 1.49 | 0.75 | |

| 24 | 7395 | 10.68 | 7.12 | 5.34 | 4.27 | 2.14 | 1.07 | |

| 24 | 16 | 6905 | 7.64 | 5.09 | 3.82 | 3.05 | 1.53 | 0.76 |

| 19 | 7980 | 8.82 | 5.88 | 4.41 | 3.53 | 1.76 | 0.88 | |

| 24 | 9805 | 10.84 | 7.23 | 5.42 | 4.34 | 2.17 | 1.08 | |

| 32 | 12705 | 14.05 | 9.37 | 7.02 | 5.62 | 2.81 | 1.4 | |

| 27 | 19 | 10290 | 8.99 | 5.99 | 4.5 | 3.6 | 1.8 | 0.9 |

| 24 | 12565 | 10.98 | 7.32 | 5.49 | 4.39 | 2.2 | 1.1 | |

| 32 | 16265 | 14.21 | 9.47 | 7.11 | 5.68 | 2.84 | 1.42 | |

| 30 | 19 | 12895 | 9.13 | 6.08 | 4.56 | 3.65 | 1.83 | 0.91 |

| 24 | 15745 | 11.14 | 7.43 | 5.57 | 4.46 | 2.23 | 1.11 | |

| 32 | 20295 | 14.36 | 9.58 | 7.18 | 5.75 | 2.87 | 1.44 | |

| 33 | 24 | 19365 | 11.33 | 7.55 | 5.66 | 4.53 | 2.27 | 1.13 |

| 27 | 21440 | 12.54 | 8.36 | 6.27 | 5.02 | 2.51 | 1.25 | |

| 32 | 24865 | 14.54 | 9.7 | 7.27 | 5.82 | 2.91 | 1.45 | |

| 36 | 24 | 23285 | 11.44 | 7.63 | 5.72 | 4.58 | 2.29 | 1.14 |

| 27 | 25735 | 12.65 | 8.43 | 6.32 | 5.06 | 2.53 | 1.26 | |

| 32 | 29810 | 14.65 | 9.77 | 7.33 | 5.86 | 2.93 | 1.47 | |

| 40 | 36360 | 17.87 | 11.91 | 8.93 | 7.15 | 3.57 | 1.79 | |

| 42 | 27 | 34785 | 12.56 | 8.37 | 6.28 | 5.02 | 2.51 | 1.26 |

| 32 | 40335 | 14.56 | 9.71 | 7.28 | 5.83 | 2.91 | 1.46 | |

| 40 | 49235 | 17.78 | 11.85 | 8.89 | 7.11 | 3.56 | 1.78 | |

| 48 | 58160 | 21 | 14 | 10.5 | 8.4 | 4.2 | 2.1 | |

| 48 | 27 | 45060 | 12.46 | 8.3 | 6.23 | 4.98 | 2.49 | 1.25 |

| 32 | 52310 | 14.46 | 9.64 | 7.23 | 5.78 | 2.89 | 1.45 | |

| 40 | 63960 | 17.68 | 11.79 | 8.84 | 7.07 | 3.54 | 1.77 | |

| 48 | 75585 | 20.9 | 13.93 | 10.45 | 8.36 | 4.18 | 2.09 | |

Example: Using our sample bin (30 ft. diameter and 19 ft. height), suppose we wish to provide an airflow rate of 1/5 (0.2) CFM/bu. Table 3 gives a total air volume of about 2719 CFM and an air velocity through the grain of 3.85 fpm. If the cone bottom has a 37° cone, use Table 4.

Determining Operating Static Pressure Due to Grain Depth

Tables 5, 6, 7, 8, and 9 can be used to determine the static pressure due to grain depth when the grain depth or bin sidewall height and the air flow rate through the grain are known. It is assumed the bin will be filled to the eaves and the top surface will be leveled, making grain depth and bin sidewall height equal. Table 5 is used when shelled corn is the grain to be aerated, Table 6 is used for barley and oats, Table 7 for soybeans and confectionary sunflowers, Table 8 for oil-type sunflowers and Table 9 for wheat and sorghum. The static pressure of canola is two to three times the static pressure of wheat. Therefore, if an existing aeration system designed for wheat is used for canola, check the velocity and pressure ratings of the system to ensure adequate airflow. Fact Sheet BAE-1110, “Storing Oklahoma Winter Canola,” covers the methods for storing Oklahoma winter canola. When the system will be used for more than one grain, design for the grain that gives the highest expected static pressure.

Table 5. Expected Static Pressure for shelled corn.

Values in the table have been multiplied by 1.5 to account for fines and packing in the bin. (If corn is stirred, which tends to decrease airflow resistance, divide table values by 1.5.)

Expected static pressure (inches of water)

| Grain depth (ft) | 0.05 | 0.1 | 0.25 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 4 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 |

| 6 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.3 | 0.3 | 0.4 | 0.6 |

| 8 | 0.1 | 0.1 | 0.1 | 0.2 | 0.3 | 0.5 | 0.6 | 0.8 | 1.2 |

| 10 | 0.1 | 0.1 | 0.2 | 0.3 | 0.5 | 0.8 | 1.1 | 1.4 | 2 |

| 12 | 0.1 | 0.1 | 0.2 | 0.5 | 0.8 | 1.2 | 1.6 | 2.1 | 3.2 |

| 14 | 0.1 | 0.1 | 0.3 | 0.7 | 1.2 | 1.7 | 2.3 | 3 | 4.6 |

| 16 | 0.1 | 0.1 | 0.4 | 0.9 | 1.6 | 2.4 | 3.2 | 4.2 | 6.4 |

| 18 | 0.1 | 0.2 | 0.5 | 1.2 | 2.1 | 3.1 | 4.3 | 5.6 | 8.7 |

| 20 | 0.1 | 0.2 | 0.7 | 1.6 | 2.7 | 4 | 5.6 | 7.3 | 11.3 |

| 25 | 0.2 | 0.4 | 1.1 | 2.6 | 4.6 | 7 | 9.7 | 12.8 | 19.9 |

| 30 | 0.3 | 0.5 | 1.6 | 4.1 | 7.2 | 11 | 15.3 | 20.3 | 31.9 |

| 40 | 0.5 | 1 | 3.1 | 8.1 | 14.6 | 22.6 | 31.9 | 42.5 | * |

| 50 | 0.7 | 1.6 | 5.3 | 14 | 25.6 | 39.9 | * | * | * |

* Static pressure is excessive--greater than 50 in. water.

Table 6. Expected Static Pressure for barley and oats.

Values in the table have been multiplied by 1.5 to account for fines and packing in the bin.

Expected static pressure (inches of water)

| Grain depth (ft) | 0.05 | 0.1 | 0.25 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 |

|---|---|---|---|---|---|---|---|---|---|

| Airflow (cfm/bu) | |||||||||

| 2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 4 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.3 | 0.3 | 0.5 |

| 6 | 0.1 | 0.1 | 0.1 | 0.2 | 0.4 | 0.5 | 0.7 | 0.8 | 1.1 |

| 8 | 0.1 | 0.1 | 0.2 | 0.4 | 0.7 | 0.9 | 1.2 | 1.5 | 2.1 |

| 10 | 0.1 | 0.1 | 0.3 | 0.7 | 1.1 | 1.5 | 2 | 2.5 | 3.6 |

| 12 | 0.1 | 0.2 | 0.5 | 1 | 1.6 | 2.3 | 3 | 3.7 | 5.4 |

| 14 | 0.1 | 0.3 | 0.7 | 1.4 | 2.2 | 3.2 | 4.2 | 5.3 | 7.8 |

| 16 | 0.2 | 0.3 | 0.9 | 1.9 | 3 | 4.3 | 5.7 | 7.2 | 10.6 |

| 18 | 0.2 | 0.4 | 1.1 | 2.4 | 3.9 | 5.6 | 7.5 | 9.5 | 14.1 |

| 20 | 0.3 | 0.5 | 1.4 | 3 | 4.9 | 7.1 | 9.5 | 12.2 | 18.1 |

| 15 | 0.4 | 0.8 | 2.2 | 4.9 | 8.2 | 11.9 | 16.1 | 20.7 | 31.1 |

| 30 | 0.6 | 1.2 | 3.2 | 7.4 | 12.4 | 18.3 | 24.8 | 32.1 | 48.7 |

| 40 | 1 | 2.1 | 6 | 14.2 | 24.4 | 36.2 | 49.8 | * | * |

| 50 | 1.6 | 3.4 | 9.9 | 23.8 | 41.4 | * | * | * | * |

* Static pressure is excessive--greater than 50 in. water.

Table 7. Expected Static Pressure for soybeans and confectionary sunflowers.

Values in the table have been multiplied by 1.5 to account for fines and packing in the bin.

Expected static pressure (inches of water)

| Grain depth (ft) | 0.05 | 0.1 | 0.25 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 |

|---|---|---|---|---|---|---|---|---|---|

| Airflow (cfm/bu) | |||||||||

| 2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 4 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 |

| 6 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.3 | 0.3 | 0.5 |

| 8 | 0.1 | 0.1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.9 |

| 10 | 0.1 | 0.1 | 0.1 | 0.3 | 0.4 | 0.6 | 0.8 | 1 | 1.5 |

| 12 | 0.1 | 0.1 | 0.2 | 0.4 | 0.7 | 0.9 | 1.2 | 1.6 | 2.3 |

| 14 | 0.1 | 0.1 | 0.3 | 0.6 | 0.9 | 1.3 | 1.7 | 2.2 | 3.3 |

| 16 | 0.1 | 0.1 | 0.3 | 0.8 | 1.2 | 1.8 | 2.4 | 3 | 4.5 |

| 18 | 0.1 | 0.2 | 0.4 | 1 | 1.6 | 2.3 | 3.1 | 4 | 6 |

| 20 | 0.1 | 0.2 | 0.6 | 1.2 | 2 | 3 | 4 | 5.1 | 7.7 |

| 25 | 0.2 | 0.3 | 0.9 | 2 | 3.4 | 5 | 6.8 | 8.8 | 13.4 |

| 30 | 0.2 | 0.5 | 1.3 | 3.1 | 5.2 | 7.7 | 10.6 | 13.7 | 21 |

| 40 | 0.4 | 0.9 | 2.5 | 5.9 | 10.3 | 15.4 | 21.4 | 28 | 43.4 |

| 50 | 0.6 | 1.4 | 4.1 | 10 | 17.6 | 26.7 | 37.2 | 49.1 | * |

* Static pressure is excessive--greater than 50 in. water.

Table 8. Expected Static Pressure for oil-type sunflowers.

Values in the table have been multiplied by 1.5 to account for fines and packing in the bin.

Expected static pressure (inches of water)

| Grain depth (ft) | 0.05 | 0.1 | 0.25 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 |

|---|---|---|---|---|---|---|---|---|---|

| Airflow (cfm/bu) | |||||||||

| 2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 4 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 | 0.3 |

| 6 | 0.1 | 0.1 | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.9 |

| 8 | 0.1 | 0.1 | 0.1 | 0.3 | 0.5 | 0.7 | 0.9 | 1.1 | 1.7 |

| 10 | 0.1 | 0.1 | 0.2 | 0.5 | 0.8 | 1.1 | 1.5 | 1.9 | 2.8 |

| 12 | 0.1 | 0.1 | 0.3 | 0.7 | 1.2 | 1.7 | 2.3 | 2.9 | 4.4 |

| 14 | 0.1 | 0.2 | 0.5 | 1 | 1.7 | 2.4 | 3.3 | 4.2 | 6.4 |

| 16 | 0.1 | 0.2 | 0.6 | 1.4 | 2.3 | 3.3 | 4.5 | 5.8 | 8.8 |

| 18 | 0.1 | 0.3 | 0.8 | 1.8 | 3 | 4.4 | 6 | 7.8 | 11.8 |

| 20 | 0.2 | 0.3 | 1 | 2.3 | 3.8 | 5.6 | 7.7 | 10 | 15.3 |

| 25 | 0.3 | 0.6 | 1.6 | 3.7 | 6.5 | 9.7 | 13.3 | 17.4 | 26.9 |

| 30 | 0.4 | 0.8 | 2.4 | 5.7 | 10 | 15.1 | 20.9 | 27.5 | 42.7 |

| 40 | 0.7 | 1.5 | 4.5 | 11.3 | 20.1 | 30.7 | 43 | * | * |

| 50 | 1.1 | 2.4 | 7.5 | 19.3 | 34.8 | * | * | * | * |

* Static pressure is excessive--greater than 50 in. water.

Table 9. Expected Static Pressure for wheat and sorghum.

Values in the table have been multiplied by 1.3 for wheat and 1.5 for sorghum to account for fines and packing in the bin.

Expected static pressure (inches of water)

| Grain depth (ft) | 0.05 | 0.1 | 0.25 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 |

|---|---|---|---|---|---|---|---|---|---|

| Airflow (cfm/bu) | |||||||||

| 2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 |

| 4 | 0.1 | 0.1 | 0.1 | 0.2 | 0.3 | 0.3 | 0.4 | 0.5 | 0.7 |

| 6 | 0.1 | 0.1 | 0.2 | 0.4 | 0.6 | 0.8 | 1 | 1.2 | 1.7 |

| 8 | 0.1 | 0.1 | 0.3 | 0.7 | 1.1 | 1.5 | 1.9 | 2.3 | 3.2 |

| 10 | 0.1 | 0.2 | 0.5 | 1.1 | 1.7 | 2.3 | 3 | 3.7 | 5.3 |

| 12 | 0.1 | 0.3 | 0.8 | 1.6 | 2.5 | 3.4 | 4.5 | 5.6 | 7.9 |

| 14 | 0.2 | 0.4 | 1 | 2.2 | 3.4 | 4.8 | 6.3 | 7.8 | 11.3 |

| 16 | 0.3 | 0.5 | 1.4 | 2.9 | 4.6 | 6.4 | 8.4 | 10.6 | 15.3 |

| 18 | 0.3 | 0.7 | 1.7 | 3.7 | 5.9 | 8.3 | 11 | 13.8 | 20 |

| 20 | 0.4 | 0.8 | 2.2 | 4.7 | 7.5 | 10.5 | 13.9 | 17.6 | 25.6 |

| 25 | 0.6 | 1.3 | 3.4 | 7.5 | 12.2 | 17.4 | 23.1 | 29.4 | 43.3 |

| 30 | 0.9 | 1.9 | 5.1 | 11.2 | 18.3 | 26.3 | 35.3 | 45 | * |

| 40 | 1.7 | 3.4 | 9.3 | 21.1 | 35.1 | * | * | * | * |

| 50 | 2.6 | 5.4 | 15 | 34.8 | * | * | * | * | * |

* Static pressure is excessive--greater than 50 in. water.

Example: To design the system for our sample bin (19 ft. height) to store either corn or soybeans, consider both Table 5 and Table 7. Since the tables do not give data for 0.2 cfm/bu airflow rates, use the next higher airflow given. In this case, we would use 0.25 cfm/bu. The tables do not give data for 19 ft. height either, so we would calculate the static pressure that would be halfway between the pressures shown for 18 ft and 20 ft heights.

For corn (Table 5): at 18 ft grain depth, pressure = 0.5 in. and at 20 ft., pressure = 0.7 in. Therefore, at 19 ft. grain depth, the pressure will be 0.6 in. or halfway between 0.5 and 0.7 in.

For soybeans (Table 7): at 18 ft grain depth, pressure = 0.4 in. and at 20 ft., pressure = 0.6 in. Therefore, at 19 ft. grain depth, the pressure will be 0.5 in.

Since we would like to design our system to handle either crop, we must design for the greater pressure requirements. In this case, it would be corn and we would use 0.6 in. for our pressure requirement due to grain depth.

Determining Static Pressure Due to Duct and Cone

Pressure requirements are also increased due to air traveling through the air ducts. To find these pressure requirements, the surface area of the ductwork must be known. Table 10 gives the duct surface area given the duct diameter and the duct length. Tables 11 and 12 use the surface area from Table 10 and the air-flow volume calculated earlier to determine the expected static pressure for the duct system and for the airflow through the cone part of the bin. This pressure added to the pressure for the grain depth is the design pressure used to select the aeration fans.

Table 10. Duct Surface Area.

| Duct Diameter (inches) |

Duct Length (ft) |

Duct Surface Area (Sq. ft.) |

|---|---|---|

| 6 | 10 | 13 |

| 15 | 19 | |

| 20 | 25 | |

| 25 | 31 | |

| 30 | 38 | |

| 35 | 44 | |

| 10 | 10 | 21 |

| 15 | 31 | |

| 20 | 42 | |

| 25 | 52 | |

| 30 | 63 | |

| 35 | 73 | |

| 12 | 10 | 25 |

| 15 | 38 | |

| 18 | 45 | |

| 20 | 50 | |

| 25 | 63 | |

| 30 | 75 | |

| 35 | 88 | |

| 15 | 10 | 31 |

| 20 | 63 | |

| 25 | 79 | |

| 30 | 94 | |

| 35 | 110 | |

| 18 | 10 | 38 |

| 15 | 57 | |

| 20 | 75 | |

| 25 | 94 | |

| 30 | 113 | |

| 35 | 132 | |

| 20 | 10 | 42 |

| 15 | 63 | |

| 20 | 84 | |

| 25 | 105 | |

| 30 | 126 | |

| 35 | 147 | |

| 24 | 10 | 50 |

| 15 | 75 | |

| 20 | 100 | |

| 25 | 126 | |

| 30 | 151 | |

| 35 | 176 | |

| 30 | 10 | 63 |

| 15 | 94 | |

| 20 | 126 | |

| 25 | 157 | |

| 30 | 188 | |

| 35 | 220 | |

| 36 | 10 | 75 |

| 15 | 113 | |

| 20 | 151 | |

| 25 | 188 | |

| 30 | 226 | |

| 35 | 264 | |

| 40 | 10 | 84 |

| 15 | 126 | |

| 20 | 167 | |

| 25 | 209 | |

| 30 | 251 | |

| 35 | 293 |

Table 11. Expected static pressure due to duct and cone for corn or soybeans.

Expected Static Pressure (inches of water)

| Duct Surface Area (sq. ft.) | 100 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 10000 | 20000 | 30000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 0.26 | 2.5 | 7.5 | * | * | * | * | * | * | * | * | * | * |

| 15 | 0.15 | 1.4 | 3.9 | 10 | * | * | * | * | * | * | * | * | * |

| 20 | 0.1 | 0.91 | 2.5 | 6 | * | * | * | * | * | * | * | * | * |

| 30 | ** | 0.54 | 1.4 | 3.7 | 6.5 | * | * | * | * | * | * | * | * |

| 40 | ** | 0.35 | 0.92 | 2.5 | 4.4 | 6.4 | 8.5 | * | * | * | * | * | * |

| 50 | ** | 0.26 | 0.7 | 1.75 | 3.2 | 5 | 6.8 | 8.5 | * | * | * | * | * |

| 60 | ** | 0.21 | 0.55 | 1.45 | 2.45 | 3.8 | 5.1 | 6.8 | 8 | * | * | * | * |

| 80 | ** | 0.14 | 0.27 | 0.94 | 1.7 | 2.5 | 3.35 | 4.45 | 5.4 | 6.5 | 8.6 | * | * |

| 100 | ** | 0.1 | 0.26 | 0.69 | 1.3 | 1.8 | 2.5 | 3.3 | 3.9 | 4.7 | 6.3 | * | * |

| 150 | ** | ** | 0.16 | 0.39 | 0.7 | 1.1 | 1.45 | 1.9 | 2.3 | 2.7 | 3.6 | * | * |

| 200 | ** | ** | 0.12 | 0.27 | 0.46 | 0.65 | 0.75 | 1.3 | 1.5 | 1.8 | 2.6 | 6.5 | * |

| 300 | ** | ** | ** | 0.15 | 0.27 | 0.39 | 0.5 | 0.7 | 0.85 | 1.05 | 1.49 | 3.75 | 6.8 |

** Static pressure is less than 0.1 in. water.

*Static pressure is excessive--greater than 10 in. water.

Table 12. Expected static pressure due to duct and cone for wheat, grain sorghum, oats, barley, or rye.

| Duct Surface Area (sq. ft.) | 100 | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 10000 | 20000 | 30000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 0.8 | 5.5 | 13 | * | * | * | * | * | * | * | * | * | * |

| 15 | 0.49 | 3.4 | 7.9 | * | * | * | * | * | * | * | * | * | * |

| 20 | 0.35 | 2.4 | 5.5 | 12 | * | * | * | * | * | * | * | * | * |

| 30 | ** | 1.45 | 3.4 | 7.8 | 12.8 | * | * | * | * | * | * | * | * |

| 40 | ** | 1 | 2.4 | 5.5 | 9 | 12.5 | * | * | * | * | * | * | * |

| 50 | ** | 0.8 | 1.85 | 4.2 | 6.8 | 10 | 13 | * | * | * | * | * | * |

| 60 | ** | 0.65 | 1.5 | 3.45 | 5.4 | 7.9 | 10.1 | 13 | 15 | * | * | * | * |

| 80 | ** | 0.45 | 0.8 | 2.4 | 3.8 | 5.5 | 7 | 9 | 10.8 | 12.5 | * | * | * |

| 100 | ** | 0.35 | 0.79 | 1.8 | 2.9 | 4.3 | 5.5 | 7 | 8.1 | 9.5 | 12.2 | * | * |

| 150 | ** | ** | 0.5 | 1.1 | 1.8 | 2.55 | 3.4 | 4.4 | 4.9 | 5.8 | 7.5 | * | * |

| 200 | ** | ** | 0.37 | 0.8 | 1.3 | 1.8 | 2.4 | 3 | 3.5 | 4.2 | 5.6 | 12.9 | * |

| 300 | ** | ** | ** | 0.5 | 0.84 | 0.12 | 1.5 | 1.85 | 2.2 | 2.6 | 3.45 | 7.9 | 13 |

** Static pressure is less than 0.3 in. water.

*Static pressure is excessive--greater than 15 in. water.

Example:

- For the sample bin using 12 in. duct diameter and 18 ft. duct length, the duct surface area is 45 sq. ft. (Table 10).

- Using Table 11 for corn or soybeans, 45 sq. ft. duct surface area, and 2719 cfm (rounded up to 3000 cfm) air volume, the static pressure due to the duct system and the cone is 3.8 in. (use pressure half way between 40 sq. ft. and 50 sq. ft. since there is not data for 45 sq. ft)

- For the total pressure requirement, add the pressure due to grain depth and the pressure through the cone and duct system: 0.5 in. + 3.8 in. = 4.3 in.

When the bin will be used to store more than one grain, the grain which produces the highest static pressure should be used for design purposes. The static pressure of canola is two to three times that of wheat.

The static pressure due to duct and cone can be reduced by choosing a larger diameter duct. Table 13 compares the results obtained for a 12-inch diameter duct with those obtained for 18- and 21-inch diameter ducts.

Selecting Fans

Fans are selected from the manufacturer’s rating curves or tables to deliver the required air volume when operating against the expected static pressure. Axial fans (propeller-type) are commonly used for aeration since they produce high air volumes at low static pressures. However, air volumes delivered by axial fans fall off rapidly as static pressures increase through the 3.5 to 5.0 inch range. Above this range, centrifugal fans with backward-inclined blades must be used. In special designs, centrifugal fans will operate efficiently at static pressures of 20 inches or more.

Centrifugal fans operate with less noise than axial fans and should be used whenever fan noise may be a nuisance to neighbors. Centrifugal fans of 3 Hp or less cost two to three times as much as axial fans of the same Hp rating. Above 5 Hp, centrifugal fans cost 1.5 to 2 times as much as axial fans of the same Hp rating.

The lowest priced fan which will deliver the required air volume when operating at the expected static pressure is, of course, the most economical fan to buy. However, the most economical fan to operate is the fan with the lowest power consumption, measured in watts, while delivering the required air volume at the expected static pressure. Nominal horsepower rating is not a good measure of power consumption.

While final fan selection must be made from manufacturer’s data, an estimate of the power requirement may be helpful for planning purposes. Equation 1 is used to estimate the power requirement, assuming a fan efficiency of 50 percent.

hp = (cfm x Ps) ÷ (63.46 x efficiency) equation 1

where:

cfm = airflow in cfm

Ps = static pressure in inches of water

efficiency = fan efficiency (%)

Example: Our example calls for an air volume of 2719 CFM. If the operating pressure is 4.3 inches, the power requirement is about 3.68 Hp (select a 5 HP motor). Table 13 also compares the power requirements resulting from the use of a 12-inch diameter duct with those resulting from the use of 18- and 24-inch diameter ducts.

When selecting fans, consult the data from several manufacturers. Tables 14 and 15 present typical performance data for axial and centrifugal fans, respectively. One manufacturer’s 5 Hp fan may be well matched to your needs while another’s 5 Hp fan may not. Fan performance data should be certified in accordance with standard test codes adopted by Air Moving and Conditioning Association, Incorporated and bear the AMCA seal.

Table 13. Static Pressures and Power Requirements resulting from three duct diameters in the example.

| 12 | 18 | 24 | |

|---|---|---|---|

| Maximum length of Perforated Duct (ft) | 18 | 17 | 16 |

| Static Pressure due to Duct and Cone (inches of water) For Corn or Soybeans | 3.8 | 2 | 1.5 |

| Total Static Pressure (inches of water) For Corn or Soybeans |

4.3 | 2.6 | 2.1 |

| Power Required assuming 50% efficiency (Hp) For Corn or Soybeans | 3.7 | 2.2 | 1.8 |

Table 14. Typical Performance Data for Axial Fans*.

| HP | RPM | 0.5 | 1 | 1.5 | 2 | 3 | 4 | |

|---|---|---|---|---|---|---|---|---|

| 1 | 3450 | 2880 | 2635 | 2360 | 1935 | 810 | 455 | |

| 3 | 3450 | 7000 | 6400 | 5700 | 5200 | 3700 | 2200 | |

| 5 | 3450 | 9700 | 9100 | 8600 | 8000 | 6500 | 4600 | |

| 7.5 | 3450 | 12800 | 12300 | 11600 | 11000 | 9800 | 7400 |

*This table is abbreviated. Intermediate static pressures and a much larger range of CFM values are normally shown

Table 15A. Typical Performance Data for Centrifugal Fan*.

Static Pressure (inches of water)

| CFM | 2 RPM | 2 HP | 4 RPM | 3 HP | 6 RPM | 6 HP | 8 RPM | 8 HP | 10 RPM | 10 HP | 12 RPM | 12 HP | 14 RPM | 14 HP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1520 | 1364 | 1.15 | 1753 | 1.96 | 2064 | 2.77 | 2332 | 3.6 | 2574 | 4.47 | 2794 | 5.37 | 3000 | 6.3 |

| 2026 | 1527 | 1.81 | 1894 | 2.89 | 2190 | 3.94 | 2446 | 4.99 | 2679 | 6.05 | 2891 | 7.14 | 3090 | 8.25 |

| 2532 | 1708 | 2.72 | 2050 | 4.07 | 2334 | 5.4 | 2584 | 6.71 | 2805 | 8.01 | 3010 | 9.3 | 3204 | 10.6 |

| 3039 | 1906 | 3.93 | 2221 | 5.5 | 2490 | 7.15 | 2730 | 8.75 | 2946 | 10.3 | 3145 | 11.8 | 3333 | 13.4 |

*This table is abbreviated. Intermediate static pressures and a much larger range of CFM values are normally shown. Various speeds may be obtained using variable frequency drives or belt and sheave systems between a roteor and fan. Typical motor operating speeds are 1,760 rpm and 3,500 rpm (nominal).

Further Examples

Example 1: An aeration system is desired for a 24 feet diameter bin with 16 feet sidewalls and 37˚ cone shaped foundation which will be used to store wheat. An airflow rate of 1/4 (0.25) CFM/bu is desired.

- Bin capacity is 6905 bu (Table 1). Airflow volume: 6905 bu x 0.25 CFM/bu = 1726 CFM (also in Table 4).

- From Table 2, maximum duct length is 14 feet.

- Air velocity through the grain is 3.82 fpm (Table 4). The static pressure due to the 16 feet grain depth is 1.4 inches (Table 9).

- Maximum perforated duct if an 18 in. dia. duct is selected: 14 ft – (2 x 1.5 ft) = 11 ft.

- Duct surface area: The duct surface area of 10ft and 15ft duct is known (Table 10).

Estimate for 11ft duct length using interpolation:|

38+((11-10)*(57-38)/(15-10)) = 38+ 3.8= 42 sq. ft. (Table 10). - Static Pressure due to cone and duct, as static pressure for 1726 cfm and 42 sq ft

area is not given directly in Table 12 therefore we calculate the static pressure

for 2000 cfm and 42 sq ft by interpolation:

5.5 + ((42-40)*(4.2-5.5)/ ((50-40)) = 5.24 in. of water (Table 12). - Total static pressure: 5.24 + 1.4 in. = 6.64.

- Approx. HP: hp =

(1726 * 6.64) / (63.46 * 50) = 3.61 HP (equation 1) - Choose a 5 HP fan.

Example 2: Suppose a producer wishes to provide 1/2 (0.5) CFM/bu. for quick cooling of damp corn during harvest. The bin is 27 feet in diameter, has 24 feet sidewalls and a 45˚ cone shaped foundation.

- Bin capacity is 13085 bu (Table 1). Airflow volume: 13085 bu x 0.50 CFM/bu = 6543 CFM (also in Table 3).

- From Table 2, maximum duct length is 18 feet.

- Air velocity through the grain is 11.43 fpm (Table 3). The static pressure due to the 24 feet grain depth is 2.4 inches (Table 5).

- Maximum perforated duct: If 30 in duct is selected, round up to 3 feet, 18 ft – (2 x 3 ft) = 13 ft.

- Duct surface area, using interpolation and Table 10:

63 + ((13-10) x (94-63) / (15-10)) = 63+18.6 =

81.6 Sq. ft.= 82 Sq. ft. (Table 10). - Pressure due to cone and duct, as static pressure for 6543 cfm and 82 sq ft area

is not given directly in Table 11 therefore we calculate the static pressure for

7000 cfm and 75.4 sq ft by interpolation:

5.4 + ((82-80) x (3.9-5.4) / (100-80)) = 5.25 (Table 11) - Total static pressure: 5.25 + 2.4 in. = 7.65.

- Approx. HP :hp= (6543 x 7.65) / (63.46 x 50)=15.8 HP (equation 1).

- Choose a 20 HP fan

Other Considerations

Aeration systems for cone-bottom bins must operate as pressure systems-blowing air upward through the grain. For more information about pressure and suction systems, see BAE-1101.

There must be sufficient roof openings to allow the air to escape. The required air escape area, in square feet, is determined by dividing the total air volume by 1,500 fpm. If the bin roof is mounted off the sidewall, the slot under the eaves serves as air escape area. When additional area is required, roof vents should be installed until the air escape area requirement is met.

When aeration systems are operating, the unloading auger tube should be sealed to prevent the escape of air.

Smooth transitions should be used to connect fan outlets with duct inlets. Sudden reductions or increases in duct diameters should be avoided.

Carol Jones

Extension Agricultural Engineer