Aeration and Cooling of Stored Grain

- Jump To:

- Aeration is an Integral Part of Integrated Pest Management Practices

- Aeration System Design Considerations

- Choosing Airflow Rate

- Time Required for Cooling

- Airflow Direction: Pressure vs. Suction

- Selecting Fans

- Grain Bin Construction and Other Considerations

- Controls for Aeration

- Aeration Procedures

- Aeration costs

- References

Many stored grain problems, such as mold, insects, fungi and spoilage, start with or are worsened by improper grain moisture and temperature. Internal air currents driven by temperature differentials in the grain cause moisture to migrate to the top and center of the grain mass; molds develop, and insects feed and reproduce. Aeration is used to cool and maintain uniform temperatures and moisture in masses of stored grain. In aeration, a fan is used to pump outside air through grain in a storage facility. The grain temperature eventually attains the temperature of air traveling through void spaces in the grain mass. Without aeration, stored grain develops wide temperature differentials, increasing the chances of mold and insect development.

Each type of grain has different storage requirements for temperature and moisture and thus has a unique aeration protocol. In Oklahoma early summer crops such as wheat can be cooled during relatively frequent cool nights soon after harvest. Crops harvested later in summer may have limited cooling opportunities immediately after harvest. Oil seeds generally require cooler and dryer storage conditions than wheat or corn to prevent development of rancidity and spoilage.

This document discusses design and operation of aeration systems for grain storage structures.

Aeration is an Integral Part of Integrated Pest Management Practices

Stored grain insects thrive at 75 F to 85 F. Aeration systems should be operated immediately after binning when nighttime temperatures allow to lower temperature to unfavorable levels for insect feeding, growth, and reproduction. Later in September aeration systems should be used to lower temperatures to the lower 60s. If the grain will remain in storage through the winter into summer, another cooling cycle is needed in mid-winter to lower the grain mass to 30 F to 35 F to reduce insect activity and equalize grain mass temperatures.

The bin’s doors, unloading auger, under floor spaces, and aeration fan openings should be cleaned and sprayed with a residual insecticide. Openings should be sealed before harvest to keep insects from inhabiting or entering lower bin areas from the outside, to keep cool air from flowing out of the bin, and to keep winds from blowing into fan openings. Keep these openings sealed year round, except when aeration fans are operating.

Aeration System Design Considerations

The design procedure for an aeration system involves first determining the airflow rate and direction needed to achieve specific aeration goals. After the aeration rate is determined the air distribution system can be designed and fans selected to deliver the required air volume. For specific design information see the following OSU Fact Sheets:

BAE-1102 Aeration Systems for Flat-Bottom Round Bins

BAE-1103 Aeration Systems for Cone-Bottom Round Bins

Choosing Airflow Rate

Airflow used for aeration is usually expressed as CFM/bu (cubic feet of air per minute, per bushel of stored grain). Aeration rates start at about 0.05 CFM/bu and increase as shown in Table 1.

Table 1. Aeration time required to cool wheat and corn versus CFM/bu.

| Time (hours) Grain Condition |

|||

| CFM/Bu. | Clean | High F.M. | Classification |

| 0.05 | 240 | 300-350 | Light |

| 0.1 | 120 | 150-175 | Light |

| 0.2 | 60 | 75-85 | Medium |

| 0.3 | 40 | 50-60 | Medium |

| 0.4 | 30 | 35-40 | Fast |

| 0.5 | 24 | 30-35 | Fast |

| 0.6 | 20 | 25-30 | Fast |

| 0.8 | 15 | 18-20 | Fast |

| 1 | 12 | 14-16 | High Speed |

| 2 | 6 | 42957 | High Speed |

| 3 | 4 | 42861 | High Speed |

| 5 | 2.5 | 42798 | High Speed |

Light aeration systems, 0.1 CFM/bu or less, require long operation times to lower grain temperatures and are best suited to cooler climates.

Medium and Fast aeration systems, 0.2 CFM/bu through 0.8 CFM/bu, are operated periodically

to lower grain temperature and equalize temperatures in stored grain. Just a few nights

of operation will lower grain temperature to nighttime air temperature. In Oklahoma

a minimum 0.2 CFM/bu is recommended.

For high speed grain cooling, 1 CFM/bu or greater is required. In this case, grain

can be cooled in one or two nights of fan operation.

Grain cooling should not be confused with natural air grain drying, which requires

high speed airflows greater than 1 CFM/bu. For natural air grain drying, damp grain

is placed in a bin and the fan is operated continuously for several weeks until all

the grain has dried to a safe moisture content. Grain cooling involves an initial

period of fan operation to cool grain followed by periodic operation to maintain even

temperatures throughout the grain mass.

The airflow rate should be chosen according to how the aeration system will be used. If grain will be stored with safe moisture content and the aeration system will be used to prevent moisture migration, a light aeration system may be chosen. When storage will be attempted with moisture contents one or two percent above safe moisture levels, grain temperature must be controlled more closely and a fast aeration system is desirable. In general, if grain must be cooled quickly, a faster airflow should be chosen.

Time Required for Cooling

The time required to cool grain to the approximate temperature of the ambient air depends largely on airflow rate, foreign material in the grain, and the amount of evaporative cooling (drying) that takes place. For dry grain, where evaporative cooling is negligible, approximate cooling times are given in Table 1. Doubling the airflow rate will cut cooling time in half.

Many on-farm aeration fans are sized for about 0.1 CFM/ bushel airflow which then

require about 120 hours (five days) of continuous operation for clean grain or 150

hours to 175 hours (six to seven days) for grain containing high levels of foreign

materials (f.m.).

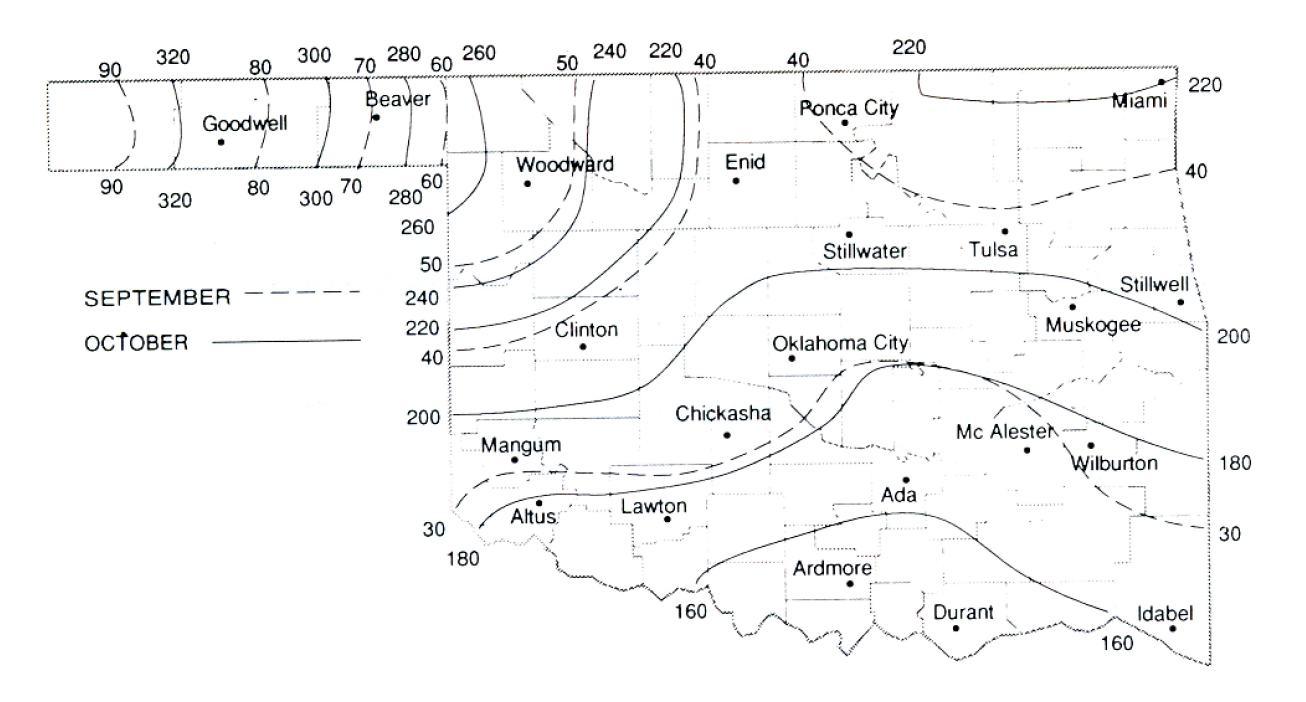

Figure 1 shows temperature data with the number of hours for the months of September

and October where the air is below 55 F. Cooling grain to 55 F or lower causes insects

to become dormant or die. It also eliminates grain temperature differentials that

cause moisture migration, top crusting, and major mold problems.

To take maximum advantage of short duration cool weather in early fall it is advised to use automatic aeration controllers and higher capacity fans that deliver at least 0.2 CFM/bushel to cool grain in less than 60 hours to 85 hours. The additional cost may be recovered in one or two seasons from savings in grain damage, moisture losses, protectant, and fumigation expenses.

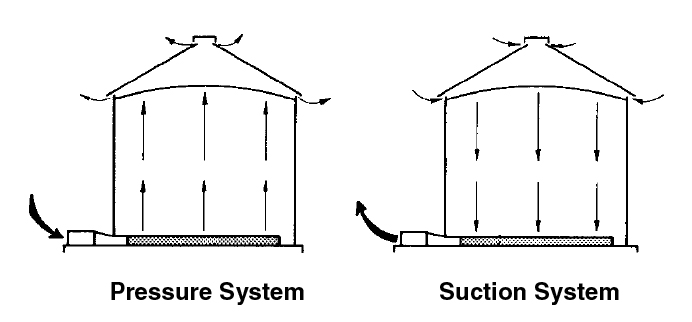

Airflow Direction: Pressure vs. Suction

Pressure (upward) airflow is preferred by many grain storage managers over suction (downward) airflow (Figure 2) because: (1) aeration fans are designed to deliver maximum airflow against pressure; fans push more mass of cool dense air than warm light air; (2) pressure fans develop more uniform airflow through the grain mass than suction systems; (3) with pressure airflow, condensation on top of the grain is visible and usually dries up by the end of the aeration cycle; the problem is visible and solvable, whereas bottom condensation damage caused by suction fans cannot be seen until the bin is unloaded; (4) pressure fans eliminate winter bin roof collapse (roof vents may freeze over during suction cooling). NOTE: Axial (Propeller) fans can usually be reversed simply by turning the fan housing around and rebolting.

Figure 2. Direction of airflow in aeration systems.

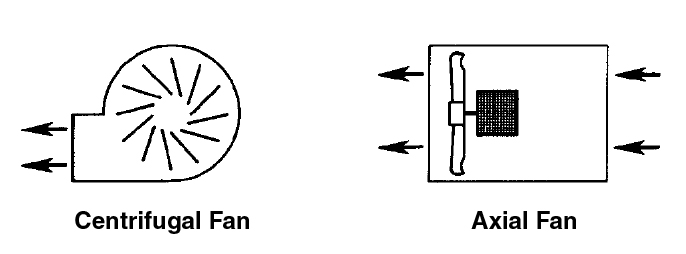

Selecting Fans

Aeration fans may be either axial (propeller) type or centrifugal (squirrel-cage) type as illustrated in Figure 3. Axial type fans are less expensive and are normally used when static pressure will not exceed 4 or 5 inches of water.

Figure 3. Centrifugal fan with backward-inclined blades and an axial fan.

Centrifugal type fans with backward-inclined blades give more consistent air delivery over a range of pressures than most axial type fans and, in special designs, can operate at 20 or more inches of static pressure.

The power required for aeration increases rapidly as airflow rate and grain depth

increase. A doubling of airflow rate or grain depth causes about a four-fold increase

in power required. Different grain types have different resistance to airflow. For

these reasons aeration fans vary greatly in horsepower. With light aeration systems

in farm-size storage, fractional horsepower fans are often used. As airflow rates

increase to 0.5 CFM/bu or more with grain depths of 20 feet or more, the power requirement

may exceed 1 horsepower for every 1,000 bu of bin capacity. In large bins, multiple

fans of 20 or 25 horsepower may be required.

Fans should not be selected by type or by horsepower. Fans for aeration should be

selected from the manufacturer’s rating tables or curves to deliver the required air

volume at the expected static pressure.

Grain Bin Construction and Other Considerations

Grain bins with fully perforated drying floors are ideal for aeration, but cleaning under the floor can be difficult and erection costs can be higher. Removable floor ducts are an alternative to drying floors and can be obtained in large square, cross, “Y,” or “U” patterns.

Cross-flow aeration systems can be used to reduce the resistance to airflow encountered

in aeration of tall grain bins. The lower power requirements reduce operating expense

and capital costs.

Bins must have adequate roof exhaust vents to minimize roof condensation and maximize

airflow. There should be a minimum of one square foot of roof vent opening for every

1500 CFM of airflow. A temporary alternative to installing roof openings during aeration

fan operation is to open roof fill caps and access doors to allow air to escape. Roof

vents that are designed to open under pressure or vacuum can remain closed between

aerations to help reduce insect infiltration.

Aeration fans can suck rain and snow into a grain bin. Rain or snow storms of short

duration (three hours to six hours) usually do not create a moisture problem. During

storms of longer duration or continuous foggy weather, stop aeration until weather

improves.

Controls for Aeration

Aeration fans may be controlled by manual, semiautomatic or automatic controls. Manual control requires only a single on-off switch. Controls which can be used with aeration fans include time clock or electric eye for night operation, high- or low-limit thermostats and high- or low-limit humidistats. Several commercial control packages are available, ranging from simple temperature and humidity controls for a single bin to elaborate controls for multiple fan operation.

When semiautomatic or automatic controls are used, an elapsed-time clock should be

placed in the circuit. If the aeration system is not operating long enough to achieve

temperature equalization within the stored grain, then the control settings should

be changed to allow longer or more frequent operation. Aeration systems often must

be operated several times during cooling seasons, each time long enough to equalize

temperatures throughout the entire grain mass (Table 1).

Small motors can be started and run by temperature and humidity control switches if

the contacts are rated for these loads. Magnetic motor starters should be used for

all motors of 0.5 horsepower or larger. Automatic aeration temperature controllers

using time-delay relays to minimize inrush current and peak power loads can control

two or more large fan motor starters in sequence. Both thermostats and humidistats

should be carefully adjusted and maintained according to manufacturer’s recommendations.

Controls should be cleaned at least once a year and more often if operated in dusty

surroundings.

An OSU-designed automatic aeration temperature controller for controlling one to three

small fans costs about $200-500 for component parts and can be assembled and wired

by a local electrician. This basic design can be adapted to operate any number of

larger fans.

Aeration Procedures

Filling the Bin and Managing Foreign Material

A level grain surface is an important part of controlling grain temperature and insect activity. Temperatures and insects in grain peaks are difficult to control. Level grain does not vary as much in temperature as peaked grain, which follows outside air temperatures because air blows against grain slopes through roof eave openings.

Grain managers can reduce storage risks from insects and mold by cleaning grain and/or

using grain spreaders to distribute foreign material (f.m.) and level the grain surface.

Level surfaces improve temperature uniformity and allow easy bin entry for inspection.

Grain fines, weed seeds, and other f.m. tend to accumulate in a column under the bin

fill point. This accumulation of f.m. restricts airflow and increases the problems

of insect and mold development, resulting in grain heating and spoilage.

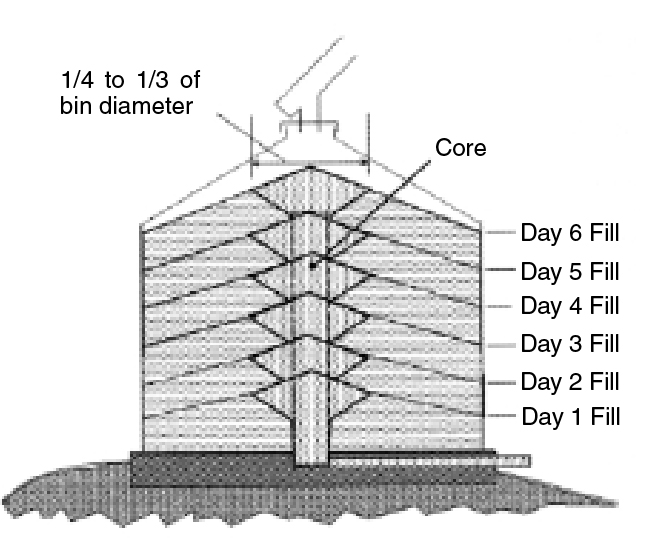

Coring is a simple method of leveling a peaked bin and removing part of the center

column of trash and foreign material. Remove 10 bushels to 20 bushels from each 3-

to 4-foot layer of grain during bin filling (Figure 4). The peak is then hand leveled

at the end of filling. An alternate coring plan after a bin is full is to unload 100

bushels to 200 bushels of grain and fines with the unload auger a week or two after

harvest, reseal the auger, and hand level the surface. (WARNING!! DO NOT enter grain

bins while unload augers are running and grain is being unloaded!) Since the removed

grain contains a high percentage of fines, it may be marketed, fed to livestock, or

cleaned.

Figure 4. Coring a grain bin to distribute foreign material.

Drying and Rewetting Grain During Aeration

Aeration is used to lower grain temperature and to equalize temperatures in stored grain. It is not intended as a drying system; yet minor changes to moisture content can occur. The air surrounding stored grain has an equilibrium moisture content (EMC) which is the point at which grain and air don’t exchange moisture. The EMC changes with temperature and moisture content of grain. If grain is aerated with air having relative humidity above the EMC, the grain will slowly gain moisture by absorbing water from the air. Conversely is the air’s relative humidity is below the EMC, the grain will dry by transferring water to the air.

The amount of drying or rewetting that takes place during aeration depends on how

dry the grain is when placed in storage, the airflow rate, how long the aeration system

is operated, and, of course, the air’s humidity. At low airflow, drying is a slow

process. Light aeration systems (less than 0.1 CFM/bu) will rarely reduce average

moisture content more than 1.0 percent, even when operated for long periods.

Fast aeration systems can cause greater moisture loss if operated continuously. This

moisture loss might be desirable if grain moisture content is above safe levels. It

can also be undesirable if the grain dries below the market standard moisture content

and the owner suffers additional shrinkage when the grain is sold. If some drying

is desired, fast aeration systems can be operated continuously while periodically

sampling grain moisture. If drying is not desired, fast aeration systems can be operated

at night only as needed for cooling and temperature equalization. Systems with grain

cooling and grain drying airflows are generally operated at night only when used for

aeration.

Rewetting of grain by aeration with humid air is a very slow process. Operation of

light or medium speed aeration systems in humid weather will have little effect on

moisture content. However, if airflow rates above 0.5 CFM/bu are used for aeration,

fans should not be operated for more than a few hours when humidity is extremely high.

Because the higher airflow will cool grain rapidly, it is practical to wait for lower

humidity before cooling.

Normal aeration rates are much too low for effectively drying grain and can’t keep

wet grain safe in warm weather. If harvested grain moisture is too high (13 percent

for wheat), solve the moisture problem before putting it in storage.

Aeration costs

The cost of installing an aeration system varies widely and depends on the specific installation. Availability of electricity, existing bin equipment such as a drying floor and roof vents, level of automation desired, and bin configuration all affect the total capital cost.

Total annual operating costs to aerate three times (summer, fall and winter) at 8

¢/KWH to 10 ¢/KWH is approximately 0.7¢/bu to 0.9¢/bu, based on minimum aeration times

from Table 1.

The cost of grain moisture removed by aeration (0.3 to 0.5 Ibs/bu/yr) at $5.00 to

$5.50/bu wheat price is 2.5 to 4.5 ¢/bu/yr; for $7.00 to $7.50/bu wheat, moisture

losses would be 3.5 to 6.3 ¢/bu/yr.

Aeration generally costs less than grain fumigants or protectants, or losses from

mold and insect damage, and maintains grain quality.

References

Noyes, R., Navarro, S. & Armitage, D. (2002). Supplemental Aeration Systems. In The Mechanics and Physics of Modern Grain Aeration Management, 413-488 (Eds S. Navarro and R. Noyes). Boca Raton, Fl: CRC Press.

Carol Jones

Assistant Professor, Stored Products Engineering

James Hardin

Research Engineer