Strategies to Reduce Moisture Condensation in Food Facilities

Introduction

The Food Safety Inspection Service of the USDA (1999) and Current Good Manufacturing Practices (cGMPs) enforced by the FDA (2014) require the control of moisture condensation when product adulteration is possible or insanitary conditions may result. Examples of when inspection personnel are required to take action in situations involving moisture condensate include:

- Drips from a ceiling in a cooler land on a meat carcass.

- Droplets from a refrigeration unit land on exposed product.

- Moisture from a loading dock ceiling drips on to boxes of product, disrupting the packaging.

Control of moisture condensation is an important aspect of food-processing facility design and operation. The purpose of this fact sheet is to review the causes of moisture condensation and present strategies to reduce moisture condensation in food processing facilities.

Moisture Condensation

Moisture condensation, for the purposes of this fact sheet, is the process of reducing water gas or vapor to a liquid or solid form. Air can only hold a certain amount of moisture at a given temperature. When air exceeds its maximum moisture-holding capacity, the excess water vapor will condense and appear as fog or rain in the air, or as a liquid or solid on a surface (see Figure 1). Water vapor condenses onto a surface when the temperature of the surface is at or below the dew point temperature. The dew point temperature is defined as “the temperature at which dew begins to form.”

Figure 1. Condensation occurring during a cleaning process in a refrigerated room of a meat-processing facility.

Dew Point temperature illustration: When a cold container is taken out of the refrigerator on a warm, humid day, condensation rapidly forms on the surface (Figure 2). This phenomenon is caused by the cold surface of the container. The temperature of the container is below the dew point temperature of the air. When warm, moist air contacts the container, condensation forms on the surface.

Relative humidity is another important term related to moisture condensation. Relative humidity is defined, at a given air temperature, as the amount of water vapor in air, expressed as a percentage of the maximum amount that the air could hold. A high relative humidity indicates that the air carries a large amount of water vapor. At 100 percent relative humidity, fog or rain are present or imminent.

Figure 2. Condensation forming on the surface of a cold container.

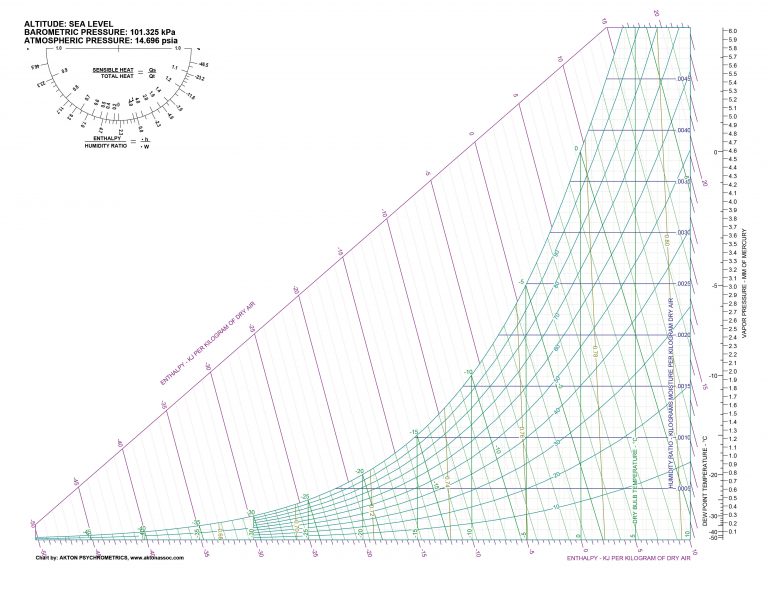

A psychrometric chart can be used to identify the physical and thermal properties of moist air. It can also be used to trace changes in air properties through various processes like heating and cooling. Knowledge of the air properties is an important aspect of understanding when condensation may occur and how to manage it. The following section is dedicated to explaining the use of a psychrometric chart.

Psychrometric Chart

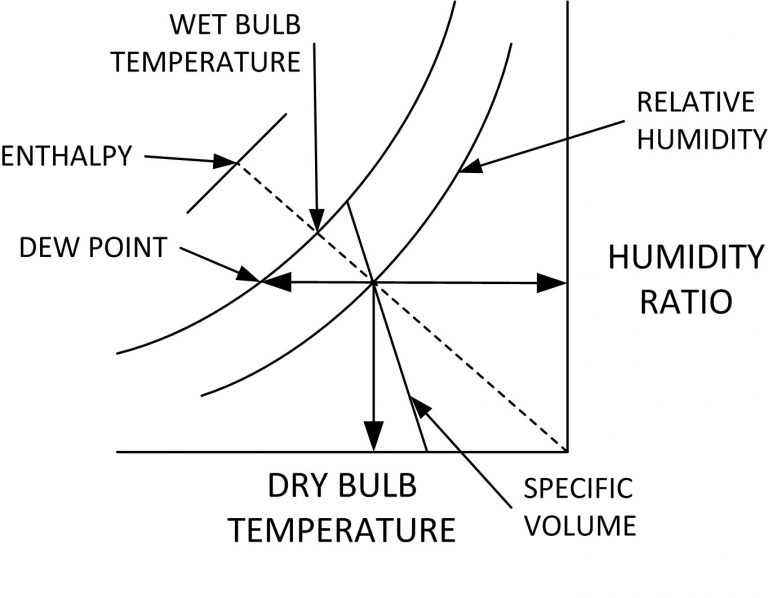

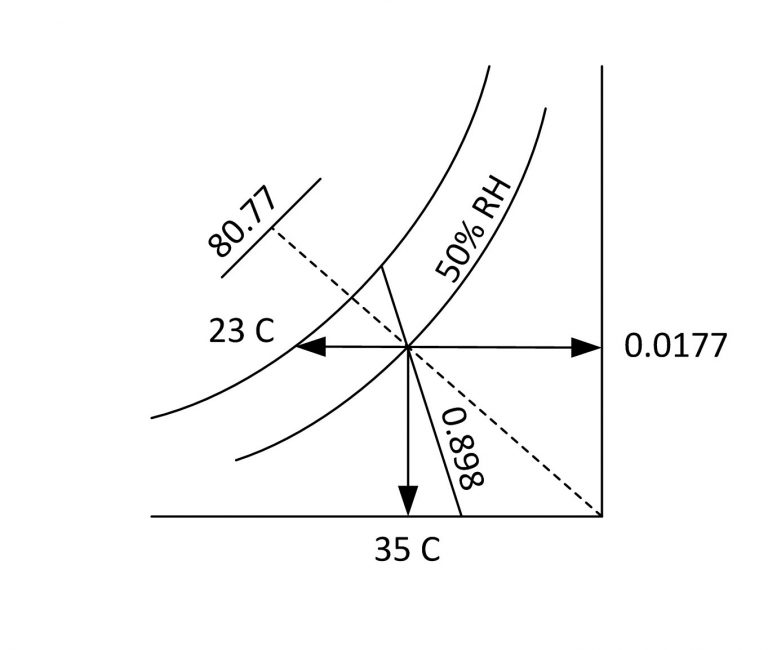

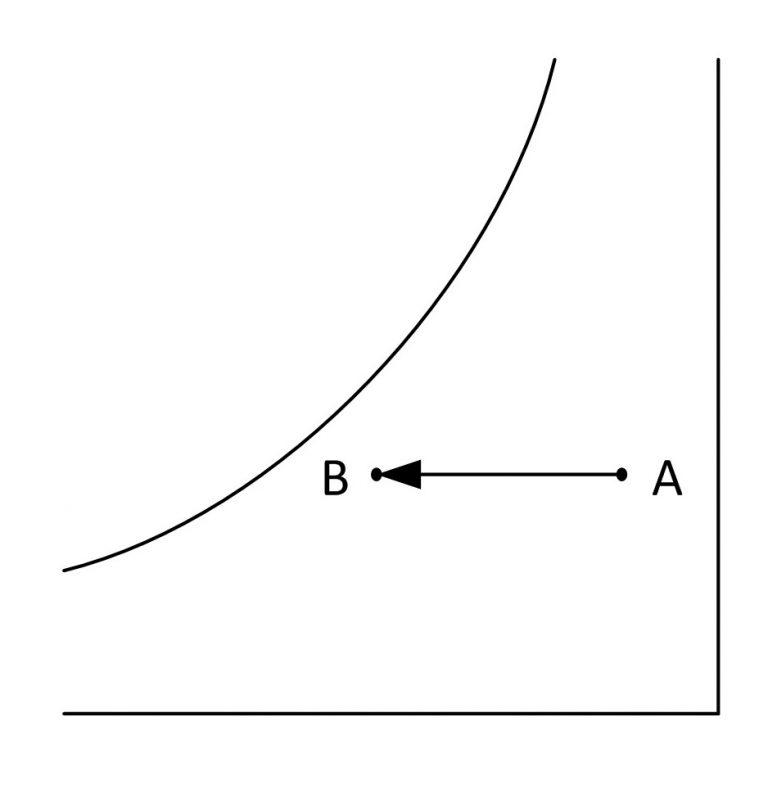

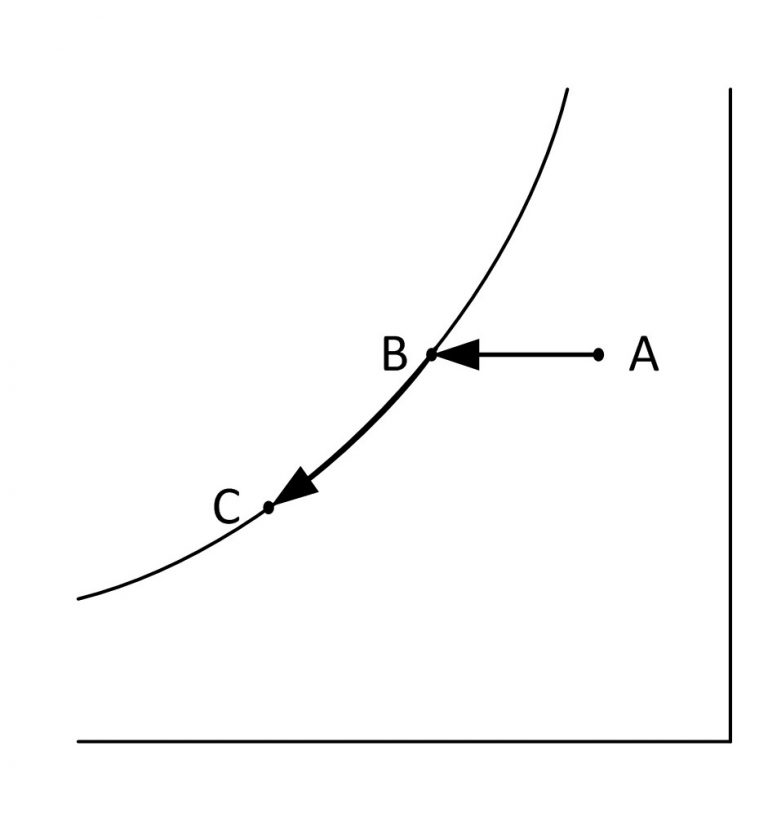

A low-temperature psychrometric chart is shown in Figure 3. The x-axis represents dry-bulb temperature and the y-axis gives the moisture content (or humidity ratio) of the air. Figure 4 shows the seven properties of moist air that can be determined using the psychrometric chart if any two of the values are known. Figure 5 gives an example of psychrometric chart values for moist air at 35 C dry bulb and 50% relative humidity. In refrigeration and freezing systems, cooling and dehumidifying are two important processes that can be tracked conveniently using a psychrometric chart. Sensible cooling is the name given to the cooling process when no condensation is produced. Sensible cooling reduces the air temperature only and is easily tracked on the psychrometric chart by a horizontal line. Figure 6 shows a sensible cooling process where air is cooled from point A to point B without dehumidification (the temperature of the cooling surface is above the dew point).

Figure 3. Low temperature psychrometric chart.

Cooling with dehumidification results in lowering the dry-bulb temperature of the air along with reducing the humidity ratio. When air is passed over an evaporator coil of an active refrigeration system, the air is often cooled to below the initial dew-point. In most cases, the final relative humidity of the air is greater than the initial. An example of this type of cooling and dehumidifying process is shown in Figure 7. Point A represents the incoming air with a given dry bulb temperature and relative humidity. The air is sensibly cooled until it reaches the dew point temperature at point B. The state of the air from this point forward tracks along with the dew point curve until it leaves the refrigeration coil at point C. Dehumidification is occurring from point B to point C. Note that the relative humidity of the air at points B and C and along the saturation line between B and C is 100%.

Figure 4. Properties that can be determined for moist air using a psychrometric chart.

Figure 5. Example of properties of moist are at 35 C dry bulb and 50% relative humidity.

Figure 6. Sensible cooling process shown on a psychrometric chart.

Figure 7. Cooling and dehumidification process using refrigeration. Segment AB represents sensible cooling. Segment BC represents a cooling with dehumidification process that traces the dew point temperature line.

Issues Associated with Moisture Condensation

Condensation on dirty or soiled surfaces can contribute to issues that are untenable in food processing facilities. Even a small amount of condensation on a food processing surface may provide favorable conditions for growth and biofilm formation of pathogens such as Salmonella and Listeria spp. The build-up of dirt, grease and other organic matter could accelerate biofilm formation and further establish microorganisms. Once firmly established, pathogens in biofilms exhibit a high level of resistance to various chemical and physical sanitation processes. If condensation takes place on a food contact surface, the risk associated with cross-contamination of food products increases many times due to the possibility of localized pathogen growth and spot contamination of food products. Additionally, moisture could also serve as a vehicle to transport soils and microorganisms from a surface to a new location.

Moisture Condensation Control Strategies

Strategies are needed to control moisture condensation in food plants. Fortunately some choices are available. Potential strategies, classified in three categories, are listed and explained in this section.

- Air flow control:

- Reduce infiltration (flow) of moist air

- Seal openings

- Control air flow

- Ventilate the space with dry air under positive pressure

- Reduce infiltration (flow) of moist air

- Moisture reduction:

- Install a dehumidifier

- Reduce water spray

- Remove or cover moist product

- Keep surfaces (e.g. floors) dry

- Surface treatment:

- Insulate surfaces

- Keep surfaces warm (abovethe dewpoint)

- Heat tape

- Heat lamp

- Thermal fluid

- Condensation resistant coatings

Air Flow Control

Control of air flow can help reduce condensation. The goal is to keep moist air from contacting surfaces that are below the dew point of the air. Four scenarios are given to help describe air flow control. In the first scenario, humid air leaked into a refrigerated space (product cooler) and moisture condensed onto the walls and ceiling of the cooler. The cooler had openings for lights and electrical conduit in the ceiling. The openings, along with a low atmospheric pressure in the cooler, allowed warm, moist air from the outdoors to enter into the refrigerated space. The result was condensation on the ceiling, walls, and many of the light fixtures. The building maintenance crew sealed the openings and eliminated the problem.

In a second scenario, the air in a large refrigerated room was stagnant. Warm, moist air generated by personnel, product, or a propane powered lift truck rose to the ceiling and the moisture condensed onto the cool surface. A low-speed, high-volume fan was installed to mix the air and the condensation problem vanished.

In a third instance a cooler was located adjacent to a warehouse. When the cooler door was opened, warm, moist air from the warehouse entered the cooler and condensed onto the surfaces near the doorway. A packaged air handling system was installed to produce refrigerated, dehumidified air which was forced into the cooler to create a positive pressure atmosphere (higher than the pressure of the adjacent warehouse). After installing and adjusting the system, when the cooler door was opened, cool air rushed out, instead of warm, moist air rushing into the cooler. The condensation problem was eliminated.

In a fourth scenario, condensation was constantly occurring on the surfaces near the door to a cooler that opened into a warehouse. Two remedies to control air flow were put in place to solve this problem. First, a small anteroom was built between the cooler and the warehouse. The anteroom served, like an airlock, to separate the atmospheres of the cooler and warehouse. Next, a dehumidifier was installed to dry the air in the anteroom. After installation of the anteroom and dehumidifier, the air that entered the cooler was mostly dehumidified (had a lower dew point), and did not condense on the cooler walls.

Moisture Reduction

Reduction of moisture in the air will reduce the dew point and can eliminate condensation. There are a number of methods to reduce the amount of moisture in the air inside of a food processing or storage facility. Some of these methods are discussed in this section.

Install a dehumidifier: Two types of dehumidification systems are popular. The first is a chiller that cools the air to below the dew point, causing moisture to condense out of the air. A drawback to this system is the high relative humidity of air that has just passed through a cooling coil. The humidity of the cooled air typically exceeds 90% (Trane, 2005). If this air contacts a slightly cooler surface, like a freezer door, it will result in condensation.

The second type of dehumidification system uses a desiccant that directly removes water molecules from the air. Desiccant systems can save money but are often more complex to operate and maintain compared to a traditional chiller. One alternative may be more efficient and appropriate depending on the given application. See the sidebar for an explanation of a desiccant dehumidification system.

Reduce water spray: Indoor humidity levels can be dramatically increased by water sprays in the air. A water spray can be associated with a hose used during cleanup or batching operations, a water curtain used for container cleaning, lubrication for a conveyor, water leaks, steam leaks, boot washers, pressure washers, and evaporative coolers. Reduction or elimination of water spray will reduce the humidity in the environment, and conserve water.

Control moisture from foods: Many foods, like fruits and vegetables, are very moist and emit water vapor into the environment during natural respiration. If possible, cover foods and ingredients that respire and ventilate the moist air out of the building. Hot product or water in kettles or vats or on griddles should also be covered or vented to prevent moisture from escaping into the air. Ovens can also produce large volumes of water vapor from cooking. The moisture-laden oven air should be vented out of the facility. Product that is removed from an oven or heater should be placed in a ventilated area to remove evaporating moisture.

Keep surfaces dry: Water will evaporate from wet surfaces and increase the local relative humidity. Moisture-laden air will be more likely to condense on cool surfaces. Wet surfaces appear in trench drains and sumps and are caused by cleanup operations, spills, drips, leaky pipes, hoses, and water used for conveyor lubrication.

Table 1. Suppliers of condensation resistant coatings that can be applied to food-contact and/or non-food contact surfaces in a food processing facility. This is an incomplete list in alphabetical order by manufacturer name and is not an endorsement of any product or manufacturer.

| # | Manufacturer | Product | Safety |

|---|---|---|---|

| 1 | Aqua Based Technologies, Northvale, NJ aquabased.com (201) 767-6040 |

Aquacoat™ 7000 and Staticon 450: Anti-fog coatings | FDA approved ingredients |

| 2 | Chemicoat, Inc., Chamblee, GA, (770) 457-2657 |

Aquaban: water-based coating that prevents condensation by absorption/desorption | Non-toxic |

| 3 | Drywired.com, Los Angeles, CA, drywired.com (310) 855-1201 |

Defense and FP-101X water fighter: hydrophobic coating for various substrates | Non-toxic |

| 4 | Hydrobead, San Diego, CA, (858) 638-0316 |

Hydrobead: superhydrophobic coating |

Non-toxic |

| 5 | Kefa Northeast, Budd Lake, NJ, kefanortheast.com (201) 664-5487 |

Kefa: microporous coating that absorbs water condensation for subsequent evaporation | FDA-175-300 |

| 6 | Rust-Oleum Corp, Vernon Hills, IL rustoleum.com (847) 367-7700 |

NeverWet™: Water repellent barrier | USDA FSIS compliant |

Surface Treatment

Surfaces in the food plant can be treated to prevent or reduce condensation. One of the most important goals of surface treatment is to increase and maintain the surface temperature above the dew point, which will eliminate condensation altogether. The first and probably the most obvious form of surface treatment is insulation. Insulation will help prevent unwanted heat loss (or gain) and may change the temperature of a surface.

When insulation is not enough, surfaces can be warmed to increase their temperature to above the dew point. Surface warming may be accomplished by several methods including heat tracing using electrical resistance heat elements (heat tape), thermal fluid or steam, and infrared lamps. Heating seems counterintuitive in a refrigerated enclosure, and will increase the amount of cooling energy required, but can reduce or eliminate condensation in problem areas.

Condensation resistant coatings are a controversial alternative that may or may not work, depending on many physical and environmental factors in the facility. A literature search for condensation or fog resistant coatings will result in a large number of products and suppliers. A small number of these products may be appropriate for application to existing surfaces in a food processing facility. They should be approved for food contact or non-food contact surfaces. Some examples are listed in table 1.

Conclusion

Moisture condensation is a critical issue impacting the food industry. Condensation and its implications for products and operations are often underestimated in food factories. Underestimation of the impact of moisture condensation may lead to injury, unscheduled downtime, maintenance issues, loss of income, food safety and product quality issues.

This fact sheet outlines proactive steps that can be taken or planned to develop a strategy for the reduction and control of moisture condensation in a food factory. If you would like guidance in the development of your moisture condensation management strategy, please call the Robert M. Kerr Food and Agricultural Products Center (405-744-6071) or e-mail fapc@okstate.edu to request assistance.

References

USDA, FSIS. 1999. Sanitation Performance Standards Compliance Guide. Accessed on: May 14, 2015.

FDA. 2014. Code of Federal Regulations Title 21, Section 110. Current Good Manufacturing Practice in Manufacturing Packing, or Holding of Human Food. May 14, 2015.

Tim Bowser

Food Process Engineer

Ravirajsinh Jadeja

Food Safety Specialist