Nitrification and Maintenance in Media Bed Aquaponics

- Jump To:

- Introduction to Aquaponics

- Nitrogen Cycling/Nitrification

- Bacteria for Nitrification

- Water Quality Management

- Ammonia

- Nitrite (NO2-)

- Nitrate (NO3-)

- pH

- Lowering pH

- Raising pH

- Water Temperature

- Cooling water

- Warming water

- Dissolved oxygen

- Algae

- Fish Acclimation

- Stocking Fish

- Plant-to-fish Ratio

- Feeding

- Sources to Purchase Fish

- Troubleshooting

The purpose of this fact sheet is to provide information on nitrogen cycling with and without fish in aquaponic systems. The fact sheet also touches on bacteria involved in nitrification, water quality management such as ammonia, nitrite (NO2-), nitrate (NO3-), pH, temperature and dissolved oxygen levels. Additionally, the fact sheet covers algae management, fish acclimation, fish stocking, fish species and feeding rates. The final topics covered are plant to fish ratios, tasks for upkeep and a troubleshooting guide.

Introduction to Aquaponics

Aquaponics is a soilless farming technique that dates back to 1400 A.D. Modern aquaponic systems are recirculating aquaculture systems (RAS) combined with soilless plant production (hydroponics) components. The beauty in aquaponics is the reliance on mutualism between fish, bacteria and plants present in the system. In exchange for nutrition from fish waste, the plants clean the water that returns to the fish with the help of bacteria. Aquaponics splits into three different design schemes: nutrient film technique (NFT), media bed and raft/deep-water culture. Often, commercial producers will rely on a combination of system designs for production. Compared to conventional agriculture, the aquaponic industry is in its infancy, and the hindrance of its commercialization is due to high initial investments, high annual production costs, and other technical issues. However, due to freshwater and arable land shortages, shifts in opinions about organic farming and the environmental degradation resulting from traditional soil-based agriculture, aquaponics is gaining popularity among farmers, educators, entrepreneurs, consumers and hobbyists alike.

Nitrogen Cycling/Nitrification

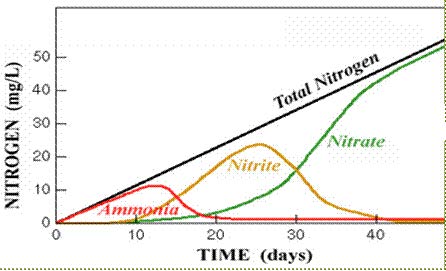

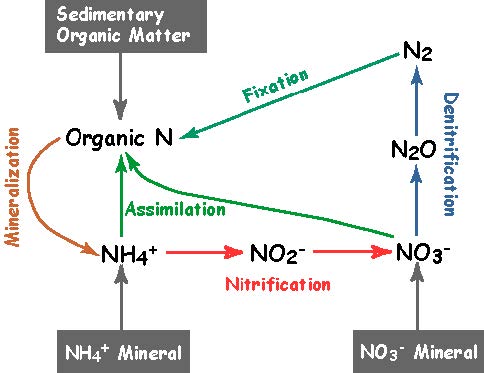

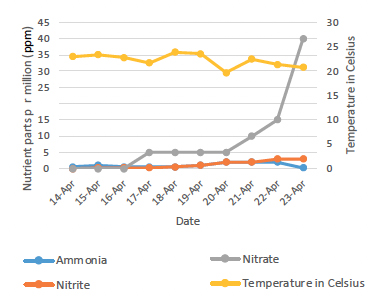

Cycling is the process where bacterial groups establish themselves in a new system over time. A standard indicator used to determine whether a system has completed its cycling period is successful nitrification. Nitrification is the process of Aquaponicsadding unionized ammonia (NH3) or ammonium (NH4+) into the aquaponics system; over time, bacteria will begin to establish themselves, which convert the ammonia/ammonium to nitrite (NO2-) and then to nitrate (NO3-) (Figure 1). Table 1 discusses the steps of cycling with and without fish in the aquaponics system. When cycling, consider that at least four weeks is needed to experience nitrification before growing anything. Figure 2 shows the length of time it takes for nitrification to take place. In Figure 3, the relationship of temperature as it pertains to the process of nitrification is shown. However, aquaponics tends to mimic natural environments in that the nitrogen cycle is ever-present in each system. This concept means that for nitrification to occur, it must follow the pathway of transformation for plants to grow (Figure 1). Growers must be vigilant, as it is critical for nitrification to occur. It is also true for denitrification to occur in a series of half-reactions, which results in nitrite production (NO2-), Nitrous Oxide (N2O), and gaseous nitrogen (N2) production accompanied by changes in pH and hydrogen sulfide production, which is toxic for fish, thus not suitable for the system. Denitrification is linked with anaerobic bacteria production, which is driven by low dissolved oxygen levels.

Bacteria for Nitrification

During nitrification, ammonia attracts ammonia-oxidizing bacteria Nitrosomonas, Nitrospira, Nitrosococcus, Nitrosolobus and Nitrosovibro, as well as nitrite-oxidizing bacteria Nitrobacter, Nitrococcus, Nitrospira and Nitrospina. Caring for bacteria is crucial while operating an aquaponics system. Like most other bacteria, nitrifying bacteria require adequate biological surface area, stable pH, dissolved oxygen, temperature and no UV light to reproduce successfully. Bacteria require a high biological surface area to thrive in a system. Typically, they need around 300 to 600 m2/m3 (a surface area measurement) for colonization. To give bacterial colonies optimal surface area, people should consider using inert, porous and lightweight media like expanded clay or expanded shale. Water pH is another factor influencing the bacteria population. A pH range of 6.5 to 8.5 is acceptable during cycling, but bacteria prefer a higher pH of 8.0 to 8.3. The optimum range of dissolved oxygen for the bacteria is 4-8 mg/L. Lastly, an ideal water temperature range is 63 F to 93 F.

Figure 1. Nitrogen cycle with transformation.

Figure 2. Total nitrogen transformation in (mg/L) over a 40-day nitrification period. Note, values may change according to inputs, but the trend should remain the same.

Figure 3. A 10-day spring cycling period without fish but only media and feed inoculation in a research greenhouse.

Table 1. Steps to start bacteria cycling with and without fish.

| Cycling Steps with fish: | |

|---|---|

| 1. Dechlorinate water for two to three days by letting water sit with consistent aeration or using chemical de-chlorinators with consistent aeration. | |

| 2. Purchase sacrificial fish, such as goldfish, as they are cheap and hardy. These fish may die due to the inexperience of the grower or if the species is susceptible to high ammonia. | |

| 3. Give bacteria time to culture after adding fish (two to six weeks). In higher temperatures, growers will see a faster bacterial growth rate. However, the water temperatureshould not exceed the fish thermal maxima. | |

| 4. Ensure good monitoring of ammonia, nitrite (NO2-) and nitrate (NO3-) levels daily for the next 15 days. | |

| 5. Add seedlings when ammonia reaches ≥ 4 parts per million. | |

| 6. Monitor nitrates. Once nitrates have reached 40 to 50parts per million, and the ammonia and nitrite levels are 0 to 0.25, the system has successfully cycled. This process can vary from two to four weeks, depending on fish density, location, pH and climate. Continue to monitor ammonia and nitrite concentrations to preserve fish.Keep monitoring the total nitrate concentration, as this is the nutrition for the crops. Do not exceed 140 parts per million nitrate as too high levels of nitrates will become harmful to the fish and plants. | |

| 7. Add fish with the goal at end harvest weight being 0.5pound of fish harvest weight per 1 gallon of water. This rate is from Rakocy’s findings with tilapia and is the critical standing crop. Note only add fish during this step if needed to replenish fish lost due to cycling. A safe rate for fish that is also suitable for the beginner is a 1 pound of fish harvest weight per 8 to 10 gallons of water. Growers will need to harvest fish to maintain water quality parameters. |

Table 1. Steps to start bacteria cycling with and without fish. (Continued)

| Cycling steps without fish: | |

|---|---|

| 1. Inoculate each 20 square feet aquaponics system with 1cup of grow bed media from a healthy aquaponic system and spread it evenly throughout each new system’s grow bed. This will help with bacterial colonization of the media. | |

| 2. Using a pH meter and a freshwater test kit, monitor pH,water temperature, ammonia, nitrite (NO2-) and nitrate(NO3-) daily throughout the cycling process. | |

| 3. Add small amounts of fish feed or nitric acid used during production. This practice may vary depending on agrower’s system. | |

| 4. Do not let the ammonia exceed 4 parts per million because this can crash the entire bacterial colony, resulting in a grower starting over. | |

| 5. Once ammonia reaches 4 parts per million, stop adding feed and let the bacteria convert ammonia to nitrates. | |

| 6. Allow for the system to reach 40 to 50 parts per million nitrate, which indicates the completion of cycling. Check if nitrates are present up to 40 to 50 parts per million after 25 days. If yes, then the system is cycled; if not, continually monitor until nitrates are at the desired range and ammonia and nitrite are 0 to 0.25 parts per million. | |

| 7. Add fish and plants to the system. Allow for 5 to 10 minutes of acclimation when adding fish, i.e., let the fish adjust to the temperature and pH of the water. Do not allow for wide fluctuations of pH and temperature to occur (no greater than 0.2 units), which can negatively impact the overall health of the fish. For the plants, give them sometime in the system to recover from transplant shock. Not applicable if direct seeding. | |

| 8. Continually monitor ammonia, nitrite (NO2-) and nitrate(NO3-). Correct as needed using the troubleshooting guide (Table 7). |

Figure 4. Small-scale 20 square feet media bed aquaponics system, donated by Symbiotic Aquaponic LLC. The filtration system in the center is an Aquadyne mechanical bead filtration unit. (Image Credit: Che Deer-Graduate Student at Oklahoma State University).

Water Quality Management

It is essential to monitor water quality including, ammonia, nitrite, nitrate, pH, temperature and dissolved oxygen, because fish, bacteria and plants can experience increased levels of stress, which can result in reductions in growth, disease or death if not properly managed (Table 2). Growers can test most of these parameters using water test kits as they are easy to acquire, but dissolved oxygen is most easily measured with a dissolved oxygen meter. Note that other methods exist, like spectrophotometry, should the grower decide to use that technique. For example, the API freshwater test kit is cost-effective and easy to use for determining nutrient concentrations. Figures 1 and 2 show how ammonia, nitrite and nitrate interact within the system. Growers associate water quality management with maintaining balance in aquaponics. Moreover, water quality management starts with adequately sizing the fish production area to the plant production area.

Ammonia

Total ammonia nitrogen (TAN) is the total amount of nitrogen in NH3 and NH4+ forms. The presence of ammonia is affected by pH and temperature; proper maintenance of these parameters results in concentrations suitable for aquaponics. Generally, water test kits will give the TAN concentrations. To avoid fish stress or potential death, maintain TAN concentrations within 0 to 0.25 parts per million in an aquaponic system. Plants primarily uptake nitrogen in nitrate or ammonium forms; however, fish benefit from the accumulation of nitrate over ammonia as this is the least lethal form of nitrogen for them.

Depending on the fish species, ammonia tolerance varies. For example, cool water fish

(trout, salmon) are more sensitive to ammonia concentrations than warm water fish

(tilapia, catfish). Ammonia stress causes loss of equilibrium, hyperexcitability,

increased breathing, cardiac output and oxygen uptake and, in extreme cases, convulsions,

coma and death at rates over threshold levels (Table 3). The stress will continue

to climb when ammonia spikes persist until a threshold of 4 parts per million ammonia

occurs. It is at this level that the bacteria will die off. Sometimes, the bacterial

colony crashes in new and cycling aquaponics systems, resulting in the grower needing

to restart the establishment of a bacteria community. One can expect to see a fish

kill overnight during an ammonia spike. Again, this may vary depending on the fish

species, and elevated ammonia levels must see treatment at first detection. Treatment

could include a reduction in feeding, removal of solid builds up, or performing a

water exchange if ammonia concentrations become too high. See the troubleshooting

for water exchange rates (Table 7). Solid waste removal takes place through backwashing.

If solids accumulate, then denitrification can occur, which will result in ammonia

concentrations increasing. Proper system management will require the periodic removal

of solids from the system to reduce the chances of ammonia shock. Otherwise, reduce

feeding inputs and perform water changes until the ammonia reaches a safe level. It

is ideal to have separate tanks for temporarily moving fish if levels are too high.

Table 2. Recommended water quality parameters for aquaponics. Adapted from Hager et al. (2021).

| Organism | Temperature (C) | pH | Ammonia (mg/L) |

Nitrate (NO2-) (mg/L) |

Nitrate (NO3-) (mg/L) |

Dissolved oxygen (mg/L) |

|---|---|---|---|---|---|---|

| Warm water fish | 22 to 32 | 6 to 8.5 | <3 | <1 | <400 | 4 to 6 |

| Cold water fish | 10 to 18 | 6 to 8.5 | <1 | <0.1 | <400 | 6 to 8 |

| Plants | 16 to 30 | 5.5 to 7.5 | <30 | <1 | <250 | >3 |

| Bacteria | 14 to 34 | 6 to 8.5 | <3 | <1 | – | 4 to 8 |

| Compromise for Aquaponics | 18 to 30 | 6 to 7 | <1 | <1 | <150 | 5 to 8 |

Table 3. Summary of fish species suitable for aquaponics and their environmental parameters. Adapted from Hager et al. (2021).

| Species | Vital temperature (C) | Optimal temperature (C) | Total ammonia (mg/L) |

Nitrate (mg/L) |

Dissolved oxygen (mg/L) |

Crude protein in feed (mg/L) |

|---|---|---|---|---|---|---|

| Nile tilapia Oreochromis niloticus | 4.0 to 34.0 | 25.0 to 30.0 | <2 | <1 | >4 | 28 to 32 |

| Common carp Cyprinus cario | 14.0 to 36.0 | 27.0 to 30.0 | <1 | <1 | >4 | 30 to 38 |

| Channel catfish Ictalurus punctatus | 5.0 to 34.0 | 24.0 to 30.0 | >1 | >1 | >3 | 25 to 36 |

| Largemouth bass Micropterus salmoides | 5.0 to 34. 0 | 24.0 to 30.0 | <1 | <2 | >4 | 45 to 48 |

| Rainbow trout Oncorhynchus mykiss | 10.0 to 18.0 | 14.0 to 16.0 | <0.5 | <0.3 | >6 | 42 |

| Barramundi Lates calcarifer | 18.0 to 34.0 | 26.0 to 29.0 | <1 | <1 | >4 | 38 to 45 |

| Bluegill Lepomis macrochirus | 13.0 to 35.0 | 21.0 to 23.0 | <2 | <1 | >5 | 36 to 38 |

Table 3. (Continued)

| Species | Growth Rate | Year-round supply of fingerlings (US) | Market Value ($ US/lb live) | Consumer acceptance |

|---|---|---|---|---|

| Nile tilapia Oreochromis niloticus | 600 grams in 6 to 8 months | Yes | $3.00 | Good |

| Common carp Cyprinus cario | 600 grams in 9 to 11 months | Yes | NA | Poor |

| Channel catfish Ictalurus punctatus | 400 grams in 9 to 10 months | Yes | $2.00 | Good |

| Largemouth bass Micropterus salmoides | 600 grams in 14 to 16 months | Seasonal | $4.00 to $5.00 | Moderate |

| Rainbow trout Oncorhynchus mykiss | 1,000 grams in 14 to 16 months | Seasonal | $3.00 | Good |

| Barramundi Lates calcarifer | 400 grams in 9 to 10 month | No | $8.00 to $9.00 | Good |

| Bluegill Lepomis macrochirus | 45 grams in 10 to 12 months | Yes | NA | Moderate |

Nitrite (NO2-)

Nitrite is also toxic to fish and should be maintained as low as possible (Table 3). Nitrite corresponds directly with ammonia and nitrates. If the system is increasing in nitrites, consider removing solids build-up within the system or performing a water exchange until concentrations reach a tolerable level. The immediate first steps would be to reduce feeding rates, then do a water exchange. The following steps would be to check for dead fish or solids accumulation within the system. If the problem persists, there may be a lack of biological surface area for bacterial colonization or the fish densities may be too high for the system.

Nitrate (NO3-)

Nitrates are the least toxic form of nitrogen to fish and can range from 50 to 90 parts per million. The ideal range for nitrates is 60 to 70 parts per million to allow nutrients for plants and bacteria, while still avoiding toxicity to fish. The concentration of nitrates (NO2-), nitrites (NO3-) and ammonia are all correlated, so it is important to keep nitrate concentrations low. Consider backwashing or changing water if rates become too high, as well as increasing planting densities or reducing feeding amounts. Increase nitrates, if needed, by adding more fish or by increasing feeding.

pH

The pH in an aquaponics system should range from 6.5 to 7.5 for fish and plant growth, and between 8.0 to 8.3 for cycling bacteria. Maintaining a suitable pH for plants, fish and bacteria is necessary for the proper function of an aquaponics system. It is also important to note that plants prefer a slightly acidic environment for nutrient absorption. The proportion of nitrogen in the system that becomes un-ionized ammonia increases with pH and temperature.

Lowering pH

Lowering pH is often not necessary in aquaponics as the natural process of nitrification lowers the pH for the grower. However, water may have a higher pH for some cities due to high carbonates in the water. To lower the pH in the system, consider using reverse osmosis water as the first choice as this is the safest method, but this may not be practical as it is expensive. If this is not an option, consider sourcing distilled water from a store. Add the water at a rate of 45 gallons per week for a 152-gallon system; this can vary with other systems.

The reverse osmosis practice is the safest technique, and it will ensure that the ideal pH range of 6.5 to 7.5 prevails in the system. Growers may elect to use phosphoric or nitric acid. However, these should only be used in emergencies and may harm the fish if not done correctly. Phosphoric acid is the best because it is safer. Another benefit of using phosphoric acid is adding phosphorous to the system, which is beneficial for plants. If algae is a problem, then consider using another acid. Growers should use titration to find the ratio of acid-to-water. To increase titrate, take 1 gallon of water from the system and add the selected amount of acid until the pH is ideal. Take the amount of acid added and multiply it by the number of gallons in the system. In general, too much phosphoric acid or other acids can harm the fish, so use caution and only use it for emergencies. Make sure that pH does not change by more than 0.2 units per day. The pH is logarithmically based, meaning that slight fluctuations have significant and often drastic effects on the overall health of the entire system.

Raising pH

The first choice in raising pH in aquaponics is to use dechlorinated tap water; however, not all tap water has high pH. Check with the city to see the water’s pH and decide if the water is suitable for the system. A grower can use an equal homogenized blend of calcium carbonate, magnesium carbonate and potassium carbonate added at a rate of 2.4 to 2.6 grams two to three times daily, with the added benefit that these chemicals serve as nutrients for plants. The grower may choose to alternate or use all chemicals at the same time. However, note that all treatments should undergo proper dosing as previously stated, for fear of inducing nutrient deficiencies in the plants. These chemicals are not caustic and are safer to use than other products that modify pH. An added benefit is that they can be organically certified, though growers will need to find the certified products as not all are certified.

Water Temperature

Water temperature between 64 F and 86 F is suitable for most plants and fish. A grower might want to consider their goals for crop production depending on the climate and the system’s requirement for water temperature. Consider building an underground sump tank at a depth of 3 feet to achieve a constant geothermal temperature of 60 F to 70 F. This technique will help during extremely hot/cold months. Also, it will save on electricity required to control water temperature.

Additionally, it is essential to know most fish are ectothermic, meaning the body temperature fluctuates with water temperature. Warm-water fish start to see extreme stress at around 45 F and cool-water fish will see stress when the water is more than 68 F. Warm-season crops have an ideal temperature range of 64 F to 86 F and cool-season crops require a temperature range of 46 F to 68 F. Consider coupling cool-season crops with cold-water fish or warm-season crops with warm-water fish if applicable during each growing season. See Table 4 for examples.

Cooling water

Fish will benefit from shade. If a grower can minimize solar energy hitting the water, the water temperature will be cooler. A shade cloth that blocks out 30% to 60% of the sunlight is ideal for fish tanks and can help prevent algae. A grower can purchase a tank chiller to reduce water temperature, but it is a more expensive solution. A cheaper solution would be to embed the fish tanks in-ground. This method will maintain a constant temperature of around 55 F if located in the Midwest. Otherwise, ground temperatures may vary.

Warming water

A grower can insulate the tanks with reflective foil, soil or cloth to preserve heat during the cold months. Embedding tanks in-ground is an inexpensive option. If the grower does not want to bury the tanks, they can use greenhouse air heaters to warm the air temperature or buy tank heaters. Make sure to keep the tanks suspended off the cold floor.

Dissolved oxygen

Many warm-water fish and plants prefer 6 to 7 parts per million of dissolved oxygen. Plants, in general, do better with a dissolved oxygen level of 6 to 9 parts per million. Catfish can survive at a range of 2.5 to 3 parts per million. Tilapia can survive as low as 1 part per million, making them an ideal, hardy choice of fish for aquaponics. Consider adding air stones if dissolved oxygen drops to less than 6 parts per million. A grower could add supplemental oxygen air pumps to the fish tank, but aeration with atmospheric air is typically sufficient at normal stocking densities. The aeration will help keep both the plants and the fish healthy. A grower could remove some of their fish to help balance the amount of dissolved oxygen. Note: as the temperature and elevation increase, dissolved oxygen will decrease. A grower may choose to use a recirculating design with water flowing back into the tank, breaking water surface tension so it also aerates the system.

Table 4. Warm water/cold water fish and plant species for aquaponics.

| Warm-water fish: | Warm-season crops: | Cold-water fish: | Cool-season crops: | |

|---|---|---|---|---|

| Barramundi Bluegill Channel catfish Goldfish Green sunfish Koi Tilapia White bass |

Basil Bean Cilantro Cucumber Dill Melon Mint Okra Oregano Pepper Squash Tomato Zucchini |

Arctic char Brook trout Brown trout Murray cod Rainbow trout Salmon |

Broccoli Cabbage Chive Kale Kohlrabi Lettuce Onion Pea Radish Spinach Swiss chard |

Algae

Algae growth in aquaponics is not ideal. The algae growth can tie up nutrients, cause oxygen depletion and lead to pH fluctuations, while also clogging the filter and other components of the system. To combat algae in the aquaponics system, consider checking and maintaining the appropriate pH and phosphorous. API also sells a phosphate (PO43-) water test kit that helps growers monitor these parameters. Keep phosphate levels within 10 to 20 parts per million for light feeding crops like leafy greens and 20 to 40 parts per million for heavy feeding crops like tomatoes. Algae grow best when the pH is 8.0 to 8.5. After cycling, make sure to drop the pH to 6 to 7. Next, consider adding shading to the tanks. Shading of 30% to 60% is ideal. Growers can also use mechanical filtration. This method is often expensive because it comprises filters, screens, vortex and centrifugal equipment. Growers can use more grow beds in their system to filter out algae as a cheap mechanical filtration method. Humic acid can control algae and can be beneficial to the fish if used in small amounts, as it changes the color of the water and ultimately reduced light penetration. Other chemical methods safe for fish, like ‘Aquashade,’ helps similarly by utilizing inert dyes to block out sunlight.

Fish Acclimation

The key factors to consider for optimal fish production are pH, dissolved oxygen, temperature and time. Make sure to place fingerlings into the system while still in the bag to allow water temperature in the bag to gradually adjust to the temperature of the tank. Test the tank water to ensure optimal water quality. Wait about 5 to 10 minutes before adding small amounts of tank water to the fish bags. This practice is a safe method of adding fish to tanks; however, 15% to 20% die-off happens when new fish adjust to the system. When the water temperature is the same in the bag and the tank, release the fish. It can take several hours for the water in the bags to reach the same temperature as the tank.

Stocking Fish

Rakocy et al. (2006) provide a well-referenced example of how to stock fish in aquaponic systems. Critical standing crop (CSC) is the maximum fish biomass a system can support without restricting fish growth. Operating at the critical standing crop provides the most efficient use of space while limiting feeding variation. The critical standing crop should not exceed a final harvest weight of 0.5 pounds of fish per 1 gallon of water. However, CSC is not the same as stocking density. One should first determine fish tank volume and stock at a safe rate, typically 1 pound fish harvest weight per 8 to 10 gallons of fish tank volume for most fish species. For example, smaller bluegill in Symbiotic Aquaponic systems were stocked at a rate of 40, 2-to-3-inch bluegill fingerlings in 152 gallons of water, as the average fish weight at harvest is about 0.4 pound. This safe stocking density results in 1 pound fish harvest weight per 8 to 10 gallons of water.

The fish species, amount of biofiltration and goals of production will determine stocking density. This rate is variable, and the grower must measure fish biomass weekly to monthly to assess whether there is a need to harvest to maintain the proper density. When the fish are young and small, reduce the number of plants in proportion to the size of the fish and their corresponding feed rate/waste production. Stocking densities may vary depending on the species of fish used. Species with limited growth potential, like bluegill, may have higher stocking densities initially. Fish that grow larger, like catfish, would require thinning as they grow if high initial stocking densities are used. Growers will need to assess their environment, market and goals when choosing a fish species for their system. Beginning growers should have high oxygen rates (6 to 7 parts per million) and low stocking rates for simple systems.

Plant-to-fish Ratio

For commercial growers, the ratio of plants to fish should be 2:1 for most crops. This ratio means one fish for every two plants. As an example, 50 fish would be used with 100 plants. Some commercial settings can have a higher ratio of 3:1 or 4:1, depending on the crop type, crop density, fish density and water flow rate. The most important factor underlying the plant-to-fish ratio is the feeding rate. Typically, growers would gradually increase feed over time, so plants have time to grow and maintain balance within the system.

Feeding

It is important to consider protein requirements when feeding fish. Some omnivorous fish, like tilapia and catfish, may need a 35% crude protein feed. Salmon and trout may be fed a higher protein rate at 45%. A grower should use feed in pellet form due to the ease of measurement and the wide selection of available products (Table 5). Fish size also must be considered. Small fish cannot ingest large feed, so match pellet size to fish size. It is essential to watch how much the fish are eating to avoid overfeeding. The concept of ‘ad libitum’ feeding is feeding until satiation. Growers will feed their fish as much at one time as they will eat. Alternatively, fish can be fed at a rate of 0.015 times the total weight of fish (which requires weighing fish monthly to account for growth). Combining these two methods results in an accurate and safe feeding schedule for fish and the system. Feeding rates can be varied with fish size for optimal production; see Table 6 for feeding rates for several commonly used species. The feed can be either sourced online or in stores. Sources include Optimal Fish Food (optimalfishfood.com), Zeigler (zeiglerfeed.com/), Cargill (cargill.com/animal-nutrition/species/aquaculture), and Aquamax (purinamills.com/fish-and-aquatics-feed).

Sources to Purchase Fish

Finding a reliable farm for sourcing fish is crucial, since it helps reduce the chance of introducing diseases into the system. Note: not all fish species are available at all times of the year as different fish species spawn at different times of the year. In Oklahoma, some sources for purchasing fish include Inslee’s Fish Farms (1400 E Seeley Chapel Road, Ada, OK 74820), Harbin Fish Farms (harbinfishfarm.com/) in Wetumka, OK, and Dunn’s Fish Farms (dunnsfishfarm.com/) in Fitzhugh, OK. This list is not exhaustive, and undoubtedly there are other suitable sources of fish for aquaponics. Growers must possess an aquaculture license. Consult with Oklahoma’s Department of Agriculture, Food and Forestry (ODAFF) for more information regarding acquiring an aquaculture license.

Standard operating procedures:

Table 6 lists the daily, weekly and monthly tasks that a grower needs to complete

in a media-based aquaponics operation. These tasks are for sanitation and food safety.

Troubleshooting

Listed below are some common issues in aquaponics systems and suggested solutions. The most common problems are low dissolved oxygen and water leaks (Table 7).

Other Related Extension Publications

EPP-7652, Non-Chemical Methods for Controlling Diseases

in the Home Landscape and Garden

HLA-6721, Aquaponics

HLA-6710, IPM in the Greenhouse Series: Integrated Pest

Management in Commercial Greenhouses: An

Overview of Principles and Practices

HLA-6038, Fungi Used for Pest Management in Crop

Production

SRAC-5007, Principles of Small-Scale Aquaponics

Table 5. Recommended feeding ratios for Bluegill and other sunfish, tilapia and channel catfish. Adopted from Missouri Extension ‘Bluegill Sunfish Production in Missouri’, SRAC Publication 282 (Delong et al., 2009), and Missouri Department of Conservation Aquaguide ‘Monoculture of Channel Catfish in Farm Ponds’.

| Species | Product type | Product size | Form | Action | Fish size (inches) | Pounds feed per pound of fish |

|---|---|---|---|---|---|---|

| Sunfish | Starter | Powder | Meal | Sink | <1.0 to 1.5 | 0.15 |

| No. 1 starter | 0.8 mm | Crumbles | Sink | 1.0 to 2.0 | 0.09 | |

| No. 2 starter | 1.2 mm | Crumbles |

Sink |

1.5 to 2.5 |

0.07 |

|

| Fingerling | 2.0 mm | Extruded | Partial Float | 2.5 to 3.5 | 0.04 | |

| Grower | 3.0 mm | Extruded | Float | 3.5 to 5.5 | 0.02 | |

| Grower | 4.0 mm | Extruded | Float | 5.5 to 8.5 | 0.015 | |

| Grower | 5.0 mm | Extruded | Float | >8.5 | 0.009 to 0.01 |

Table 5. (Continued)

| Species | Product type | Product size | Form | Action | Fish size (inches) weight (g) |

Range of feeding rate (% biomass/day) |

|---|---|---|---|---|---|---|

| Talapia | #00 Crumble | Powder | Meal | Sink | <1/<0.5 | 20 to 15 |

| #0 Crumble | Powder | Meal | Sink | 1 to 2.5/0.5 to 5 | 15 to 10 | |

| #1 Crumble | 0.8 mm | Crumbles | Sink | 2.5 to 4/5 to 22 | 10.0 to 5.0 | |

| Stage 1 | 1.0 mm | Extruded | Float | 4.0 to 6.0/ 22 to 75 | 5.0 to 3.0 | |

| Stage 2 | 2.0 mm | Extruded | Float | 6.0 to 8.0/75 to 150 | 3.0 to 1.5 | |

| Stage 3 | 3.0 mm | Extruded | Float | 8.0 to 13.0/150 to market | 3.0 to 1.5 | |

| Stage 4 | 4.0 mm | Extruded | Float | >13/market | 1 |

Table 5. (Continued)

| Species | Product type | Product size | Form | Action | Fish size (inches) | Pounds feed per pound of fish |

|---|---|---|---|---|---|---|

| Channel Catfish | No. 1 starter | 0.8 mm | Crumbles | Sink | 1.0 to 2.0 | satiation feeding—feed until fish stop with in 20 to 25 minutes for all types |

| No. 2 starter | 1.2 mm | Crumbles | Sink | 2.0 to 4.0 | ||

| Fingerling | 2.0 mm | Extruded | Float | 5.0 to 6.0 | ||

| Grower | 3.0 mm | Extruded | Float | 7.0 to 8.0 | ||

| Grower | 4.0 mm | Extruded | Float | 9.0 to 10.0 | ||

| Grower | 5.0 mm | Extruded | Float | 10.0 to 12.0 | ||

| Grower | 5.0 mm | Extruded | Float | >12.0 |

Table 6. RGJ Aquaponics routine management practices.

| Daily Management: | Weekly Management: | Monthly Management: | |

|---|---|---|---|

| Make sure both water and filtration pumps are working and clear of any debris. | Perform water quality tests for pH, ammonia, nitrite (NO2-) and nitrate(NO3-) before feeding the fish. | Stock additional new fish, if needed, to the original population number in the tank due to harvesting or water quality issues. | |

| Make sure the water is flowing. | Monitor and adjust pH to the optimum level. | Clean the biofilter, clarifier and all other filters. | |

| Maintain water level; replace any water lost through evaporation. | Inspect plants looking for deficiencies. Add chelated iron (no more than 0.005 parts per million at a time for small fish), beneficial bacteria, calcium, magnesium or potassium as necessary. | Clear the bottom of the tank using fishnets. | |

| Watch for leaks in the system. | Clear fish waste from the bottom of fish tanks and in the biofilter. | Weigh a specimen of fish for growth rate analysis. | |

| Monitor water temperature. | Plant and harvest vegetables, as required. | ||

| Fish should be fed tow to three times daily; remove floating uneaten pellets. | Remove fish through harvest or culling, if needed. Water quality will indicate a need for removal. | ||

| Monitor behavior and appearance of fish. | Clear root obstructions from pipes or drains in beds. | ||

| Scout crops for pests. See fact sheet HLA-6710. | |||

| Clear dead fish/plant materials from the system. | |||

| Remove solids from the clarifier and rinse filters. |

Table 7. RGJ Aquaponics Electricity and system problems

| Situation | Reason | Problem | Solution | |

|---|---|---|---|---|

| 1.) Mechanical problems Pump isn’t working; electricity is off |

No power. | Dissolved oxygen will decrease. |

|

|

| Pump not working while power is on. | Pump is broken, faulty, clogged. | Dissolved oxygen will decrease. |

|

|

| Pool of water beneath system or water is too low. | Leaks or cracks. | All water will drain out, stressing and killing the fish and plants. |

|

|

| Water in the system and sides of tanks look green. | Algal bloom. | Dissolved oxygen will decrease, and nutrients will not be available to crops. |

|

| Situation | Reason | Problem | Solution | |

|---|---|---|---|---|

| 2.) Water quality problems Ammonia or Nitrite > 1 ppm |

|

Dissolved oxygen will decrease. |

|

|

| Nitrate levels > 120 ppm for more than one week. |

High feed rate ratio. | Dissolved oxygen will decrease. |

|

|

| Carbonate hardness (KH) is 0 ppm. |

All the carbonate is used by acid created in the aquaponics system. | All water will drain out, stressing and killing the fish and plants. |

|

|

| Water temperature is too high (>91 F) or too low (<59 F ). | Climate. | Dissolved oxygen will decrease, and nutrients will not be available to crops. |

|