Principles of Small-Scale Aquaponics

Aquaponics is the integration of a hydroponic plant production system with a recirculating aquaculture system. A hydroponic system (closed or open) involves growing plants without soil (i.e., in a nutrient solution or in some type of artificial media). A recirculating aquaculture system (RAS) is most often a closed fish production system in which water quality is maintained through a filter system. Independently, hydroponic systems and RAS can be productive and commercially viable. However, because of concerns about the sustainability of modern aquaculture, growers and consumers are interested in aquaponics as a potentially more sustainable system.

The origin of aquaponics is uncertain, but it has existed in one form or another since about 1,000 A.D. in Mayan, Aztec and Chinese cultures. The term aquaponics was coined in the 1970s. Modern aquaponic systems have existed both in growers’ trials and in institutional research since that time, and much information has been produced about both small and large systems. This publication provides an overview of the principles and practices of a small-scale aquaponic system. For more detailed information, please see SRAC Publication No. 454, Recirculating Aquaculture Tank Production Systems: Aquaponics—Integrating Fish and Plant Culture; SRAC Publication No. 5006, Economics of Aquaponics; and the Suggested Readings section.

A small-scale system may be a “home” or “hobby” unit, or it could be a scaled-up version that produces more than required by a single family.

In a simple aquaponic system, nutrient-rich effluent from the fish tank flows through filters (for solids removal and biofiltration), then into the plant production unit before returning to the fish tank. Solid fish wastes can be removed (depending on system design). Ammonia/ammonium in the water is converted to nitrite and then to nitrate by microbes living in the system. Microbes play a key role in the nitrification process in aqueous solutions. Plants remove nitrogenous waste from the water so it can be returned to the fish tank, and the nitrate and other minerals in turn feed the plants. Plants, fish, and microbes thrive in a balanced symbiotic relationship. All three organisms must be managed for a system to be successful.

System Design and Components

Greenhouse/Lighting

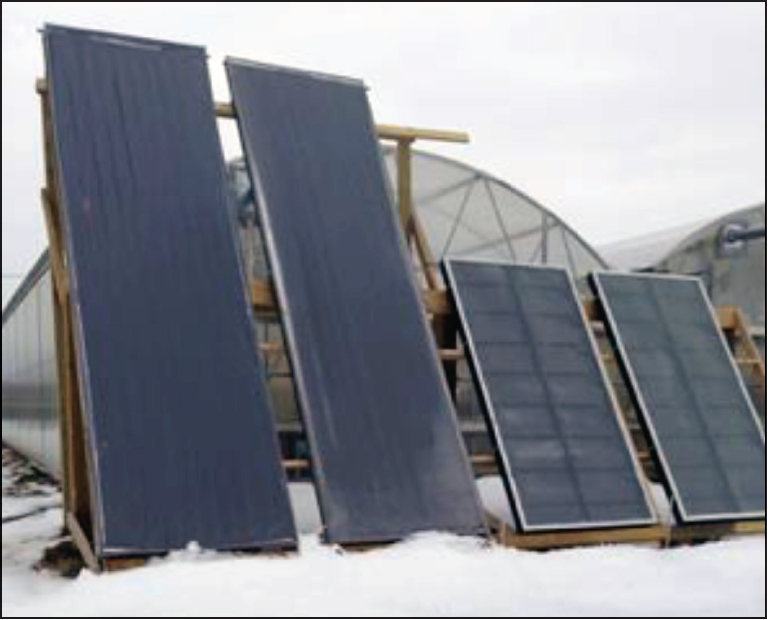

In temperate zones, year-round production requires a greenhouse or lighted production area (Figure 1). Small greenhouses work well and are readily available. Greenhouse prices can range from $5 to $15 per square foot, depending on automation, glazing and structural material. Glazing can be polyethylene, polycarbonate, acrylic, fiberglass or glass. Polyethylene sheeting is the lowest cost option for most small growers. The energy cost for heating (propane, natural gas, electricity, etc.) can become a large expense and may make small-scale production in temperate regions cost prohibitive. Growers should investigate alternative methods of heating the greenhouse or system water, such as geothermal water, in-pond heat exchangers, solar (Figure 2) and wood heat.

Figure 1. Hobby-scale greenhouse.

Figure 2. Thermal solar panels.

An alternative to a greenhouse is a well-insulated space with good lighting. While not as good as natural sunlight, improved lighting technology has provided choices such as compact fluorescence, high-pressure sodium, metal halide, high-intensity discharge lamps, LED (light-emitting diode) and induction. High-intensity discharge lamps and fluorescent are the most cost-effective options and provide better photosynthetically active radiation (PAR) values for plant growth. LEDs are not inexpensive to purchase and have yet to be proven viable as the sole source of light for adequate plant growth.

Fish Unit

The first management component of the small-scale aquaponic system is the fish tank from which the nutrients for plant growth will be obtained. Generally, the fish tank volume is less than 500 gallons; the average is 300 gallons. One pound of fish per 10 gallons of water is a common final density at the time of harvest for new or inexperienced growers, but the density can vary greatly depending on grower experience, system design and whether or not solids are removed.

Although any shape tank is acceptable, since small-scale units may not be intensively operated, the best design is a circular tank with a central drain for easy self-cleaning of settled solids. Tanks can be constructed from UV-protected plastic, fiberglass, metal with liner, wood with liner, intermediate bulk container (IBCs) or barrels. Only used bulk containers that held food-grade material and have been thoroughly washed should be used. Ensure fish tanks are constructed and placed to protect small children and pets from accidental drowning.

Fish tanks should be covered to prevent fish from jumping out, keep out predatory birds and reduce algal growth. Shade cloth, foam board and netting can be used to cover tanks. Covers should not hinder the fishes’ access to floating feed.

Plant Unit

The plant growth units most often used are media beds, nutrient film technique (NFT) and deep water culture (DWC, sometimes referred to as raft culture).

Media beds are easy and inexpensive to set up and can be a good choice for small-scale systems. A media bed system (Figure 3) is some type of container that holds media for plants to grow in. The media supports the roots of the plants and can act as a biofilter and solids filter. Types of containers used most often are 4-foot by 8-foot lined wooden beds, intermediate bulk containers (IBCs) and barrels. Beds either go through cycles of being flooded and drained or water flows through them continuously. Water should rise to only 1 inch from the top of the media to prevent excess algal growth, which encourages pests. Pumps, timers and/or a bell siphon can move water from the fish tank to the plant unit and then back to the fish tank. Media used in beds includes river rock (which has tested free of limestone), expanded clay pebbles, plastic biomedia, vermiculite and perlite, although perlite is less used now because of its undesirable characteristics. Collected rocks should be evaluated to make sure they do not contain limestone, which will increase alkalinity and cause an undesirably high pH.

Figure 3. Media bed filled with vermiculite.

While the ability of the media to act as a filter adds to the simplicity of system design, it necessitates the need to manage and clean the media periodically. Otherwise, it will become clogged and create anaerobic zones. In some designs, worms (the same types used in vermicomposting systems) are added to the media to help digest solid material trapped by the media. Usually a small fraction of the bed retains water all the time. Media depth can vary with the type of plant being grown and the depth of its root zone, but most media beds are 6 to 12 inches deep. Started seedlings are transplanted into the media, as direct seeding does not work well in aquaponic systems.

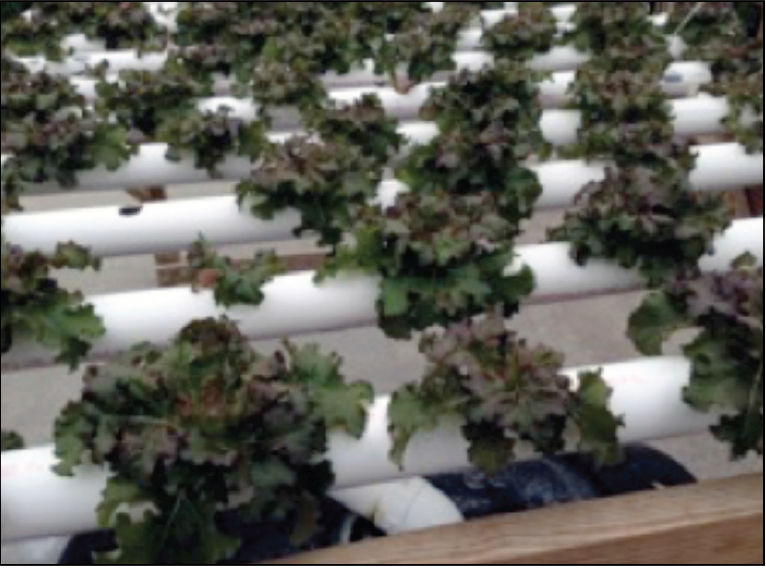

Nutrient film technique (Figure 4) is a system that uses horizontal pipes or gutters for growing the plants. Specially made channels or PVC pipes (Figure 5) are used to support the plants and convey the fish tank effluent past the roots of the plants and back to the fish tank. Channels should be sloped approximately ½ inch per 10 feet to allow for easy drainage through the channel. This system also allows for vertical arrangement of the channel to maximize yield per square foot (Figure 6). Channels can vary in length and are generally less than 12 feet long. Spacing between channels and hole spacing in channels depends on the size of the plants being grown. Channels for lettuce are usually spaced 8 inches apart with 8 inches between holes in the channel.

Figure 4. Commercially manufactured NFT production channels.

Figure 5. NFT production channels made from PVC pipe.

Figure 6. NFT channels arranged vertically to maximize production.

Seedlings are placed in holes in the channel and remain there through harvest. Seeds are started in media cubes or pellets, or in net pots filled with clay pebbles, soilless media or rockwool. Seedlings are planted into the holes in the pipes, where they sit directly on the bottom or slightly raised up, due to pipe design or placement. Hole size depends on whether cubes or net pots are used.

Deep water culture (Figure 7) or floating bed/raft bed is a system that grows plants on a floating raft on water from the aquaculture system. Like the NFT system, fish tank effluent moves through filters, then to the float bed before returning to the fish tank. Also like the NFT system, DWC is more management intensive and costly for the beginning grower than the media bed system.

Figure 7. Deep-water culture.

Float beds can be built on the ground of dimensional lumber and lined with plastic. They also can be built of concrete, cinder blocks or fiberglass. In the case of air lift and gravity flow systems, the beds may be elevated so the water can flow unaided by pumps through filter media or into a central sump. Polyethylene or fiberglass containers, such as IBCs and barrels, can be used as trays or troughs. The length and width of the beds are based on the dimensions of the float trays to make sure the bed is covered to prevent algal growth. Generally, a depth of 10 to 12 inches is adequate for plant root development, but beds as shallow as 6 inches will work in many instances. Rafts can be purchased specifically for certain plants, or they can be made by making planting holes in closed-cell polystyrene insulation board (regular polystyrene will break apart). Hole spacing depends on the plant, but an 8-inch spacing will work for most leafy greens. Like NFT systems, seeds are started in media cubes or net pots filled with media.

To ensure proper aeration for the roots, air stones should be placed in the float bed—one for every 10 square feet. Since nitrifying microbes colonize the rafts, the rafts should be washed with water to remove algae and debris, but should not be allowed to dry out and kill those microbes. The height of beds should ensure easy access from all sides.

Solids Removal

Fish waste and uneaten food pose a problem for an aquaponic system because this material can quickly lead to toxic conditions for fish and ultimately clog systems and disrupt water flow. Much of this waste can be removed with filters (clarifiers) such as bead filters, screens, drum filters, vortex filters and solids settling tanks/clarifiers. Screen filters and settling tanks tend to be the simplest for small-scale systems.

The screen filter or settling tank is placed directly after the fish tank and before the biofilter. A solids settling tank would consist of a dedicated tank that has an inlet, outlet and some type of baffle system, screen or waterflow diffusing media. As water enters the tank, it slows down and allows solid material to settle to the bottom of the tank where it can be removed by a siphon or bottom drain. Meanwhile, the clear water passes on to the biofilter. Figure 8 shows a swirl or vortex separator, where water enters the tank at an angle to create a swirl effect on a conical bottom tank and pushes solids down so that clear water leaves the tank near the top. The design of a solids settling tank depends on water flow rate and retention time.

Figure 8. Swirl separator.

Biofiltration

Biofiltration is the chemical process by which microbes convert ammonia to nitrite and then to nitrate. This process, called nitrification, can occur on every surface the system water contacts. In many systems there is a dedicated area for this to happen, a biofilter tank. Like the clarifier, the biofilter tank should contain 15 to 20 percent of the volume of the fish tank. The biofilter tank (Figure 9) needs two things: media that has a high surface area for nitrifying bacteria to colonize, and sufficient aeration for the bacteria. Biofilter media can be bought commercially and will have a high-surface-area-to-volume ratio. Growers also can use other material such as plastic bottle caps, lava rock, or packaging material. The media should be inert, easy to clean in de-chlorinated water and lightweight.

Since the microbes that colonize the media need to operate in an oxygenated environment, aeration is important. Dissolved oxygen levels in the biofilter tank should be maintained at more than 5 ppm. Stirring the media occasionally will maintain its efficiency by ensuring that water flow does not bypass active surface areas. See SRAC Publication Nos. 451, 452 and 4502 for more information on biofiltration in tank systems.

Figure 9. Biofilter tank.

Movement of Water

Water movement involves the device to move the water, the piping system and gravity. A single air-lift or oil-free submersible water pump should be located at the lowest point, which is the bottom of the sump. When a pool style centrifugal pump is used, the pump should be located at the sump outlet. Gravity is used to lower the cost of water movement throughout the system. Whenever possible, the grower should use oversized pipes to avoid any clogging that can occur.

Management

Daily and overall management of the aquaponic system is critical for success. Fish management involves species selection, fry/fingerling procurement, scheduling, stocking rates and feeding rates. Management areas for plants include seed selection, propagation, water quality, planting, harvest, post-harvest, scheduling and pest management.

Fish Management

The types of fish produced depend on the intended use, availability, ease of maintenance and water temperature. Fish may be produced for consumption, for ornamental uses, and for bait. However, the purpose of aquaponic systems is food production. Without a fish species to be harvested for food or sold to offset production costs, it is more economically feasible to operate a pure hydroponic system for the plants. Many species of foodfish can be grown in aquaponic systems in the southern region, including hybrid striped bass, channel catfish, largemouth bass, bluegill and hybrid sunfish. This publication will focus on tilapia (Figure 10), as they do well in aquaponic systems and are arguably the most frequently used species in commercial aquaponic operations.

Figure 10. Tilapia production tank with netting.

Tilapia tolerate a broad range of water quality and environmental conditions, reproduce volitionally and frequently at acceptable water temperatures, and are resistant to stress-related disease. Potential drawbacks of tilapia are their availability, local/state regulations, and their limited growth at water temperatures below 68 F (they are tropical fish). Depending on the species (which may also be mandated by local/state regulations), tilapia may start to die at temperatures of 55 F to 45 F and below. Most tilapia species suitable for food culture grow best at about 85 F.

At least one tilapia species is readily available in most of the southern region. However, in a few southern areas, and in other regions, tilapia may not be widely available. In these instances fish may have to be air-shipped or picked up by the producer from distant reliable suppliers.

Using mono-sex male tilapia may increase production because males grow larger and more uniformly than females. If a mixed-sex populations is used, the producer eventually will have to manage the offspring. Offspring should be removed from the system and can be transferred to aerated tanks until used to replace harvested fish in the aquaponic system. Check with the local Cooperative Extension office or state fish regulatory agency to be sure that all permits and regulations on fish production are understood. See SRAC Publication Nos. 280, 281, 282 and 283 for more information on the biology and culture of tilapia.

Fish consume pelleted food and release nutrients that can be used by plants. A simple system can be stocked with multiple size tilapia in a highly aerated tank. When larger fish are harvested, replacements are stocked. A single-sized pellet can be consumed by both the smaller and larger fish. Floating food pellets that contain 28 to 36 percent crude protein should be offered to tilapia. Certain species such as koi may require as little as 22 percent protein, while other species such as hybrid striped bass may require 40 percent or more protein. Pellets should be small enough to be consumed by fish more than 2 inches long. For smaller fish, pellets can be mashed into a powder, but higher protein concentrations are often required. Feed should be stored in a cool, dry environment, preferably in a sealed container to keep out insects or rodents.

The University of Virgin Islands recommends feeding 2 to 4 ounces of fish food per day to support 10 square feet of plants in raft aquaponics (56 to 100g feed per square meter per day). If using the nutrient film technique (NFT) production system, the feeding rate would depend on the plant species and system design and area, but would generally be only 25 to 75 percent of the raft feeding rate.

Although keeping the water warm in winter may be costly and plants may not be growing during this period, tropical fish species must have warm water, and temperate fish can be harmed by toxic nitrogen concentrations that can occur if fish are fed without actively growing plants. Temperatures necessary for tropical fish can be artificially maintained with heaters, but in-tank units should be protected to prevent the fish from damaging them.

Daily maintenance includes observation, feeding, draining/siphoning of settleable solids and recording data such as pH (the most critical), dissolved oxygen, temperature, feeding activity and quantity fed. Fish should not be handled unless absolutely required.

Settleable solids removed from the fish tank can be applied to gardens in some states, but not all. Be sure to check with local and state regulatory agencies for regulations pertaining to wastewater discharge and manure application to edible raw crops.

Plant Management

Crop selection is very important, as the grower wants to match fish and plants that have similar requirements for pH and temperature. The quality and quantity of food provided to the fish should be matched with the nutrient needs of the crops.

Many plants can grow successfully in an aquaponic system. More than 100 types have been grown in the last 20 years. Culinary herbs and leafy greens perform well and are a great choice for beginning growers. Lettuce, basil, swiss chard, bak choi and watercress are examples. These crops have lower nutrient requirements than many others. Fruiting crops such as peppers, cucumbers, and tomatoes require additional nutrients and possibly at different periods of their growth. One advantage of leafy greens is that they can be grown with static nutrient levels throughout the life of the crop, which is ideal for small-scale aquaponics.

The production system design plays a role in plant selection. Low-growing plants work well in all systems, while trellised crops such as tomatoes, melons and peppers work best grown on the ground in media-based systems. Dutch bucket production (Figure 11), essentially a media bed system, can work well for trellised crops.

Figure 11. Dutch bucket tomato production.

Plants require 16 essential nutrients. An aquaponic system provides these from the air, the water and the breakdown products of fish. Nutrients are a function of the food fed to the fish. A general guideline for feeding is 2 to 4 ounces of fish food per 10 square feet of plant production area. (For more information on nutrient rates and ratios, see SRAC Publication No. 454, Recirculating Aquaculture Tank Production Systems: Aquaponics— Integrating Fish and Plant Culture.) Having too much of a certain nutrient (toxicity) is rare in an aquaponic system. However, even in a balanced system some nutrients such as iron, potassium, and calcium may be deficient and will have to be added to the system. They are generally added as chelated iron, potassium hydroxide and calcium hydroxide. The first is slowly released over time, and the latter two add minerals and raise pH. Symptoms of deficiencies include chlorosis, tip burn, blossom end rot and yellow leaves. The level of pH can affect the ability of a plant to take up certain nutrients. Most plants adapted for an aquaponic system have an optimum pH of 6.2 to 6.5; at levels below and above that, certain nutrients become less available to the plant.

Growers should keep a constant supply of seeds, especially those with short maturity time. This will eliminate downtime between planting and harvest. Seeds should be kept in dry, cool storage to prevent poor germination. Most leafy greens will be started from seed about two weeks before planting into the system, but tomatoes and peppers require a longer starting time. Some growers build a subirrigation propagation area or table where media can be planted and watered. Similar to a float bed, this could be a lined wood table or other container that can be flooded and drained.

Transplanting seedlings into the system can be done in a staggered manner to allow for a weekly or timed harvest, which will maintain a more constant supply of nutrients and keep the water filtered.

Plants and fruit should be harvested when mature and not left in the system for too long. Lettuce can turn bitter as it overmatures, and fruit can develop fungus problems. Follow good agricultural practices such as washing hands before harvest. Make sure to remove all plant material from the area, such as roots and leaves stuck in the media bed.

Whether in an enclosed structure or outside, insect pests can be a problem. Typical pests found in aquaponics are aphids, whiteflies, spider mites, thrips, and caterpillars. Growers should use an integrated pest management approach (IPM) to controlling pests. This means combining mechanical, physical, biological, cultural, and chemical methods to keep pest populations in check. However, in aquaponic systems, most chemical control methods should not be used, as they can be potentially harmful to fish. The key to an IPM approach is to know about potential insect pests and their life cycles. Beneficial insects can be an effective tool to control insects, especially in the greenhouse environment. Monitoring pest populations with yellow and blue sticky cards and using yellow sticky tape (Figure 12) is important. Be sure to scout under leaves and in blooms to detect insect problems.

Figure 12. Use of yellow sticky tape to trap insects in tomato production.

Water Quality

Water quality is critical to a successful system. Certain parameters such as dissolved oxygen, temperature, pH, and total nitrogen should be tested weekly. For some parameters, a compromise should be reached for fish, plants, and microbes.

Small-scale aquaponic systems lose 1 to 5 percent of system water each day through evaporation, transpiration, plant assimilation, and splashing. Good quality water should be used to replace lost water. Sources can be municipal, ground, or rainwater, but should be tested for suitability. For example, municipal water is often treated with chlorine or chloramines that could be harmful to organisms in the system. Making this water safe might involve letting it sit or “off gas” or, in the case of chloramines, using a dechlorinating treatment such as sodium thiosulfate. An inexpensive way to treat municipal water is to use 500 milligrams ascorbic acid (Vitamin C) per 50 gallons of reservoir water to rapidly remove chloramines.

Temperature should be a consideration when selecting fish species and plant types. Crops with similar temperature requirements should be cultured together. For example, warm water fish like tilapia and a warm season crop like basil should be grown together. DWC systems hold onto heat better than NFT systems, as the pipes tend to give back heat to the environment. An optimum range for warm water fish and warm growing season plants is 72 F to 90 F, while winter crops and cool water species do well in temperatures from 50 F to 68 F.

pH is the relative quantity of H+ ions in solution and is a measure of the acidity and basicity of a solution. A pH of 7 indicates a neutral level, with <7 being acidic and >7 being basic. While most fish can tolerate a broad range of pH levels (5.5 to 10.0 acceptable, 6.5 to 9.0 desirable, see SRAC Publication No. 4606, Interpretation of Water Analysis Reports for Fish Culture), plants can show nutrient deficiencies and microbes become less effective at narrower pH ranges. For aquaponics, a pH range of 6.5 to 7.5 should be maintained. Plants absorb some nutrients better at slightly acidic pH ranges, while microbes nitrify better at slightly to moderately alkaline pH ranges. Therefore, a moderate pH range of 6.8 to 7.2 is often recommended, but may be too restrictive for all situations and systems. One of several processes in the system that affects pH is nitrification. As microbes convert ammonia to nitrate H ions are released, thus lowering pH. In many systems, this makes it necessary to add a base (potassium hydroxide and calcium hydroxide).

Dissolved oxygen levels above 5 ppm are ideal for fish, plants, and microbes in the system. Oxygen is dissolved from the air into water, but it is necessary to provide supplemental aeration by means of air diffusers in the water. Growers should remember that as temperature increases, the solubility of oxygen decreases.

Conclusion

A small-scale aquaponic system cannot provide all the food a family requires, but it can provide a healthy source of food, promote family independence, provide a fun hobby for adults and children and possibly provide a small income through the sale of fish and produce. Operating a small-scale aquaponic system can be rewarding and educational for a family producer.

Suggested Readings

Ako, H. and A. Baker. 2009. Small-Scale Lettuce Production with Hydroponics or Aquaponics. Sustainable Aquaculture SA-2. College of Tropical Agriculture and Human Resources. University of Hawaii at Manoa.

Diver, S. and L. Rinehart. 2010. Aquaponics—Integration of Hydroponics with Aquaculture. ATTRA IP163. National Center of Appropriate Technology – ATTRA, Butte, MT.

Losordo, T., M.P. Masser, and J. Rakocy. 1998. Recirculating Aquaculture Tank Production Systems: An Overview of Critical Considerations. SRAC Publication No. 451, Southern Regional Aquaculture Center, Stoneville, MS.

Menon, R., G. Sahana, V. Shruthi, and R. Suganya. 2013. Small Scale Aquaponic System. International Journal of Agricultural and Food Science Technology. 4(9): 941-946.

Rakocy, J., M. Masser, and T. Losordo. 2006. Recirculating Aquaculture Tank Production Systems: Aquaponics— Integrating Plants and Fish Culture. SRAC Publication No. 454. Southern Regional Aquaculture Center, Stoneville MS.

Somerville, C., M. Cohen, E. Pantanella, A. Stankus, and A. Lovatelli. 2014. Small-Scale Aquaponic Food Production. FAO Fisheries and Aquaculture Technical Paper No. 589. Food and Agriculture Organization of the United Nations, Rome, Italy.

Christopher Mullins

Cooperative Extension, Virginia State University

Brian Nerrie

Cooperative Extension, Virginia State University

Todd D. Sink

Texas A&M AgriLife Extension Service

Extension Aquaculture Specialist