Home Slaughtering and Processing of Beef

- Jump To:

- Preparing for Slaughter

- Equipment Needed for Slaughter

- How to Stun Animal

- How to Bleed Animal

- How to Skin Animal

- Opening the Carcass

- Splitting the Carcass

- Cutting Beef

- Forequarter

- Hindquarter

- Packaging Beef for the Home Freezer

- How to Wrap

- Labeling

- Freezer Storage Time

- Thawing Frozen Meat

- Cooking Frozen Meat

A beef animal selected for slaughter should be healthy and in thrifty condition. Keep the animal off feed 24 hours before slaughter, but provide free access to water.

Do not run or excite the animal prior to slaughter because this may cause poor bleeding and give the carcass a bloody appearance.

The weather, especially expected temperatures the few days following slaughter, is extremely important. Night temperatures should be 32°F or lower for the carcass to chill properly without refrigeration.

The meat will spoil if improperly chilled and stored during warm weather. Also, during extremely cold weather, the meat should be protected from freezing by covering it with a clean cover.

Preparing for Slaughter

Slaughter should be done in a dry, clean, dust-free area. A well-drained grassy area is recommended.

Take precautions during slaughter, chilling, and processing to keep the carcass and cuts clean and free from contamination. Use clean equipment, keep hands clean, wear clean clothing, and keep work and storage areas clean.

The carcass can be chilled without refrigeration by hanging it in a dry, clean building. Freedom from odors or contamination is essential.

Most meat spoilage and off-odors and flavors can be attributed to one or more of the following causes:

- Improper chilling of the carcass. The internal temperature of the round and other thick parts should be lowered to 40-45°F within 24 hours after slaughter.

- Adsorption of off-odors. When the carcass is chilled and aged in an area with any odor (manure, gasoline, paint, musty odor, etc) the carcass will absorb it.

- Poor sanitation during slaughter, chilling, and processing. This contamination with microorganisms causes off-odors, off-flavors, and spoilage.

- Improper freezing and storage of frozen meat. Packaged meat should be quick-frozen and stored at 0° to 5°F. Home freezers are for storage of products already frozen, not for quick-freezing large quantities of meat. Small quantities, preferably less than 25 pounds, can be satisfactorily frozen at home by placing meat in the freezer with at least one inch of space between each package.

Equipment Needed for Slaughter

The minimum required items of equipment for home slaughtering are as follows.

- Stunning device such as 22 caliber rifle.

- Block and tackle, chain hoist, or tractor equipped with hydraulic lift.

- Beef spreader (singletree equipped with hooks on both ends and a ring in the center will do).

- 24- or 28-inch meat saw.

- 6-inch sharp skinning knife, 6-inch boning knife, and 8-inch butcher knife.

- 10- or 12-inch steel bucket to hold water for washing hands.

- Ample clean water and clean hand towels.

How to Stun Animal

Kill the animal as humanely as possible. If a rifle is used, exercise recommendations for safe use of firearms. The proper place for the bullet to strike is at the intersection of two imaginary lines extending from the right horn or anima, edge of poll to the left eye and from the left horn or edge of poll to the right eye (Figure 1). A sharp blow at this point with a sledge hammer will also stun the animal.

Figure 1. Proper point for stunning animal.

How to Bleed Animal

As soon as the animal is down, bleed it without delay. Stand behind the animal as in Figure 2 and with the sharp skinning knife make an incision through the hide in the middle of the dewlap immediately in front of the breastbone.

Hold the knife so the point is directed toward the rear of the animal, insert the knife under the breastbone toward the rump of the animal and cut toward the backbone. This will cut the arteries that cross just beneath the point of the breastbone.

Be careful not to stick too deep into the chest cavity. Cut straight with the backbone. Pump the foreleg back and forth a few times to help bleeding.

Figure 2. Bleed the animals without delay following stunning.

How to Skin Animal

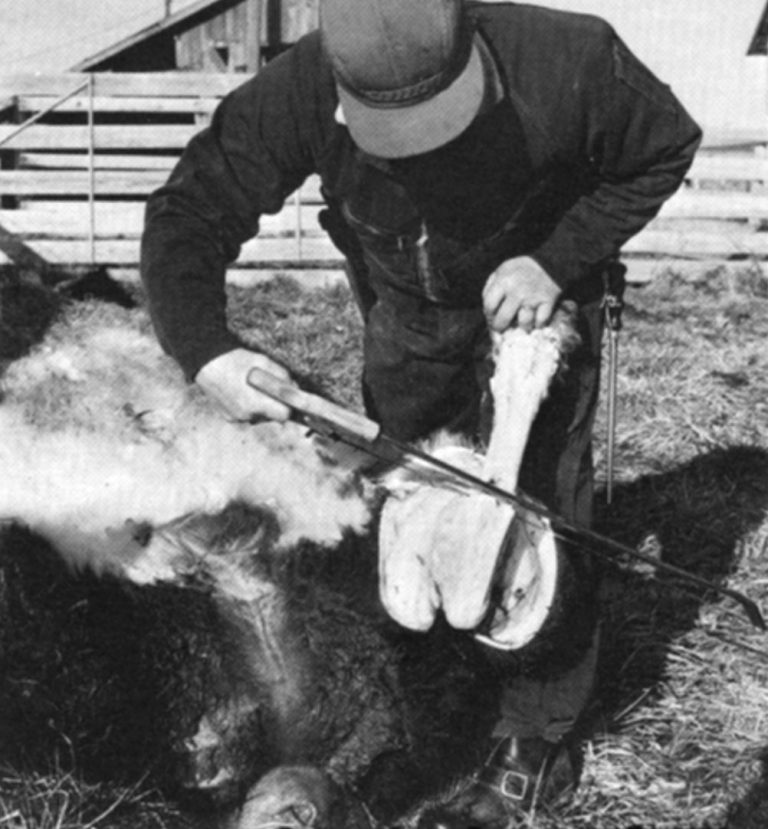

Turn the animal on its back and place a short prop (square post) on either side to hold it there. Remove the forefeet and shanks at the knee as in Figure 3 by locating and cutting through the flat joint with a knife. Skin out the hind legs and remove the hind feet and shanks by sawing as in Figure 4.

Next, split the hide from the opening in front of the brisket down the midline of the belly to the bung. Hold the skinning knife at a slight angle as in Figure 5.

Then split the hide at the rear of each hind leg beginning where the shank was removed, moving to the udder or scrotum. Do not skin the outside of the hind legs nor front legs until the carcass is being hoisted. The intact hide will keep the shanks clean during hoisting.

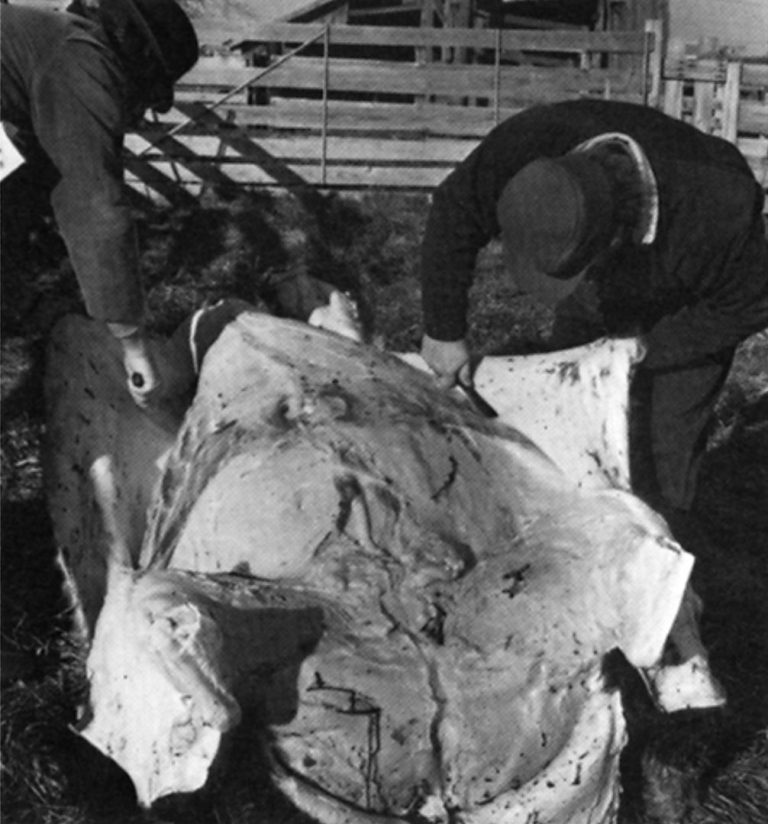

The next part of skinning is known as “siding.” Begin the siding by sliding the knife under the skin that has been cut over the belly. Grasp the loosened hide with hand (hair side is easiest to hold) and pull it up and outward. Place the knife firmly against the hide with the cutting edge turned slightly toward the hide as in Figure 6.

Use long, smooth strokes of the knife, to remove the hide down over the sides. This is one of the most difficult tasks in skinning.

Figure 3. To remove the forefeet and shanks, cut through the flat joint.

Figure 4. Saw off the hind feet and shanks after skinning out the hind legs.

Figure 5. Split the hide by holding the skinning knife at a near flat angle.

Figure 6. Use long, smooth strokes with the knife when skinning. Keep the knife firmly against the hide with the cutting edge slightly toward the hide.

Opening the Carcass

After siding is done, cut through the center of the brisket with a knife and saw through the breastbone as in Figure 7. Insert the handle of the knife in the abdominal cavity with the blade leaning backward to open the belly cavity as in Figure 8. In case of a male, remove the penis before opening the carcass.

The inside of each round muscle over the pelvis is covered with a thick white membrane. Follow this membrane and avoid cutting into the muscle. The knife can be forced between the soft cartilage that joins the pelvic bone. See Figure 9. In older animals, the pelvis must be sawed.

The carcass is now ready for hoisting. Insert the hooks of a beef spreader or singletree in the tendons of the hind legs as in Figure 10. After the carcass is partially hoisted, complete skinning the rounds and the back of the carcass.

Remove the bung by cutting around it on the two sides and back and pulling through the opening of the pelvic cavity. Continue pulling the bung and intestines and cutting the ligaments that attach the intestines to the back as in Figure 11.

Pull down on the paunch to tear it loose from the carcass, cut the esophagus where it goes through the diaphragm, and allow the intestines and paunch to drop into a container or on the ground. The liver should still be attached to the carcass and can next be removed. Remove the gall bladder from the liver.

Continue hoisting the carcass until the head clears the ground as in Figure 12. Remove the heart and lungs by first cutting out the diaphragm, the white connective tissue that separates the abdominal and thoracic cavities. Grasp the heart and lungs, pull forward and downward, and cut the large blood vessel attached to the backbone. Remove the heart, lungs, and esophagus as one unit.

Complete skinning the carcass and remove the head. The head is removed by cutting across the neck above the poll and through the atlas joint as illustrated in Figure 13.

Carefully examine all the internal organs and the dressed carcass for any abnormalities or conditions (such as abscesses or inflammation) that might affect the wholesomeness of the meat.

Figure 9. To separate the rounds, cut along the thick white membrane at the pelvis.

Figure 10. Carcass ready for hoisting with singletree hooked in the tendons of the hind legs.

Figure 11. Removing the bung by cutting along the two sides and back and pulling it through the pelvic opening.

Figure 12. Carcass hoisted with head clearing the ground, ready to complete skinning and to remove the head.

Figure 13. Head is removed by cutting across the neck above the poll and through the atlas joint at the base of the skull.

Splitting the Carcass

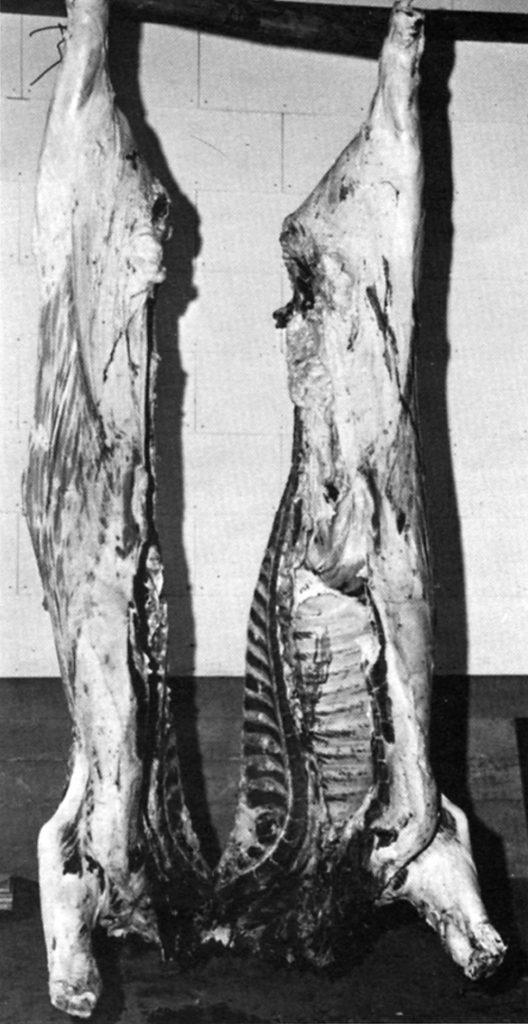

The carcass should be split into two sides. Start the splitting by first sawing through the sacral vertebrae from the inside as in Figure 14. As soon as the cut is made through the pelvic area, sawing can be done easier from the back as in Figure 15. Make the split down the center of the backbone to the neck. Leave the neck attached as in Figure 16 to balance the sides on the singletree.

Trim any soiled, bruised, or bloody pieces of meat. Wash the carcass with cold water to remove any remaining blood and dirt. Pump the forelegs up and down a few times to aid in draining blood from the forequarters.

To improve the appearance of the carcass, shroud it tightly with wet, clean white muslin to smooth the exterior fat during chilling. Use skewers or ties to tighten the shroud.

Figure 14. Begin splitting the carcass by first sawing through the sacral vertebrae. Also see Figure 15.

Figure 15. When the pelvic area has been split, sawing is more easily done from the backside of the carcass.

Figure 16. Split the carcass to the neck, but leave the area attached to balance the two sides on the singletree.

Cutting Beef

Beef should be aged a few days before cutting. The amount of aging will depend on the amount of fat covering, desired flavor, and temperature.

Carcasses that have only a thin fat covering should be aged three to five days; those with more fat, five to seven days. Very little tenderization occurs after five to seven days. Longer aging may result in off-flavors and odors due to microbial growth.

If the temperature of the carcass rises above 40°F, the time required for aging is reduced. Also, chances of spoilage are increased.

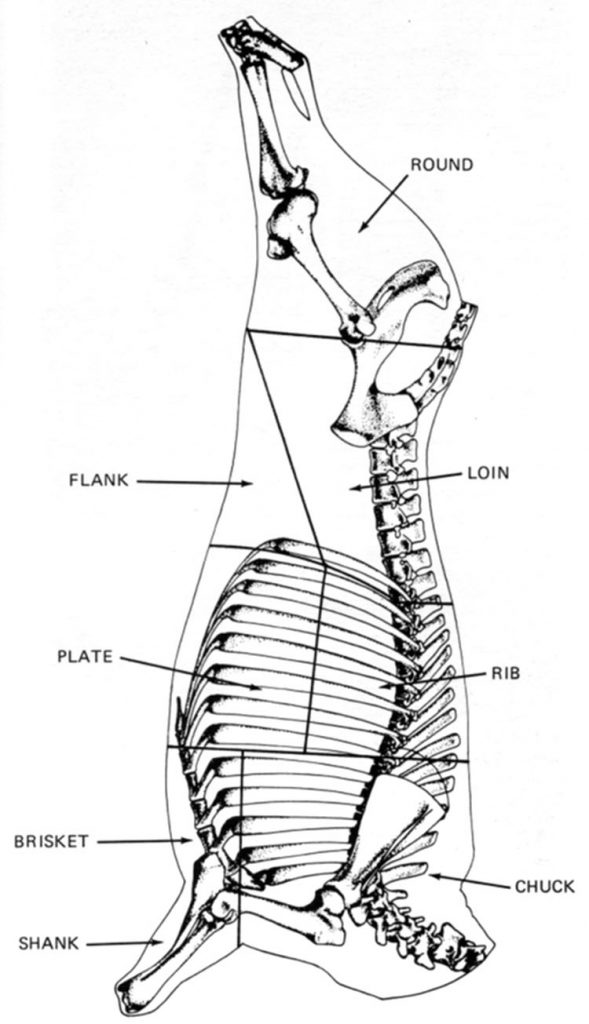

The sides of the carcass are quartered by cutting between the 12th and 13th rib (Figure 17). Following is a common procedure for cutting the quarters into wholesale cuts.

Figure 17. Wholesale cuts of a beef side in reference to the skeleton.

Forequarter

Remove the rib and plate from the chuck and brisket by cutting between the fifth and sixth rib. Cut perpendicular to the top line of the carcass. Separate the rib cut from the plate at a point 11/2 inches below the rib eye muscle on the end where the side was quartered, and cut parallel to the back.

The rib may be cut into rib steaks by cutting the desired thickness. The larger part may be made into a roast, or the entire cut boned into boneless rib steaks or roasts. The rib cuts are rather tender and may be broiled or dry roasted.

The plate may be processed by cutting two or three rows (11/2-2 inches) of short ribs and the remaining boned for ground beef.

To remove the brisket and foreshank from the chuck, first locate the arm bone joint near the surface of the carcass. Cut about 1 inch above the top of the joint, perpendicular to the cut made when the quarter was first divided (Figure 17).

The brisket may be separated from the shank by cutting through the natural seam that joins them. The shank is usually boned for grinding but cross-cut shank or soup bones may be made. The brisket should be boned for a roast or for grinding.

The blade end of the square-cut chuck may be cut into steaks or roast.

The arm end of the chuck may be cut into steaks or roasts. The neck portion can best be used for ground beef.

Hindquarter

The hindquarter should be placed on the cutting table with the outside down.

The flank is removed by starting the cut on the round near the cod area following the round muscle. Cut closely to avoid cutting into the lean on the round near the stifle joint. Continue the cut forward on a line to a point 2 or 3 inches below the loin eye muscle at the 13th rib.

The flank steak, the prominent muscle on the inside near the center of the flank, may be stripped out for a steak and the remaining lean trimmed for grinding.

Separate the loin from the round by cutting between the fourth and fifth sacral vertebrae at a point approximately 1 inch in front of the aitch bone. The loin should then be cut into steaks. Begin cutting at the sirloin end and cut toward the small end of the loin.

Remove the rump by cutting parallel to the two ends of the aitch bone and just behind the aitch bone. The rump is usually boned and tied for roasts. The sirloin tip is removed by following the round boned to the knee cap. The tip can be used as a roasts or steaks.

The remainder of the round may be cut into steaks or roasts most easily by separating the top and bottom round. The hind shank should be boned for ground beef.

Packaging Beef for the Home Freezer

Successful freezing depends on proper packaging to protect foods in freezers.

Ordinarily Kraft or waxed papers do not adequately protect foods in freezers. Use moisture-vapor-proof material, designed especially to wrap foods for freezing. These materials are strong, easy to handle, resist grease, are moisture proof, and will not transfer odors. Plastic and Kraft laminated material is probably the most economical and is easiest to use in most cases.

How to Wrap

The drugstore fold is the approved method to seal the moisture in and air out. To make the drugstore fold:

- Place the meat in the center of the paper.

- Bring the two horizontal ends together and fold over until tight against the meat.

- Tightly fold one end, then the other, turn each end underneath, and secure with tape.

For easier separation of steaks when frozen, place a double thickness of waxed or freezer paper between each piece with plastic sides to the meat. Before packaging remove or cover sharp bone edges with double thickness of freezer paper so they will not puncture the wrapping paper.

Labeling

Label each package clearly with a crayon or grease pencil. Include the name of the cut, the quantity, and the packaging date.

Freezer Storage Time

The maximum recommended period of freezer storage for beef is nine months.

Thawing Frozen Meat

For best results, thaw in original package in the refrigerator. Allow approximately three hours per pound for small roasts and steak packages, and four to five hours for larger roasts. If thawed at room temperature allow one hour per pound.

Cooking Frozen Meat

Frozen meat may be cooked satisfactorily either by thawing prior to or during cooking. When cooking steaks or roasts from the frozen state, allow additional cooking time.

Frozen roasts require approximately a third longer for cooking than roasts that have been thawed. Allow additional time for cooking steaks or ground beef patties compared to thawed cuts. When broiling place frozen steaks and ground beef patties further from the heat or at a lower temperature than thawed cuts so the meat will be cooked to the desired degree of doneness without becoming too brown on the out-side.

Harold R. Hedlick and William C. Shingel

Department of Food Science and Nutrition

Maurice Alexander

Former Animal Science Specialist