Gas Oven Optimization – Waste Reduction

Food processors account for about 8.5 percent (Deevy et al., 1990) of the nation’s total industrial consumption of natural gas (6.64 MMcf in 2007, Energy Information Administration, 2008) or about 564 billion cubic feet. Assuming a value of $8 per thousand cubic feet of natural gas, this translates to an annual cost of $4.5 billion to the food industry. An industry-wide savings of just 10 percent would return an estimated $450 million per year! Ovens are one of the largest users of natural gas in the food industry (Minsker and Salama, 1988).

There are numerous ways to reduce energy and operational waste when it comes to gas-powered ovens. For example, think about how much energy is wasted by bringing an oven up to operating temperature long before baking begins. More energy may be lost through openings, leaks, doors and missing insulation. Operational waste comes from sources like overcooked or undercooked product. Like any sort of everyday waste, waste from gas-powered ovens can add up during the years to surprising amounts. Reducing energy and operational waste will save money in both the short and long run, and with rising energy and ingredient costs, this becomes more important than ever. The purpose of this fact sheet is to help identify and reduce waste from gas-powered ovens.

Five Steps to Reduce Oven Waste

Reducing oven waste can add dollars directly to the profit of your operation. Five steps to reduce waste in oven systems are:

Analyze the oven system.

Identify current (and future) use of ovens, including periodic loads.

Understand the fuel supply system and controls.

Diagram the oven process, including air handling, electrical and fuel supply and what happens to waste products.

Identify system deficiencies.

Evaluate actions to correct deficiencies.

Implement the best actions.

Track results.

The five steps are described further below.

-

Analyze the Oven System

Identify current (and future) use of ovens, including periodic loads. Examine all uses of energy and air by enlisting the help of engineers, technicians and line personnel. Do not forget to ask the cleanup crew about oven operation during cleanup.

Review the cooking requirements of products. Identify required temperature set points and time requirements. Understand the use of “safety factors” included in the cooking requirements.

Understand the fuel supply system and controls. Visit with an engineer, technician or supplier to determine how the oven fuel train operates.

Find out how much it costs to operate and maintain your system per year based on actual expenses or estimates.

Examine air flow and pressure in the oven room and adjacent areas open to the oven room. Determine if seasonal or periodic changes (e.g. open doors, vents, windows or fan settings) may be affecting oven operation.

Diagram the oven system, including utilities and piping. Everyone will be able to view and discuss the system using diagrams, which helps streamline the identification and correction of deficiencies.

-

Identify Oven System Deficiencies

Conduct a self-audit of your oven or hire an auditor. Top targets of an oven audit should include:

Burner tuning and efficiency. Properly tuned burners are a must.

Oven and air pressure and flow controls. Flues and fans can move air in unintended directions. Room and exhaust air flow must be controlled to optimize energy efficiency and operation of the oven.

Control of gas and combustion air. Often these variables are mechanically linked in control systems. Independent actuators installed on gas and air supplies will provide more precise control accompanied by fuel savings.

Waste heat recovery. Exhaust heat can be recovered and transferred to burner or makeup air, water or other process streams.

Oven temperature set point. Tightening of oven controls and product specifications may allow a reduction in oven set point temperature, which will reduce fuel consumption and product waste.

Fuel train vent valve leaks. Vent valves occasionally leak fuel directly out of the plant. Check these valves to insure that they are working properly.

Insulation. Oven skin temperature should be less than 160 F. Consider upgrading insulation.

Load management. Are frequent shutdowns and changes in production rate characteristics of your system? Level and maximize the input load to your oven to improve efficiencies.

Startup/shutdown cycles. Improved procedures for system startup and shutdown can reduce energy costs and improve product quality.

New technology. Occasionally new technology becomes available that can provide a rapid payback on investment. Examples are the new generation of gas burners and spiral ovens.

-

Evaluate Actions to Correct Oven

Deficiencies

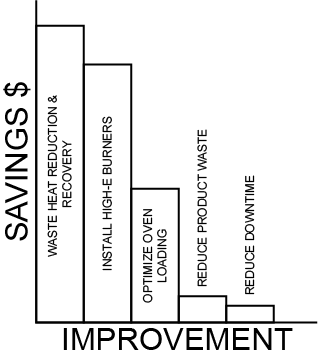

Pick the “low hanging” fruit first. Correct the deficiencies that are costing the most, but are the least expensive to repair. A Pareto diagram (a type of bar graph) can be useful in this case to help separate the “critical few” deficiencies from the “trivial many” possibilities that exist. An example Pareto diagram is shown in Figure 1, where the source of the remedy for the problem is listed on the x-axis. The y-axis shows the estimated savings (less the cost of implementation) that would result from correcting the deficiency. The projects with the tallest bars on the Pareto chart should be selected for implementation first.

Figure 1. Pareto diagram used to help select the most effective action(s) (categories are examples only).

-

Implement the best actions

This step requires action to be taken to implement the best alternative(s) identified in step three. Some processors postpone action because of time constraints. It may be worthwhile to hire extra help to implement actions immediately. Each action should be verifiable in terms of results (e.g. increased capacity, reduced utility consumption, reduction of downtime or quality improvement). Actions also should be measurable in terms of cost savings.

-

Track results

All actions taken should be reviewed periodically to ensure results are as expected or to determine if something has changed that requires additional attention or action. When changes have occurred, the five-step process can be reiterated to solve new problems. The process of making incremental changes for the best is called “continuous improvement.”

Food Safety

Ovens are often regarded as a major concern for food safety. If internal temperature is a critical control point (CCP) for cooked products, then pay particular attention to oven performance and reliability. Product temperature at the discharge of any oven will be variable. Standard deviation, or sigma, is a measurement of the variability of the cooked product temperature. When the oven temperature is set to produce product with a mean temperature equal to the CCP plus six times the sigma of the cooked product’s temperature, the process is said to meet six-sigma requirements for cooking. Once an oven system is under six-sigma control, it is statistically capable of producing fewer than two defects (undercooked products) per million units cooked (Joglekar, 2003).

Equipment

Temperature data loggers and imaging cameras are very useful for detecting thermal

“leaks” and inconsistencies in ovens. If at all possible try one or more units before

making a purchasing decision, or ask an experienced user. The units shown in figures

2 through 4 are for example only and their use in this publication is not an endorsement

of the manufacturer, supplier or the performance of the equipment.

Figure 2. Super Mole Gold temperature data logger by ECD. www.bakewatch.com

Figure 3. Datatrace data logging system by Mesa Labs. www.mesalabs.com

Figure 4. Infrared camera by Fluke Corp. www.fluke.com

Resources for Further Study

A useful list of online resources is available at the U.S. Department of Energy Web site for its Industrial Technologies Program. Best practices for process heating are listed at www1.eere.energy.gov/industry/bestpractices/process_heat.html. The Alliance to Save Energy maintains a “clearinghouse” of methods to save industrial energy at https://www.ase.org/.

Conclusion

Gas oven systems in food processing operations are often overlooked as a source of waste. Many systems are inefficient and pose potential food safety and quality hazards. A wide variety of resources, tools and techniques are available to help diagnose and improve oven systems. Identifying and repairing problems in ovens can be a rewarding experience that results in increased cash flow and improved food quality. As energy prices continue to rapidly increase, the efficiency of oven systems is even more important.

References

Deevy, L.M. ; Looby, G.P. ; Kirsch, F.W. 1990. Role of natural gas in food-processing plants: Present and future. Final Report, June 1989-November 1990. University City Science Center, Philadelphia, PA. OSTI ID: 5161735. Gas Research Inst., Chicago, IL.

Energy Information Administration. 2008. U.S Natural Gas Consumption. Internet: http://tonto.eia.doe.gov/dnav/ng/hist/n3035us2A.htm. Accessed on May 19, 2008

Joglekar, A.M. 2003. Statistical methods for six sigma in R&D and manufacturing. John Wiley and Sons. New Jersey.

Minsker, B.S., and S.Y. Salama. 1988. Competitive Position of Natural Gas: Industrial Baking. Energy and Environmental Analysis, Inc., Arlington, VA. Gas Research Inst., Chicago, IL.

Timothy J. Bowser

FAPC Food Process Engineer

Ben Smith

FAPC Student Researcher

Figure 1. Pareto diagram used to help select the most effective action(s) (categories are examples

only).

Figure 1. Pareto diagram used to help select the most effective action(s) (categories are examples

only).