Selecting and Purchasing Food Process Equipment

- Jump To:

- Introduction

Introduction

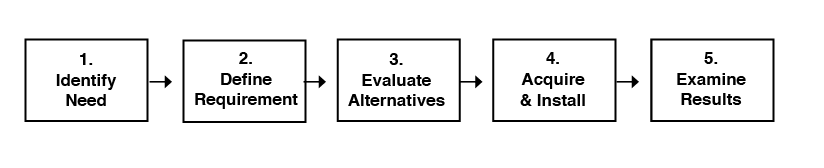

Selecting and purchasing food processing equipment can be time consuming and difficult. This fact sheet presents a five-step method that makes this task more manageable. The five-step method is outlined in Figure 1.

Figure 1. Five-step method for selecting and purchasing food-processing equipment.

The first step in selecting and purchasing food-processing equipment is a clear identification of the need. The expense of purchasing and installing capital equipment can be a tremendous burden for any business. Questions should be asked such as:

- Will the business profit more from the fulfillment of this need compared to the other needs?

- How will this item fit in with, or satisfy future needs?

- Is the need consistent with the businesses’ long-term goals?

- Does the need satisfy a safety or regulatory requirement?

- Will the end result improve product quality?

Once the need has been clearly identified, the second step in selecting and purchasing

food-processing equipment is to define the requirement. What will satisfy the need?

This step requires the most work, but achieves the highest reward. A complete definition

of your requirement will enable you to effectively communication with potential suppliers.

The result minimizes confusion between the purchaser and the supplier, allowing firm

bids that eliminate hidden costs. Customer dissatisfaction and frequency of equipment

returns or retrofits are reduced.

One type of document that is commonly used by government and industry to define requirements

is called a specification. Over the years, specifications have been stereotypes as

being unnecessarily wordy and confusing. This need not be the case. A good specification

should be brief, simply worded, and useful for the intended purpose. Unfortunately,

a recognized specification format does not exist for food processing equipment; however,

the author has developed a model based on experience in the food industry. An example

specification for a product filler is given in the appendix.

Useful specifications often include, but are not limited to, the following information:

- System description – a detailed narrative of the operation and functioning of the equipment or system being specified, including a definition of the product to be processed, the container and/or other packaging used for the product (if applicable), systems interface, and performance criteria.

- Project conditions – information relating to the system in which the equipment is to be installed and operated. This section usually includes details on available utilities and the operating environment.

- References – identification of standards directly pertaining to the manufacture and components included on the specified equipment. Examples are: Dairy and Food Industries Supply Association, Inc. (3-A); United State Department of Agriculture (USDA); Food and Drug Administration (FDA); American Welding Society (AWS); Occupational Safety and Health Association (OSHA); and the American Society of Testing Materials (ASTM).

- Materials – Specification of materials of construction including gaskets, metals, composites, plastics, rubber and coatings.

- Controls – indication of, as a minimum, the level of control desired (fully automatic vs. manual) and may provide a detailed description of the control logic, operating sequence, and control panel layout.

- Maintenance and Service – detailed description of any repair and ongoing maintenance requirements necessary for the equipment.

- Manufacturers – lists of any required manufacturers of parts or sub assemblies such as motors, switches, pumps, valves, drives, steam-handling components, and controls. Many organizations require that machinery be equipped with parts made by their preferred manufacturer to reduce spare parts inventory and minimize training requirements for maintenance technicians and operators.

- Submittals – lists the specific information about the equipment required for bidding and/or supplying the specified equipment. Examples are utility usage, drawings, quotations, equipment weight, foundation requirements, warranties, manuals, and spare parts kits or spare parts requirements.

- Inspection and acceptance testing – an inspection notice alerts the supplier that the purchaser wishes to inspect the equipment during and/or after the fabrication and construction phase. An acceptance test requires a functional test of the equipment prior to shipment. The requirements for the inspection and acceptance test should be described in detail, including timing and the consequence of failed tests.

- Delivery – information relating to the preparation (crating and protection) and delivery of equipment, including the desired date of delivery or deadline and the actual address for equipment delivery.

- Equipment identification – details pertaining to nameplate, tags, and labels that will be permanently attached to the equipment.

- Safety – a listing of safety requirements for the equipment such as operator guards, unique environmental concerns, and product safety.

- Bonuses and Penalties – Bonuses and/or penalties specified for the equipment manufacturer may be appropriate to help achieve certain critical goals such as equipment delivery or installation date and equipment performance.

- Business information – details relating to the financial soundness and reputation of the equipment supplier. For example, credit rating, time in business, list of references, share of market, percentage of international sales, and repeat sales.

- Demonstrations – requires the supplier to provide a list of users of their equipment with similar installations that can be visited for demonstration purposes.

- Installation – can the company provide competent personnel to assist you with or conduct the installation of the equipment? What rates do they charge, including expenses (travel, food and lodging).

One can easily develop a specification template that can be used to write custom specifications for food-processing equipment needs given the following items:

- Example specification given in the appendix

- List of items often found in specifications (given above) edited and rewritten to include the general details pertaining to your installation site and process

The template will contain the boilerplate for future specifications, such as site

conditions, delivery addresses, a list of references, manufacturers, equipment identification

requirements, and others. Blanks can be left in the template for parameters that are

specific to a given project. The template then can be used to write specifications

for equipment by filling in the blanks, deleting unnecessary information, and adding

new details pertinent to the equipment and process requirements. Each specification

written for a particular project should receive a unique title and number to avoid

mix-ups.

Once a detailed specification has been written, the third step in the selection and purchase process is to evaluate the possible alternatives. This step begins by sending your specification to the most capable suppliers that can be identified. Lists of suppliers are available from catalogs such as the Thomas Register of American Manufacturers (Thomas Publishing Company, New York) and online resources such as the Food Explorer and Food Online. A list of online resources is given in Table 1. At least one industry organization the Food Processing Machinery and Supplies Association (FPM&SA), Alexandria Virginia, maintains its member database and provides free consultation aimed at linking potential customers with their members.

Table 1. List of online resources of food processing equipment suppliers and information.

| Web address | Organization/Sponsor | Comments | |

|---|---|---|---|

| www.thomasregister.com | Thomas Publishing Company | Comprehensive catalog of equipment manufacturers | |

| www.foodexplorer.com | Cahners, a subsidiary or Reed Elsevier, plc | Extensive listing of food processing equipment and ingredient suppliers. The definitive source. | |

| www.foodonline.com | VerticalNet, Inc. | Resource for the food industry professional. Including articles, technology trends, software downloads, library and community events. | |

| www.foodprocessing.com | Putnam Publishing Co. | Resource associated with the magazine, Food Processing | |

| www.ift.org | Institute of Food Technologists (IFT) and the International Assoc. of Food Industry Suppliers | Resource for the food industry professional including a virtual exhibit hall, forums, online seminars and member assistance | |

| www.fpsa.org | Food Processing Machines and Supplies Association (FPM&SA) | Member database and free service to help link potential clients to member suppliers | |

| www.packnet.com | Packaging Machinery Manufactures Institute (PMMI) | Packaging machinery only. Searchable member database and links to member websites. |

Telephone each potential supplier to determine their capabilities and obtain or verify

the contact information needed to send them your specification. Send a complete specification

to each potential supplier on your list. You can expect to receive a formal bid within

about two weeks. Review and compare bids to determine the most likely alternative

for your operation. Obtain legal assistance, if necessary, when evaluating the terms

of the proposed purchase agreement. Many suppliers will be open to negotiation during

this stage of the process. Use this opportunity to obtain the most competitive value

and price. Remember that the lowest big may not completely provide for your immediate

and future needs.

Act on the best alternative and purchase the equipment. The delivery, installation, and startup should be processed smoothly, as a result of efforts to develop a detailed specification. The last step in the equipment selection and purchasing process is to examine the results. What could be done differently the next time to improve the process? Review the five-step selection and purchasing process and make notes of improvements for future reference.

Tim Bowser

FAPC Food Process Engineer