On-site Wastewater Treatment Systems Permitted in Oklahoma

During the last four years, roughly 23,700 private permits for on-site wastewater treatment systems (or on-site septic systems) were issued by the Oklahoma Department of Environmental Quality (DEQ) (Oklahoma DEQ, 2013). During the same period, 42,300 new houses were built in Oklahoma (U.S. Census Bureau, 2013). Assuming all permits eventually resulted in an actual installation of a system, these two data sets indicate that 56 percent of new houses in Oklahoma have on-site septic systems. This is higher than the estimate of only 20 percent of houses nationwide and 46 percent of the southern states that have on-site septic systems (USEPA, 2008). With such a considerable fraction of houses in Oklahoma having on-site septic systems, it is critical that site-appropriate systems be installed to prevent widespread problems associated with improperly treated septic wastewater.

The decision regarding what type of septic system is appropriate is largely based on site and soil properties. Soil properties such as soil texture and depth to limiting layers, such as a shallow water-saturated layer or an impervious rock layer, are factors that partly determine the appropriate choice of a system (see Extension Fact Sheet PSS-2271 for more details). There are currently five types of systems ordinarily permitted for installation in Oklahoma. This includes: Conventional System, Low-pressure Dosing System, Evapotranspiration/Absorption (ET/A) System, Aerobic Treatment System, and the Treatment Lagoon. This Fact Sheet is focused on specific information about design and treatment of septic wastewater for each of these different systems.

Conventional System (Subsurface Sewage Treatment System)

A conventional system is the most common and least expensive type of on-site wastewater treatment system. This system can be installed in approximately 60 percent of the soils in Oklahoma. It relies heavily on the ability of the soil to treat dissolved and microbial contaminants in the wastewater –therefore, proper characterization of the soil profile in the target area is of the utmost importance. The design details of the system largely depend on the properties of the soil; specifically texture and structure.

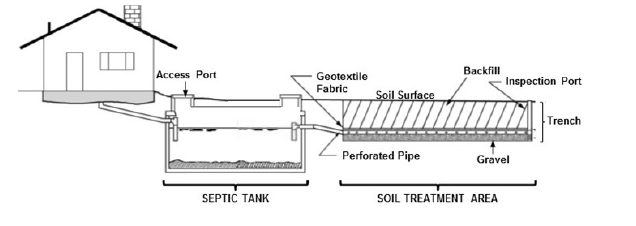

A conventional system is composed of two components: the septic tank and the subsurface absorption field or soil treatment area (STA) (Figure 1). The septic tank is where the pre-treatment of the wastewater occurs. When the wastewater enters the tank, the solid fraction settles out of suspension, and the lighter grease and scum float on top of the effluent. Bacteria partially degrade the settled solids and some of the dissolved contaminants. The septic effluent then flows out of the septic tank to be further treated by the soil. Solids left in the septic tank must be periodically pumped-out to prevent clogging.

Figure 1. Schematic illustration of a conventional septic system.

The STA is composed of lateral perforated pipes (or lateral lines) that distribute the wastewater from the septic tank to a treatment field. These lines are buried in trenches where they are surrounded by a storage media such as gravel or tire chips and backfilled with native soil. The final treatment of the wastewater is achieved by the soil underneath the storage media. Effective treatment depends on the ability and capacity of the soil to sorb nutrients, household chemicals and microorganisms, as well as the soil’s ability to temporarily store water for treatment before it flows down to the underlying groundwater.

The soil beneath the trenches can neither be too fine, which impedes percolation, nor too coarse, which facilitates rapid flow of water without effective treatment. Sufficient vertical separation distance between the bottom of the trench and the seasonal high water table or the underlying impervious rock layer is another critical consideration in deciding if this system is suitable for the site.

Because wastewater distribution in a conventional system and driven by gravity, it is crucial that the STA be in a flat area so the wastewater may be distributed evenly. The most common malfunction of this system is blocked lines leading to uneven wastewater distribution and the unwanted release of wastewater only to an isolated/smaller area.

Low-Pressure Dosing System

Low-pressure dosing (LPD) systems are essentially the same as conventional systems, except that pressure is applied to distribute wastewater through the lateral pipe lines and into the STA. This system is permitted in areas with good quality soil that does not meet the vertical separation distance and/or the surface area requirement for a conventional system. The use of pressure facilitates a more effective and even distribution of the wastewater to the STA than the gravity-driven distribution in the conventional system. The more effective distribution of wastewater results in a marked improvement in the utilization of the STA, which would offset possible drawbacks brought by the narrower vertical separation distance or the smaller surface area of an STA.

An area that has good quality soil and sufficient vertical separation, but does not qualify for the installation of a conventional system because of the slope (e.g. 2 percent to 10 percent) could be utilized as STA for LPD systems. The use of pressure in LPD systems allows wastewater to be pumped evenly throughout the STA despite the slope.

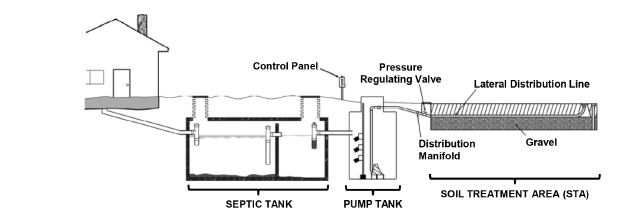

A key addition to the system treatment design is the pump tank between the septic tank and the STA (Figure 2). Activation of the pump may be driven by a mechanism that detects whether a threshold volume in the pump tank is achieved or may be triggered by a timer. The pump in the tank is driven by electricity. This system requires more upkeep than a conventional system because, in addition to possible problems with blocked lines, the pump, the electronics driving the pump and pump activation mechanism could be sources of system malfunctions.

Figure 2. Schematic illustration of a low-pressure dosing system. (Adapted from CIDWT, 2009)

Evapotranspiration/Absorption System

The evapotranspiration/absorption system (more commonly known as ET/A system) is designed for areas that do not meet the requirements for the conventional and LPD systems due to the presence of soil with too much clay, soil expansion properties and soil structure issues. This system is a particularly good alternative to conventional and LPD systems in areas where evapotranspiration—the sum of water evaporation from the soil and transpiration via plant leaves to the atmosphere—exceeds rainfall. In Oklahoma, for example, this would be more suited for use in the panhandle than in the southeast.

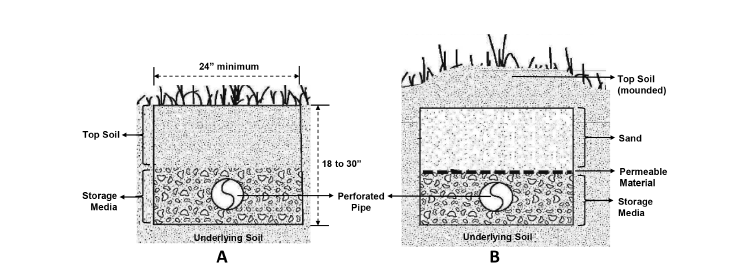

Like conventional and LPD systems, the ET/A system needs a septic tank and an STA, but they differ in trench design (see Figure 3). ET/A systems depend on wastewater removal from the site mainly via evapotranspiration, thus relying on the plant growth on the trench to facilitate the loss of water from the soil into the atmosphere. If there are no plants growing on the trench site, water removal from the soil will occur slowly and will impair the system’s effectiveness.

Figure 3. Schematic cross-sectional illustration of trenches in conventional and LPD systems (A) and in ET/A systems (B). (Adapted from Oklahoma DEQ, 2012)

In addition to this requirement of plant growth, ET/A systems must also be installed on sites with an area of at least one acre. The design of the system is also dependent on the topography of the site; the net evaporation “zone” listed for an area; estimated water usage; water well locations and location of creeks, rivers, springs, ponds and lakes.

The sand above the storage media in the trenches takes up the wastewater via capillary action, allowing it to be lost through evaporation and absorption of the plant roots to be eventually transpired to the atmosphere.

Aerobic Treatment System/Unit (ATU)

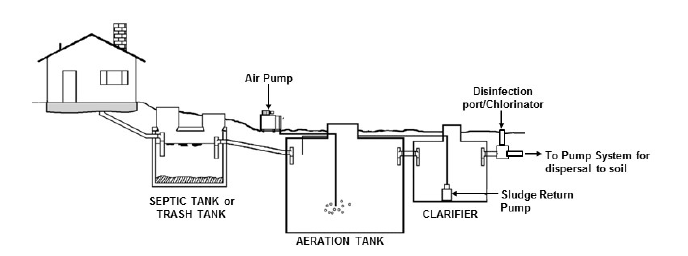

This system has been the most popular system in Oklahoma in recent years. This is due to the construction of new housing developments on poor soils (very shallow, clayey soils) wherein the use of ATUs is considered as most practical. In addition to a septic tank (also known as trash tank) and a soil dispersal area, an ATU has an Aeration Tank – a tank into which atmospheric air is forced to add oxygen to the wastewater (Figure 4).

Figure 4. Schematic illustration of an aerobic treatment system. (Adapted from CIDWT, 2009)

Atmospheric air (roughly 21 percent oxygen) is bubbled through the wastewater to primarily facilitate two processes: 1) the decomposition of organic materials in the water and 2) the weakening or killing of pathogenic microorganisms.

Introducing oxygen causes conditions in the aeration tank to become aerobic. This enhances the activity of aerobic microorganisms. In the presence of oxygen, the efficient energy-generation process of aerobic respiration occurs – causing microorganisms to be more active, leading to the enhanced decomposition of dissolved and suspended particulate organic materials in the wastewater.

Pathogenic microorganisms in the wastewater are from the digestive system of humans. These microorganisms are adapted to the anaerobic conditions in the human digestive system and will thrive in the usually anaerobic conditions in the septic tank. Aerobic condition in the aeration tank possibly kills or weakens anaerobic microorganisms, causing them to be overcome by the aerobic bacteria in the aeration tank. This process reduces microbial pathogens in the wastewater. After aeration, wastewater flows into a clarifier (Figure 4) which allows particles to settle. In most systems, the aeration chamber and the clarifier are combined in one tank.

From the clarifier, treated wastewater is disposed to a field either by spray irrigation or drip irrigation. Drip irrigation systems may be installed in very thin soil, but are more expensive than spray irrigation systems. With drip irrigation, the wastewater does not require disinfection because it is applied directly to the subsurface for dispersal. Wastewater disposed by spray irrigation needs to be chemically disinfected because wastewater in this case is applied on the surface of a vegetated STA. A specified amount of bleach is usually used to chemically disinfect the wastewater prior to surface-application.

Of the five on-site septic systems permitted in Oklahoma, the ATU needs the most upkeep. This system has pumps, an aerator and complicated electronics controlling the timing of effluent flow through the ATU treatment train – all of which are possible sources of malfunctions. In addition, possible blocking of dispersal lines and of nozzles/orifices of the spray/drip irrigation system could occur. It is critical that this system be only installed and maintained by a licensed professional.

Treatment Lagoon

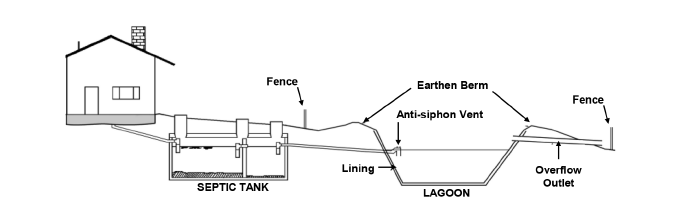

A treatment lagoon is a good alternative in poor soils located in areas where net evaporation exceeds total rainfall. It relies on evaporation as mode of disposal of wastewater. This system uses an open pond as the storage/evaporative area and a septic tank for pre-treatment of wastewater (Figure 5). Lagoons are permitted on any type of soil that has a lot size of at least two and a half acres. To prevent accidents involving children and pets, the lagoon area has to be fenced.

Lagoons works better in central and western Oklahoma where rainfall is relatively low. Lagoons in areas with sparser rainfall would more likely be emptied by evaporation. The required size of the lagoon differs throughout the state. The northeastern side of the state has relatively lower net evaporation per area and will need larger lagoon sizes to accommodate a relatively extended retention time of the wastewater in the lagoon.

Alternative Systems

The design and installation of an on-site septic system is dependent on many factors. Apart from the soil properties, site properties such as lot size and size of residence are considered in the design, as well as other specifics. There are instances when none of the systems described above can be allowed, or is practical. In these instances an alternative on-site system is needed. During the last decade, between 1 to 4 percent of new systems installed in Oklahoma each year are alternative systems. These systems must be approved by the DEQ prior to installation. For additional information concerning the types of alternative systems available and the application/approval process for alternative systems, please contact your local DEQ office or call 405-702-6100.

Acknowledgments

Research by Jordan Wilmot of OSU is appreciated. Figures are modified from those prepared by the Oklahoma Department of Environmental Quality (DEQ, 2012) and the Consortium of Institutes for Decentralized Wastewater Treatment (CIDWT, 2009).

References

Consortium of Institutes for Decentralized Wastewater Treatment (CIDWT). 2009. Installation of Wastewater Treatment Systems. 1st Ed. 454 pp.

Oklahoma Department of Environmental Quality (DEQ). 2012. Individual and Small Public On-site Sewage Treatment Systems. Title 252: Oklahoma Admin Code Chapter 641.

Oklahoma Department of Environmental Quality (DEQ). 2013. Department of Environmental Quality’s Annual Reports. At: http://www.deq.state.ok.us/mainlinks/reports.htm. Accessed in May 2014.

U.S. Census Bureau, 2013. New Residential Construction. http://www.census.gov/construction/bps/stateannual.html. Accessed in May 2014

United States Environmental Protection Agency (USEPA). 2008. Septic System Factsheet. EPA # 832-F-08-057.

Sergio M. Abit Jr.

Extension Specialist for Soils, Non-agricultural Uses