Soil-Based Septic System Decisions in Oklahoma

Household and commercial sewage that cannot be routed to a centralized facility for treatment are processed using onsite septic systems. These include a wide range of individual and cluster treatment systems used in approximately 20 percent of all homes in the United States. An estimated 10 to 20 percent of these systems malfunction each year, causing pollution to the environment and creating a risk to public health (USEPA, 2008). One cause of malfunction is the inappropriate choice of installed system for the type of soil in an area (USEPA, 2013).

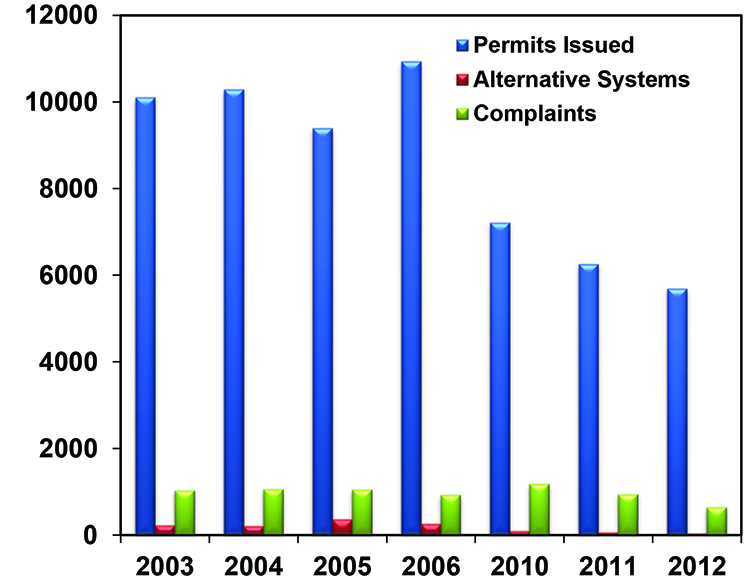

In the first half of the last decade, an average of 10,000 new treatment systems per year had been authorized in Oklahoma (Figure 1). A slowdown in the housing market has contributed to the decrease in new treatment authorizations to an average of 6,400 over the last three years. The percentage of malfunctioning units out of the existing onsite septic systems in the State is unknown. However, the Oklahoma Department of Environmental Quality (DEQ)-reported complaints about onsite septic systems range from roughly 600 to 1,100 annually during the last decade.

Figure 1. Total sewage systems authorizations, alternative systems issued and septic system-related complaints in Oklahoma. Data source: DEQ (2013).

The decisions relating to the type of septic system permitted for installation in an area depend on one or both of the following information: 1) observed soil profile properties and 2) an estimate of the degree of water flow through the soil profile. Septic system installation in Oklahoma is regulated by DEQ and the type of septic system permitted is largely based on observed soil properties –mainly soil texture of the porous material as well as soil color and the presence of restricting layers.

Soil Texture and Water Flow

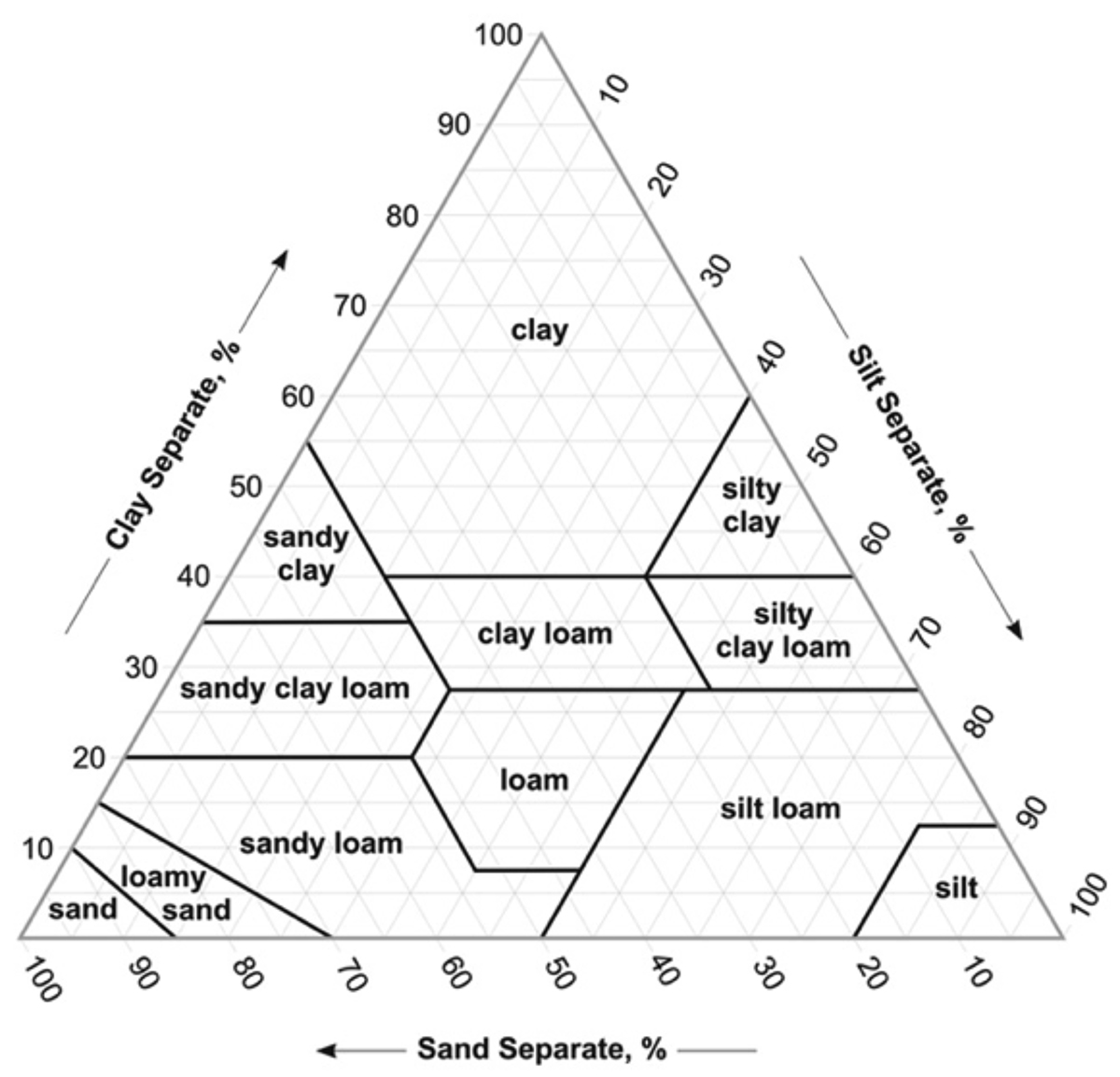

Soil texture is the relative proportions of the inorganic soil separates: sand, silt and clay. It is practically viewed as a physical parameter that indicates the relative coarseness or fineness of a soil material. To aid in land use decisions, the USDA-NRCS came up with a textural triangle (Figure 2) to classify soils into twelve textural classes. Soils in a textural class, which may have different sand, silt and clay contents, are expected to have similar properties and hence could be managed or utilized in the same manner.

Figure 2. Textural Triangle. Source: USDA-NRCS.

Soil texture affects the size distribution and the connectivity of the pores in a soil body. Fine-textured soils (clay, silty clay, sandy clay) would tend to have greater proportion of smaller-sized pores that are likely less-connected and more tortuous causing ineffective water flow. Coarse-textured soils (coarse sand, loamy coarse sand, soils with more than 35 percent rock fragments by volume) tend to have large pores that are well-connected allowing very effective water flow.

Both fine- and coarse-textured soils are undesirable media for treating onsite septic wastewater. Fine-textured soils may cause wastewater to pond over a subsurface application location that could eventually break through the soil surface (“surfacing”). Conversely, coarse-textured soils allow wastewater to flow through the soil profile rather quickly and could recharge the groundwater without effective treatment. Non-conventional or more advanced systems will be required for areas having these soils to be permitted for septic wastewater application.

Other soils (medium-textured and some coarse-textured soils) that allow effective enough water flow to prevent surfacing, but at a rate slow enough to prolong the residence time of the wastewater in the soil allowing effective treatment, are generally permitted for installation of most septic systems permissible in Oklahoma.

In Oklahoma, the different USDA-NRCS textural classes are further re-categorized into Soil Groups that serve as primary basis in decisions related to onsite septic systems (Table 1). Soils that are categorized into these different groups are those in the Vertical Separation. The Vertical Separation refers to the soil that vertically separates the trench bottom of the septic system and a limiting layer (e.g. rock layer) or the seasonal high water table (as indicated by the presence of redoximorphic features; see discussion below about redoximorphic features).

Table 1. Soil Groups used as basis in septic system decisions in Oklahoma. Source: DEQ, 2012.

| Soil Groups | Corresponding Soil Textural Classes | |

|---|---|---|

| 1 | Coarse sand Loamy coarse sand All soils with rock fragment content of more than 35 percent by volume having continuous voids more than 1 mm |

|

| 2 | Sand Loamy sand (not including coarse sand or loamy coarse sand) |

|

| 2a | Sandy loam | |

| 3 | Sandy clay loam Loam Silt loam with less than 20 percent clay Silt |

|

| 3a | Sandy clay without slickensides with moderate and strong soil structure Silt loam with more than 20 percent clay |

|

| 4 | Clay loam Silty clay loam |

|

| 5 | Sandy clay with slickensides or weak soil structure Clay Silty clay |

Soil Red Flags: Restricting Layers and Redoximorphic Features

In many cases, particulars about the design of septic system components are determined by the presence and the depth of certain soil characteristics. These include the presence of a restricting layer or of redoximorphic features.

Restricting layers are those that are impervious to boring by hand auger or layers that may limit water movement through the ground (Carter, 2008). In Oklahoma, the most common restricting layers are Lithic or Paralithic materials – rocks and fractured rocks not considered as soil that are made up of sandstone or shale for example (Figure 3A). These layers are designated as R or Cr in soil profile descriptions.

Redoximorphic features are soil morphological elements that develop when a particular section in the soil had been saturated (i.e. under the water table) for durations long enough to cause anaerobic conditions which promote iron reduction. Particular attention is given to features called Redox Depletions – sections in the soil profile are gray having Munsell® colors of chroma < 2 and value > to 4 or have colors in the Gley

page of a Munsell® color book (Figure 3 B).

Figure 3. Rock layer (A) and horizons with redoximorphic features (B). Photos by John A. Kelley, USDA Natural Resources Conservation Service.

Alternative Systems

As indicated in Table 2, the design and installation of an on-site septic system is dependent on many factors. Apart from the soil properties, site properties such as lot size and size of residence, among others, are considered in the design. There are instances when a system described in Table 2 cannot be designed and an alternative on-site system is needed. Over the last decade, between 1 to 4 percent of new systems installed in Oklahoma each year are alternative systems (Figure 1). These systems must be approved by the DEQ prior to installation. For additional information concerning the types of alternative systems available and the application/approval process for alternative systems, please contact your local DEQ office or call 405-702-6100.

Table 2A. System with minimum vertical separation requirements. Source: DEQ, 2012.

| Septic System Options | ||||

|---|---|---|---|---|

| Prevalent Soil Group in Vertical Separation Range | Conventional System and Shallow Extended Subsurface Absorption Field | Low Pressure Dosing Field | Evapotrans- piration/ Absorption Field |

|

| 1 | NOT ALLOWED | ALLOWED - with at least 24" vertical separation | ALLOWED - in Group 5 soil with at least 6" vertical separation | |

| 2 | ALLOWED - with at least 24" vertical separation | ALLOWED - with at least 16" vertical separation | Requires a lot area of at least 1 acre | |

| 2a | ALLOWED - with at least 21" vertical separation | ALLOWED - with at least 14" vertical separation | Subject to Oklahoma net evaporation zone restrictions | |

| 3 | ALLOWED - with at least 18" vertical separation | ALLOWED - with at least 12" vertical separation | ||

| 3a | ALLOWED - with at least 14" vertical separation | ALLOWED - with at least 10" vertical separation | ||

| 4 | ALLOWED - with at least 10" vertical separation | ALLOWED - with at least 6" vertical separation | ||

| 5 | NOT ALLOWED | NOT ALLOWED |

Table 2B. System with minimum vertical separation requirements. Source: DEQ, 2012.

| Septic System Options | ||||

|---|---|---|---|---|

| With Aerobic Treatment Units | ||||

| Prevalent Soil Group in Vertical Separation Range | Lagoons | Drip Irrigation Field | Spray Irrigation Field | |

| 1 | ALLOWED - No applicable vertical separation range | ALLOWED - with at least 18" vertical separation | ALLOWED - No applicable vertical separation range. | |

| 2 | ALLOWED - with at least 14" vertical separation | |||

| 2a | Requires a lot size of at least 2½ acres | ALLOWED - with at least 12" vertical separation | ||

| 3 | ALLOWED - with at least 10" vertical separation | |||

| 3a | Subject to Oklahoma net evaporation zone restrictions. | ALLOWED - with at least 8" vertical separation | ||

| 4 | ALLOWED - with at least 6" vertical separation | |||

| 5 | ALLOWED - with at least 6" vertical separation |

References

Carter, B. 2008. DEQ/OSU Soil Classification Manual. Oklahoma Agricultural Research Station. B-819.

Oklahoma Department of Environmental Quality (DEQ). 2012. Individual and Small Public On-site Sewage Treatment Systems. Title 252: Oklahoma Admin Code Chapter 641.

Oklahoma Department of Environmental Quality (DEQ). 2013. Department of Environmental Quality’s Annual Reports. At: http://www.deq.state.ok.us/mainlinks/reports.htm. Accessed in May 2013.

USDA-NRCS. 2013. Soil texture calculator. At: http://soils.usda.gov/technical/aids/investigations/texture/. Accessed in May 2013.

USEPA. 2008. Septic System Factsheet. EPA # 832-F-08-057.

USEPA. 2013.Water: Septic (Onsite / Decentralized) Systems: Failure Causes. at: http://water.epa.gov/infrastructure/septic/failure-causes.cfm. Accessed in May 2013.

Sergio M. Abit Jr.

Extension Specialist for Soils under Non-agricultural Uses