Inspection of Septic Systems

- Jump To:

- I. Septic Systems:

- II. Preparing for an Inspection/Evaluation

- III. Inspection of Plumbing Fixtures

- IV. Location of Outdoor Components and Baseline Observations

- V. Inspection of the Septic Tank

- VI. The Water Stress Test

- VII. Inspection of the Components of an Aerobic Treatment System

- VIII. Safety

- IX. Reporting

Onsite wastewater treatment systems or septic systems are proven effective in treating household wastewater at locations outside the service area of the city sewer system. This gives many of us the option to live in the countryside to be closer to nature, grow crops and farm animals and enjoy simple and laid back lives in rural areas where home properties are usually less expensive.

However, it should be noted that septic systems can only treat household wastewater effectively if they are maintained properly and used as designed. Their effectiveness drops when one or more components malfunction. Depending upon the type of malfunction, septic system repairs may involve a simple, inexpensive remedy or a major fix costing hundreds, or even thousands of dollars which requires earthwork on the property that takes several days to complete. Malfunctioning septic systems could also lead to a decrease in property value and may even negatively affect its marketability. Moreover, dispersal of improperly treated wastewater may lead to the homeowner being fined, may threaten the health of the homeowners and their neighbors and in some cases, can even harm the groundwater and/or nearby surface water bodies. These economic, community and environmental costs could be prevented if septic systems are installed correctly, maintained properly and inspected professionally.

This fact sheet focuses on the professional inspection of septic systems. It involves a brief description of the functions of basic components followed by a discussion of a suggested process of how key components are inspected. By inspection, we mean the inspection by a house inspector before a sale transaction is finalized or a routine inspection by a septic system service provider to assess the functioning of a system. We use the term “suggested process” as we recognize that others may have their own way of going about an effective septic system evaluation. Our goal is for this fact sheet to serve as reference for those who may be developing their evaluation protocol or who may be looking to improve their evaluation process and/or for homeowners who are interested in gaining some insights on what goes on during a septic system evaluation.

I. Septic Systems:

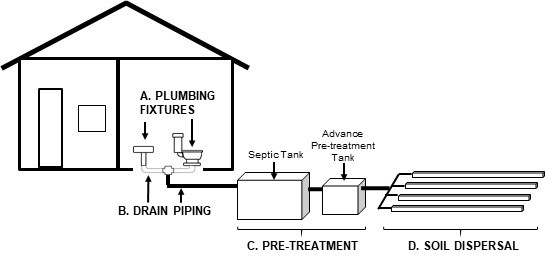

A Plumbing Fixture –Drain Piping–Pretreatment–Soil Dispersal Continuum

The first thing to remember with septic systems is that it is a “system” – meaning, each part contributes to the proper functioning of the whole. Thus, it is important to keep in mind that a septic system is a continuum of components composed of: A. the plumbing fixtures (sinks, tubs, toilets, etc.), B. the drain piping (pipes where sewage flows), C. pre-treatment tanks (septic tank and advanced pre-treatment tank), and D. the soil at the dispersal field (Figure 1).

While a problem in one component may be due to problems within that component, it is also possible that a malfunction in one component might be due to a problem in another. Here’s an example: a malfunction in the flushing mechanism in the toilet tank (running toilet) has led to water surfacing on the dispersal field. In this particular example, there is nothing wrong with the dispersal field, but water is ponded at the surface because the leaking toilet tank produced a much greater wastewater volume than the dispersal field can handle. It is therefore understood that in performing an inspection, one has to examine and assess the function of each component and how one component could affect the proper function of another.

When performing an inspection, we suggest that one must first observe initial (pre-test or baseline) conditions and then follow the flow of the water through each component. An inspector should begin with the assessment of the plumbing fixtures, followed by the evaluation of any visible drain piping (if possible), and then finally the observation of the pre-treatment tanks and the dispersal field.

II. Preparing for an Inspection/Evaluation

Before you begin, make sure you have a plan of how to go about the inspection process. It is best to have a checklist of what to do or better yet, to use a system evaluation form that serves both as an inspection guide and as a tool for documenting observations. Make sure that you have the necessary tools and materials. At the minimum, you need the following: a cordless drill (with screwdriver tips), disposable gloves, disposable face mask, bleach and hand sanitizer, safety glasses, probe, sludge judge-type sampler, a shovel or trowel, a camera and a measuring tape. You also want to bring a garden hose and a five-gallon bucket. In cases where the tank(s) are in a lawn or garden area where the residents and their pets frequently go, you may want to lay a tarp on the surface where you do most of the work. For safety and for ease in recording, it is best practice to have a companion when performing the evaluation.

Before you perform any septic system evaluation, make sure that everyone in the house is aware of what you will be doing. No household member should use any plumbing fixture in the house and/or go near any outdoor component while you are performing the evaluation.

Figure 1. Main components of a septic system. (Illustration by SM Abit)

III. Inspection of Plumbing Fixtures

The inspector could start with the two-way cleanout. Remove any debris in the cleanout that could hamper liquid flow. If water is running through the cleanout even if none of the plumbing fixtures are in use, an inspection of the sinks/toilets would be necessary. If allowed by the homeowner, the inspector can take a look at the plumbing fixtures of the house by focusing on possible leaking faucets and running toilets. If not granted access, the inspector should suggest to the homeowner that an inspection of the plumbing fixtures be performed by a certified plumber very soon. This can also be done by reviewing the leak indicator on the water meter if it is accessible and if the inspector has previous experience in doing that procedure.

IV. Location of Outdoor Components and Baseline Observations

It is best to conduct an inspection when the ground surface is dry. Prior to inspecting each outdoor component, an inspector should initially ascertain the location of the tank as well as the location of the trenches, spray heads, or subsurface driplines in the dispersal field. The inspector should note if there are any permanent structures, paving and/or landscaping located on the dispersal field. After locating the outdoor components, baseline observations should be performed on the following: 1) wetness of soil on or around the dispersal field, 2) presence and wetness of patches of grass that have a darker green color relative to the surroundings, 3) wetness at the general area of the tanks (particularly where the lids are located) and 4) the wetness at the general location of the clean-outs. Make notes and take pictures of observed baseline conditions including all locations of damp soil and/or standing water in the general location of the tank and the dispersal field.

How to locate outdoor tanks and the dispersal field?

Ideally, the inspector should acquire a copy of the approved on-site sewage treatment final inspection report. Should the homeowner not have a copy of the report, the Department of Environmental Quality’s (DEQ) Central Records office can be contacted to obtain a copy. This report should indicate the system type, date of installation, and the location of all system components (cleanouts, tanks, dispersal field). The tank for aerobic treatment systems is easy to locate because the lids should be two inches above ground-level. If the lids are not visible (like those of septic tanks of older conventional systems), you can use the following hints to locate the tank: 1) the location of the two-way cleanout should provide some idea of the general direction that the tank is located, 2) it is between the dispersal field and the house and 3) the grass on top of the tank may appear brown in relation to the rest of the grassy area. If none of these works, follow the sewer pipe from the house and stick a thin metal probe into the ground near the sewer line. Probe every two feet. Most septic tanks are located around 10 to 25 feet from the house and cannot be closer than 5 feet. Once you feel the probe striking flat concrete, fiberglass or composite plastic, you have likely located the tank. If unable to locate the tank, the use of a sewer camera and locater can be used. All newly installed septic tanks are now required to have the access lids installed two inches above ground-level.

The dispersal field is located after the pre-treatment tank(s). The location of the subsurface trenches or the drip-lines may be identified by the relatively darker green growth of grasses on them. The locations of the trenches may also be determined by probing the ground using a thin metal probe. Once you feel the probe hitting gravel or composite plastic (in the case of a chamber system), you have likely located the trenches. It is not recommended to probe drip lines due to their thin-walled piping. If not easily visible, the location of the sprinkler heads can be determined when the effluent pump is turned on.

V. Inspection of the Septic Tank

If the septic tank lids are accessible, open the lids while being mindful that fumes in the tank could be harmful. For safety, never put your head inside the tank. There is a risk of falling into the tank or breathing harmful fumes. You should initially inspect the integrity of the risers (in systems where risers are used) making sure they are watertight and not broken or cracked, and there is no water mark indicating that the water level has reached the risers. To check whether risers are watertight, use the hose to apply water just outside of the risers. If water from the hose leaks into the tank, it is a sign that rainwater could also seep into the tank. Do this for all risers.

The next thing to do is to inspect the inlet and outlet pipe baffles. At the minimum, make sure that the baffles are not clogged. If there is evidence that a lot of scum has entered the baffles or if there is toilet paper on top of it, then it is a sign that a backup has occurred at some point. You also need to observe the scum layer. Scum layers that appear like soil and may have organism growing on it (e.g. worms) is normal. Black scums devoid of any signs of life combined with a very strong foul odor could mean that chemicals or pharmaceuticals from the house may have adversely affected the population of organisms that are necessary in pre-treatment of sewage.

You also need to check the liquid level inside the tank. The liquid level at the outlet end of the tank should be equal to the bottom of the outlet pipe. Water level above the pipe could indicate that the outlet pipe may be blocked. On the other hand, if the water level is too low, then it could indicate that the tank could be leaking. Inspecting the sludge level in the tank is the next step. Using a sludge judge sampler or a comparable device will help in accurately determining the level of sludge build-up. The tank should be pumped empty if the sludge layer has built up to at least 1/3 of the liquid capacity of the tank. To assure proper handling and disposal of the septage, any tank pumping should be done by a licensed septic hauler. If it is a two-compartment tank, determine the sludge level in both compartments. The 2nd compartment (closer to outlet) should have significantly lesser sludge. When possible, take pictures of the top layer of the scum and the liquid level relative to the outlet pipe. For safety, cover access ports and fasten the lids with at least one screw before leaving the tanks to do further inspection.

In aerobic treatment systems, the septic tank or the trash tank is simply the first compartment in a multi-chamber tank. The above discussions should also generally apply to the inspection of the trash tank in a multi-chamber tank.

VI. The Water Stress Test

It should be noted that there are no state guidelines about how to perform a water stress test on a septic system. We are simply describing one way to perform this test, and this is not meant to be a method that applies to all systems and situations.

Turn on the water in the bathtub for 30 minutes. Bathtubs usually flow at a rate of five gallons per minute. Over the course of 30 minutes, approximately 150 gallons of water will have flown through the system – equivalent to around ½ of the daily water use of most houses. Once you observe that the water in the tub is effectively draining, go outside to check the two-way cleanout to see if water is running through it. Reopen the lids of the septic tank to check if liquid is effectively flowing from the inlet to the outlet end of the tank. Pay particular attention to the liquid level at the outlet pipe while the liquid is flowing. If the liquid level goes above the outlet pipe, this indicate that there is a blockage in the outlet pipe and/or the lines at the dispersal field.

For conventional systems, inspect the drain field, giving particular attention to any possible damp soil or standing water. Use the digital photos taken earlier (during the baseline inspection) to assess whether there is indeed an increase in wetness following the onset of the water stress test. After the test, make sure you secure the lids of the septic tank and turn off the water in the bathtub.

VII. Inspection of the Components of an Aerobic Treatment System

The Control Panel and Timer

Open the control panel and closely inspect the integrity of the connections. When possible, check if the alarm sound and light works. Check for accumulation of debris, rust or corrosion, and accumulation of moisture in the control panel. Check if the on-off switch works. If you are proficient with the brand and model of the system, set the timer to a few minutes ahead of the current time to determine if the timer works to drive the system. Don’t forget to reset the timer to spray ac-cording to state regulations. Make sure that you also perform other tests needed or applicable for the brand and model of the control panel you are inspecting.

The Aerator

Check the aerator for an accumulation of dirt and debris. Using an appropriate gauge, determine the air flow rate coming out of the aerator. Determine whether the flow reading is within the optimum range for the aerator brand and model.

The Aeration Chamber/Tank

The first thing to check in the aeration chamber is the odor. If you smell a strong pungent odor similar to the smell of the trash tank, this may be an indicator that the aeration components are not working well. If the design of the tank al-lows, check if bubbles are produced in the aeration chamber. For some systems, you can pull-up the diffuser and check for any solid accumulation that blocks the air from bubbling-out. If there is no evidence of blockage of the air path yet bubbling is limited, this could mean that there is something wrong with the aerator pump. Do not forget to check the level of sludge accumulated in the aeration chamber. Different brands/models have different limits on the thickness of the sludge in the aeration chamber. Make sure you are familiar with those limits.

The Pump Tank

Open the pump tank and initially check the electrical connections making sure that they are fastened tightly. Some systems have a junction box. Check the junction box for any signs of corrosion. Check if the liquid level in the tank is where it is supposed to be and if there are visible leaks in the discharge pipe. You also don’t want solids floating in the pump tank and wires touching the floats as they could affect how the floats work. Actuate the floats to trigger the pumps and alarms. You need to do three tests: Test 1: Actuate the pump float (bottom float) to check the pump in conjunction with the timer. Test 2: Raise the pump float, then actuate the override float (middle float). This should override the timer and cause the pump to turn on. Test 3: Check if the high-water alarm works by raising the high-water alarm float (top-most float). The alarm should be triggered by raising the top-most float. Take note that some systems use sensors in place of mechanical floats. Therefore, it is very important that the inspector is familiar with the parts and mechanisms involved in the brand and model of the system being inspected. Ideally, the pump tank should not have sludge built-up in it. It is also recommended that a clarity test on the water in the pump tank be performed using a secchi disc.

Disinfectant

In systems where effluent is sprayed on the soil surface as a method of dispersal, the addition of a disinfectant to the effluent is required. Some systems have a liquid chlorine (bleach) chamber while some use bleach tablets that need to be periodically added to the effluent. Check whether there is enough liquid bleach or tablets. A chlorine test kit may be used to confirm proper chlorine levels in the effluent of the pump tank.

The Sprinkler or Drip Dispersal System

While manipulating the floats in the pump tank, observe if the sprinkler heads pop-up and disperse effluent while the pump is turned on. Pay close attention to the pattern of dispersal and the surface area covered by a sprinkler head. Also, pay attention to possible overlaps in the dispersal area of each sprinkler head taking note that overlaps are alright if the system was designed and approved to have some overlaps. After pumping the liquid, walk on the drain field and check for visible signs of water pooling on the surface. In systems where the effluent is dispersed by subsurface drip, take note if surfacing of the effluent occurs. Excessive surfacing of the effluent at a particular spot could indicate a major leak in the drip lines.

VIII. Safety

Household wastewater has contaminants that are possible environmental and health hazards. It is very important that the inspector takes every step to protect himself and the homeowner from possible illnesses caused by pathogens or chemicals in the wastewater. The inspector should use disposable masks when appropriate, use disposable gloves, replace the gloves often and use a hand sanitizer before touching anything in the house. It is also important to make sure that any tool or material that touched the sewage should be cleaned or disposed of as appropriate. We suggest that tools be rinsed/cleaned with 1:5 bleach-to-water solution. The rinsing solution should be disposed of appropriately and should not be dumped within the property of the homeowner. The inspector must also inform the homeowner of any spill or possible safety concerns.

IX. Reporting

The completed inspection report should include the system type, inspection time and date, integrity of all components, key observations and a list of recommended repairs or replacements to improve or maintain the effective and safe functioning of the system. It is suggested that inspection reports be attached to any available DEQ documents related to the inspected system.