Nutritive Value of Feeds

Introduction

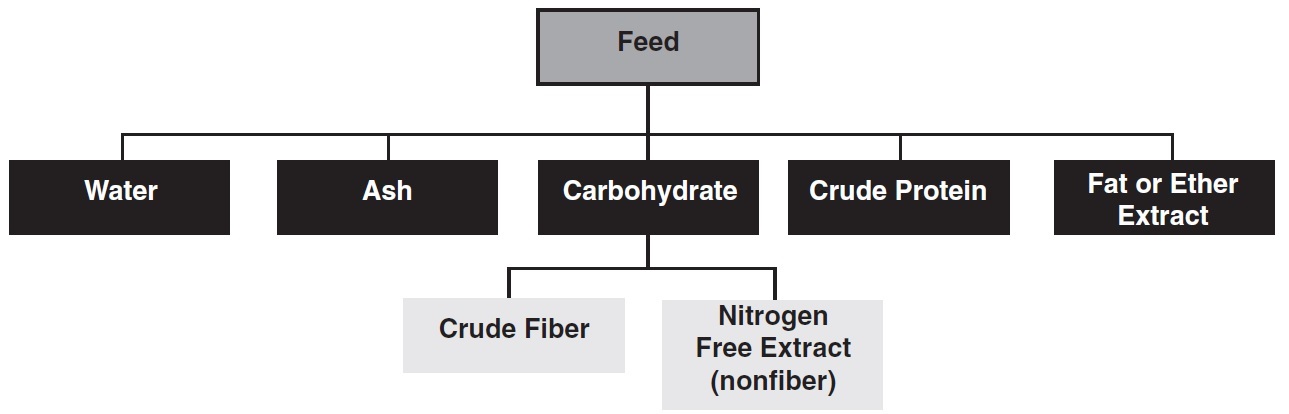

Animals require consumption of chemical elements and compounds to sustain bodily functions to support the reproductive process and for skeletal and tissue growth. The necessary chemical elements and compounds are referred to as nutrients and can be classified into six categories: water, carbohydrates, lipids or fats, proteins, minerals and vitamins. The objective of feed evaluation is to provide a rapid and economical method to determine the nutrients available (nutritional value) of a feed. For more than 100 years, the proximate analysis system has been used to describe the chemical composition of feeds. Components of proximate analysis are shown in Figure 1.

Nutritional value is determined by nutrient concentration and nutrient digestibility. Proximate analysis is one method used to determine nutrient concentration, although very little information about nutrient digestibility is gained. True nutrient digestibility information is determined using digestion trials, but it is not practical to test digestibility on all feeds. Therefore, previous digestibility information from similar feeds and previous relationships between digestibility and some nutrient concentration measures is commonly used to estimate digestibility. Table 1 contains average nutrient concentration values for numerous feeds that can be used in cattle diets. Values in the table represent averages from numerous different sources, such as the National Academy of Sciences, Engineering and Medicine’s, Nutrient Requirements of Beef and Dairy Cattle publications, commercial laboratories, research trials and other publications.

Producers must recognize values published in any table are merely averages. Variation among grains, oilseeds, byproducts and, in particular, forages and roughages, can be extreme. Furthermore, various processing methods also may alter digestibility. For this reason, producers are advised to have their feeds and forages tested for nutrient composition by a feed testing laboratory. To improve quality control and standardization among commercial laboratories, the National Forage Testing Association (NFTA), found at foragetesting.org, provides a unique certification service. At this website, one also can view the NFTA’s recommendations for laboratory procedures and equations for use in predicting energy availability for different forage types.

Figure 1. Nutrient components of feed determined from proximate analysis.

Wet chemistry procedures are more expensive, although they represent the standard for nutritive values. Many laboratories will offer both. One of the primary decisions to make is whether to use wet chemistry procedures and Near Infrared Reflectance Spectrophotometer (NIRS) procedures to determine protein and energy values.

NIRS analyses are less expensive. Basically, random portions of a sample are loaded into an NIR sample holder and reflected light from the ground sample is measured in the infrared region (generally 1,100 nm to 2,500 nm). The NIRS instrument is part of a system calibrated by using representative samples from the population (forage type) to be tested. Prediction equations are selected based on calibration statistics. Consequently, it is important to know whether the laboratory is using equations developed with forage similar to that which you intend to have tested. For example, since alfalfa hay is common across the country, most laboratories use equations specifically designed to determine protein and energy content of alfalfa hay. However, grass and other legume species can vary widely in cell structure and chemical composition. Generally, NIRS is less costly because it predicts wet chemistry values by bouncing light through samples. With this type of analysis, the lab should have a list of types of feed samples they can analyze by this method. For instance, most labs can perform quality NIRS analysis on alfalfa samples. Consider having wet chemistry analysis completed on feeds that the laboratory has not calibrated for NIRS.

Dry Matter

Dry matter (DM) expresses the proportion of the feed that is not water. The moisture concentration is determined by weighing the feed sample soon after it has been collected. Next, the sample is placed in a drying oven until all of the water has evaporated. Finally, the dried sample is weighed again and the DM content is calculated by the difference. Other than physical characteristics of the feed, moisture content has little to no bearing on the availability of nutrients within that feed.

Dry matter is an extremely variable component among and within types of feeds. Fresh forages, silages and wet byproduct feeds are likely to vary the most in DM content. Some silages and byproduct feeds contain as little as 25% DM (75% moisture). A good rule of thumb is that dry feeds should contain no more than 12% moisture for safe long-term storage in bins.

Fiber

The original proximate analysis system separated carbohydrates into crude fiber and nitrogen-free extract (NFE) fractions. The crude fiber portion of the feedstuff was intended to represent the indigestible fiber fraction, while NFE was supposed to represent the more readily digestible carbohydrates, such as sugars and starches. However, it was soon discovered this system had serious limitations, particularly for fibrous feeds like forages.

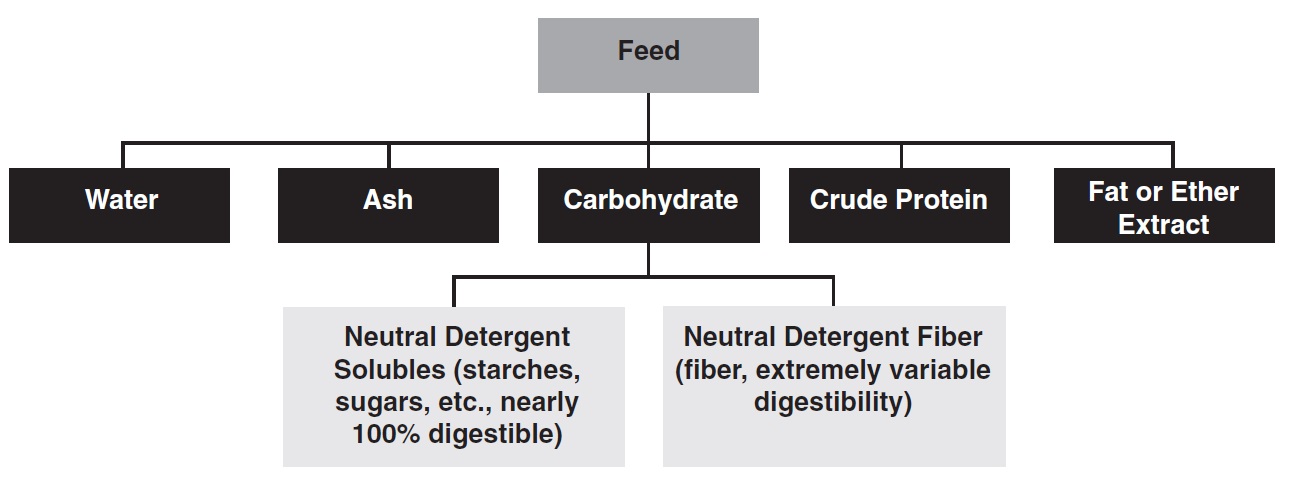

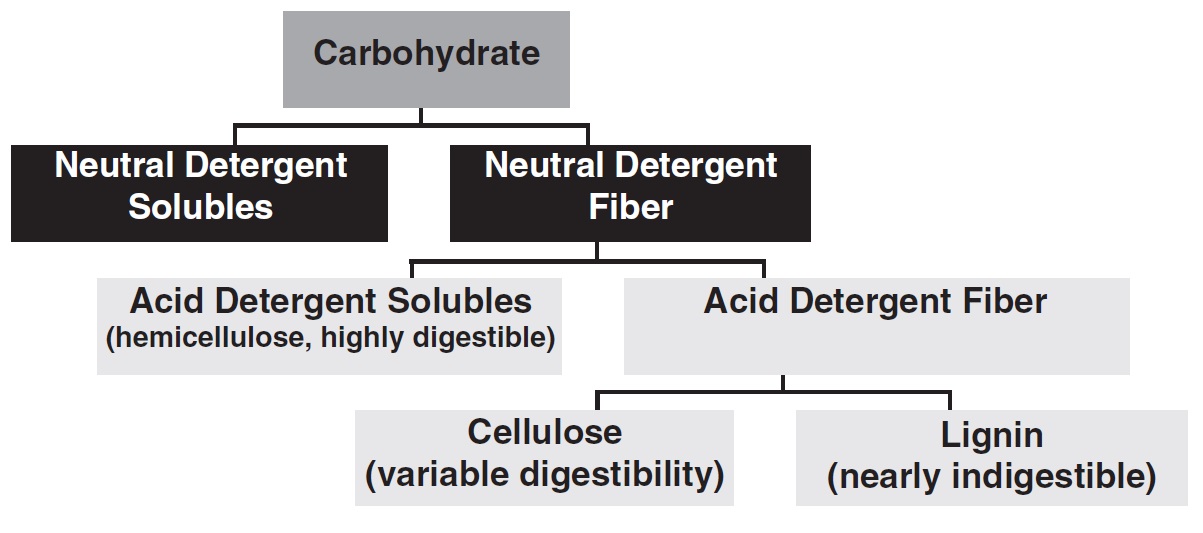

Because of the wide variation in chemical analyses for crude fiber and NFE, a new system called the detergent fiber system was developed, which better reflects true carbohydrate digestibility in ruminants (Figure 2). The neutral detergent solubles (NDS) fraction is comprised of cell contents that are nearly 100% digestible. The neutral detergent insoluble fiber (NDF) fraction is primarily cell wall tissue, which consists of hemicellulose, cellulose and lignin. The NDF fraction also contains small amounts of silica and fiber-bound or heat-damaged protein. The NDF fraction of feeds and forages is quite variable in digestibility. Using an acid solution, the NDF residue can be further separated into acid detergent solubles (ADS; primarily hemicellulose) and acid detergent insoluble fiber (Figure 3). The acid detergent insoluble fiber fraction contains cellulose and lignin. The lignin portion is nearly indigestible, whereas the cellulose portion is variable in digestibility.

With purchased feeds that come with a feed tag, crude fiber is the only fiber analysis required. Unfortunately, this provides little assistance in determining the nutrient value or digestibility of the feed. However, it may be possible for a feed representative to provide NDF and ADF values. NDF concentration is inversely related to the amount of the feed the cattle will eat. Because digestibility of fiber is proportional to the amount of lignin in the plant material, ADF is inversely related to the digestibility of feed ingredients. This relationship explains why some forages and feeds contain high NDF concentrations, but remain high in digestibility, while others may contain moderate or low NDF concentrations, yet are low in digestible energy.

Figure 2. The detergent fiber system.

Effective NDF

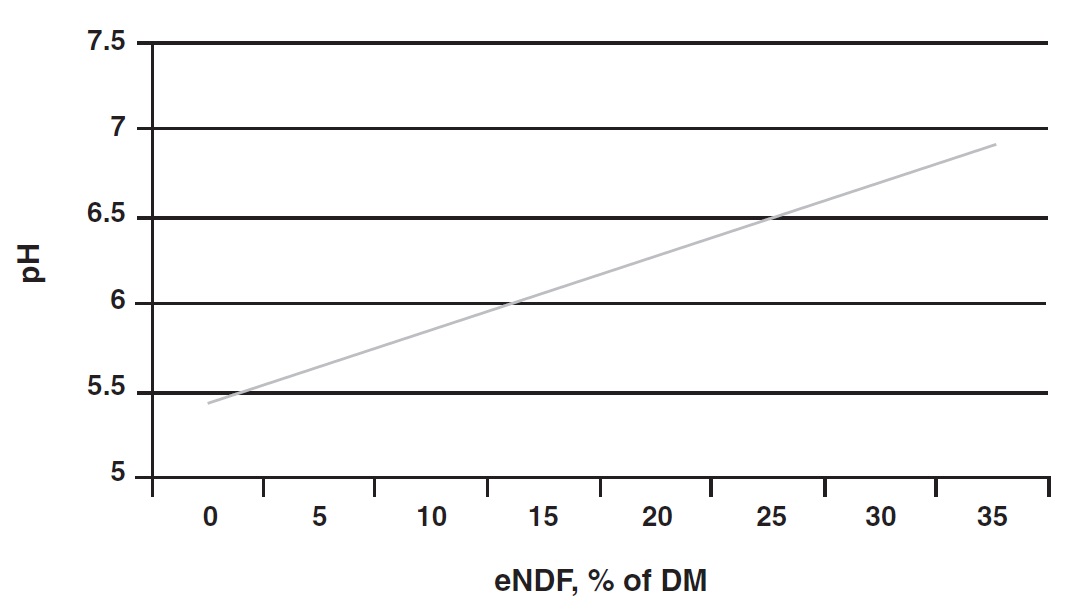

The physical effectiveness factor (pef) value shown in Table 1 is a measure of the feed particle size and an indication of its potential to stimulate chewing. NDF is effective in stimulating rumen motility or churning (Figure 4). The physical effectiveness factor ranges from 0 to 1.0. This factor is multiplied by the NDF concentration to determine the physically effective NDF content of the feed (peNDF). Long-stem grass hay has a pef of 1.0 and other feeds are rated relative to grass hay according to particle size. Most of the pef values provided in Table 1 are estimates based on particle size and nDF content.

For example, chopped alfalfa haylage has NDF of 42% (dry matter basis) and pef of 0.6. Therefore the peNDF value is 25.2%. From there, average diet peNDF is calculated and used to predict ruminal pH. Diets containing lower peNDF and lower ruminal pH require more intensive management due to increasing risk of acidosis, bloat and founder. Between 12% and 20% peNDF is recommended for growing cattle and for limit-fed diets (NASEM 2016). The layman term for eNDF is the scratch value of the feed. If the rumen stops churning, acidic gases build up causing the pH to drop. The result is bloat, acidosis and/or founder, as well as reduced diet digestibility. Table 1 expresses eNDF as a percentage of NDF. This value is determined by several factors including particle size, density, hydration and degree of lignification. To maintain optimal forage digestion, the diet should contain a minimum of 20% eNDF on a DM basis.

Protein

Protein values in Table 1 reflect CP, which is simply nitrogen concentration multiplied by 6.25. The rumen degradable intake protein (RDIP) column is an estimate of the proportion of the crude protein that is actually degradable in the rumen and is expressed as a percentage of CP. Rumen undegradable protein (percent of CP) can be calculated by subtracting the RDIP value from 100.

Figure 3. Fiber fractions in the detergent fiber system.

Figure 4. The relationship of effective NDF and rumen pH.

Feed Energy Values

Feed energy values are expressed on a DM basis as percent total digestible nutrients (TDN), net energy for maintenance (NEm) and net energy for gain (NEg) units (mega calories per 100 pounds of feed). TDN is determined by carrying out a digestion trial and summing the digestible protein and carbohydrates plus 2.25 times digestible ether extract. Ether extract (EE) is the fat or lipid portion of the feed. The net energy system is generally thought to be more precise in estimating the energy value of feeds, particularly roughages. The net energy of feed is the portion available to the animal for maintenance or various productive purposes. The portion used for maintenance (NEm) is used for muscular work, maintenance and repair of tissues, maintaining a stable body temperature and other body functions. Most of this digested energy will leave the animal’s body as heat. Energy used for productive purposes (NEg) may be recovered as growth through retaining energy in tissues. Energy for productive purposes is less efficient than energy used for maintenance. Milk production is unique because its energy efficiency is similar to maintenance uses.

Minerals

Minerals needed by animals in larger quantities are referred to as macro minerals. These minerals are shown in Table 1 and feed concentration is expressed on a percent of DM basis. Minerals needed by animals in much smaller quantities are referred to as micro minerals and feed concentration is expressed in parts per million (ppm) in Table 1. To convert ppm to percent, simply move the decimal place four places to the left. For example, if a feed contained 12 ppm copper, the copper concentration expressed as a percentage would be 0.0012%.

Conclusion

Producers need to ensure their animals’ diets include the proper balance of the six essential nutrients in a physical form that maintains digestive system health and function. To accomplish this, producers must have good knowledge of available feed nutrient composition, physical and digestive characteristics and the animal’s nutrient requirements.

Nutrient concentration and digestibility data can be determined by using digestion trials or measuring chemical composition and applying this information to estimate digestibility. It is imperative producers recognize the values published in any table are merely averages and variation among feed commodities, oilseeds and, in particular forages and roughages, can be extreme. For this reason, producers are advised to have their feeds and forages tested for nutrient composition by commercial laboratories.

References

2014 Feed Composition Guide. (2014) Beef. Retrieved from Beef Magazine

NRC. (2000) Nutrient Requirements of Beef Cattle (7th Edition). National Academy Press, Washington, DC.

National Academy of Sciences, Engineering and Medicine (NASEM). Nutrient Requirements of Beef Cattle (8th Revised Edition), 2016.

Table 1. Typical composition of feeds and forages.

| FEEDSTUFF | DM % |

CP % |

DIP % of CP |

TDN % |

NEm (Mcal/cwt.) |

|---|---|---|---|---|---|

| Alfalfa hay, early bloom | 88 | 20 | 80 | 63 | 66 |

| Alfalfa hay, midbloom | 88 | 18 | 80 | 60 | 60 |

| Alfalfa hay, mature | 88 | 14 | 75 | 52 | 47 |

| Barley hay | 91 | 10 | 59 | 54 | 28 |

| Bermuda hay, vegetative | 90 | 15 | 80 | 57 | 55 |

| Bermuda hay, early bloom | 90 | 10 | 72 | 53 | 49 |

| Bermuda hay, full bloom | 90 | 8 | 68 | 47 | 39 |

| Bermuda hay, mature | 88 | 6 | 70 | 49 | 42 |

| Birdsfoot trefoil, hay | 89 | 16 | 78 | 57 | 57 |

| Bromegrass hay | 89 | 10 | 80 | 55 | 55 |

| Clover ladino hay | 90 | 21 | 75 | 61 | 62 |

| Clover red hay | 88 | 15 | 72 | 55 | 55 |

| Clover sweet hay | 91 | 16 | 70 | 53 | 53 |

| Corn stover (stalk hay) | 85 | 6 | 70 | 50 | 44 |

| Corn, whole hay | 88 | 7.5 | 61 | 70 | 0.74 |

| Fescue hay, early bloom | 87 | 15 | 72 | 59 | 59 |

| Fescue hay, full bloom | 88 | 9 | 68 | 50 | 52 |

| Lespedeza hay | 92 | 14 | 40 | 54 | 54 |

| Meadow hay | 90 | 7 | 77 | 50 | 50 |

| Millet hay | 92 | 11 | 75 | 53 | 45 |

| Milo stalk hay | 90 | 4 | — | 49 | 50 |

| Milo-soybean hay | 90 | 11 | 72 | 55 | 48 |

| Oat hay | 91 | 9 | 75 | 59 | 53 |

| Oat straw | 91 | 4 | 60 | 48 | 48 |

| Orchardgrass hay | 88 | 10 | 73 | 59 | 59 |

| Old world bluestem hay, early bloom | 90 | 10 | — | 58 | 59 |

| Old world bluestem hay, mature | 90 | 6 | 51 | 52 | 25 |

| Peanut hay | 91 | 11 | — | 57 | 54 |

| Peavine hay | 91 | 13 | — | 57 | 52 |

| Prairie hay | 91 | 6 | 63 | 52 | 50 |

| Rice hay | 93 | 7 | 70 | 55 | 48 |

| Rice straw | 91 | 4 | 100 | 40 | 42 |

| Rye grass hay | 90 | 10 | 70 | 58 | 58 |

| Rye straw | 89 | 4 | 100 | 44 | 44 |

| Sorghum hay | 91 | 10 | — | 55 | 47 |

| Sorghum-sudan, hay | 92 | 11 | 100 | 54 | 46 |

| Soybean hay | 92 | 15 | 100 | 60 | 57 |

| Soybean straw/residue | 88 | 5 | 100 | 42 | 43 |

| Sudan hay, boot stage | 91 | 9 | 70 | 58 | 54 |

| Sudan hay, mature | 91 | 5 | — | 52 | 52 |

| Sugarcane hay | 92 | 6 | 70 | 50 | 38 |

| Sunfower hay | 90 | 7 | 70 | 64 | 68 |

| Timothy hay, early bloom | 88 | 11 | 78 | 59 | 59 |

| Timothy hay, full bloom | 88 | 8 | 75 | 57 | 57 |

| Triticale hay | 91 | 11 | 80 | 59 | 53 |

| Wheat hay, immature | 87 | 12 | 75 | 58 | 70 |

| Wheat hay, mature | 88 | 9 | 75 | 48 | 56 |

| Wheat straw | 89 | 4 | 40 | 41 | 29 |

| Wheat straw, ammoniated | 85 | 9 | 75 | 50 | 50 |

| FEEDSTUFF | NEg (Mcal/cwt.) | NDF % |

pefa % |

ADF % |

EE % |

|---|---|---|---|---|---|

| Alfalfa hay, early bloom | 38 | 45 | 0.7 | 34 | 3.0 |

| Alfalfa hay, midbloom | 34 | 46 | 0.8 | 34 | 2.6 |

| Alfalfa hay, mature | 22 | 47 | 0.9 | 36 | 1.3 |

| Barley hay | 58 | 98 | 0.8 | 35 | |

| Bermuda hay, vegetative | 29 | 69 | 0.7 | 37 | 2.3 |

| Bermuda hay, early bloom | 24 | 75 | 0.8 | 37 | 1.9 |

| Bermuda hay, full bloom | 15 | 79 | 0.9 | 36 | 1.8 |

| Bermuda hay, mature | 18 | 78 | 0.9 | 39 | 3.8 |

| Birdsfoot trefoil, hay | 25 | 50 | 0.8 | 38 | 2.2 |

| Bromegrass hay | 21 | 66 | 0.8 | 41 | 2.3 |

| Clover ladino hay | 31 | 36 | 0.7 | 32 | 2.0 |

| Clover red hay | 21 | 51 | 0.7 | 39 | 2.5 |

| Clover sweet hay | 18 | 50 | 0.8 | 38 | 2.4 |

| Corn stover (stalk hay) | 19 | 67 | 1.0 | 39 | 1.3 |

| Corn, whole hay | 0.46 | 43 | 1.0 | 25 | 2.8 |

| Fescue hay, early bloom | 29 | 68 | 0.8 | 31 | |

| Fescue hay, full bloom | 16 | 73 | 0.9 | 42 | 3.5 |

| Lespedeza hay | 20 | 65 | 0.8 | — | 3.0 |

| Meadow hay | 12 | 70 | 0.8 | 44 | 2.5 |

| Millet hay | 20 | 63 | 0.8 | 40 | 1.7 |

| Milo stalk hay | 16 | 78 | 1.0 | — | |

| Milo-soybean hay | 23 | 58 | 0.9 | 35 | 1.5 |

| Oat hay | 28 | 59 | 0.8 | 38 | 2.3 |

| Oat straw | 9 | 73 | 1.0 | 48 | 2.3 |

| Orchardgrass hay | 28 | 67 | 0.8 | 40 | 3.3 |

| Old world bluestem hay, early bloom | 34 | — | 0.8 | — | 2.8 |

| Old world bluestem hay, mature | — | — | 0.8 | — | 2.4 |

| Peanut hay | 28 | 49 | 0.8 | 39 | 2.8 |

| Peavine hay | 27 | 47 | 0.9 | 35 | 2.1 |

| Prairie hay | 12 | 73 | 0.9 | 47 | 2.0 |

| Rice hay | 23 | 60 | 1.0 | 41 | 1.8 |

| Rice straw | 0 | 72 | 1.0 | 47 | 1.4 |

| Rye grass hay | 26 | 65 | 0.9 | 39 | 3.3 |

| Rye straw | 1 | 71 | 1.0 | 55 | 1.5 |

| Sorghum hay | 22 | 62 | 1.0 | 40 | 1.8 |

| Sorghum-sudan, hay | 21 | 64 | 1.0 | 40 | 1.8 |

| Soybean hay | 31 | 47 | 0.9 | 37 | 2.3 |

| Soybean straw/residue | 0 | 70 | 1.0 | 54 | 1.4 |

| Sudan hay, boot stage | 26 | 67 | 0.8 | 43 | 2.6 |

| Sudan hay, mature | 24 | 68 | 1.0 | 44 | 2.4 |

| Sugarcane hay | 16 | 66 | 1.0 | 43 | 1.9 |

| Sunfower hay | 41 | 55 | 1.0 | 43 | |

| Timothy hay, early bloom | 28 | 63 | 0.8 | 39 | 2.7 |

| Timothy hay, full bloom | 25 | 65 | 0.9 | 40 | 2.6 |

| Triticale hay | 27 | 59 | 0.8 | 38 | 2.1 |

| Wheat hay, immature | 40 | 66 | 0.8 | 38 | 2.2 |

| Wheat hay, mature | 31 | 58 | 0.9 | 42 | 2.1 |

| Wheat straw | 5 | 81 | 1.0 | 58 | 1.8 |

| Wheat straw, ammoniated | 12 | 76 | 0.9 | 55 | 1.5 |

| Standing forage/Pasture/Green chop | DM % |

CP % |

DIP % of CP |

TDN % |

NEm (Mcal/cwt.) |

|---|---|---|---|---|---|

| Alfalfa | 24 | 19 | 82 | 61 | 62 |

| Barley forage | 38 | 14 | — | 62 | 60 |

| Bermuda, vegetative | 30 | 16 | 85 | 65 | 67 |

| Bermuda, boot stage | 35 | 13 | 75 | 60 | 59 |

| Bermuda, fall, mature | 80 | 8 | 60 | 48 | 41 |

| Bermuda, winter, mature | 90 | 5 | 55 | 44 | 34 |

| Bermuda, stockpiled, Nov.-Dec. |

85 | 11 | 65 | 54 | 50 |

| Bermuda, stockpiled, Sep.-Oct. |

35 | 13 | 70 | 57 | 55 |

| Bermuda, stockpiled, Jan.-Feb. | 90 | 7 | 60 | 47 | 39 |

| Birdsfoot trefoil | 22 | 21 | 80 | 66 | 68 |

| Bluestem, mature | 61 | 6 | 100 | 50 | 50 |

| Brassica, immature | 24 | 19 | — | 68 | 71 |

| Brassica, mature | 32 | 13 | — | 79 | 88 |

| Bromegrass | 30 | 15 | 88 | 64 | 65 |

| Cheatgrass | 21 | 16 | 100 | 68 | 70 |

| Clover ladino | 19 | 25 | 80 | 69 | 71 |

| Clover red | 24 | 18 | 79 | 64 | 65 |

| Corn forage | 37 | 8 | — | 72 | 75 |

| Corn stalks | 39 | 7 | — | 53 | 43 |

| Fescue, vegetative | 29 | 18 | 80 | 64 | 65 |

| Fescue, boot stage | 33 | 12 | 75 | 57 | 55 |

| Fescue, mature | 70 | 8 | 70 | 49 | 42 |

| Fescue, stockpiled, Nov.-Dec. | 40 | 13 | 75 | 52 | 47 |

| Fescue, stockpiled, Jan.-Feb. | 60 | 11 | 68 | 40 | 27 |

| Fodder, oat | 13 | 18 | 82 | 70 | 76 |

| Fodder, wheat | 24 | 18 | 82 | 83 | 92 |

| Fodder, wheat, short germination | 12 | 24 | 82 | 68 | 71 |

| Legume pasture | 56 | 27 | — | 68 | 72 |

| Lespedeza | 25 | 16 | 50 | 60 | 60 |

| Millet forage | 38 | 16 | — | 60 | 55 |

| Native range, Jan.-March | 85 | 4 | 55 | 49 | 42 |

| Native range, April-June | 30 | 14 | 75 | 70 | 74 |

| Native range, July-Aug. | 35 | 10 | 70 | 64 | 65 |

| Native range, Sept.-Oct. | 46 | 7 | 65 | 59 | 58 |

| Native range, Nov.-Dec. | 75 | 5 | 65 | 55 | 52 |

| Oat forage | 39 | 17 | 80 | 63 | 62 |

| Orchardgrass | 24 | 14 | 77 | 65 | 66 |

| Peanut forage | 26 | 20 | — | 61 | 60 |

| Peavine forage | 42 | 20 | — | 65 | 66 |

| Pineapple forage | 38 | 8 | — | 59 | 55 |

| Rye forage | 41 | 20 | 70 | 66 | 67 |

| Sorghum forage | 44 | 9 | — | 62 | 58 |

| Sorghum stover | 87 | 5 | 100 | 54 | 54 |

| Sorghum-sudan forage | 67 | 13 | 71 | 63 | 60 |

| Soybean forage | 74 | 19 | — | 62 | 60 |

| Sudangrass, mature | 36 | 12 | 72 | 58 | 52 |

| Sudangrass, immature | 18 | 17 | 100 | 70 | 73 |

| Sunflower | 18 | 13 | — | 66 | 70 |

| Timothy | 26 | 11 | 80 | 64 | 65 |

| Triticale forage | 34 | 15 | 85 | 63 | 61 |

| Wheat forage | 21 | 22 | 84 | 71 | 76 |

| Standing forage/Pasture/Green chop | NEg (Mcal/cwt.) | NDF % |

pefa % |

ADF % |

EE % |

|---|---|---|---|---|---|

| Alfalfa | 31 | 46 | 0.41 | 34 | 3.0 |

| Barley forage | 34 | 54 | — | 33 | 3.3 |

| Bermuda, vegetative | 40 | 68 | 0.80 | — | 3.0 |

| Bermuda, boot stage | 33 | 72 | 1.0 | — | 2.7 |

| Bermuda, fall, mature | 16 | 77 | 1.0 | — | 2.1 |

| Bermuda, winter, mature | 10 | 80 | — | — | 1.5 |

| Bermuda, stockpiled, Nov.-Dec. |

25 | 74 | 1.0 | — | 2.1 |

| Bermuda, stockpiled, Sep.-Oct. |

29 | 70 | 1.0 | — | 2.5 |

| Bermuda, stockpiled, Jan.-Feb. | 15 | 77 | 1.0 | — | 1.5 |

| Birdsfoot trefoil | 38 | 47 | 0.8 | 31 | 4.4 |

| Bluestem, mature | 12 | 1.0 | 5.0 | ||

| Brassica, immature | 44 | 26 | 0.8 | 21 | 4.2 |

| Brassica, mature | 59 | 22 | 0.9 | 20 | 0.9 |

| Bromegrass | 36 | 54 | 0.8 | 33 | 4.1 |

| Cheatgrass | 41 | 68 | 0.9 | 2.7 | |

| Clover ladino | 43 | 35 | 0.6 | 33 | 4.8 |

| Clover red | 36 | 44 | 0.6 | 33 | 4.0 |

| Corn forage | 48 | 42 | 0.9 | 24 | 2.9 |

| Corn stalks | 18 | 67 | — | 44 | 1.6 |

| Fescue, vegetative | 39 | 60 | 0.7 | 32 | 4.5 |

| Fescue, boot stage | 29 | 65 | 0.8 | 31 | 3.8 |

| Fescue, mature | 18 | 74 | 0.9 | 42 | 3.2 |

| Fescue, stockpiled, Nov.-Dec. | 22 | 72 | 0.8 | 36 | 2.7 |

| Fescue, stockpiled, Jan.-Feb. | 3 | 75 | 0.9 | 37 | 2.2 |

| Fodder, oat | 49 | 30 | 0.8 | 7 | 7.0 |

| Fodder, wheat | 62 | 31 | 0.8 | 6 | 7.0 |

| Fodder, wheat, short germination | 44 | 31 | 0.7 | 27 | 7.0 |

| Legume pasture | 44 | 33 | 0.7 | 24 | 3.7 |

| Lespedeza | 30 | 60 | 0.7 | — | 2.0 |

| Millet forage | 29 | 60 | 0.8 | 36 | 2.5 |

| Native range, Jan.-March | 18 | 80 | 1.0 | — | 1.7 |

| Native range, April-June | 47 | 68 | 1.0 | — | 3.2 |

| Native range, July-Aug. | 39 | 71 | 1.0 | — | 3.0 |

| Native range, Sept.-Oct. | 32 | 75 | 1.0 | — | 2.5 |

| Native range, Nov.-Dec. | 26 | 78 | 1.0 | — | 2.2 |

| Oat forage | 36 | 52 | 0.7 | 33 | 3.8 |

| Orchardgrass | 37 | 54 | 0.8 | 32 | 4.0 |

| Peanut forage | 34 | 50 | 0.7 | 36 | 0.0 |

| Peavine forage | 39 | 43 | 0.8 | 32 | 3.4 |

| Pineapple forage | 29 | 57 | 0.9 | 33 | 1.9 |

| Rye forage | 40 | 50 | 0.8 | 30 | 4.2 |

| Sorghum forage | 32 | 56 | 0.9 | 34 | 2.2 |

| Sorghum stover | 20 | 65 | 1.0 | 41 | 1.8 |

| Sorghum-sudan forage | 33 | 60 | 1.0 | 35 | 2.6 |

| Soybean forage | 34 | 44 | 0.8 | 32 | 3.8 |

| Sudangrass, mature | 27 | 62 | 1.0 | 38 | 2.7 |

| Sudangrass, immature | 44 | 55 | 0.8 | 29 | 3.9 |

| Sunflower | 43 | 40 | 0.9 | 29 | 6.3 |

| Timothy | 36 | 59 | 0.8 | 36 | 3.8 |

| Triticale forage | 35 | 55 | 0.8 | 33 | 2.9 |

| Wheat forage | 48 | 50 | 0.7 | 30 | 4.0 |

| Standing forage/Pasture/Green chop | Ca % |

P % |

S % |

Cu ppm | Mn ppm | Zn ppm | Se ppm |

|---|---|---|---|---|---|---|---|

| Alfalfa | 1.35 | 0.27 | 0.29 | — | — | 18 | — |

| Barley forage | 0.44 | 0.34 | 0.19 | 8 | 36 | 40 | — |

| Bermuda, vegetative | 0.46 | 0.31 | 0.33 | 13 | 185 | 32 | 0.12 |

| Bermuda, boot stage | 0.59 | 0.28 | 0.30 | 12 | 160 | 36 | 0.12 |

| Bermuda, fall, mature | 0.26 | 0.18 | 0.21 | 9 | 140 | 20 | 0.05 |

| Bermuda, winter, mature | 0.30 | 0.15 | 0.15 | 7 | 45 | 15 | 0.05 |

| Bermuda, stockpiled, Nov.-Dec. |

0.52 | 0.22 | 0.27 | 5 | 117 | 26 | 0.05 |

| Bermuda, stockpiled, Sep.-Oct. |

0.66 | 0.24 | 0.26 | 6 | 151 | 27 | 0.05 |

| Bermuda, stockpiled, Jan.-Feb. | 0.48 | 0.18 | 0.25 | 4 | 116 | 26 | 0.05 |

| Birdsfoot trefoil | 1.78 | 0.25 | 0.25 | — | — | 31 | — |

| Bluestem, mature | 0.40 | 0.12 | 0.05 | — | — | 28 | — |

| Brassica, immature | 1.71 | 0.39 | 0.60 | 8 | 52 | 70 | — |

| Brassica, mature | 0.97 | 0.33 | 0.43 | 4 | 27 | 30 | — |

| Bromegrass | 0.45 | 0.34 | 0.21 | — | — | 20 | — |

| Cheatgrass | 0.60 | 0.28 | — | — | — | — | — |

| Clover ladino | 1.27 | 0.38 | 0.20 | — | — | 20 | — |

| Clover red | 1.70 | 0.30 | 0.17 | — | — | 23 | — |

| Corn forage | 0.21 | 0.22 | 0.09 | 6 | 28 | 23 | — |

| Corn stalks | 0.33 | 0.16 | 0.08 | 8 | 57 | 25 | — |

| Fescue, vegetative | 0.50 | 0.40 | 0.24 | 13 | 175 | 36 | — |

| Fescue, boot stage | 0.45 | 0.30 | 0.21 | 10 | 150 | 32 | — |

| Fescue, mature | 0.38 | 0.20 | 0.18 | 7 | 120 | 26 | — |

| Fescue, stockpiled, Nov.-Dec. | 0.45 | 0.30 | 0.21 | 12 | 150 | 32 | — |

| Fescue, stockpiled, Jan.-Feb. | 0.38 | 0.20 | 0.18 | 7 | 120 | 26 | — |

| Fodder, oat | 0.28 | 0.53 | — | — | — | — | — |

| Fodder, wheat | 0.40 | 0.40 | 0.22 | — | — | — | — |

| Fodder, wheat, short germination | 0.40 | 0.40 | 0.22 | — | — | — | — |

| Legume pasture | 1.24 | 0.36 | 0.28 | 9 | 53 | 39 | — |

| Lespedeza | 1.20 | 0.24 | 0.21 | — | — | — | |

| Millet forage | 0.47 | 0.33 | 0.22 | 15 | 110 | 41 | — |

| Native range, Jan.-March | 0.23 | 0.07 | — | — | — | — | — |

| Native range, April-June | 0.30 | 0.20 | 0.15 | 11 | — | — | — |

| Native range, July-Aug. | 0.33 | 0.15 | — | — | — | — | — |

| Native range, Sept.-Oct. | 0.28 | 0.12 | — | — | — | — | — |

| Native range, Nov.-Dec. | 0.25 | 0.09 | — | — | — | — | — |

| Oat forage | 0.48 | 0.35 | 0.22 | 8 | 70 | 29 | — |

| Orchardgrass | 0.33 | 0.39 | 0.20 | — | — | 21 | — |

| Peanut forage | 1.45 | 0.30 | 0.23 | 8 | 150 | 36 | — |

| Peavine forage | 1.03 | 0.36 | 0.21 | 10 | 55 | 38 | — |

| Pineapple forage | 0.47 | 0.17 | 0.14 | 11 | 121 | 48 | — |

| Rye forage | 0.56 | 0.40 | 0.26 | 10 | 67 | 44 | — |

| Sorghum forage | 0.35 | 0.22 | 0.13 | 8 | 42 | 29 | — |

| Sorghum stover | 0.50 | 0.12 | — | — | — | — | — |

| Sorghum-sudan forage | 0.45 | 0.29 | 0.18 | 9 | 74 | 26 | — |

| Soybean forage | 1.43 | 0.31 | 0.26 | 10 | 78 | 28 | — |

| Sudangrass, mature | 0.48 | 0.30 | 0.18 | 11 | 44 | 36 | — |

| Sudangrass, immature | 0.46 | 0.36 | 0.11 | — | — | 24 | — |

| Sunflower | 1.33 | 0.28 | 0.24 | 14 | 148 | 37 | — |

| Timothy | 0.40 | 0.28 | 0.15 | — | — | 28 | — |

| Triticale forage | 0.38 | 0.32 | 0.18 | 8 | 48 | 30 | — |

| Wheat forage | 0.35 | 0.36 | 0.22 | 10 | 85 | 35 | — |

| Silage/Haylage | DM % |

CP % |

DIP % of CP |

TDN % |

NEm (Mcal/cwt.) |

|---|---|---|---|---|---|

| Barley silage | 38 | 12 | — | 61 | 59 |

| Bermudagrass silage | 39 | 13 | 75 | 56 | 50 |

| Corn silage, well eared | 34 | 8 | 72 | 71 | 73 |

| Corn stalklage | 49 | 6 | 70 | 53 | 45 |

| Distillers corn stillage | 7 | 22 | 45 | 92 | 103 |

| Grass silage | 30 | 11 | 76 | 61 | 62 |

| Legume silage | 40 | 21 | 75 | 58 | 32 |

| Millet silage | 38 | 13 | 75 | 55 | 47 |

| Millet/soybean silage | 38 | 12 | 72 | 57 | 52 |

| Milo/soybean silage | 31 | 12 | — | 60 | 58 |

| Grass silage, mixed forage | 39 | 16 | 78 | 60 | 56 |

| Legume silage, mixed forage | 39 | 19 | 78 | 60 | 57 |

| Oat silage | 35 | 13 | 79 | 60 | 56 |

| Peanut silage | 41 | 15 | 60 | 57 | 54 |

| Peavine silage | 35 | 17 | — | 60 | 58 |

| Corn silage, processed | 33 | 8 | — | 71 | 74 |

| Rice silage | 62 | 7 | — | 55 | 49 |

| Rye grass silage | 32 | 14 | 75 | 59 | 59 |

| Small grain silage | 38 | 13 | — | 61 | 57 |

| Sorghum silage, early bloom | 36 | 10 | 71 | 58 | 53 |

| Sorghum Silage, late bloom | 26 | 7 | 71 | 61 | 62 |

| Sorghum-sudan silage | 45 | 12 | 71 | 58 | 52 |

| Soybean silage | 56 | 16 | 65 | 57 | 53 |

| Sudangrass silage | 31 | 10 | 72 | 58 | 56 |

| Sugarcane bagasse, silage | 68 | 4 | 100 | 42 | 25 |

| Sugarcane silage | 54 | 6 | — | 52 | 42 |

| Sunfower silage | 27 | 11 | — | 70 | 78 |

| Sweet corn silage | 23 | 10 | — | 67 | 66 |

| Triticale silage | 34 | 14 | 100 | 60 | 56 |

| Wheat silage | 34 | 13 | 79 | 60 | 56 |

| Silage/Haylage | NEg (Mcal/cwt.) | NDF % |

pefa % |

ADF % |

EE % |

|---|---|---|---|---|---|

| Barley silage | 33 | 55 | 0.7 | 35 | 3.5 |

| Bermudagrass silage | 25 | 67 | 0.8 | 40 | 3.3 |

| Corn silage, well eared | 46 | 44 | 0.8 | 26 | 3.3 |

| Corn stalklage | 20 | 65 | 1.0 | 47 | 1.9 |

| Distillers corn stillage | 70 | 21 | 0.5 | 10 | 8.1 |

| Grass silage | 31 | 60 | 0.8 | 39 | 3.4 |

| Legume silage | 44 | 44 | 0.7 | 34 | 3.8 |

| Millet silage | 22 | 62 | 0.7 | 40 | 2.4 |

| Millet/soybean silage | 26 | 57 | 0.7 | 40 | 3.0 |

| Milo/soybean silage | 32 | 44 | 0.7 | 37 | 3.4 |

| Grass silage, mixed forage | 30 | 56 | 0.9 | 35 | 3.8 |

| Legume silage, mixed forage | 31 | 48 | 0.8 | 36 | 3.9 |

| Oat silage | 30 | 59 | 0.8 | 39 | 3.7 |

| Peanut silage | 28 | 52 | 0.7 | 39 | 4.4 |

| Peavine silage | 32 | 50 | 0.8 | 36 | 3.8 |

| Corn silage, processed | 47 | 44 | 0.7 | 26 | 3.4 |

| Rice silage | 24 | 53 | 0.7 | 39 | 2.5 |

| Rye grass silage | 28 | 59 | 0.7 | 37 | 3.3 |

| Small grain silage | 31 | 57 | 0.7 | 37 | 3.6 |

| Sorghum silage, early bloom | 28 | 58 | 0.8 | 37 | 3.0 |

| Sorghum Silage, late bloom | 35 | 59 | 0.9 | 38 | 3.0 |

| Sorghum-sudan silage | 27 | 61 | 0.8 | 39 | 3.3 |

| Soybean silage | 28 | 48 | 0.7 | 38 | 4.3 |

| Sudangrass silage | 31 | 64 | 0.8 | — | 3.0 |

| Sugarcane bagasse, silage | 7 | 75 | 1.0 | 62 | 1.2 |

| Sugarcane silage | 18 | 64 | 0.9 | 45 | 1.8 |

| Sunfower silage | 50 | 48 | 0.9 | 39 | 14.4 |

| Sweet corn silage | 39 | 64 | 0.8 | 36 | 5.3 |

| Triticale silage | 30 | 58 | 0.8 | 38 | 3.7 |

| Wheat silage | 30 | 57 | 0.7 | 37 | 3.5 |

| Silage/Haylage | Ca % |

P % |

S % |

Cu ppm | Mn ppm | Zn ppm | Se ppm |

|---|---|---|---|---|---|---|---|

| Barley silage | 0.45 | 0.30 | 0.17 | 8 | 43 | 32 | — |

| Bermudagrass silage | 0.53 | 0.29 | 0.24 | 14 | 98 | 43 | — |

| Corn silage, well eared | 0.25 | 0.24 | 0.10 | 7 | 31 | 25 | 0.09 |

| Corn stalklage | 0.90 | 0.16 | 0.09 | 8 | 82 | 38 | — |

| Distillers corn stillage | 0.14 | 0.72 | 0.60 | — | — | 60 | — |

| Grass silage | 0.70 | 0.24 | 0.22 | 11 | 92 | 29 | — |

| Legume silage | 1.41 | 0.33 | 0.25 | 10.3 | 48.6 | 27.2 | 0.17 |

| Millet silage | 0.54 | 0.33 | 0.20 | 14 | 130 | 47 | — |

| Millet/soybean silage | 0.84 | 0.32 | 0.19 | 9 | 76 | 41 | — |

| Milo/soybean silage | 0.72 | 0.28 | 0.16 | 11 | 55 | 34 | — |

| Grass silage, mixed forage | 1.43 | 0.33 | 0.25 | 9 | 66 | 31 | — |

| Legume silage, mixed forage | 1.25 | 0.33 | 0.23 | 9 | 44 | 26 | — |

| Oat silage | 0.52 | 0.33 | 0.19 | 9 | 66 | 28 | — |

| Peanut silage | 1.25 | 0.26 | 0.18 | 15 | 176 | 41 | — |

| Peavine silage | 1.03 | 0.33 | 0.21 | 12 | 65 | 35 | — |

| Corn silage, processed | 0.23 | 0.24 | 0.10 | 9 | 28 | 29 | — |

| Rice silage | 0.24 | 0.21 | 0.12 | 11 | 570 | 34 | — |

| Rye grass silage | 0.43 | 0.38 | 0.23 | 11 | 90 | 36 | — |

| Small grain silage | 0.54 | 0.32 | 0.19 | 9 | 78 | 33 | — |

| Sorghum silage, early bloom | 0.48 | 0.24 | 0.14 | 10 | 55 | 40 | 0.22 |

| Sorghum Silage, late bloom | 0.35 | 0.21 | 0.11 | 15 | 60 | 32 | 0.22 |

| Sorghum-sudan silage | 0.57 | 0.28 | 0.17 | 12 | 67 | 34 | — |

| Soybean silage | 1.36 | 0.30 | 0.20 | 12 | 81 | 65 | — |

| Sudangrass silage | 0.58 | 0.27 | 0.14 | 13 | 69 | 29 | — |

| Sugarcane bagasse, silage | 0.35 | 0.06 | 0.10 | 8 | 74 | 18 | — |

| Sugarcane silage | 0.36 | 0.12 | 0.30 | 8 | 77 | 102 | — |

| Sunfower silage | 1.42 | 0.33 | 0.24 | 15 | 33 | 35 | — |

| Sweet corn silage | 0.21 | 0.27 | 0.12 | 11 | 27 | 39 | — |

| Triticale silage | 0.50 | 0.34 | 0.20 | 11 | 50 | 36 | — |

| Wheat silage | 0.41 | 0.34 | 0.18 | 10 | 56 | 29 | — |

| Pellets/Cubes | DM % |

CP % |

DIP % of CP |

TDN % |

NEm (Mcal/cwt.) |

|---|---|---|---|---|---|

| Alfalfa cubes | 91 | 18 | 70 | 57 | 52 |

| Alfalfa pellets | 91 | 18 | 70 | 57 | 53 |

| Alfalfa, dehydrated 17% CP | 92 | 19 | 41 | 61 | 61 |

| Barley malt pellets with hulls | 90 | 18 | 64 | 68 | 71 |

| Grass cubes | 92 | 12 | — | 55 | 48 |

| Grass pellets | 91 | 14 | — | 59 | 55 |

| Pellets/Cubes | NEg (Mcal/cwt.) | NDF % |

pefa % |

ADF % |

EE % |

|---|---|---|---|---|---|

| Alfalfa cubes | 27 | 44 | 0.4 | 34 | 2.3 |

| Alfalfa pellets | 27 | 46 | 0.25 | 34 | 2.4 |

| Alfalfa, dehydrated 17% CP | 35 | 45 | 0.25 | 34 | 3.0 |

| Barley malt pellets with hulls | 44 | 50 | 0.25 | — | 1.9 |

| Grass cubes | 23 | 59 | 0.5 | 40 | 2.1 |

| Grass pellets | 29 | 54 | 0.3 | 36 | 2.8 |

| Pellets/Cubes | Ca % |

P % |

S % |

Cu ppm | Mn ppm | Zn ppm | Se ppm |

|---|---|---|---|---|---|---|---|

| Alfalfa cubes | 1.52 | 0.24 | 0.26 | 9 | 46 | 24 | 0.2 |

| Alfalfa pellets | 1.47 | 0.28 | 0.25 | 11 | 58 | 35 | 0.20 |

| Alfalfa, dehydrated 17% CP | 1.42 | 0.25 | 0.24 | 9 | 34 | 21 | 0.2 |

| Barley malt pellets with hulls | 0.21 | 0.59 | 0.32 | 10 | 44 | 61 | 0.25 |

| Grass cubes | 0.76 | 0.22 | 0.20 | 22 | 94 | 72 | — |

| Grass pellets | 0.82 | 0.29 | 0.20 | 10 | 86 | 48 | — |

| Byproducts | DM % |

CP % |

DIP % of CP |

TDN % |

NEm (Mcal/cwt.) |

|---|---|---|---|---|---|

| Almond hulls, dry | 89 | 6 | — | 60 | 58 |

| Almond hulls, wet | 80 | 6 | — | 61 | 61 |

| Apple pomace, wet | 21 | 7 | — | 66 | 67 |

| Bakery byproduct, dry | 90 | 13 | — | 91 | 108 |

| Beet pulp, dry | 92 | 9 | 56 | 66 | 66 |

| Beet pulp, wet | 23 | 10 | — | 63 | 61 |

| Bread, wet | 66 | 15 | — | 90 | 103 |

| Breading | 93 | 13 | — | 105 | 131 |

| Breweres condensed solubles | 25 | 26 | — | 88 | 100 |

| Brewers grains, dry | 93 | 26 | 46 | 73 | 79 |

| Brewers grains, wet | 26 | 30 | — | 74 | 81 |

| Candy byproduct, dry | 91 | 9 | 100 | 94 | 113 |

| Carrots, wet | 14 | 10 | — | 73 | 78 |

| Cerial byproduct, dry | 91 | 11 | — | 84 | 95 |

| Chocolate byproduct, dry | 91 | 11 | 80 | 95 | 117 |

| Citrus pulp, dry | 88 | 7 | — | 70 | 75 |

| Citrus pulp, wet | 20 | 9 | — | 70 | 75 |

| Coconut meal, dry | 93 | 22 | — | 70 | 78 |

| Cookie byproduct, dry | 91 | 10 | — | 93 | 111 |

| Corn cobs, dry | 93 | 5 | 30 | 61 | 56 |

| Corn cobs, wet | 66 | 4 | 30 | 59 | 51 |

| Corn gluten feed, dry | 89 | 24 | 75 | 73 | 78 |

| Corn gluten feed, wet | 61 | 22 | 75 | 76 | 84 |

| Corn gluten meal | 91 | 67 | 40 | 87 | 98 |

| Corn steep liquor | 41 | 37 | 70 | 84 | 94 |

| Cotton gin trash (burrs) | 92 | 11 | 100 | 44 | 34 |

| Cottonseed hulls, dry | 91 | 4 | 55 | 35 | 14 |

| Cottonseed, whole | 91 | 24 | 62 | 77 | 93 |

| Cottonseed, whole, delinted | 92 | 27 | 61 | 90 | 113 |

| Cottonseed, whole, extruded | 94 | 31 | 50 | 67 | 74 |

| Distillers condensed solubles | 32 | 20 | 100 | 102 | 126 |

| Distillers dried solubles | 93 | 31 | 53 | 87 | 96 |

| Distillers grain, corn, wet | 36 | 30 | 53 | 90 | 101 |

| Distillers grain, sorghum, wet | 35 | 33 | 45 | 86 | 95 |

| Distillers grains with solubles, corn, dry |

89 | 31 | 50 | 89 | 100 |

| Distillers grains with solubles, sorghum, dry | 92 | 31 | 47 | 88 | 99 |

| Fruit byproduct, dry | 86 | 8 | — | 72 | 76 |

| Fruit byproduct, wet | 28 | 8 | — | 72 | 77 |

| Fuzzpellet | 92 | 23 | 50 | 90 | 102 |

| Malt sprouts, dry | 92 | 24 | — | 68 | 68 |

| Oat hulls | 92 | 7 | 75 | 54 | 45 |

| Palm kernel meal | 90 | 17 | — | 68 | 71 |

| Pasta, dry | 90 | 12 | — | 92 | 106 |

| Peanut hulls | 93 | 11 | 40 | 39 | 24 |

| Peanut skins | 92 | 17 | 100 | — | — |

| Pet food | 91 | 24 | — | 93 | 112 |

| Pineapple forage, dry | 90 | 6 | — | 60 | 55 |

| Potato byproduct, dry | 85 | 15 | — | 79 | 87 |

| Potato byproduct, wet | 27 | 11 | — | 80 | 89 |

| Poultry litter, dry | 94 | 25 | 90 | 57 | 53 |

| Poultry manure, wet cage | 67 | 27 | 90 | 57 | 53 |

| Rice bran, full fat | 91 | 14 | 55 | 84 | 100 |

| Rice byproducts | 92 | 8 | 39 | 68 | 68 |

| Rice hulls | 92 | 3 | 45 | 13 | 35 |

| Rice mill byproduct | 91 | 7 | 60 | 42 | 43 |

| Rice polishings | 90 | 13 | — | 83 | 99 |

| Snack food | 48 | 10 | — | 86 | 100 |

| Snack Food, dry | 93 | 9 | — | 100 | 125 |

| Soy byproduct, dry | 89 | 34 | — | 85 | 99 |

| Soy byproduct, wet | 39 | 31 | — | 82 | 97 |

| Soybean hulls | 91 | 14 | 47 | 63 | 60 |

| Sugarcane bagasse | 39 | 4 | 100 | 43 | 25 |

| Sugarcane bagasse, dry | 93 | 3 | 100 | 48 | 34 |

| Sunfower seed hulls | 90 | 4 | 35 | 40 | 42 |

| Sunfower seeds | 92 | 22 | 7 | 113 | 150 |

| Tapioca (cassava), dry | 88 | 4 | 62 | 75 | 80 |

| Tapioca meal, cassava byproduct | 89 | 1 | 63 | 82 | 89 |

| Vegetable byproduct, wet | 27 | 20 | 85 | 62 | 61 |

| Wheat germ meal | 88 | 29 | 75 | 85 | 99 |

| Wheat midds | 90 | 18 | 78 | 73 | 79 |

| Wheat mill run | 90 | 17 | 72 | 75 | 81 |

| Wheat shorts | 89 | 19 | 75 | 78 | 83 |

| Whey, dry | 94 | 14 | 85 | 82 | 89 |

| Whey, wet | 23 | 14 | 85 | 82 | 93 |

| Yeast, dry | 29 | 44 | — | 82 | 91 |

| Byproducts | NEg (Mcal/cwt.) | NDF % |

pefa % |

ADF % |

EE % |

|---|---|---|---|---|---|

| Almond hulls, dry | 32 | 36 | 0.4 | 30 | 2.9 |

| Almond hulls, wet | 35 | 34 | 0.3 | 28 | 4.0 |

| Apple pomace, wet | 40 | 48 | 0.3 | 40 | 6.8 |

| Bakery byproduct, dry | 75 | 11 | 0.2 | 6 | 9.8 |

| Beet pulp, dry | 39 | 42 | 0.3 | 26 | 1.3 |

| Beet pulp, wet | 35 | 48 | 0.25 | 28 | 1.1 |

| Bread, wet | 72 | 5 | 0.1 | 3 | 8.4 |

| Breading | 94 | 7 | 0.1 | 4 | 17.9 |

| Breweres condensed solubles | 69 | 5 | 0.1 | 2 | 4.2 |

| Brewers grains, dry | 51 | 51 | 0.25 | 24 | 8.7 |

| Brewers grains, wet | 53 | 49 | 0.25 | 24 | 9.4 |

| Candy byproduct, dry | 80 | 14 | 0.1 | 7 | 15.2 |

| Carrots, wet | 50 | 25 | 0.35 | 21 | 4.3 |

| Cerial byproduct, dry | 65 | 12 | 0.1 | 6 | 5.2 |

| Chocolate byproduct, dry | 83 | 18 | 0.15 | 12 | 20.0 |

| Citrus pulp, dry | 47 | 24 | 0.3 | 20 | 2.6 |

| Citrus pulp, wet | 47 | 27 | 0.25 | 23 | 3.5 |

| Coconut meal, dry | 49 | 52 | 0.3 | 31 | 13.1 |

| Cookie byproduct, dry | 78 | 10 | 0.1 | 5 | 11.8 |

| Corn cobs, dry | 30 | 65 | 0.9 | 35 | 1.9 |

| Corn cobs, wet | 25 | 80 | 0.8 | 44 | 0.7 |

| Corn gluten feed, dry | 50 | 36 | 0.4 | 11 | 4.1 |

| Corn gluten feed, wet | 55 | 35 | 0.3 | 12 | 5.3 |

| Corn gluten meal | 67 | 8 | 0.2 | 5 | 3.0 |

| Corn steep liquor | 64 | 3 | 0 | 1 | 3.0 |

| Cotton gin trash (burrs) | 10 | 70 | 0.9 | 51 | 2.7 |

| Cottonseed hulls, dry | 2 | 79 | 0.9 | 65 | 4.3 |

| Cottonseed, whole | 63 | 53 | 0.8 | 40 | 19.9 |

| Cottonseed, whole, delinted | 80 | 43 | 0.8 | 29 | 22.9 |

| Cottonseed, whole, extruded | 46 | 45 | 0.7 | 37 | 9.7 |

| Distillers condensed solubles | 90 | 4 | 0.1 | 2 | 17.9 |

| Distillers dried solubles | 64 | 22 | 0.2 | 7 | 13.0 |

| Distillers grain, corn, wet | 69 | 31 | 0.3 | 16 | 12.0 |

| Distillers grain, sorghum, wet | 63 | 34 | 0.3 | 19 | 12.0 |

| Distillers grains with solubles, corn, dry |

69 | 33 | 0.35 | 18 | 13.0 |

| Distillers grains with solubles, sorghum, dry | 68 | 46 | 0.35 | 18 | 10.0 |

| Fruit byproduct, dry | 48 | 40 | 0.4 | 29 | 4.9 |

| Fruit byproduct, wet | 49 | 35 | 0.35 | 25 | 4.9 |

| Fuzzpellet | 70 | 47 | 0.6 | 39 | 18.4 |

| Malt sprouts, dry | 41 | 43 | 0.4 | 19 | 2.1 |

| Oat hulls | 20 | 65 | 0.7 | 36 | 3.2 |

| Palm kernel meal | 43 | 64 | 0.6 | 40 | 9.1 |

| Pasta, dry | 73 | 3 | 0.25 | 2 | 6.2 |

| Peanut hulls | 5 | 65 | 0.5 | 54 | 5.3 |

| Peanut skins | 0 | 28 | 0.2 | 20 | 22.0 |

| Pet food | 79 | 17 | 0.3 | 7 | 14.1 |

| Pineapple forage, dry | 29 | 61 | 0.4 | 31 | 1.5 |

| Potato byproduct, dry | 58 | 19 | 0.35 | 14 | 4.5 |

| Potato byproduct, wet | 60 | 23 | 0.3 | 16 | 6.8 |

| Poultry litter, dry | 29 | 38 | 0.5 | 26 | 2.5 |

| Poultry manure, wet cage | 29 | 36 | 0.5 | 25 | 3.6 |

| Rice bran, full fat | 69 | 23 | 0.5 | 17 | 16.0 |

| Rice byproducts | 41 | 52 | 0.4 | 45 | 3.7 |

| Rice hulls | — | 81 | 0.6 | 70 | 0.9 |

| Rice mill byproduct | — | 60 | 0.3 | 50 | 5.7 |

| Rice polishings | 68 | 24 | 0.2 | 16 | 14.1 |

| Snack food | 68 | 20 | 0.2 | 14 | 11.1 |

| Snack Food, dry | 89 | 12 | 0.25 | 7 | 22.6 |

| Soy byproduct, dry | 68 | 29 | 0.25 | 20 | 12.1 |

| Soy byproduct, wet | 66 | 31 | 0.3 | 22 | 12.9 |

| Soybean hulls | 33 | 63 | 0.4 | 44 | 3.3 |

| Sugarcane bagasse | 11 | 75 | 0.9 | 61 | 0.9 |

| Sugarcane bagasse, dry | 12 | 80 | 1.0 | 62 | 0.9 |

| Sunfower seed hulls | 73 | 0.9 | 63 | 2.2 | |

| Sunfower seeds | 109 | 38 | 0.8 | 29 | 35.2 |

| Tapioca (cassava), dry | 52 | 20 | 0.2 | 16 | 0.8 |

| Tapioca meal, cassava byproduct | 59 | 34 | 0.2 | 8 | 0.8 |

| Vegetable byproduct, wet | 35 | 43 | 0.3 | 35 | 8.8 |

| Wheat germ meal | 68 | 22 | 0.2 | 6 | 6.3 |

| Wheat midds | 51 | 38 | 0.3 | 13 | 5.9 |

| Wheat mill run | 53 | 37 | 0.35 | 12 | 4.4 |

| Wheat shorts | 54 | 30 | 0.3 | 10 | 5.3 |

| Whey, dry | 59 | 0 | 0 | — | 0.9 |

| Whey, wet | 63 | 1 | 0 | 1 | 3.9 |

| Yeast, dry | 62 | 7 | 0.1 | 4 | 3.5 |

| Byproducts | Ca % |

P % |

S % |

Cu ppm | Mn ppm | Zn ppm | Se ppm |

|---|---|---|---|---|---|---|---|

| Almond hulls, dry | 0.28 | 0.12 | 0.05 | 5 | 18 | 18 | — |

| Almond hulls, wet | 0.29 | 0.13 | 0.04 | 5 | 19 | 16 | — |

| Apple pomace, wet | 0.18 | 0.15 | 0.07 | 10 | 15 | 10 | — |

| Bakery byproduct, dry | 0.28 | 0.34 | 0.16 | 5 | 30 | 38 | — |

| Beet pulp, dry | 0.94 | 0.08 | 0.29 | 9 | 61 | 23 | — |

| Beet pulp, wet | 1.07 | 0.10 | 0.21 | 10 | 58 | 24 | — |

| Bread, wet | 0.19 | 0.21 | 0.18 | 3 | 13 | 17 | — |

| Breading | 0.11 | 0.20 | 0.17 | 2 | 6 | 10 | — |

| Breweres condensed solubles | 0.54 | 0.71 | 0.46 | 27 | 19 | 48 | — |

| Brewers grains, dry | 0.30 | 0.65 | 0.31 | 14 | 54 | 90 | — |

| Brewers grains, wet | 0.35 | 0.68 | 0.00 | 11 | 52 | 92 | — |

| Candy byproduct, dry | 0.25 | 0.23 | 0.09 | 5 | 18 | 20 | — |

| Carrots, wet | 0.86 | 0.35 | 0.12 | 9 | 30 | 28 | — |

| Cerial byproduct, dry | 0.23 | 0.37 | 0.13 | 6 | 37 | 84 | — |

| Chocolate byproduct, dry | 0.24 | 0.31 | 0.13 | 9 | 25 | 31 | — |

| Citrus pulp, dry | 1.88 | 0.12 | 0.10 | 6 | 13 | 11 | — |

| Citrus pulp, wet | 1.50 | 0.15 | 0.10 | 6 | 13 | 12 | — |

| Coconut meal, dry | 0.15 | 0.61 | 0.28 | 38 | 104 | 55 | — |

| Cookie byproduct, dry | 0.20 | 0.29 | 0.12 | 4 | 24 | 30 | — |

| Corn cobs, dry | 0.15 | 0.14 | 0.09 | 7 | 21 | 27 | — |

| Corn cobs, wet | 0.11 | 0.08 | 0.05 | 7 | 9 | 25 | — |

| Corn gluten feed, dry | 0.11 | 1.04 | 0.50 | 6 | 22 | 69 | 0.3 |

| Corn gluten feed, wet | 0.36 | 1.26 | 0.47 | 6 | 24 | 70 | — |

| Corn gluten meal | 0.07 | 0.54 | 0.86 | 3 | 7 | 31 | — |

| Corn steep liquor | 0.08 | 2.74 | 1.41 | 6 | 50 | 155 | 0.30 |

| Cotton gin trash (burrs) | 0.90 | 0.12 | 0.05 | 10 | 55 | 10 | 0.25 |

| Cottonseed hulls, dry | 0.35 | 0.21 | 0.12 | 5 | 28 | 22 | 0.30 |

| Cottonseed, whole | 0.19 | 0.69 | 0.23 | 6 | 16 | 34 | 0.25 |

| Cottonseed, whole, delinted | 0.34 | 0.75 | 0.56 | 8 | 25 | 37 | — |

| Cottonseed, whole, extruded | 0.29 | 0.81 | 0.30 | 10 | 20 | 43 | — |

| Distillers condensed solubles | 0.10 | 1.55 | 1.06 | 5 | 32 | 87 | — |

| Distillers dried solubles | 0.35 | 1.20 | 1.10 | — | — | 91 | — |

| Distillers grain, corn, wet | 0.09 | 0.75 | 0.70 | 5 | 21 | 65 | 0.42 |

| Distillers grain, sorghum, wet | 0.20 | 0.68 | 0.50 | 5 | 21 | 50 | 0.42 |

| Distillers grains with solubles, corn, dry |

0.07 | 0.87 | 0.65 | 5 | 21 | 68 | 0.42 |

| Distillers grains with solubles, sorghum, dry | 0.25 | 0.65 | 0.40 | 5 | 21 | 68 | 0.42 |

| Fruit byproduct, dry | 0.36 | 0.19 | 0.15 | 9 | 56 | 18 | — |

| Fruit byproduct, wet | 0.42 | 0.21 | 0.12 | 10 | 34 | 19 | — |

| Fuzzpellet | 0.17 | 0.52 | 0.27 | 9 | 15 | 37 | 0.25 |

| Malt sprouts, dry | 0.21 | 0.60 | 0.31 | 10 | 46 | 64 | — |

| Oat hulls | 0.16 | 0.22 | 0.09 | 8 | 50 | 29 | — |

| Palm kernel meal | 0.41 | 0.62 | 0.20 | 24 | 263 | 43 | — |

| Pasta, dry | 0.10 | 0.16 | 0.12 | 2 | 8 | 10 | — |

| Peanut hulls | 0.33 | 0.13 | 0.11 | 13 | 45 | 21 | — |

| Peanut skins | 0.19 | 0.20 | — | ||||

| Pet food | 1.63 | 1.11 | 0.35 | 22 | 63 | 190 | — |

| Pineapple forage, dry | 0.37 | 0.14 | 0.12 | 10 | 155 | 15 | — |

| Potato byproduct, dry | 0.30 | 0.30 | 0.21 | 7 | 23 | 23 | — |

| Potato byproduct, wet | 0.46 | 0.31 | 0.13 | 9 | 30 | 31 | — |

| Poultry litter, dry | 2.56 | 1.44 | 0.52 | 291 | 421 | 480 | — |

| Poultry manure, wet cage | 4.12 | 1.86 | 0.00 | 349 | 483 | 441 | — |

| Rice bran, full fat | 0.66 | 1.70 | 0.19 | 12 | 396 | 40 | — |

| Rice byproducts | 0.11 | 0.27 | 0.08 | 16 | 226 | 41 | — |

| Rice hulls | 0.14 | 0.07 | 0.08 | 3 | 320 | 24 | — |

| Rice mill byproduct | 0.40 | 0.31 | 0.30 | — | — | 31 | — |

| Rice polishings | 0.93 | 1.28 | 0.15 | 10 | 146 | 80 | — |

| Snack food | 0.58 | 0.30 | 0.15 | 8 | 17 | 25 | — |

| Snack Food, dry | 0.65 | 0.21 | 0.09 | 3 | 13 | 16 | — |

| Soy byproduct, dry | 0.41 | 0.44 | 0.30 | 12 | 27 | 51 | — |

| Soy byproduct, wet | 0.42 | 0.32 | 0.00 | 20 | 24 | 43 | — |

| Soybean hulls | 0.64 | 0.18 | 0.13 | 9 | 24 | 46 | 0.14 |

| Sugarcane bagasse | 0.09 | 0.02 | 0.04 | 7 | 56 | 9 | — |

| Sugarcane bagasse, dry | 0.35 | 0.04 | 0.09 | 7 | 59 | 12 | — |

| Sunfower seed hulls | 0.00 | 0.11 | 0.19 | — | — | 200 | — |

| Sunfower seeds | 0.33 | 0.68 | 0.00 | 19 | 30 | 57 | — |

| Tapioca (cassava), dry | 0.30 | 0.08 | 0.04 | 7 | 58 | 29 | — |

| Tapioca meal, cassava byproduct | 0.03 | 0.05 | 0.04 | 7 | 58 | 29 | — |

| Vegetable byproduct, wet | 0.81 | 0.43 | 0.34 | 10 | 46 | 35 | — |

| Wheat germ meal | 0.11 | 1.23 | 0.26 | 7 | 193 | 138 | — |

| Wheat midds | 0.15 | 1.07 | 0.19 | 12 | 126 | 84 | 0.21 |

| Wheat mill run | 0.12 | 1.00 | 0.22 | 21 | — | 90 | — |

| Wheat shorts | 0.10 | 0.93 | 0.20 | — | — | 118 | — |

| Whey, dry | 0.98 | 0.88 | 0.92 | 4 | 2 | 10 | — |

| Whey, wet | 1.10 | 1.37 | 0.23 | 4 | 2 | 24 | — |

| Yeast, dry | 0.42 | 1.37 | 0.00 | 17 | 20 | 85 | — |

| Grains/Concentrate | DM % |

CP % |

DIP % of CP |

TDN % |

NEm (Mcal/cwt.) |

|---|---|---|---|---|---|

| Barley, dry | 90 | 12 | — | 81 | 89 |

| Buckwheat, dry | 90 | 17 | — | 76 | 82 |

| Canola seed | 94 | 25 | 70 | — | — |

| Corn bran | 92 | 13 | 100 | 83 | 95 |

| Corn grain, high moisture | 74 | 9 | 58 | 93 | 104 |

| Corn grain rolled | 88 | 9 | 46 | 88 | 98 |

| Corn grain, steam faked | 87 | 9 | 41 | 93 | 104 |

| Corn grain, whole | 88 | 9 | 42 | 88 | 99 |

| Corn screenings | 87 | 9 | 48 | 87 | 96 |

| Corn snaplage, wet | 59 | 8 | 70 | 81 | 90 |

| Corn, ear | 89 | 9 | — | 84 | 94 |

| Corn, high moisture ears | 64 | 8 | — | 83 | 93 |

| Fat, animal or vegetable | 99 | — | 100 | 195 | 285 |

| Flax seed | 91 | 29 | — | 110 | 144 |

| Glycerol (glycerin) | 88 | — | 100 | 90 | 100 |

| Hominy feed | 89 | 10 | 52 | 86 | 99 |

| Lupine beans, dry | 91 | 33 | — | 81 | 93 |

| Milk replacer, dry | 92 | 27 | — | 108 | 138 |

| Milk, dry, skim | 94 | 36 | 100 | 87 | 96 |

| Millet, dry | 84 | 12 | 43 | 77 | 85 |

| Milo/sorghum, dry | 90 | 11 | 45 | 84 | 93 |

| Milo/sorghum, steam faked | 82 | 11 | 38 | 90 | 102 |

| Molasses cane, dried | 94 | 9 | 100 | 74 | 78 |

| Molasses cane, wet | 73 | 9 | 100 | 72 | 77 |

| Mung beans | 90 | 23 | 25 | 79 | 87 |

| Mung bean cracks | 90 | 25 | 25 | 88 | 96 |

| Oats, rolled | 89 | 12 | 82 | 75 | 77 |

| Pearl millet grain | 87 | 13 | 100 | 82 | 89 |

| Peas, dry | 89 | 24 | 17 | 79 | 86 |

| Potatoes, wet | 24 | 11 | — | 81 | 89 |

| Rice | 89 | 8 | 70 | 79 | 85 |

| Rye | 89 | 14 | 80 | 80 | 86 |

| Triticale | 89 | 12 | — | 82 | 91 |

| Wheat bran | 90 | 18 | 72 | 72 | 76 |

| Wheat grain | 89 | 14 | 77 | 84 | 93 |

| Wheat grain sprouted | 86 | 12 | 82 | 88 | 98 |

| Grains/Concentrate | NEg (Mcal/cwt.) | NDF % |

pefa % |

ADF % |

EE % |

|---|---|---|---|---|---|

| Barley, dry | 60 | 19 | 0.3 | 8 | 2.4 |

| Buckwheat, dry | 54 | 27 | 0.3 | 19 | 3.7 |

| Canola seed | — | 28 | 0.3 | 20 | 39.7 |

| Corn bran | 65 | 33 | 0.35 | 10 | 8.4 |

| Corn grain, high moisture | 71 | 10 | 0.3 | 4 | 4.1 |

| Corn grain rolled | 65 | 10 | 0.2 | 4 | 4.2 |

| Corn grain, steam faked | 71 | 9 | 0.25 | 4 | 3.6 |

| Corn grain, whole | 65 | 9 | 0.35 | 3 | 4.3 |

| Corn screenings | 64 | 10 | 0.2 | 4 | 3.8 |

| Corn snaplage, wet | 61 | 24 | 0.8 | 12 | 3.6 |

| Corn, ear | 64 | 19 | 0.8 | 8 | 3.9 |

| Corn, high moisture ears | 63 | 21 | 0.6 | 10 | 3.6 |

| Fat, animal or vegetable | 230 | — | 0 | — | 99.0 |

| Flax seed | 104 | 32 | 0.2 | 19 | 23.2 |

| Glycerol (glycerin) | 68 | 0 | 0.15 | — | — |

| Hominy feed | 68 | 17 | 0.2 | 6 | 6.9 |

| Lupine beans, dry | 63 | 28 | 0.25 | 21 | 6.5 |

| Milk replacer, dry | 100 | 2 | 0 | — | 20.9 |

| Milk, dry, skim | 64 | — | 0 | — | 0.9 |

| Millet, dry | 56 | 21 | 0.3 | 12 | 3.1 |

| Milo/sorghum, dry | 63 | 16 | 0.35 | 9 | 3.4 |

| Milo/sorghum, steam faked | 70 | 20 | 0.1 | — | 3.1 |

| Molasses cane, dried | 49 | 7 | 0 | 3 | 0.3 |

| Molasses cane, wet | 49 | 1 | 0.1 | — | 2.3 |

| Mung beans | 58 | 28 | 0.3 | 8 | 3.0 |

| Mung bean cracks | 64 | 20 | 0.2 | 8 | 1.3 |

| Oats, rolled | 52 | 30 | 0.4 | 15 | 5.4 |

| Pearl millet grain | 59 | 18 | 0.25 | 6 | 4.5 |

| Peas, dry | 57 | 14 | 0.2 | 9 | 2.0 |

| Potatoes, wet | 60 | 11 | 0.2 | 8 | 3.7 |

| Rice | 55 | 16 | 0.15 | 12 | 1.9 |

| Rye | 56 | 19 | 0.2 | 8 | 2.5 |

| Triticale | 61 | 15 | — | 0.15 | 1.7 |

| Wheat bran | 48 | 40 | 0.2 | 14 | 4.5 |

| Wheat grain | 63 | 13 | 0.15 | 5 | 2.0 |

| Wheat grain sprouted | 65 | 13 | 0.2 | 4 | 2.0 |

| Grains/Concentrate | Ca % |

P % |

S % |

Cu ppm | Mn ppm | Zn ppm | Se ppm |

|---|---|---|---|---|---|---|---|

| Barley, dry | 0.10 | 0.40 | 0.14 | 6 | 20 | 32 | 0.22 |

| Buckwheat, dry | 0.13 | 0.58 | 0.20 | 8 | 38 | 30 | — |

| Canola seed | 0.55 | 0.72 | 0.43 | 3 | 50 | 60 | — |

| Corn bran | 0.06 | 0.51 | 0.25 | 5 | 17 | 70 | — |

| Corn grain, high moisture | 0.03 | 0.31 | 0.10 | 2 | 6 | 19 | — |

| Corn grain rolled | 0.02 | 0.30 | 0.14 | 3 | 9 | 24 | 0.15 |

| Corn grain, steam faked | 0.03 | 0.24 | 0.09 | 2 | 5 | 17 | — |

| Corn grain, whole | 0.02 | 0.30 | 0.12 | 3 | 8 | 18 | — |

| Corn screenings | 0.04 | 0.25 | 0.11 | — | — | 16 | — |

| Corn snaplage, wet | 0.06 | 0.27 | 0.10 | 4 | 11 | 22 | — |

| Corn, ear | 0.42 | 0.31 | 0.10 | 4 | 12 | 26 | — |

| Corn, high moisture ears | 0.05 | 0.29 | 0.10 | 3 | 10 | 20 | — |

| Fat, animal or vegetable | 0.00 | 0.00 | — | — | — | — | — |

| Flax seed | 0.31 | 0.71 | 0.30 | 15 | 38 | 57 | — |

| Glycerol (glycerin) | — | — | — | — | — | — | — |

| Hominy feed | 0.04 | 0.55 | 0.12 | 4 | 13 | 40 | 0.11 |

| Lupine beans, dry | 0.29 | 0.40 | 0.22 | 7 | 279 | 36 | — |

| Milk replacer, dry | 0.93 | 0.77 | 0.36 | 10 | 40 | 74 | — |

| Milk, dry, skim | 1.36 | 1.09 | 0.34 | — | — | 41 | — |

| Millet, dry | 0.83 | 0.30 | 0.39 | 6 | 22 | 26 | — |

| Milo/sorghum, dry | 0.15 | 0.36 | 0.11 | 4 | 20 | 22 | 0.22 |

| Milo/sorghum, steam faked | 0.04 | 0.28 | 0.14 | 5 | 15 | 18 | — |

| Molasses cane, dried | 1.10 | 0.15 | 23 | 61 | 30 | — | — |

| Molasses cane, wet | 1.00 | 0.25 | 1.00 | 23 | 61 | 71 | — |

| Mung beans | 1.19 | 0.68 | 0.25 | — | — | — | — |

| Mung bean cracks | 0.15 | 0.39 | 0.25 | — | — | — | — |

| Oats, rolled | 0.09 | 0.33 | 0.23 | 7 | 42 | 41 | 0.26 |

| Pearl millet grain | 0.03 | 0.36 | — | — | — | — | — |

| Peas, dry | 0.14 | 0.42 | 0.18 | 8 | 19 | 38 | — |

| Potatoes, wet | 0.14 | 0.29 | 0.14 | 6 | 15 | 19 | — |

| Rice | 0.07 | 0.32 | 0.05 | 5 | 47 | 17 | — |

| Rye | 0.07 | 0.55 | 0.17 | 5 | 49 | 36 | — |

| Triticale | 0.08 | 0.36 | 0.15 | 5 | 42 | 90 | — |

| Wheat bran | 0.16 | 1.08 | 0.18 | 12 | 135 | 87 | — |

| Wheat grain | 0.12 | 0.39 | 0.15 | 4 | 41 | 31 | 0.29 |

| Wheat grain sprouted | 0.04 | 0.36 | 0.17 | — | — | 45 | — |

| Protein Meals | DM % |

CP % |

DIP % of CP |

TDN % |

NEm (Mcal/cwt.) |

|---|---|---|---|---|---|

| Biuret | 99 | 248 | 100 | — | — |

| Blood meal, dry, non-ruminant | 90 | 100 | 40 | 72 | 77 |

| Canola meal, dry | 91 | 40 | 71 | 69 | 73 |

| Corn germ meal | 90 | 23 | 50 | 81 | 92 |

| Cotton seed meal | 91 | 43 | 73 | 70 | 74 |

| Feather meal | 93 | 88 | 27 | 78 | 91 |

| Fish meal | 92 | 61 | 40 | 77 | 91 |

| Linseed meal, mech. extracted | 91 | 37 | 60 | 82 | 89 |

| Linseed meal, solv. extracted | 91 | 39 | 64 | 72 | 78 |

| Meat meal, dry | 96 | 59 | — | 67 | 79 |

| Peanut meal | 94 | 44 | 73 | 79 | 89 |

| Poultry meal, blood & feather | 95 | 67 | 46 | 75 | 91 |

| Safower meal | 95 | 24 | — | 58 | 56 |

| Soybean meal, 44% | 89 | 49 | 65 | 84 | 92 |

| Soybean meal, 48% | 91 | 54 | 64 | 87 | 98 |

| Soybeans whole | 88 | 41 | 72 | 92 | 103 |

| Soybeans whole, extruded | 88 | 40 | 65 | 93 | 104 |

| Soybeans whole, roasted | 88 | 40 | 52 | 93 | 104 |

| Sunfower meal | 92 | 33 | 68 | 66 | 69 |

| Sunfower meal, solvent extracted | 91 | 39 | 73 | 64 | 65 |

| Urea 46% N | 99 | 288 | 100 | — | — |

| Protein Meals | NEg (Mcal/cwt.) | NDF % |

pefa % |

ADF % |

EE % |

|---|---|---|---|---|---|

| Biuret | — | — | 0 | — | — |

| Blood meal, dry, non-ruminant | 50 | 2 | 0.1 | 1 | 1.1 |

| Canola meal, dry | 45 | 30 | 0.25 | 21 | 7.4 |

| Corn germ meal | 61 | 39 | 0.2 | 14 | 10.1 |

| Cotton seed meal | 47 | 32 | 0.25 | 23 | 5.7 |

| Feather meal | 61 | 17 | 0.15 | 3 | 10.0 |

| Fish meal | 62 | 23 | 0.15 | 4 | 12.1 |

| Linseed meal, mech. extracted | 59 | 24 | 0.15 | 18 | 6.0 |

| Linseed meal, solv. extracted | 53 | 26 | 0.15 | 18 | 1.9 |

| Meat meal, dry | 51 | — | 0.15 | 29 | 14.2 |

| Peanut meal | 59 | 24 | 0.15 | 16 | 8.8 |

| Poultry meal, blood & feather | 61 | 0 | 0.1 | 0 | 13.9 |

| Safower meal | 30 | 53 | 0.3 | 38 | 9.1 |

| Soybean meal, 44% | 61 | 15 | 0.15 | 10 | 1.5 |

| Soybean meal, 48% | 67 | 9 | 0.15 | 6 | 1.2 |

| Soybeans whole | 70 | 15 | 0.3 | 11 | 18.8 |

| Soybeans whole, extruded | 71 | 15 | 0.25 | 11 | 18.8 |

| Soybeans whole, roasted | 71 | 15 | 0.3 | 11 | 18.8 |

| Sunfower meal | 42 | 41 | 0.1 | 29 | 11.5 |

| Sunfower meal, solvent extracted | 36 | 36 | 0.1 | 22 | 2.0 |

| Urea 46% N | — | — | 0 | — | 0.0 |

| Protein Meals | Ca % |

P % |

S % |

Cu ppm | Mn ppm | Zn ppm | Se ppm |

|---|---|---|---|---|---|---|---|

| Biuret | — | — | — | — | — | — | — |

| Blood meal, dry, non-ruminant | 0.18 | 0.2 | 0.56 | 5 | 6 | 29 | — |

| Canola meal, dry | 0.74 | 1.1 | 0.71 | 6 | 65 | 60 | — |

| Corn germ meal | 0.06 | 0.8 | 0.28 | 3 | 15 | 77 | — |

| Cotton seed meal | 0.31 | 1.2 | 0.43 | 13 | 27 | 64 | 0.32 |

| Feather meal | 0.56 | 0.4 | 1.77 | 12 | 10 | 89 | 0.9 |

| Fish meal | 5.04 | 2.9 | 0.84 | 7 | 37 | 113 | — |

| Linseed meal, mech. extracted | 0.42 | 0.9 | 0.46 | 19 | 50 | 70 | — |

| Linseed meal, solv. extracted | 0.43 | 0.9 | 0.52 | 19 | 50 | 70 | — |

| Meat meal, dry | 7.89 | 4.40 | 0.45 | 19 | 17 | 130 | — |

| Peanut meal | 0.21 | 0.6 | 0.27 | 15 | 33 | 51 | 0.12 |

| Poultry meal, blood & feather | 4.04 | 2.4 | 0.73 | 16 | 11 | 104 | — |

| Safower meal | 1.06 | 0.6 | 0.26 | 29 | 111 | 140 | — |

| Soybean meal, 44% | 0.36 | 0.7 | 0.41 | 23 | 41 | 62 | 0.11 |

| Soybean meal, 48% | 0.28 | 0.7 | 0.47 | 23 | 41 | 61 | 0.11 |

| Soybeans whole | 0.27 | 0.6 | 0.34 | 15 | 32 | 43 | — |

| Soybeans whole, extruded | 0.27 | 0.6 | 0.34 | 14 | 34 | 50 | — |

| Soybeans whole, roasted | 0.27 | 0.6 | 0.34 | 13 | 30 | 44 | — |

| Sunfower meal | 0.45 | 1.1 | 0.00 | 29 | 43 | 87 | 0.18 |

| Sunfower meal, solvent extracted | 0.42 | 1.00 | 0.37 | 20 | 35 | 70 | — |

| Urea 46% N | 0.00 | 0.00 | 0.00 | — | — | — | — |

a Physical effectiveness factor.

| Number | Feed Name | DM % |

|---|---|---|

| Calcium | Calcium Carbonate | 99 |

| Calcium phosphate (monobasic) | 99 | |

| Limestone, dolomitic | ||

| Limestone, ground | ||

| Cobalt | Cobalt Carbonate | 99 |

| Cobalt Sulfate | 99 | |

| Copper | Copper chloride dihydrate | |

| Copper Sulfate | 99 | |

| Copper Oxide | 99 | |

| Phosphorous | Dicalcium phosphate | 99 |

| Phosphoric acid | 99 | |

| Magnesium | ||

| Magnesium chloride | 99 | |

| Magnesium hydroxide | 99 | |

| Magnesium Oxide | 99 | |

| Magnesium sulfate heptahydrate | ||

| Manganese | Manganese chloride | 99 |

| Manganese sulfate monohydrate | ||

| Manganese sulfate pentahydrate | ||

| Potassium | Potassium bicarbonate | 99 |

| Potassium carbonate | 99 | |

| Potassium chloride | 99 | |

| Potassium iodidea | 99 | |

| Sodium | Sodium chlorideb | 99 |

| Sodium bicarbonate | 99 | |

| Sodium phosphate (monobasic) | 99 | |

| Selenium | Selenium 600 | 99 |

| Sodium selenate decahydrate | ||

| Sodium selenite | ||

| Sodium | Sodium Chloride | 99 |

| Zince | Zinc carbonate | |

| Zinc chloride | ||

| Zinc Oxide | 99 | |

| Zinc sulfate monohydrate | 99 |

| Number | Feed Name | CA % | Phos % | Na % | K % | MG % | S % |

|---|---|---|---|---|---|---|---|

| Calcium | Calcium Carbonate | 38 | 0.04 | 0.06 | 0.05 | 0.01 | |

| Calcium phosphate (monobasic) | 16.4 | 21.6 | 1.2 | ||||

| Limestone, dolomitic | 22.3 | 9.9 | |||||

| Limestone, ground | 34 | 2.1 | |||||

| Cobalt | Cobalt Carbonate | ||||||

| Cobalt Sulfate | |||||||

| Copper | Copper chloride dihydrate | ||||||

| Copper Sulfate | 38 | ||||||

| Copper Oxide | |||||||

| Phosphorous | Dicalcium phosphate | 22 | 19.3 | 0 | 0.59 | 1.14 | |

| Phosphoric acid | 31.6 | 1.55 | |||||

| Magnesium | |||||||

| Magnesium chloride | 3.1 | 12 | |||||

| Magnesium hydroxide | 41.7 | ||||||

| Magnesium Oxide | 56.2 | ||||||

| Magnesium sulfate heptahydrate | 9.8 | ||||||

| Manganese | Manganese chloride | ||||||

| Manganese sulfate monohydrate | |||||||

| Manganese sulfate pentahydrate | |||||||

| Potassium | Potassium bicarbonate | 39 | |||||

| Potassium carbonate | 57 | ||||||

| Potassium chloride | 0.05 | 50 | 0.11 | 0.19 | |||

| Potassium iodidea | 21 | ||||||

| Sodium | Sodium chlorideb | 39.3 | |||||

| Sodium bicarbonate | 27 | ||||||

| Sodium phosphate (monobasic) | 22.5 | 16.7 | |||||

| Selenium | Selenium 600 | ||||||

| Sodium selenate decahydrate | |||||||

| Sodium selenite | 26.6 | ||||||

| Sodium | Sodium Chloride | 39 | |||||

| Zince | Zinc carbonate | ||||||

| Zinc chloride | |||||||

| Zinc Oxide | |||||||

| Zinc sulfate monohydrate |

| Number | Feed Name | CO ppm |

CU ppm | FE ppm | MN ppm |

SE ppm |

ZN ppm |

|---|---|---|---|---|---|---|---|

| Calcium | Calcium Carbonate | 33 | 300 | 300 | 39 | ||

| Calcium phosphate (monobasic) | 15800 | ||||||

| Limestone, dolomitic | |||||||

| Limestone, ground | |||||||

| Cobalt | Cobalt Carbonate | 430000 | |||||

| Cobalt Sulfate | 210000 | ||||||

| Copper | Copper chloride dihydrate | 372000 | |||||

| Copper Sulfate | 254500 | ||||||

| Copper Oxide | 798800 | ||||||

| Phosphorous | Dicalcium phosphate | 0 | 10 | 14400 | 330 | 0 | 100 |

| Phosphoric acid | 17500 | ||||||

| Magnesium | |||||||

| Magnesium chloride | |||||||

| Magnesium hydroxide | |||||||

| Magnesium Oxide | 600000 | ||||||

| Magnesium sulfate heptahydrate | |||||||

| Manganese | Manganese chloride | 430000 | |||||

| Manganese sulfate monohydrate | 325069 | ||||||

| Manganese sulfate pentahydrate | 227891 | ||||||

| Potassium | Potassium bicarbonate | ||||||

| Potassium carbonate | |||||||

| Potassium chloride | 600 | ||||||

| Potassium iodidea | |||||||

| Sodium | Sodium chlorideb | ||||||

| Sodium bicarbonate | |||||||

| Sodium phosphate (monobasic) | |||||||

| Selenium | Selenium 600 | 600 | |||||

| Sodium selenate decahydrate | 213920 | ||||||

| Sodium selenite | 456000 | ||||||

| Sodium | Sodium Chloride | ||||||

| Zince | Zinc carbonate | 521400 | |||||

| Zinc chloride | 479700 | ||||||

| Zinc Oxide | 780000 | ||||||

| Zinc sulfate monohydrate | 363600 |

a Potassium iodide = 681,700 ppm iodine

b Sodium chloride = 60.6% chloride

Source: Nutrient Requirements of Beef Cattle, 2016 and Nutrient Requirements of Dairy

Cattle, 2001

The Oklahoma Cooperative Extension Service Extension Everywhere for Everyone

The Cooperative Extension Service is the largest, most successful informal educational

organization in the world. It is a nationwide system funded and guided by

a partnership of federal, state, and local governments that delivers information to

help people help themselves through the land-grant university system.

Extension carries out programs in the broad categories of agriculture, natural resources

and environment; family and consumer sciences; 4-H and other youth; and community

resource development. Extension staff members live and work among the people they

serve

to help stimulate and educate Americans to plan ahead and cope with their problems.

Some characteristics of the Cooperative Extension system are:

- The federal, state, and local governments cooperatively share in its financial support

and program

direction. - It is administered by the land-grant university as designated by the state legislature through an Extension director.

- Extension programs are nonpolitical, objective, and research-based information.

- It provides practical, problem-oriented education for people of all ages. It is designated to take the knowledge of the university to those persons who do not or cannot participate in the formal classroom instruction of the university.

- It utilizes research from university, government, and other sources to help people

make their own

decisions. - More than a million volunteers help multiply the impact of the Extension professional staff.

- It dispenses no funds to the public.

- It is not a regulatory agency, but it does inform people of regulations and of their

options in meeting

them. - Local programs are developed and carried out in full recognition of national problems and goals.

- The Extension staff educates people through personal contacts, meetings, demonstrations,

and the

mass media. - Extension has the built-in flexibility to adjust its programs and subject matter to

meet new needs.

Activities shift from year to year as citizen groups and Extension workers close to the problems advise changes.