Metal Detectors for Food Processing

Introduction

Why should a food processor consider a metal detector? Some of the reasons are:

- Product safety

- Equipment protection

- Contract (customer) requirement

- Regulatory compliance

Of the reasons listed, perhaps the most compelling is found in the Federal Register (Vol. 51, No. 118):

“Effective measures shall be taken to protect against the inclusion of metal or other extraneous material in food. Compliance with this requirement may be accomplished by using sieves, traps, electric metal detectors or suitable means.”

Metal detectors will not guarantee a metal-free food product, but a properly designed, installed and maintained unit, along with a metal contamination control program, can be extremely effective. This fact sheet discusses the following topics regarding metal detection and removal.

- How a metal detector works

- What can be detected

- Product conditions

- Rejection mechanisms

- Purchase and installation

- Metal detection program

1. How a metal detector works

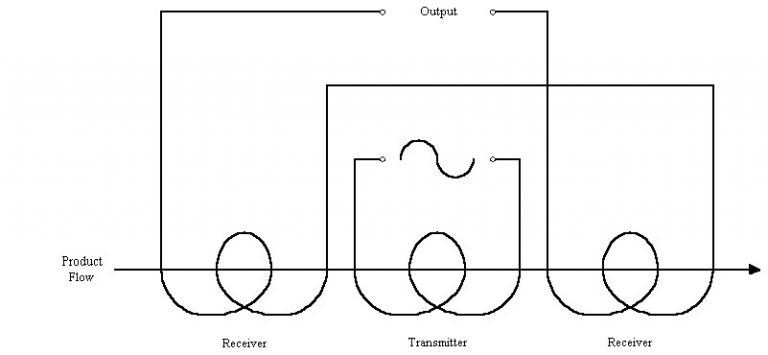

Most metal detectors use a balanced, three-coil, system to detect small particles of non-ferrous and stainless steel. The coils are wound on a non-metallic frame, each parallel with the other. The center coil is connected to a high frequency radio transmitter. Coils on either side of the transmitter coil are receivers. As these two coils are identical and placed the same distance from the transmitter, they receive the same signal and produce an identical output voltage. When the coils are connected in opposition, the output is cancelled, resulting in a zero value. A schematic of the coil configuration is shown in figure 1.

Figure 1.

When a particle of metal passes through the coils of a metal detector, the high frequency field is disturbed under one coil, changing the voltage by a few microvolts. The state of balance is lost and the output from the coils is no longer zero. It is this phenomenon that is used to detect metal.

An important aspect of metal detector operation is the metal free zone, which is needed for proper operation. The zone includes a space on each side of the aperture that must be free from any metal structure such as rollers and supports. As a general rule, this needs to be approximately 1.5 times the aperture height for fixed structures and 2 times the aperture height for moving metal such as reject devices or rollers.

2. What can be detected

All metals are either ferrous, nonferrous or stainless steel. The ease of detection will depend on their magnetic permeability and electrical conductivity. Table 1 shows metal types and their ease of detection. The size, shape and orientation (with respect to the detector coils) of the metal particle also is important. Since size, shape and orientation of metal contaminants is not possible to control, it is best to operate a metal detector at the highest possible sensitivity setting.

Table 1. Metal types and their ease of detection

| Metal Type | Magnetic Permeability | Electrical Conductivity | Ease of Detection |

|---|---|---|---|

| Ferrous (iron) | Magnetic | Good | Easy |

| Non-ferrous (copper, lead, aluminum) | Non-magnetic | Good or excellent | Relatively easy |

| Stainless steel | Usually non-magnetic | Usually poor | Relatively difficult |

3. Food product conditions

Food product conditions can have a major effect on metal detection. Electrical conductivity in foods such as cheese, fresh meat, warm bread, jam and pickles can generate a signal in a metal detector even though metal is not present. This phenomenon is known as the “product effect.” It is best to be aware of this phenomenon and to work with your metal detector supplier or manufacturer to determine the best means to compensate for product effect.

Figure 2.

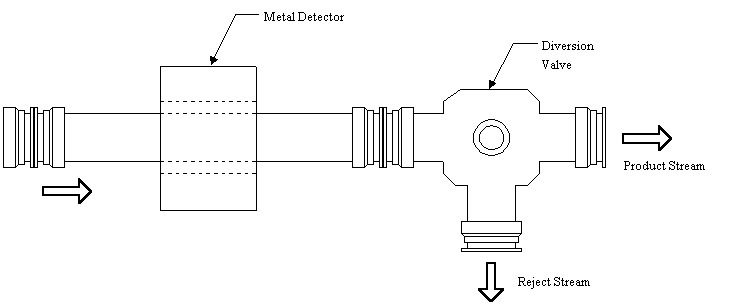

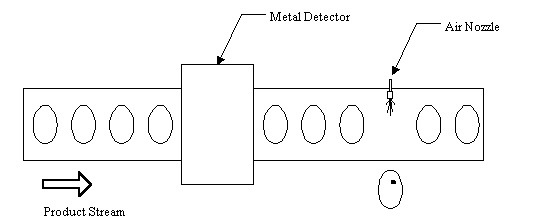

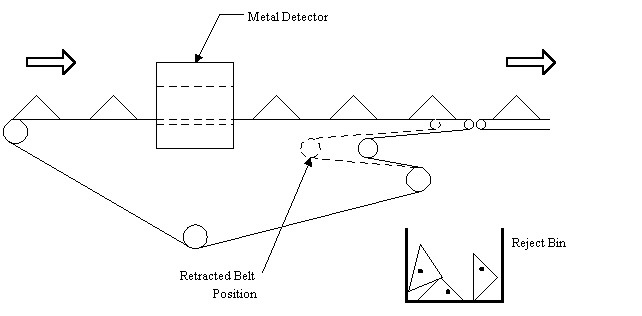

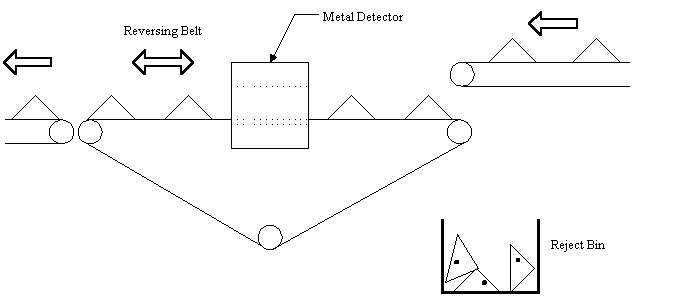

Conveyor detectors are by far the most common; examples are given in figure 3. Many variations of manual, semi-automated and fully automated rejection mechanisms are possible, such as air blow (figure 3a), push arms, retractable conveyor bed (figure 3b), reversible conveyor (figure 3c), slider gate, ink marker or coder, diversion conveyors and robotic grippers.

Figure 3a.

Figure 3b.

Figure 3c.

Free-fall detectors are often found on dry product fillers and are useful for any material that can be dropped through an aperture. A fast-acting valve or deflector plate is used to divert detected material to a separate container.

4. Purchase and installation

Some of the information needed to specify a metal detector includes:

- Thorough definition of product (or ingredient) to be inspected, including an ingredient list, physical properties and a description of the package if the product is packaged. One of the most important physical properties is moisture content.

- List of available utilities at installation site (e.g. compressed air and electric).

- Description of the operating environment (temperature, humidity, corrosive materials, etc.).

- Description of the process (how product is being made and handled in the area where the metal detector is to be installed).

- Description of controls desired (manual, automatic, semiautomatic).

- Description of the desired reject mechanism (if purchasing from the same source as the metal detector).

Table 2 lists some manufactures of metal detectors. For a more detailed list, visit the website maintained by BNP Media (Troy, Mich.) at www.foodmaster.com and search the food master equipment database for “metal detectors.” Installation of the metal detector will require a qualified electrician and a mechanical contractor familiar with metal detectors and the type of conveyors used in the operation. If there is a chance that the metal detector or the rejection mechanism could impede the normal flow of production, it may be desirable to install and test the unit during a scheduled down time to avoid production losses. An alternative is to install and test the unit on a mock production line.

Table 2.

| Advanced Detection Systems 4740 W. Electric Ave., Milwaukee, WI 53219-1626 Phone: (414) 672-0553, Fax: (414) 672-5354 |

HI-Speed Checkweigher Co., Inc. A Meter Toledo Co. 5 Barr Rd., Ithaca, NY 14850-9117 Phone: (607) 257-6000, Fax: (607) 257-6396 |

|

| Cintex of America Inc. 6919 51st St., Kenosha, WI 53144-1741 Phone: (262) 657-7848, Fax: (262) 657-3056 |

Lock Inspection Systems, Inc. 207 Authority Dr., Fitchburd, MA 01420-6094 Phone: (978) 343-3716, Fax: (978) 343-6278 |

|

| EG&G Astrophysics Inspection Systems 4031 Via Oro Ave., Long Beach, CA 90810 Phone: (310) 816-1600, Fax: (310) 513-6593 |

Loma International, Inc. 283 E. Lies Rd., Carol Stream, IL 60188 Phone: (630) 588-0900, Fax: (630) 588-1394 |

|

| Engineered Magnetics 55 Stephens St., Belleville, NJ 07109-3114 Phone: (973) 759-0818, Fax: (973) 759-6449 |

Ohio Magnetics, Inc. Stearns Magnetics Div. 5400 Dunham Rd., Maple Heights, OH 44137 Phone: (216) 662-8484, Fax: (216) 662-2911 |

|

| Eriez Magnetics 2200 Asbury Rd., P.O. Box 10608, Erie, PA 16514-0608 Phone: (814) 835-6000, Fax: (814) 838-4960 |

Par Vision Systems Corp. 8383 Seneca Turnpike, New Hartford, NY 13414-1103 Phone: (315) 738-0600, Fax: (315)-738-0562 |

|

| Thermo Electron Corp. 642 Blackhawk Dr., Westmont, IL 60559 Phone: (877) 290-7422, Fax: (763) 783-2525 |

Safeline Metal Detection 6005 Benjamin Rd., Tampa, FL 33634 Phone: (813) 889-9500, Fax: (813) 881-0840 |

*Oklahoma State University and FAPC do not endorse any specific equipment or manufacturer. The listing is given for information purposes only.

5. Metal detection program

A formal metal detection program will help to insure product quality. Metal detectors may be used in various phases of production. A combination of finished and bulk ingredient and product inspection gives the best performance. Detectors may need to be placed after certain process equipment (such as size-reduction) that are prone to breaking or chipping metal materials.

A sensitivity standard (or standards) should be set for the entire facility. An important aspect of this is to identify an agreed upon minimum particle type and size. For example, a typical detection standard for finished product might be to remove all spherical, non-magnetic particles larger than 2.0-mm and all spherical, magnetic particles larger than 1.5-mm. Only detectors that meet these standards would be considered for purchase and installation. The conditions should be clearly marked on the side of any installed detector and samples of the correct diameters should be available for testing the unit.

Metal detectors should be operated at the maximum sensitivity setting for a given product. The maximum acceptable sensitivity setting will allow the detector to perform reliably for extended periods of time without excessive false rejects. Scheduled testing of the detector and reject device (with ferrous and nonferrous metal samples) will confirm proper operation. Intervals between tests can be determined by the consequence of a failed test. Testing every two to four hours is typical. A testing procedure should be established and followed. A plan of action must be specified for failed tests. Every effort should be made to identify, document and correct the source of detected metal.

Conclusion

Metal detectors are an important part of a comprehensive contamination control program. If they are specified, installed, operated and maintained correctly, they will contribute to improving product quality and reducing losses. A properly used metal detector should not be considered as insurance against metallic contamination. Rather, it is a diagnostic device that can help to discover accidental metallic contamination. Plans and procedures should be in place to prevent contamination. If contamination does occur, contaminants must be identified immediately, traced back to their source and eliminated.

This fact sheet has focused on metal detectors; however, other devices are available to remove metallic and other product contaminants. Line strainers are useful for removing foreign particles from liquid products and magnets have long been used to remove ferrous materials from particles and pumpable liquids.

Reference

Lock, Andrew. 1990. The Guide to Reducing Metal Contamination in the Food Processing Industry. Safeline Inc., Tampa, Florida.

Tim Bowser

FAPC Food Process Engineer