Meat Inspection and Grading

Too many times consumers take things for granted about their food products. Meat inspection and grading are those activities related to meat products that are important in assuring the best product in the world for the consumer. The purpose of this fact sheet is to broaden your knowledge of meat inspection and grading and reinforce your confidence in the wholesome meat products you are buying.

What is meat and Poultry Inspection?

Meat inspection assures the consumer that the meat and poultry products are clean, safe, and wholesome for human consumption at the time of purchase. This involves inspection of the live animal, carcass, internal organs, plant facilities, equipment, personnel, and transportation system.

Meat inspection became law under the Federal Meat Inspection Act of 1906. It required inspection of red meat products sold in interstate and foreign commerce. The Act established strict sanitation requirements for plants and called for examination of all labels for truthfulness and accuracy. In 1967, the Federal Meat Inspection Act was amended with the Wholesome Meat Act. This amendment established the Federal-State Cooperative inspection program, which required State Inspection programs to be “at least equal to” the Federal inspection program. The 1968 Wholesome Poultry Products Acts extended the same provisions to poultry inspection. In Oklahoma, we have both State and Federal inspection services available.

The Difference Between state and Federal Inspection

As previously mentioned, both programs are basically the same. The difference relates to limitations of sales and distribution on the state inspected operation and to who administers the services.

First, the Federal Meat and Poultry Inspection Program is administered by the U.S. Department of Agriculture’s Food Safety and Inspection Service (FSIS). The organizational structure of FSIS consists of a slaughter inspection division, a processed meat inspection division, a technical services, and a compliance and evaluation staff. Each division has defined responsibilities in monitoring meat and poultry products for wholesomeness and labeling accuracy.

Meat inspectors are divided into two classes: (1) veterinary inspectors and (2) lay inspectors. In both cases, they are employed and paid by the U.S. government and not by the individual processors. The veterinary inspectors are college trained veterinarians, while the lay inspectors are individuals who have training and experience in handling meat. The lay inspectors are under the direction of a veterinary inspector.

The same organizational structure exists in a state inspection program. The Oklahoma state inspection division is under the direction of the Oklahoma State Department of Agriculture. The cost of operating the inspection division is budgeted through state appropriations. The State Inspection Program is subject to a Federal review to certify that it is equal to federal inspection.

The major difference between Federal inspection and state inspection is the restriction that state inspected plants are under in distributing their products. Meat that receives Oklahoma state inspection must be used and sold within the state. It cannot be shipped out of the state of Oklahoma. Federally inspected products may be sold or shipped across state lines or exported to foreign countries.

Marks of Wholesomeness

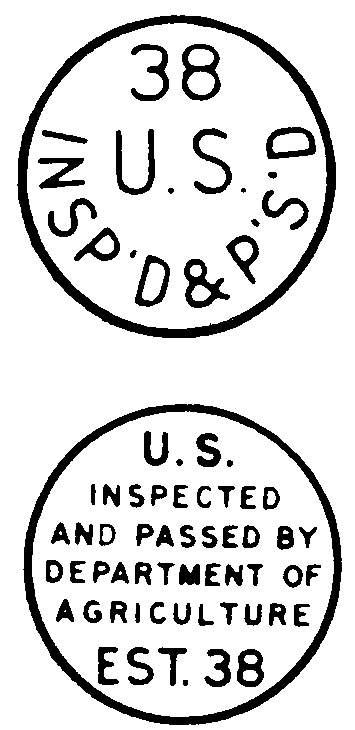

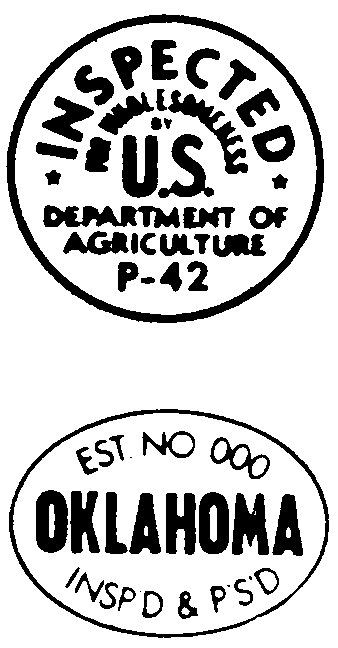

Inspection stamps are the consumer’s assurance that a product is wholesome and accurately labeled. The plant where the product was slaughtered or produced is identified by the number on the inspection stamp.

ABOVE: This is the official USDA mark for approved meat carcasses. It is stamped only on major cuts of the carcass, so it may not always be visible on consumer cuts like roasts and steaks. The blue ink used for branding of fresh meat is a food grade dye and safe for consumption.

BELOW: This mark is on all federally inspected pre-packaged processed meat products from

vacuum-packed beef brisket to frankfurters.

ABOVE: Federally inspected fresh and frozen poultry and processed products carry this mark. Although visible on the packages of all frozen and processed products, the mark may not always appear on the fresh poultry which has been bulk shipped and then packaged at the retail level.

BELOW: This is the official Oklahoma inspected mark on all approved meat for sale.

Inspection Process

Inspection begins with the review of the plans for a slaughtering or processing plant. Plans for the facilities, equipment and procedures must be approved to insure that the plant will have a safe and sanitary operation. The floor plans, water supply, waste disposal system, lighting, and other parts of the plant must be approved either by the state inspection technical services office or the USDA Meat Inspection Office.

The inspector conducts a pre-op inspection of the plant and equipment before operations begin each day and continues this inspection throughout the day to see that sanitary conditions are maintained. The inspector has the authority to stop the plant operation any time unsanitary conditions arise in a processing operation.

Inspection also checks the animals before slaughter to be sure they are not diseased. Any animal appearing sick undergoes a special examination. No dead or dying animal can be brought into a slaughtering plant. After slaughter, each carcass and the internal organs are examined for signs of disease or contamination that would make all or part of the carcass unfit as human food. In addition, government inspectors regularly send tissue samples to their laboratories to determine the presences of illegal drug and chemical residues. If illegal amounts of toxic residues are detected, the meat from that carcass is not permitted to enter the meat distribution system, but will go to inedible rendering.

Much of the meat and poultry slaughtered in the United States today finds its way into products like ham, sausages, soups, frankfurters, frozen dinners, pizza, and pot pies. The inspection service is responsible for the safety, content, and labeling accuracy of these products. The inspection service reviews the procedures, recipes, and labels used by the meat processors to assure that meat and poultry products will be safe to eat and accurately labeled.

Inspection at Retail Level

The inspection that takes place at the retail level is primarily conducted by the county health department. The health department will be primarily concerned with sanitation and labeling. The state department of meat inspection compliance staff will spot check labels and net weight and check for adulteration of fresh meats. Retail stores are most often inspected because of consumer complaints.

The Difference Between Meat Inspection and Meat Grading

Meat inspection is a careful and continuous examination of the meat and meat products for wholesomeness. Inspection is mandatory when meat is being slaughtered and processed for sale. Those plants that custom slaughter for the owners of animals are exempt from daily inspection since the owner of the animal assumes responsibility for the wholesomeness of the product. However, custom plant facilities must be approved by the inspection service and the plant is subject to a monthly sanitary inspection. Our federal tax dollars support the federal inspection system. Federal monies also support approximately 50 percent of each state’s inspection system.

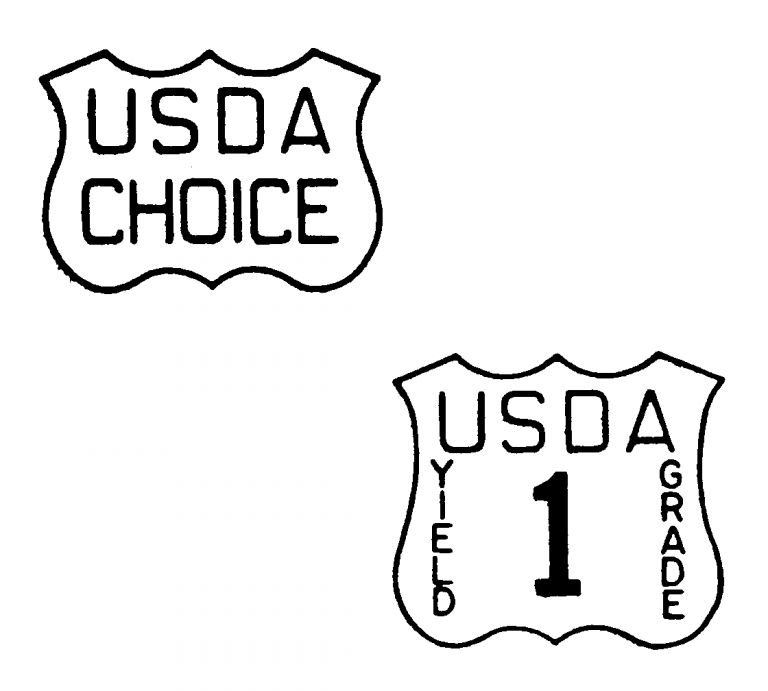

Meat grading is a procedure by which carcasses are segregated on the basis of their expected palatability (how it will taste with respect to tenderness, juiciness, and flavor) and yield attributes (closely trimmed edible cuts from the carcass). Grading serves to separate products into standardized groups of common characteristics to aid in the marketing of these products.

To determine the quality grade of the carcass, the USDA grader considers the marbling of rib eye, maturity of skeletal bone, and the color and texture of the lean. The quality grades of beef are USDA Prime, USDA Choice, USDA Good, and USDA Standard, Commercial and Utility.

When beef is graded and stamped for quality, it must also be graded and stamped for yield or quantity of edible meat cuts. Beef yield grades are 1, 2, 3, 4, and 5. Yield grade 1 is the leanest and highest in yield or cutability and yield 5 is the fattest and lowest in yield or cutability. Beef yield grades are determined on the basis of areas of rib eye muscle; thickness of fat over the rib eye; percent of kidney pelvic and heart fat; and the carcass weight. These four factors are used by the USDA grader in a formula to determine yield grade.

Meat grading is not mandatory. If the packer desired to sell graded beef, he pays the government the cost of having a USDA grader to be in his plant to grade the carcasses.

Most beef sold at the retail meat counter is USDA Choice, Yield 2 or 3. Some retail chains may be selling their “house brand,” which may not be USDA graded, but meets the retailer’s own specifications of marbling and yield grade.

Lamb is also quality and yield graded similar to the grading of beef carcasses. The grades of lambs are Prime, Choice, Good, Utility, and Cull. The determination of Quality is made by considering three factors: bone maturity, fat streaking in flank muscles, and the firmness of the fat and lean. The yield grade of lamb is determined on the basis of leg conformation, percent of kidney and pelvic fat, and fat thickness over the rib eye. There are five yield grades ranging from 1 to 5, with yield grad 1 providing the greatest amount of edible meat and 5 the least amount from a carcass.

Grades for barrow and gilt carcasses are based on two general considerations: (1) quality, indicating characteristics of the lean and (2) expected combined yields of the four lean cuts (ham, loin, picnic shoulder, and boston butt). One January 13, 1985, new U.S. standards for grades of barrow and gilt carcasses were put into effect. The new grades are based on the backfat thickness over the last rib, with an adjustment up or down for superior or inferior muscling, respectively. There are three degrees of muscling: thick (superior), average and thin (inferior). Hog carcasses having adequate quality are assigned one of four cutability grades: No. 1, No. 2, No. 3, or No. 4.

Beef and lamb grading identification labels: quality grade label (top left); yield grade label (bottom right).

Summary

Remember that there is a difference between inspection and grading. Inspection is mandatory on meat products that are for sale to the public and may be conducted by the State Department of Agriculture or the U.S. Department of Agriculture. Grading is a voluntary program that segregates meat products on the basis of their expected palatability or yield attributes. The service is provided by the U.S. Department of Agriculture.

Frederick K. Ray

Former Animal Foods Specialist