Land Application of Biosolids in Oklahoma Soils

Biosolids are byproducts left over from the treatment of waste by municipal wastewater treatment plants. Biosolids consist primarily of partially decomposed organic matter and plant nutrients including nitrogen (N), phosphorus (P), potassium (K), sulfur (S), calcium (Ca), magnesium (Mg), as well as micronutrients iron (Fe), copper (Cu), manganese (Mn), zinc (Zn), nickel (Ni), boron (B) and molybdenum (Mo). However, biosolids may contain certain undesirable components such as heavy metals, organic chemicals, and pathogens. The quality of biosolids depends on both the characteristics of the original wastes and the treatment processes. The treatment process involves reduction of pathogens and the stabilization of organic matter. Once treated, biosolids may be recycled and land applied as soil amendments to improve and maintain soil quality and stimulate plant growth. Land application of biosolids occurs in all 50 states.

Nationally, biosolids are commonly disposed by incineration, landfill or land application. Approximately 60 percent of the biosolids produced each year in the U.S. are land applied. Biosolids have been successfully used as soil amendments to forests, rangeland, reclamation sites, agricultural lands, public parks and golf courses. More than 50,000 dried tons of stabilized municipal biosolids are land applied in Oklahoma each year (ODEQ, 2013a). More than 60 percent of the municipal biosolids produced in Oklahoma have been successfully land applied (ODEQ, 2013b). The remainder of the produced biosolids is landfilled and none of the biosolids are incinerated in Oklahoma (personal communication, Biosolids Coordinator ODEQ). The treatment of wastewater and disposal of biosolids in Oklahoma are regulated by the Department of Environmental Quality (ODEQ).

Overview of Part 503 Rule

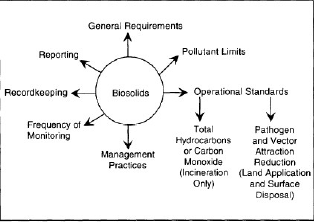

In 1993, the U.S. Environmental Protection Agency (USEPA) implemented regulations on land application of biosolids under Code of Federal Regulations Title 40, Part 503. The regulations are commonly referred to as Part 503 rule. Basically, the Part 503 rule established pollutant limits and operational standards to control disease-causing organisms and to reduce the attraction of vectors (disease-carrying organisms) to biosolids. Additionally, the Part 503 rule determined general requirements and management practices, recordkeeping and reporting, as well as frequency of monitoring (Figure 2). The Part 503 rule utilizes risk-based pollutant limits to protect human health and the environment. Although the individual states must meet EPA requirements, they may pass regulations that exceed EPA requirements.

Figure 1. An example of biosolids after most water has been removed.

Figure 2. The basic components of the Part 503 standard (USEPA, 1994).

The regulations regarding land application of biosolids are contained in Oklahoma Administrative Code (OAC) 252:606: Oklahoma Pollutant Discharge Elimination System (OPDES) Standards, Chapter 8: Biosolids Requirements (http://www.deq.state.ok.us/rules/606.pdf). According to the Biosolids Coordinator for ODEQ, the state of Oklahoma follows the federal regulations with the exception that Oklahoma does not allow the surface disposal of biosolids.

Basically, the Part 503 rule established two quality criteria for heavy metals in biosolids – the pollutant Ceiling Concentrations and a “exceptional quality” Pollutant Concentrations (Table 1), two quality criteria for pathogens in biosolids – Class A and Class B (discussed below), and two approaches for meeting vector attraction reduction (discussed below).

To qualify for land application in Oklahoma, biosolids must (a) contain heavy metal levels that are less than the pollutant Ceiling Concentrations (Table 1), (b) meet Class B pathogen reduction requirements and (c) meet vector attraction reduction requirements. Other general requirements include:

- Soil pH: soil with pH less than 5.5 cannot receive biosolids unless amended to adjust pH prior to land application;

- Phosphorus and nitrogen: annual biosolids land application rate cannot exceed nitrogen and phosphorus rates for the crop grown and cannot be applied in rates that result in phytotoxicity;

- Topography: no land application of liquid biosolids on land with a slope greater than 5 percent but less than 10 percent unless erosion or runoff controls are used – land having a slope greater than 10 percent may be utilized for land application of dewatered and dried biosolids only with special approval from DEQ;

- Karst soils: use of land application sites that overlie areas subject to karstification is prohibited;

- Soil sampling: (a) Background and other soil sampling and analyses must be a composite sample taken from 80 acres or less for each land application site; (b) Applier must collect representative soil samples and have them analyzed as follows: (1) For soil pH and the nutrients – nitrogen (N), ammonia (NH4), nitrates (NO3), potassium and phosphorus prior to the next annual application of biosolids; (2) For metals in Table 3 of 40 CFR § 503.13 (b) after every third year of use prior to the fourth year of use; and (3) For all required background metals prior to the fourth year of biosolids application on each site.

Table 1. Pollutant limits and loading rates for the land application of biosolids.

| Pollutant | Ceiling Concentration Limits (mg/kg) | Pollutant Concentration Limits (mg/kg) |

|---|---|---|

| Arsenic (As) | 75 | 41 |

| Cadmium (Cd) | 85 | 39 |

| Copper (Cu) | 4300 | 1500 |

| Lead (Pb) | 840 | 300 |

| Mercury (Hg) | 57 | 17 |

| Molybdenum (Mo) | 75 | 40† |

| Nickel (Ni) | 420 | 420 |

| Selenium (Se) | 100 | 100 |

| Zinc (Zn) | 7500 | 2800 |

| Applies to: | All sewage sludge | Bulk or bagged sewage sludge |

| Table 1, | Table 3, | |

| From Part 503 | Section 503.13 | Section 503.13 |

| Pollutant | Cumulative Pollutant Loading Rate Limits (kg/ha) | Annual Pollutant Loading Rate Limits (kg/ha/365 d) |

|---|---|---|

| Arsenic (As) | 41 | 2 |

| Cadmium (Cd) | 39 | 1.9 |

| Copper (Cu) | 1500 | 75 |

| Lead (Pb) | 300 | 15 |

| Mercury (Hg) | 17 | 0.85 |

| Molybdenum (Mo) | 40† | ‡ |

| Nickel (Ni) | 420 | 21 |

| Selenium (Se) | 100 | 5 |

| Zinc (Zn) | 2800 | 140 |

| Applies to: | Bulk sewage sludge | Bagged sewage sludge |

| Table 2, | Table 4, | |

| From Part 503 | Section 503.13 | Section 503.13 |

† Original Part 503 value is under re-examination by USEPA, this value was obtained from O?Connor et al. (2001).

‡ Under re-examination by USEPA.

(Source: USEPA 1995, Process Design Manual: Land Application of Sewage Sludge and Domestic Septage, also available at http://www.ecfr.gov/cgi-bin/text-idx?SID=2d7db00a014cc868bb9c0ed112256dd1&mc=true&node=se40.32.503_113&rgn=div8

Regulatory Limits of Metals in Biosolids

Ceiling Concentration Limits (CCL).

For land application in Oklahoma, all biosolids must contain less pollutant than the CCL, meet certain pathogen reduction requirements, and meet certain vector attraction reduction requirements. These concentrations are also known as EPA Table 1.

Pollutant Concentration Limits (PCL).

The PCLs are monthly average concentrations. Biosolids may qualify as “Exceptional Quality” (EQ) if they contain levels less than the Pollutant Concentration Limits, meet Class A pathogen levels (virtual absence of pathogens) and meet certain vector attraction reduction requirements. These biosolids have fewer restrictions on use, rate of application or application record keeping and are not subject to cumulative loading rates. For instance, there are no limits on lifetime quantity of pollutants that can be applied to a site and the biosolids application rate is dependent only on the agronomic rate. These concentrations are also known as EPA Table 3 limits, and are the most stringent pollutant limits included in Part 503 for land application. The majority of EQ biosolids produced in Oklahoma are bagged by municipalities and sold as compost.

Cumulative Pollutant Loading Rate Limits (CPLR).

Biosolids which do not qualify as EQ biosolids are subject to loading rate limits. The maximum amount of a pollutant that can be applied to a site by bulk biosolids is known as the CPLR. The CPLRS represent the maximum amount of a pollutant that can be added to a soil without causing adverse effects on plants, animals, and humans. These biosolids must be applied in bulk form and records are kept until the CPLR of the first pollutant is reached. Once the CPLR has been reached, no more biosolids may be land applied to the site. These concentrations are also known as EPA Table 2.

Annual Pollutant Loading Rate Limits (APLR).

The maximum amount of a pollutant that can be applied to a site by bagged or biosolids in any other container in a 12-month period is the APLR. These concentrations are also known as EPA Table 4.

Pathogen Reduction

Biosolids are classified into two classes (Class A or Class B) based on the density (numbers per unit of mass) of pathogens present in the biosolids. Class A biosolids contain no detectable levels of pathogens (i.e. Salmonella sp. bacteria, enteric viruses and viable helminth ova). Class B biosolids have been treated, but still contain levels of detectable pathogens that do not pose a threat to public health and the environment as long as actions are taken to prevent exposure to the biosolids after their use or disposal. The Part 503 rule pathogen reduction requirements may be met by (a) treatment of biosolids with specific technologies or (b) evaluation of the quality of biosolids using certain performance results.

When biosolids contain detectable levels of pathogens, six available treatment alternatives are listed by the Part 503 rule so biosolids may be treated and classified as Class A with respect to pathogens. Only one of these six alternatives must be met for the biosolids to be deemed Class A. The six alternatives are listed and discussed briefly below:

- Thermally Treated Biosolids: Biosolids must be treated with one of four time-temperature regimes;

- Biosolids Treated in a High pH-High Temperature Process: Biosolids must meet specific pH, temperature and air-drying requirements;

- Biosolids Treated in Other Processes: It must be demonstrated that the process can reduce enteric viruses and viable helminth ova. Maintain operating conditions used in the demonstration after the pathogen reduction is finished;

- Biosolids Treated in Unknown Processes: Demonstration of the process is unnecessary, instead testing for Salmonella sp. bacteria or fecal coliform bacteria, enteric viruses and viable helminth ova is conducted at the time the biosolids are used or disposed of or are prepared for sale or give-away;

- Use of Processes to Further Reduce Pathogens (PFRP): Biosolids are treated with one of the PFRPs. Processes include: composting, heat drying, heat treatment of liquid biosolids, thermophilic aerobic digestion of liquid biosolids, beta ray irradiation, gamma ray irradiation and pasteurization;

- Use of a Process Equivalent to PFRP: Biosolids are treated in a process equivalent to one of the PFRPS, as determined by the permitting authority.

However, in addition to meeting the requirement of one of the six alternatives listed above, the following requirements must be met for all six Class A pathogen alternatives: Either (a) the density of fecal coliform in the biosolids must be less than 1,000 most probable numbers (MPN) per gram total solids (dry-weight basis), or (b) the density of Salmonella sp. bacteria in the biosolids must be less than 3 MPN per 4 grams of total solids (dry-weight basis). Alternatives three and four require the density of enteric viruses in the sewage sludge shall be less than one Plaque-forming Unit (PFU) per 4 grams of total solids (dry weight basis) and the density of viable helminth ova in the sewage sludge shall be less than one per four grams of total solids (dry weight basis).

Additionally, either of these requirements must be met at one of the following times: when the biosolids are used or disposed; when the biosolids are prepared for sale or give-away in a bag or other container for land application; or when the biosolids or derived materials are prepared to meet the requirements for EQ biosolids. Pathogen reduction must take place before or during vector attraction reduction, except when the pH adjustment, percent solids vector attraction, injection or incorporation options are met.

Because Class B biosolids may contain some pathogens, land application requirements include site restrictions that prevent crop harvesting, animal grazing and public access for a certain period of time until environmental conditions have further reduced pathogens. Similarly to Class A, Part 503 rule lists multiple treatment options for biosolids with respect to pathogens for the Class B classification. Only one of these three alternatives must be met for the biosolids to be deemed Class B. The alternatives are listed and discussed briefly below:

- The Monitoring of Indicator Organisms – Test for fecal coliform density as an indicator for all pathogens. Seven samples of treated biosolids should be collected shortly before biosolids use or disposal and the geometric mean fecal coliform should be less than 2 million colony-forming units (CFU) or the most probable number (MPN) per gram of biosolids (dry-weight basis);

- Biosolids Treated in a Process to Significantly Reduce Pathogens (PSRP): Biosolids must be treated in one of the PSRPs. Processes include: aerobic digestion, anaerobic digestion, composting and lime stabilization;

- Biosolids Treated in a Process Equivalent to a PSRP: Biosolids must be treated in a process equivalent to one of the PSRPs, as determined by the permitting authority.

Vector Attraction Reduction Options

Because vectors such as rodents, birds and insects can spread disease by harboring and transferring pathogens, reduction of the attractiveness of biosolids to these vectors decreases the potential for disease. The Part 503 rule specifies that at least one of the following 10 vector attraction reduction options be met when biosolids are land applied: reduction in volatile solids content, additional digestion of anaerobically digested biosolids, additional digestion of aerobically digested biosolids, specific oxygen uptake rate (SOUR) for aerobically digested biosolids, aerobic processes at average temperatures greater than 40 C for 14 days or longer (e.g., during biosolids composting), addition of alkaline materials to raise pH under specified conditions, moisture reduction of biosolids containing no unstabilized solids (75 percent solids), moisture reduction of biosolids containing unstabilized solids (90 percent solids), biosolids injection and incorporation of biosolids into the soil.

Conclusion

Land application of biosolids is a beneficial way to recycle organic matter and plant nutrients. Biosolids have successfully been used to improve physical, chemical and biological properties of soils and to restore degraded ecosystems. However, biosolids may contain heavy metals, organic chemicals and pathogens that may be detrimental to human health and the environment. Therefore, state and federal rules should be followed to prevent potential agronomic and environmental effects from biosolids land application.

References

O’Connor, G.A., R.B. Bropst, R.L. Chaney, R.L. Kincaid, L.R. McDowell, G.M. Pierzynski, A. Rubin, and G.G. Van Riper. 2001. A modified risk assessment to establish molybdenum standards for land application of biosolids. J. Environ. Qual. 30:1490–1507.

Oklahoma Department of Environmental Quality (ODEQ). 2013a. Land Application of Biosolids in Oklahoma – Background. https://www.deq.state.ok.us/factsheets/water/Land%20Application.pdf

Oklahoma Department of Environmental Quality (ODEQ). 2013b. Biosolids Management in Oklahoma. https://www.deq.state.ok.us/factsheets/water/ConsiderationBiosolidsMgt.pdf

USEPA. 1995. Process design manual: Land application of sewage sludge and domestic septage. EPA/625/R-95/001. Office of Research and Development, Cincinnati, OH.

USEPA. 1994. A plain English guide to the EPA Part 503 biosolids rule. EPA-832/R-93/003. Office of Wastewater Management, Washington, DC.

Hailin Zhang

Department of Plant and Soil Sciences