Grading “Cheaty” Wheat

The presence of “chess” or “cheat” in a sample provides a challenge in grading since this material is similar in size and shape to wheat kernels. When wheat containing chess is graded under standard procedures, most of the chess is not removed as dockage and remains in the sample to influence test weight, the percentage of shrunken and broken kernels (SBK), and the percentage of foreign material (FM). Not removing chess as dockage lowers the test weight and raises the level of SBK and FM. This lowers the numerical grade. However, even when the grade premiums and discounts are considered, elevators which fail to use special cheat procedures will usually cost themselves money by paying wheat price for material that will be considered dockage when they deliver it to the port or terminal elevator. Flour millers and exporters are beginning to include upper limits for FM and SBK in their contracts. These contract changes will limit the terminal elevators’ opportunities to blend out “cheaty” wheat.

Official Grading Procedures

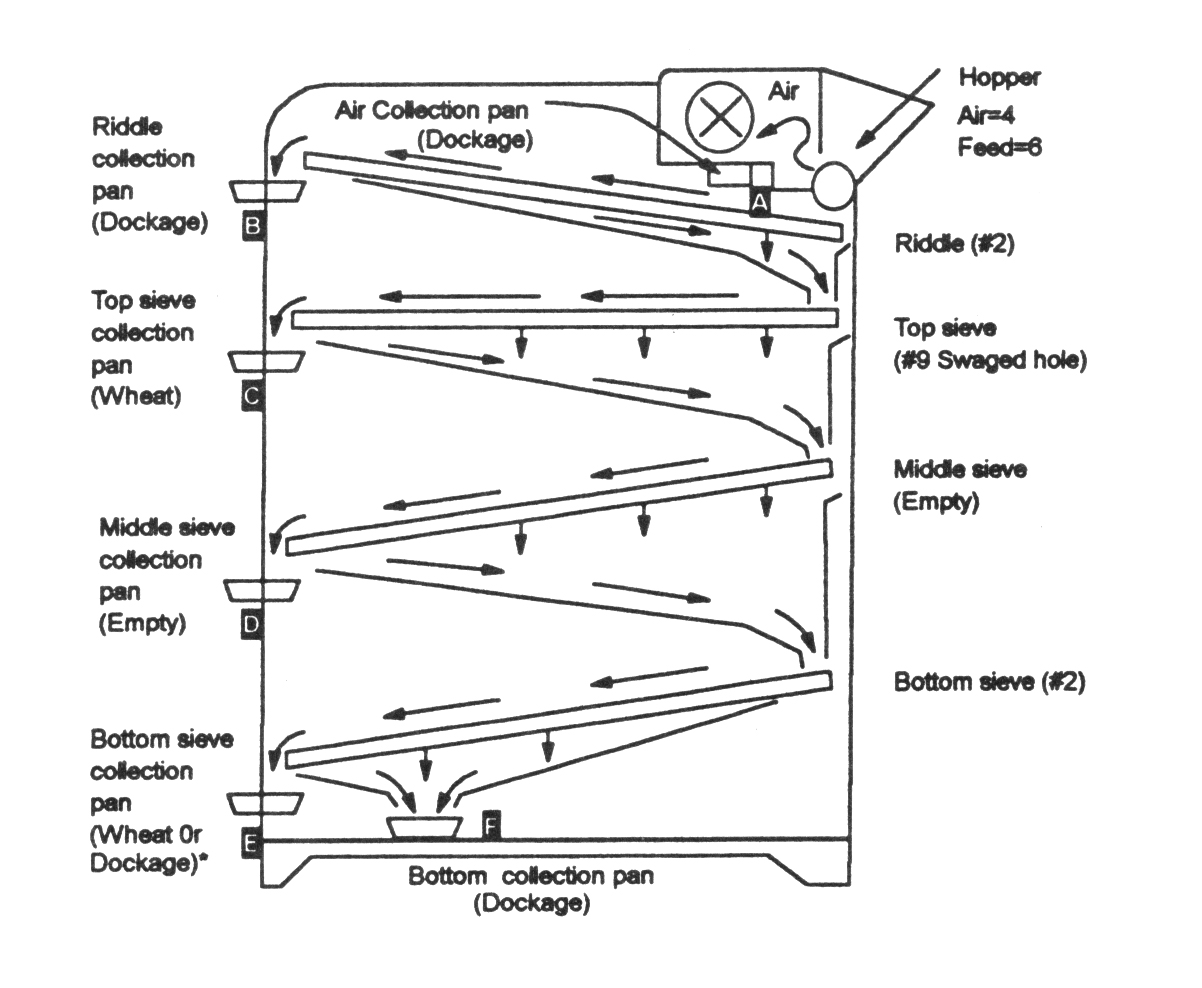

The Federal Grain Inspection Service (FGIS) has specific procedures for officially grading wheat with a large proportion of chess or cheat. A sample of approximately 1000 grams is used to determine the percentage of dockage. Wheat dockage is certified to the nearest tenth percent (0.1%, 0.2%, 0.3%, etc.). When a visual inspection indicates that chess is present in the sample, the inspector hand picks a 50-gram sample to determine the percentage of chess by weight. If more than 0.5% chess (by weight) is present, the sample is run on a mechanical dockage tester under special chess procedures. The special chess procedures for a Carter Day Dockage Tester1 are:

Set-up:

- Set air control at 4.

- Set feed control at 6.

- #2 riddle in the riddle carriage.

- #9 swaged-hole sieve in the top sieve carriage.

- No sieve in the middle sieve carriage.

- #2 sieve in the bottom sieve carriage.

Dockage will consist of:

-

The material removed by the aspirator that is found in the air collection pan (pan A in Figure 1).

-

The material going over the riddle and falling in the riddle collection pan (pan B in Figure 1).

-

The material passing through the #9 swaged-hole sieve and passing over the top of the #2 sieve that falls in the bottom collection pan (pan E in Figure 1) provided that this material is at least 50% chess.

-

The material that passed through the bottom #2 sieve which falls in the bottom collection pan (pan F in Figure 1).

Note that this procedure requires that all of the material passing through the #9 sieve and remaining on top of the #2 sieve (pan E in Figure 1) be hand picked to determine the percentage of chess by weight. When there is less than 50% chess in pan E, the sample is re-run under standard procedures. In summary, there are two thresholds which determine whether a given sample should be graded under the chess procedures: 0.5% or more chess (by weight) hand picked from a 50-gram portion prior to grading, and at least 50% chess (by weight) in pan E.

Hand Sieving Procedures for Wheat Containing Cheat or Chess

Remove dockage prior to determining the test weight. The size of the test weight kettle determines the sample size for determining dockage. Most elevators will need a sample of approximately 1,000 grams. FGIS’s Practical Procedures for Grain Handlers guidelines allows elevators that use a one pint test weight kettle to use a smaller portion (approximately 500 grams) to determine dockage, provided there is sufficient dockage-free wheat to overflow the kettle. Wheat dockage is certified to the nearest tenth percent (0.1%, 0.2%, 0.3%, etc.). There are no approved hand sieving procedures for grading cheaty wheat. Elevators that grade wheat by hand should try to establish grading procedures yielding grades that most closely correspond to the official grades for the same or similar samples. The following practical procedures for grading cheaty wheat were tested at the OSU grain grading schools. When the samples contained 10% or more chess, these procedures outperformed standard hand sieving procedures in approximating actual official grades.

Our recommended special hand sieving procedures are:

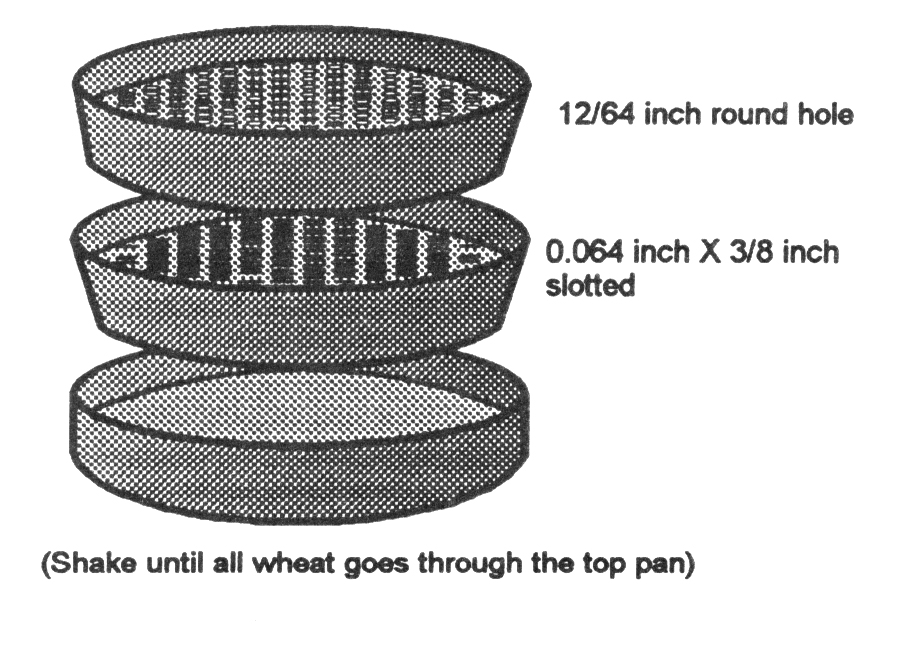

For sieving, place a 12/64 round-hole sieve on top of a 0.064-3/8 slotted sieve (Figure

2). (Note that the 0.064 by 3/8 oblong-hole sieve is replacing the standard 5/64 round-hole

as the bottom sieve.) Place approximately 1/3 of the sample at a time on top of the

sieve and shake the sieve vigorously until all of the wheat passes through it. Determine

the percentage of dockage by combining and weighing all of the material which remained

on top of the top (12/64 round-hole) sieve and which passed through the bottom (064-3/8

slotted) sieve. Calculate the percentage by dividing the weight of the dockage by

the total sample weight.

After the percentage of dockage is determined, use the dockage-free sample to determine the test weight. Divide out representative portions to determine the percentage of shrunken and broken kernels (250 grams), foreign material (30 grams), and damaged kernels (15 grams). Note that the same 0.064 by 3/8 oblong-hole sieve which was used in the special chess dockage procedure is also used to determine shrunken and broken kernels.

Economic Impact of Grading Procedures

Using standard grading procedures on samples containing high levels of cheat or chess will usually result in a loss to the elevator. Table 1 compares the grade on the same sample of wheat obtained with standard hand sieving procedures and special chess hand panning procedures with the official grade. As the table indicates, the standard grading procedures understate the test weight and overstate the amount of SBK and FM, relative to the official grade. An elevator using standard hand sieving procedures would have designated the wheat as U.S. #5 with 2% dockage and would have paid the producer $1,548 for a 500-bushel load (at a market price of $3.00). Had the elevator used our special chess hand panning procedures, it would have designated the wheat U.S. #4 with 11% dockage and paid $1,424. When the elevator sells the load of wheat, based on an official grade, it will be designated U.S. #2 wheat with 19% dockage with a value of $1,316 under the current schedule of grade discounts.

Table 1. Comparison of Grading Methods for a Sample Containing Chess.

| Grading Procedure | Standard Hand Sieving | Special Chess Hand Sieving Procedure | Official Grading Dockage Procedure (Mechanical Tester) |

|---|---|---|---|

| Dockage | 2% | 13% | 19% |

| Test Weight | 51.2# | 54# | 58# |

| Shrunken & Broken Kernels | 12.90% | 4.50% | 0.50% |

| Foreign Material | 5% | 2% | 1% |

| Damaged Kernels | 1% | 1% | 1% |

| Total Defects | 18.90% | 7.50% | 2.50% |

| Grade | U.S. #5 HRW | U.S. #4 HRW | U.S. #2 HRW |

| Bushels paid for | 490 | 435 | 405 |

| Grade Discount/bu. | 7¢ | 5¢ | 0¢ |

| Test Weight Discount/bu | 4.5¢ | 3¢ | 1¢ |

| Dockage Discount/bu | 4¢ | 5.2¢ | 7.2¢ |

| FM Discount/bu | 8¢ | 2¢ | 0¢ |

| Net Price/bu | $2.77 | $2.48 | $2.27 |

| Value of 500-Bushel Load | $1,354.80 | $1,078.80 | $919.38 |

In this example, an elevator which uses standard hand sieving procedures and resells the grain, based on an official grade, loses $435/load. Switching to the special chess hand panning procedures reduces the loss to $159/load. Elevators using the official chess procedures with Carter Day Dockage Testers (or other equivalent machine) would, of course, match the official grades and suffer no loss due to grade differences. In this extreme example, an elevator could pay for a mechanical dockage tester with less than 40 loads of high chess wheat.

Extension Economist

Extension Economist