Drill Condition and Wheat Emergence in Oklahoma: A Survey

Introduction

Stand establishment is the first step in producing a good wheat crop, and most producers intend to obtain a uniform stand of wheat. However, intentions are not always the same as reality when it comes to wheat establishment. A study conducted in the early 1990s by the OSU Small Grains Extension Program compared producer perception of wheat seeding accuracy with actual field measurements. Researchers found that producers expected an average of 77 percent planted seeds to result in established wheat plants, but in reality only 57 percent of viable wheat seed actually emerged. Poor emergence was partially explained by the fact that a mere 21 percent of producers were planting at their target seeding depth and 90 percent of fields surveyed had greater than 0.25-inch variation in seeding depth.

Several improvements in drill design and seed quality have occurred during the past 20 years, so we designed a similar study to determine if these advances have resulted in actual improvements in stand establishment. During the 2009 and 2010 wheat planting seasons, producers who were in the process of sowing were stopped and asked to participate in our survey. Upon their consent, we made visual observations of overall drill condition, soil seeding condition and surface residue. We surveyed a total of 30 producers (one field per producer) across western Oklahoma.

Field and wheat drill condition

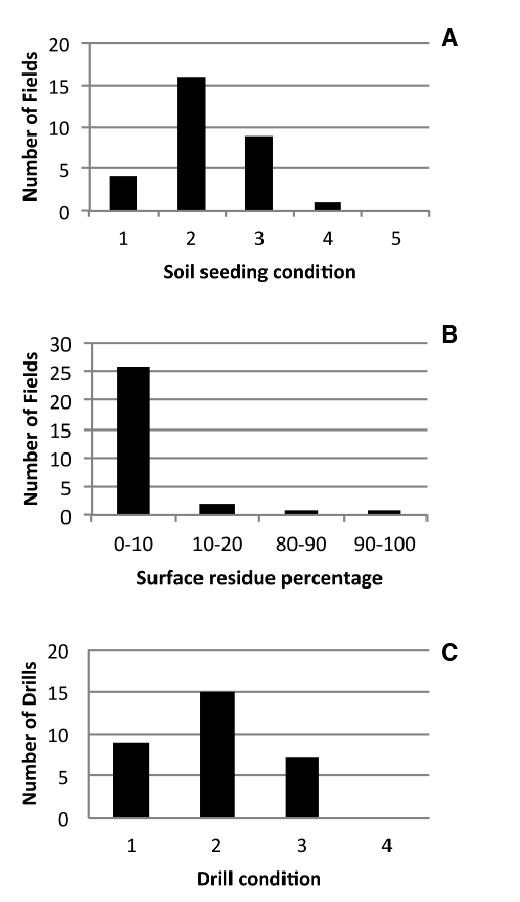

Soil seeding condition was determined by moisture, firmness and size of clods and rated on a scale of 1 to 5 with 1 being excellent and 5 being poor condition. No fields received a soil seeding condition rating of 5. Soil seeding condition was rated 2 or 3 for 83 percent of the fields and 13 percent had an excellent rating of 1 (Figure 1A). Surface residue ratings were based on percent ground coverage by residue using 10 percent increments. Most of the fields surveyed were conventionally tilled and had less than 10 percent surface residue (Figure 1B). The exceptions were two no-till fields, that had greater than 80 percent surface residue. Drill condition was rated on a scale of 1 to 4 with 1 being excellent and 4 being poor condition. Overall drill condition was better than expected with 80 percent of drills having condition ratings of 1 and 2 and no drills receiving condition ratings greater than 3 (Figure 1C). These observations indicate that seeding conditions and equipment was generally in above-average condition.

Figure 1. Soil seeding condition rating (A), surface residue (B) and drill condition rating (C) from on-farm evaluations during the 2009 and 2010 wheat planting seasons.

Planting accuracy and wheat emergence

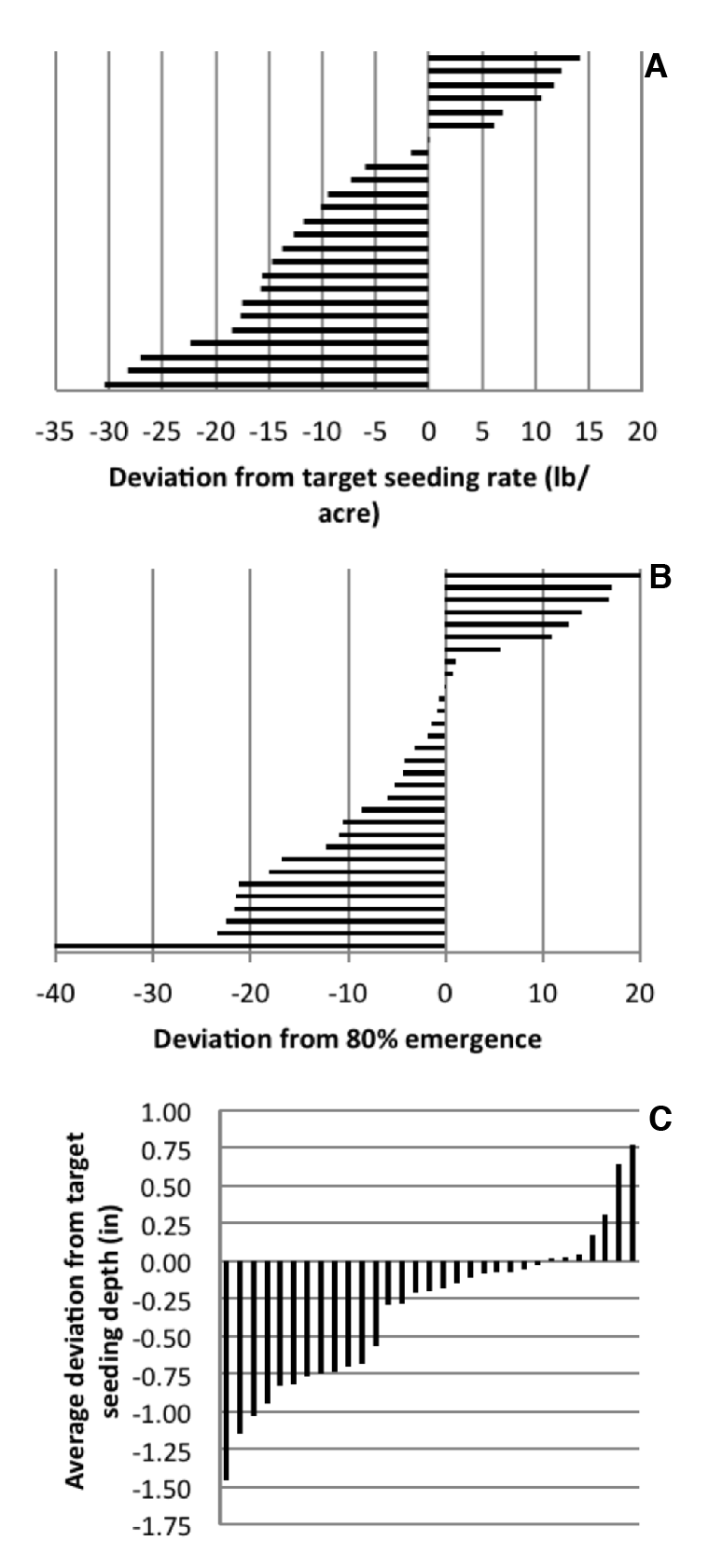

Drill calibration accuracy was determined by placing containers on several drill tubes, traveling 100 feet and weighing caught seed. Actual seeding rate calculated from the in-field drill calibration was compared to the producer’s self-reported target seeding rate. Results show the majority of producers’ actual seeding rates were lower than their target seeding rates (Figure 2A).

Drill calibration is not an exact science, so we also looked at the data using a ± 10 percent window of accuracy for each producer’s target seeding rate. For example, if a producer had a target seeding rate of 100 pounds per acre, their accuracy window was between 90 and 110 pounds per acre. As long as they were sowing within this range, their seeding rate was considered accurate. Using this more lenient accuracy threshold still resulted in only 25 percent of producers surveyed falling within their ± 10 percent accuracy window.

Some of the inconsistency between the measured seeding rate and reported seeding rate is likely attributable to calibration method. Many growers calibrate according to total seed applied to a given acreage. That is, if they wish to sow 100 pounds per acre on 80 acres, they would expect to use 8,000 pounds of seed. However, this does not allow for overlap. A grower using this method and overlapping 20 percent would actually apply approximately 80 pounds per acre on the bulk of the field and a 2X rate on the overlap areas.

Stand counts were taken in a 1-yard by one-row area in five random locations throughout the field approximately two weeks after the initial visit with the producer. In situations where seed germination was hindered because of a lack of moisture, stand counts were not taken until the area received rainfall sufficient for wheat emergence. The length of time between the initial and second visit to the field, however, never exceeded three weeks. Percentage emergence was calculated by dividing the average number of plants per yard of row by the number of seeds sown per yard of row (determined from calibration measurements at planting).

All but one of the 30 seed lots tested had germination of 85 percent or greater in the laboratory. Field emergence deviated significantly from lab germination with a range of 36 percent to 100 percent emergence (Figure 2B). While none of the producers surveyed expected their emergence to be below 80 percent, 20 of the 30 producers fell below this benchmark. One seed lot had 70 percent germination in lab tests, and poor field emergence was attributed to bad seed in this case. However, the remaining 19 survey sites with less than 80 percent emergence were the result of seeding issues rather than seed quality. Our results are similar to those from the early 1990s study where researchers determined that poor stand establishment was generally not the result of poor seed germination and further indicate the need for improved precision and attention to detail when seeding wheat.

Figure 2. Deviation from target seeding rate (A), deviation from 80 percent emergence (B), and average deviation from target seeding depth (C) from on-farm evaluations during the 2009 and 2010 wheat planting seasons.

Seeding Depth

When checking emergence, we excavated 6 inches of row to measure depth of seed placement at four of the five stand count sites in each field. Seeding depth was determined by measuring excavated seedlings from seed remnant to soil surface. Since target seeding depth is frequently determined by soil conditions, we compared actual seeding depth to target seeding depth, which was self reported by producers during our initial visit. A producer planting within ± 0.25 inch of target seeding depth was considered to be planting accurately. Actual seeding depth ranged from 1.5 inches deeper than target to 0.75 inch shallower than target seeding depth (Figure 2C). Twelve producers’ actual seeding depth fell within the range to be considered accurate, leaving 18 of our surveyed producers (60 percent) planting at depths much different than their target depth. Most (77 percent) producers were planting deeper than their target depth.

Comparison with 1992 survey

Researchers conducting the 1992 survey concluded that most producers were planting less than their target rate. The majority of producers in our survey were also sowing less than their target rate, and 75 percent of the producers were sowing outside of the ± 10 percent window of accuracy. These results indicate that drill calibration is still not being performed on a regular basis by Oklahoma wheat producers and is resulting in lower than optimal seeding rates in many fields.

Producers in 1992 averaged 57 percent emergence with only 13 percent of the fields having at least 80 percent emergence. Producers surveyed in the 2010 study were better at obtaining a stand of wheat with an average emergence of 75 percent and 33 percent of producers having greater than 80 percent emergence. While this trend is promising, there is still room for improvement.

Results for seeding depth in 1992 showed that 78 percent of producers planted seed at depths different than their target, and the majority of these producers were planting deeper than their target depth. In our study, we found that 60 percent of producers were planting at a depth different than target. Similar to the previous study, the majority of producers were planting deeper than their target depth.

Conclusions

Most producers were operating drills that were either in good or functioning condition. However, a few drills in the survey needed maintenance such as replacing worn disks, press wheels, bearings, drive chains and sprockets. Soil seeding condition ratings indicated most producers were doing an adequate job of preparing seed beds for sowing. The sites considered to have poor soil seeding condition were generally the result of a lack of moisture and large clods. Improvements in soil seeding condition can be obtained by tilling in favorable conditions to reduce clods and by increasing seedbed firmness.

A small percentage of producers had their drills planting at an accurate rate, but most drills were set to deliver less than the target seeding rate. This issue could be easily corrected by a quick drill calibration every time the field conditions change. The settings provided on the underside of the drill box lid can be used to get close to the desired seeding rate, and this setting is a good starting point when performing calibration on a drill.

Seedling emergence results were generally lower than germination. Planting high quality seed, having functioning press wheels and double-disc openers, decreasing the depth of the tillage operation prior to sowing, and occasionally checking seeding depth throughout the field will all improve seedling emergence. A seed treatment also can be used to improve emergence in situations where disease is likely.

Seeding depth frequently differed from the target depth and in several cases by more than 1/2 inch. Seeding depth is particularly important because wheat varieties differ in coleoptile length. If a producer is planting a variety with a short coleoptile and the planting depth is deeper than targeted, emergence will be significantly hindered. Seeding depth should be checked randomly across the field and should be adjusted as field conditions change.

Dillon Butchee

Graduate Assistant

Casey Andrews

Graduate Assistant

Jeff Edwards

Small Grains Extension Specialist

Randy Taylor

Extension Agricultural Engineer