Container Cleaning in Food Processing Operations

Introduction

Thinking about food contamination and responding appropriately to ensure safe food is a crucial part of food processing operations. Containers are a convenient and attractive means of packaging products; they also protect food from environmental influences and damage during distribution. Rigid and semi-rigid containers made of a wide variety of materials are filled with product and securely closed. In some cases, the heated food product is used to sterilize the container and closure after filling, or a post-fill sterilization process is implemented, such as a hot-water bath or pressure cook. Before filling, however, the container should be cleaned to remove soil, foreign objects, and chemical contaminants.

Container cleaning and inspection is an important step in food packaging operations. According to current Good Manufacturing Practices (Code of Federal Regulations, Title 21, Parts 100, 110, and 113), containers must be clean. Many small- and medium-scale food processors regard container cleaning as an unnecessary step since containers are received in a clean condition and are handled and inspected individually before, during, and after filling. Cracked, damaged, soiled, contaminated or otherwise unsuitable containers are manually removed from the filling operation. However, as automation and the volume of processing increases, it becomes difficult to rely only on visual inspection.

The process of cleaning food containers, even when they are new, is indispensable to ensure a safe product. Empty food containers can harbor foreign materials such as insects and pieces of glass or plastic. Sterilizing food containers (for example, by irradiation) without cleaning them eliminates biological hazards but may leave physical and chemical hazards in the container that affect the safety of the food product. When consumers discover foreign materials in a product, the results may include a loss of confidence in the manufacturer, sales reductions, product recalls, and lawsuits. Therefore, a system to clean containers and improve the safety of food products should be established.

Container-cleaning Machines

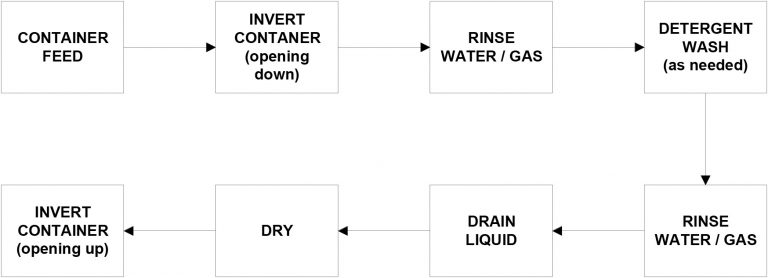

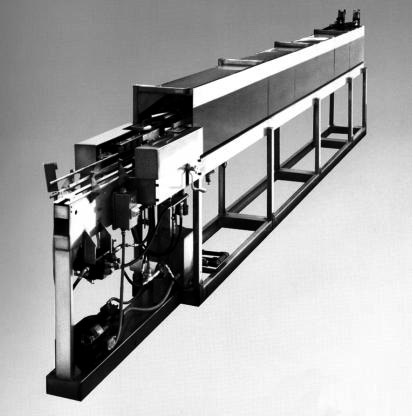

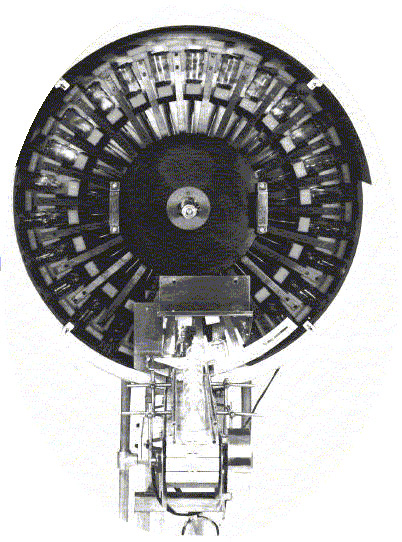

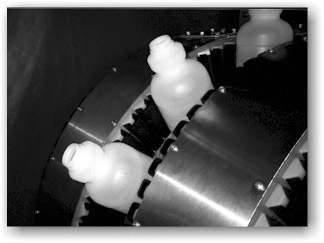

Food containers can be cleaned using a variety of available equipment. Container-cleaning machines are designed to clean the inside and/or the outside of containers using water, a water-based cleaning compound, air, steam, vacuum, or a combination. A typical container-cleaning process is outlined in Figure 1. An example of a continuous container-cleaning machine is shown in Figure 2. Containers are continuously conveyed into the washer, cleaned, and discharged at the opposite end of the machine. A continuous glass container washer is shown in Figure 3. The glass washer includes a tempering zone to prevent thermal shock and glass breakage. An example of an over-the-conveyor continuous cleaner is given in Figure 4. The containers are held captive in the disk and are cleaned with an air or steam blast as they are inverted. A common method used to clean plastic containers is inversion and rinsing with pressurized, ionized air. Figure 5 shows a “gripper” conveyor that holds the plastic container captive for inversion and cleaning operations.

Figure 1. Typical container-cleaning process.

Figure 2. Continuous container cleaner, SJ Industries, Inc.

Figure 3. Glass container washer, Krones Corporation, model Lavatec KEK.

Figure 4. Over-conveyor cleaners, McBrady Engineering Company, model Orbit 100.

Figure 5. Plastic container held captive in a “gripper conveyor,” Amber Corporation.

Dishwashers, rack washers or pan washers (Figure 6) can also be used to clean containers in a batch process. Batch washers may be an inexpensive alternative to continuous container cleaning equipment. Batch washers allow additional process flexibility for product changes, stop and start situations, and may be used for post-pasteurization of finished products, if storage space and handling are not obstacles.

Figure 6. Batch container cleaner, Hobart Corporation, model CPW-80A.

Selecting Container Cleaning Equipment

Several options and brands of container cleaning equipment are available. The ideal cleaning system for a food processor depends on, but is not limited to, factors such as:

- Versatility – the type and quantity of items to be washed or cleaned on a single line

- Desired cleaning time

- Capacity – the combination of options that lets the processor achieve optimum productivity levels

- Expenses – water, compressed air, vacuum, cleaning chemicals, maintenance, operation, and energy source (e.g., gas, oil, or electric)

- Facility – space limitations on the overall size and shape of the cleaning system

- Budget – expected return on investment (ROI)

- Container – special handling or other considerations

- Safety – operator, product, and environmental hazards

For additional information on selecting and purchasing equipment used for food processing, read the OSU Extension Fact Sheet FAPC-102 by Bowser (1999).

Design of a Container Cleaning System

A container-cleaning system can be designed to clean both the inside and outside surfaces of a container, or merely the inside. A wide range of equipment is available, from fully automated, high-speed continuous systems to manual, batch operations. Equipment may be off-line, mounted on an existing conveyor, or freestanding with feed and discharge conveyors.

Draining and rinse time, temperature, flow rate, chemical concentration, and water pressure may be regulated. The electrical installation should be watertight. The machine should be constructed of stainless steel to resist corrosion, and components and supports should be designed for ease of cleaning. The machine should be adjustable to accommodate the range of container dimensions for the given production line. In addition, the machine should be flexible enough to accommodate containers that may be considered for future products. If desired, the wash liquid can be collected in a holding tank for recycling. When batch washers are used, the containers must be placed into racks and fed into the dishwasher. Adequate space and facility must be included for rack loading for both manual and automatic operations.

Table 1 is a partial listing of companies that manufacture and/or supply container-cleaning machines. Contact the companies and talk to other processors that are performing container cleaning. Evaluate product features and find out what works well for other processors. Web sites with packaging related information such as Pack Expo Trade Shows, Packaging World, Food Explorer, and Thomas Net could be valuable sources of information in selecting an appropriate container-cleaning system.

Table 1. List of companies and contact information of container cleaning manufacturers/suppliers*.

| Company | Contact Information | Comments |

|---|---|---|

| Ambec, Inc. | 10330 S. Dolfield Rd. Owings Mills, MD 21117 Phone: 410-363-440, Fax 410-363-3876 Toll Free: 800-899-4406 http://www.ambec.com |

Washers, conveyors |

| B&J Machinery, Inc. | P.O. Box 62076, Cincinnati, OK 45262 Phone: 513-771-7374, Fax: 513-771-3820 |

Rinsing machines |

| Damas Corporation | 1977 N. Olden Ave. Ext., Ste. 289, Trenton, NJ 08618 Phone: 609-695-9121, Fax: 609-695-9225 |

Washing and drying machines |

| Douglas Machines Co | 2101 Calumet Street, Clearwater, FL 66765 Phone:: 727-461-3477, Fax: 727-449-0029 |

Washing and sanitizing systems: rack/pan/tunnel washers |

| Gherri Food Technology | Strada Nuova Naviglio, No. 8, Parma 43100, IT Phone: 3-05-2-127-3473, Fax: 3-952-177-4719 http://www.gherri.it |

Washing and cleaning machines |

| Hobart Corp. | 701 S. Ridge Ave., Troy, OJ 45274-0001 Phone: 937-332-3000, Fax: 937-332-2633 http://www.hobartcorp.com |

Batch dish and pan washers, restaurant and food service equipment |

| Horix Mfg. Co. | 1284 Island Ave., Mckees Rocks, PA 15136 Phone: 412-771-1111, Fax: 412-331-8599 |

Container rinsing/sterilizing and filling machines |

| Kaps-All Packing Systems | 200 Mill Road, Riverhead, NY11901 Phone: 516-727-0300, Fax: 516-369-5939 |

Air/vacuum cleaning machines and Cappers |

| Krones, Inc. | 9600 S. 58th St., Franklin, WI 53132-0100 Phone: 4114-421-5650, Fax: 414-421-2222 http://www.krones.de |

Continuous washers, complete food processing systems |

| Kuhl Corporation | P.O. Box 26, Flemmington, NJ 08822 Phone: 414-421-5650, Fax: 908-782-2751 http://www.kuhlcorp.com |

Cleaning and sanitation systems |

| McBrady Engineering Co. | P.O. Box 2549, Joliet, IL 60434 Phone: 815-744-8900, Fax: 815-744-8901 |

Air/vacuum/water, over-the-conveyor systems |

| Niagara Bottle Washer Mfg. Co. | 13402 Glenside R., Cleveland, OH 44110 Phone: 216-541-0500, Fax: 216-541-5005 |

Cleaning machines for any size container |

| Packaging Systems | 1501 Airway Circle, New Smyrna Beach, FL 32168 Phone: 702-369-2315, Fax: 702-734-7513 |

In-line container rinsers |

| SJ Industries Inc. | 6009-T Farrington Ave., Alexandria, VA 22304 Phone: 703-751-5400, Fax: 703-370-3672 |

In-line, continuous cleaning systems |

| Uni-Pak Corporation | 1015-T N. County Rd. 427, Longwood, FL 32750 Phone: 407-830-4108, Fax: 407-830-4106 http://www.uni-pak.com |

Bottle cleaning equipment, air and water; conveyors |

| U.S. Bottlers Machinery Co. | 11911 Steele Creek Rd., Charlotte, NC 28241 Phone: 704-588-4750, Fax: 704-588-3808 http://www.usbottlers.com |

Container washing and filling systems |

| VR Food Equipment, Inc. | P.O. Box 216, Penn Yan, NY 14527 Phone: 315-531-8132, Fax: 315-531-8134 |

Container washing systems, air and water |

*Oklahoma State University and FAPC do not endorse and specific company.

Tim Bowser

FAPC Food Processing Engineer