Consistent Lethality Treatment for Small-Scale Jerky Dehydrators

Introduction

Dehydration of meat products is an important process that can be extremely profitable for meat processors of any size. Large-volume jerky processors use specialized equipment that has been developed over many years under rigorous scrutiny in an inspected environment. Smaller processors may not require large capacity industrial equipment or be able to afford custom-made dehydrators. In this case, processors may turn to commercially available products or homemade equipment. When this is true, performance of the dehydrator may be substandard to the industrial version, especially when considering the lethality step. The purpose of this fact sheet is to provide guidelines for ensuring a robust lethality process.

Lethality Treatment for Jerky

For food safety requirements, all jerky products must include a lethality treatment prior to sale to the public under USDA inspection (USDA FSIS, 2007). Two methods of achieving lethality are feasible for the small-scale processor. They include moist heat per Appendix A “Compliance Guidelines for Meeting Lethality Performance Standards for Certain Meat and Poultry Products” and a customized, validated process (other options like irradiation and high-pressure processing are too expensive to consider). The two lethality treatments are described below.

Moist Heat

Moist heat lethality treatment requires heating product in a high-humidity environment, which is more effective at killing microbes at lower temperatures compared to the dry heat method. Table 1 shows required times to achieve lethality at different wet-bulb temperatures, with data taken from USDA FSIS (1999). Water vapor must be introduced to the environment around the product to achieve the required wet-bulb temperatures.

Table 1. Required time and temperatures for beef jerky lethality compliance at high humidity (>90%) conditions.

| Minimum internal temperature | Minimum processing time after minimum temperature has been reached for 7-log10 lethality |

|---|---|

| 130 | 121 min |

| 135 | 37 min |

| 140 | 12 min |

| 145 | 4 min |

| 150 | 72 sec |

| 155 | 23 sec |

| 156 | 19 sec |

| 157 | 15 sec |

| 158 | 0 sec |

Customized Validation Process

Heat, marinade and other factors may be combined as microbial interventions (USDA FSIS, 2007). Since no combination of product, marinade recipes, equipment and drying conditions are alike, a custom validation of this process is required. The USDA has suggested that a jerky making process has sufficient lethality if it results in 5-log reduction of Salmonella (Buege et al., 2005). Validation should be conducted by a qualified laboratory (e.g. the Robert M. Kerr Food & Agricultural Products Center, www.fapc.biz). The parameters used in the customized validation shall model the exact conditions of the actual process; dry bulb, wet bulb, humidity, time, marinade pH, recipe, etc.

Temperature

Regardless of the lethality treatment selected, temperature consistency in the dehydrator is important. All of the product in the dehydrator should experience the required temperature (or greater) for the prescribed time period to achieve pathogen reduction. This section describes how to measure temperature in the dehydrator, how to minimize temperature variations and how to select the temperature setting of the dehydrator.

Measuring Temperature

Dry-bulb and wet-bulb are the terms most frequently used for temperature measurement in dehydration systems. Dry-bulb temperature is the temperature of the air (in the dehydrator) as measured by a sensor that is shielded from moisture (ordinary sensor open to the air). Wet-bulb temperature is the temperature of the air (in the dehydrator) as measured by a sensor that is wrapped with a cloth that is kept continuously wet with water by wicking action. Because of the evaporative cooling on the wet-bulb sensor, it is impossible for the wet-bulb temperature to exceed the dry-bulb temperature.

Generally speaking, thin meat products initially undergoing heat treatment have an internal temperature that tracks closely with the wet-bulb temperature of the environment (Buege et al., 2005). This is because the moist meat looses moisture at a rate similar to that being lost by the wet cloth covering the wet-bulb temperature sensor. As the meat product loses (evaporates) most of its natural moisture, evaporative cooling decreases and the product temperature begins to approximate the ambient dry-bulb temperature.

Types of sensors used to measure temperature vary, but include thermocouples, RTDs, thermistors and thermometers. The first three are the easiest to interface with data loggers and are explained in more detail.

Thermocouples

Thermocouples are two wires made of different materials that are connected in a closed loop. Each connection, or junction, is a “thermocouple” that converts thermal energy to electrical energy. If one junction is kept at a constant temperature, the other junction can be used to sense an unknown temperature. Thermocouples are inexpensive but can be relatively difficult to interface with electronics. They also have the widest temperature range.

RTDs

“RTD” is an abbreviation for “resistance thermal device” that makes use of the physical property of some material (usually platinum) to change resistance with temperature. RTDs are expensive temperature sensors, but they are very stable, perform well during a wide range of temperatures, are easy to interface, and are more reliable in an electrically noisy environment.

Thermistors

A thermistor is a temperature sensitive resistor made from a specially processed oxide material. Resistance of a thermistor varies with temperature. Thermistors have high sensitivity, are fairly inexpensive and are easy to interface with data loggers. Disadvantages include a limited temperature range, fragile nature and non-linearity.

Dataloggers

Data loggers are used to automatically record temperatures during a given period of time. When purchasing a data logger, search for a unit that is compatible with the temperature sensors selected. A data logger with a “universal” input can accept most sensor types. Another important feature is the capability of the data logger to interface with a personal computer. This feature will assist with logger setup functions and the transfer of collected data from the logger to the computer. The format of transferred data should be compatible with spreadsheet or graphing software. Figures 1 and 2 show examples of multi-channel data loggers that are capable of recording data from more than one sensor simultaneously.

Figure 1. 8-channel data logger for universal inputs (includes thermocouples). www.iseincstore.com

Figure 2. 4-channel data logger for thermistors, RTDs, voltage and current sources.

Wet-bulb Temperature Measurement

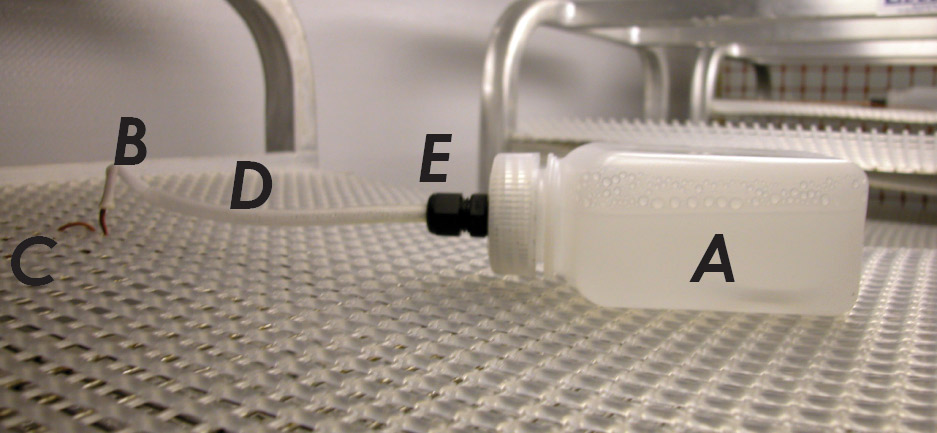

Wet-bulb temperature can be measured by placing a wet cotton sock or tube (available, for example, from Pepperell Braiding Co., Pepperell, Mass.) over the active portion (e.g. bulb or tip) of the temperature sensor (see figure 3). The sock must be kept continuously moist and clean for accurate readings. Placement of sensors should be adjacent to the product at locations in the dehydrator where temperature variation is the greatest (e.g. corners or edges or areas where air flow and heat treatment may be blocked or limited).

Figure 3. Setup for wet-bulb temperature sensing with a water reservoir “A” (plastic container) and 36-inch long by 1/4-inch diameter cotton sock “B” placed over the tip of the thermocouple “C.” A clear 10 cm long Tygon ® tube “D” covers the cotton wick from the reservoir to within about 2 cm of the terminus of the wick to maintain cleanliness. When the exposed portion of the cotton wick becomes soiled, fresh material is exposed by pulling the wick out of the reservoir and cutting off the soiled portion. A Nylon liquid-tight cord grip “E” (69915K47, McMaster Carr, Atlanta, GA) was threaded into the lid of the container and used to hold the Tygon® tubing in place.

Fans, Fan Placement and Air Flow

Good air circulation will reduce temperature variation in the dehydrator (Bowser and Weckler, 2008). Airflow should be uniformly directed over the heating source, across the product and returned back to the fan for recirculation. Some air should be exhausted during the drying process to remove moisture. Return air to the fan is always directed to the suction (or low pressure) side of the blades. Fan speed, or air flow volume, can be set to provide enough air velocity to maintain the desired temperature in the dehydration chamber and consume a minimum of energy; see Bowser and Weckler (2008) for details.

Temperature Setting

Dehydrator temperature setting is an important factor for effective pathogen reduction. To determine the temperature set point, two pieces of information are needed: a numerical value that represents the natural variation of temperature in the dehydrator (called the standard deviation) and the total temperature variation that can be tolerated in the jerky dehydrator.

Standard Deviation

Standard deviation is a measurement of variation of a data set (temperature data) collected at different locations in the dehydration chamber. To determine the standard deviation of a data set for the dehydrator, collect at least 12 temperature data points at different locations in the dehydrator and perform the following calculation:

Where x is an individual temperature data point, x is the average value of all of the data points, and n is the total number of data points collected. More data (temperatures at different points in your dehydrator) will result in a more accurate number for the standard deviation. The value “s” is the standard deviation of the data set and can be used as an estimate of the standard deviation “σ” of the population of all possible data, and x can be used to estimate μ, the average of the population of all data.

Acceptable Variation

What is an acceptable variation for the application? The distribution of temperatures measured in most dehydrator systems will approximate a bell curve (known as a “normal” distribution) shown in figure 4. The distance from the mean, μ, to the point of inflection of the curve is one standard deviation (σ, or sigma).

If the lethality process temperature set point (wet-bulb temperature in the dehydrator) is equal to μ, then there is a chance that half of the product will not meet the lethality requirement (the amount of product under the bell curve to the left of μ). To reduce chances that product does not meet lethality requirements, μ can be increased by a given amount or the processing time (for lethality) can be increased according to Table 1. Increasing μ and/or the processing time may cause issues related to product quality, consistency and economy.

The lethality process set point temperature, μ, or the processing time should be increased enough to reduce the risk of producing under processed product to an acceptable level. Modern statistical control schemes often determine equipment settings by adding a multiple of sigma to μ. Table 2 (Joglekar, 2003) shows several levels of sigma and their effect on the process. For example if the lethality process temperature is set at μ + 3 σ, the result would be 33,400 possible defects (under-processed product) per million pieces of product. If the temperature setting is μ + 6 σ, the number of defects per million pieces is statistically less than 2. Many companies are working to reach a six-sigma goal for their processes.

Table 2. Wet-bulb temperature setting for a dehydrator (μ + sigma level) and the expected number of products not reaching target temperatures (assumes a normal distribution with a 1.5 σ shift in the mean).

| Sigma Level | % Lethality | Number of units not reaching lethality temperature per 1,000,000 units processed |

|---|---|---|

| 3 σ | 96.66 | 33,400.0 |

| 4 σ | 99.699 | 3.105.0 |

| 5 σ | 99.9884 | 116.5 |

| 5.5 σ | 99.9969 | 31.5 |

| 6 σ | 99.99983 | 1.7 |

Example 1:

If the average wet-bulb temperature in a dehydrator is μ = 140.0 F with σ = 0.83 F, and the processor wishes to achieve a six-sigma level of product lethality, then the temperature set point of the dehydrator should be adjusted to μ + 6 σ or 140.0 F + 6 x (0.83) = 145.0 F with the process time remaining at 12 minutes (for a 140.0 F process).

Example 2:

The average wet-bulb temperature in a dehydrator is μ = 140.0 F with σ = 0.83 F, and the processor wishes to achieve a six-sigma level of product lethality by increasing the processing time. The processing time should be set according to the lowest lethality temperature (μ – 6 σ) reached in the dehydrator. The lowest temperature is calculated as 140.0 F – 6 x (0.83) = 135.0 F. The process time should be set to 37 minutes according to Table 1.

Food Safety

Jerky is considered a safe food, but studies have shown that pathogens can survive the moderate drying conditions of some jerky processes (Allen et al., 2007). A process that meets six-sigma requirements (as described in table 2) for lethality is statistically capable of producing fewer than two defects (under-processed products) per million units (Joglekar, 2003). Jerky processors can improve food quality and safety by understanding and minimizing temperature variation in their dehydrator and establishing a lethality process that minimizes the likelihood of under-processed products.

Conclusion

Dehydrated meat products are a popular snack item in today’s food market. The proper understanding, measurement, and control of heat and moisture are crucial to manufacturing a product that meets regulatory requirements, satisfies consumer demands and, most importantly, is profitable.

References

Allen, K.D., D. Cornforth, D. Whittier, M. Vasavada, and B. Nummer. 2007. Evaluation of high humidity and wet marinade methods for pasteurization of jerky. Journal of Food Science; (72)7: 351-355.

Joglekar, A.M. 2003. Statistical methods for six sigma in R&D and manufacturing. John Wiley and Sons. New Jersey.

Bowser, T.J. and P.R. Weckler. 2008. Validation guidelines for a jerky pasteurization process in a low-cost dehydrator. Bentham Science Publications, www.bentham.org/open/index.htm, The Open Food Science Journal (2) 43-48.

Bowser, T.J. 2007. Construction and operation manual for: Low-cost, safe dehydrator for small and very small meat processors. Oklahoma State University, Robert M. Kerr Food & Agricultural Products Center. Internet: http://fapc.biz/files/DehydratorManualV1.pdf (accessed May 23, 2008).

Buege, D.R., Searls, G., Ingham, S.C. 2005. Lethality of commercial whole-muscle beef jerky manufacturing process against Salmonella serovars and Escherichia coli O157:H7. J Food Protection; 69(9): 2091-99.

USDA FSIS. 2007. Compliance guideline for meat and poultry jerky produced by small and very small plants. Internet: http://www.fsis.usda.gov/PDF/Compliance_Guideline_Jerky.pdf. (accessed May 23, 2008).

USDA FSIS. 1999. Appendix A of the “Compliance Guidelines for Meeting Lethality Performance Standards for Certain Meat and Poultry Products”. Internet: http://www.fsis.usda.gov/oa/fr/95033F-a.htm; updated June, (accessed May 23, 2008).

Timothy J. Bowser

FAPC Food Process Engineer

Jacob Nelson

FAPC Value-Added Meat Processing Specialist