Commercial Production of Fresh Market Tomatoes

- Jump To:

- Introduction

- Production Requirements

- Variety Selection

- Sites & Soils

- Fertilization

- Sources of Transplants

- Soil Preparation and Bedding

- Mulching

- Spacing and Transplanting

- Weed Control

- Irrigation

- Pruning & Training

- Insect & Disease Control

- Harvesting

- Grading and Packing

- Post-Harvest Holding

- Costs & Returns

- Marketing

Introduction

Commercial production of fresh market tomatoes in Oklahoma is primarily for local outlets. Harvest begins in late June or early July and continues into August and September. Almost all of the Oklahoma crop is transplanted in early spring for summer production. Major competitive areas are East Texas, Arkansas, Tennessee and other eastern and southeastern states.

Expected tomato yields vary extensively with growing conditions, cultural practices and management skills. Tomato is a high cost, high value and high risk crop. Yields of 650 to 850 boxes (30 lbs. per box) per acre can be reached or exceeded. Production and marketing costs can exceed $9,000/acre.

Before making a commitment to grow tomatoes, the farmer should thoroughly investigate market possibilities and arrangements, capital requirements, labor requirements and competition for those resources from other enterprises on the farm.

Production Requirements

The tomato is a warm season crop, killed by freezing temperatures and injured by light frosts. Tomato blossoms will not set fruit for economical yields if day temperatures rise above 94 F, or if night temperatures remain above 70 F or drop below 60 F. Tomato fruit that set under low night temperatures are often cat-faced, reducing their market value. Tomato fruit sets best if the average temperature is below 75 F.

About 70 days are required from tomato transplanting to harvest of red-ripe fruit. It takes 40 to 50 days from the time a tomato flower opens until it produces a ripe fruit. Setting plants in the field early encourages early blossom formation. Early spring transplanting is important to enable the plants to set fruit before high temperatures occur. Early production usually provides higher prices.

Variety Selection

One of the most critical decisions a grower makes, aside from the decision to plant the crop, is the variety to use. Only tried and true varieties should be utilized. Observation of untried varieties is encouraged but should be limited to 15 to 20 plants per variety. Recommendations for commercial tomato varieties are available in Extension Fact Sheet HLA-6035, “Commercial Vegetable Varieties for Oklahoma.” Tomato variety trial results are available in MP-164 Vegetable Trial Report, all available on-line at: Trial Reports. Select varieties that perform well under Oklahoma conditions and have disease and nematode resistance if nematodes are a likely problem. Check seed catalogs for disease resistance codes that accompany variety descriptions.

Tomato plants are determinate or indeterminate in growth habit. The determinate-type plant terminates its growth with a flower bud. The plant is called “self-topping” or “self-pruning.” It does not vine out and can be grown with short 3-foot stakes or occasionally without staking. Most blossoms and fruit develop on the plant at about the same time. Uniform fruit ripening is desirable for commercial tomato growers who do not desire abundant vine growth and want a concentrated harvest season.

The indeterminate type never terminates in a flower bud. It always produces leaves, flower clusters and more stem from the growing tip. The vine continues to grow until it is killed by frost. Blossoms and fruit develop progressively as the vine grows, so tomatoes in all stages of development may be on the vine at one time. The harvest may last for several months if high summer temperatures do not prevent fruit set. Indeterminate varieties and vigorous determinates are best adapted to staking, caging or trellising.

Mature green fruit may exhibit either the green shoulder or the uniform ripening trait. Most modern varieties have the uniform ripening trait. Also consider whether the pedicel (fruit stalk) is jointed or jointless. If jointless, fruit will separate entirely from the stem when picked.

Sites & Soils

Tomatoes require a well-drained soil for optimum growth. For early production, tomatoes should be planted on loamy sand or sandy loam soils. Tomatoes should be planted in a 3 or 4 year rotation to minimize disease problems that carry over in the soil. Pepper, eggplant and potato are closely related to tomato and should not be in the crop rotation plan with tomatoes, since they all have several common disease problems. Rotation is especially useful in reducing the incidence of wilts, bacterial diseases, nematodes and some foliage diseases. Corn, small grains and legumes are good rotation crops.

Select soils that are at a high level of fertility, well drained, and not subject to flooding. Soils with more organic matter are usually most productive. Organic matter may be improved by growing a green manure crop, such as rye, hybrid sudan or some other small grain, or adding properly composted manure. If bringing in organic matter/compost you should be certain to ask about potential herbicide carryover in the source. The site should allow for good air drainage, which will help to reduce damage from late spring frosts, foliage diseases during the season, and early fall frosts. Select a site well in advance to allow for soil testing and necessary amendments in the fall before the crop is to be planted the following spring. If a cover crop is used, it should be seeded by September 15 and turned under 2 or 3 weeks before spring planting.

Nutrient needs for the best production of tomatoes are fairly exact. To add the right amount of the various elements, it is necessary to know what is already available in the soil. Guesswork will be expensive, either in more fertilizer than needed, which is wasteful – or not enough, which reduces the yield potential of the crop.

Sample your soil properly following directions from Extension Fact Sheet PSS-2207 and have it tested long before preparing the field, preferably the fall before. Use the soil test results as a guide for the specific amounts of lime and fertilizer to be added. Extension Fact Sheet HLA-6036 provides guidance regarding fertilizer recommendations based on soil test results. Also have a nematode assay on a portion of the soil sample to determine the need for using nematode resistant cultivars and other cultural techniques for nematode management or the use of nematicides for nematode management. Your local county Extension educator is available to assist with these services and to interpret the reports. The nematode analysis is particularly important if the field has been planted to a nematode susceptible crop. Refer to Extension Fact Sheets EPP-7625, EPP-7626 and EPP-7627 for detailed information on diseases of tomatoes.

Fertilization

Tomatoes do best at a pH of 6.0 to 6.8. Submit a soil sample in the fall or well ahead of planting time to allow adequate time to apply lime to adjust pH. If a fall cover crop is to be planted, apply lime at that time. Liming of acid soils, particularly in southeastern Oklahoma, will increase fertilizer efficiency and help reduce the incidence of some physiological disorders such as blossom end rot.

Based on OSU soil test results, below are the quantities of P2O5 and K2O recommended. Add all the P2O5 and K2O preplant in accordance with the tables below. Apply 50 Ibs. of nitrogen (N) per acre preplant if soil test results indicate surface nitrate level is near zero. Otherwise, deduct surface nitrate level from recommended N needs. For most efficient utilization, preplant fertilizer should be placed in an open furrow down the row and mixed at a depth of 6 inches to 8 inches with sweeps or chisels. The furrow should then be closed and the row bedded if needed. If used, plastic mulch should be applied at bedding.

Starter Solution—Dissolve three pounds of soluble high phosphorous fertilizer such as 11-48-0 or 15-30-15 in 50 gallons of water. Apply one cup to one pint at the base of each plant with the transplanter or by hand at time of transplanting. Soil insecticide can be added to the starter solution to reduce cutworm damage.

Sidedress Nitrogen (N) Application—Irrigated tomatoes will need an additional 50 pounds of N per acre when the first fruits are about the size of a nickel. Higher N side-dress rates will generally retard maturity, but give higher seasonal yield. Therefore, no more than 50 Ibs. N/A is suggested when early maturity is desired. A second sidedress of 50 Ibs. N per acre will likely be needed one month later, especially on sandy soils in periods of high rainfall.

For extended harvest, a third 50 Ibs. N/A sidedress application may be needed if adequate fruit remain on the plants and plant condition is adequate to support fruit development.

Pounds of Phosphorus per Acre (all soils).

| When Test Shows | 0 | 10 | 20 | 40 | 65+ |

|---|---|---|---|---|---|

| Add lbs. P2O5/A | 150 | 125 | 100 | 55 | none |

Pounds of Potassium per Acre (all soils).

| When test shows | 0 | 75 | 125 | 200 | 250+ |

|---|---|---|---|---|---|

| Add lbs. K2O/A | 225 | 165 | 120 | 50 | none |

Sources of Transplants

Practically all the Oklahoma tomato crop is transplanted. Transplanting is necessary in the spring to give the plants a six-week size advantage over direct field seeding. This allows the plant to set a crop of fruit before onset of high summer temperatures. Transplanting also reduces seed required per acre. Hybrid tomato seed cost may approach 10¢ per seed or more than $250 per ounce. Approximately 1 oz. to 2 oz. of seed are required to grow transplants for one acre.

Growers should be careful to use only the highest quality transplant. These can be purchased from plant producers either locally or from regional plant growers who ship into Oklahoma. It is generally best for the farmer to order the seed and provide it to the local plant grower to ensure the proper variety.

Locally grown plants allow you to maintain close contact with the plant grower. This can be beneficial for scheduling purposes.

Regional plant growers produce extremely large volumes of plants at minimal cost per plant. Effective coordination is required to ensure timeliness of delivery.

Whether you purchase plants locally or regionally, be sure to use a plant grower with a reputation for timely provision of vigorous plants free of insect and disease damage. Remember that approximately 4 weeks to 6 weeks are required to grow a tomato plant. Secure your seed and coordinate with the plant grower well ahead of planting time.

Some growers prefer to grow their own plants. This is possible. However, plants can often be purchased less expensively, particularly if the planted acreage is 2 acres to 3 acres or less. Transplant growing is very demanding and tomato producers without transplant growing experience are advised to purchase plants from reliable plant growers.

Soil Preparation and Bedding

The tomato is a relatively deep rooted plant. If unobstructed, its roots will penetrate 5 feet or more in depth. The soil should be plowed deep well ahead of planting, preferably in the fall during preparation for a cover crop. Prior to planting in the spring, disk the ground to thoroughly mix the cover crop stubble. In most areas of Oklahoma, but particularly in west and southwest Oklahoma, benefit will be realized by leaving 3-foot wide strips of cover intact for wind breaks. This can often be done in connection with drive rows needed to facilitate spraying, harvesting, etc. The number and spacing of drive rows needed will vary with equipment, land, etc.

Rows for irrigated tomatoes should be prepared on 6-foot centers. At this spacing, 7,260 feet of row is equivalent to one linear row acre (LRA); e.g., 36 rows 200 feet long would cover about one acre of land. The ground should be clear of clods, sticks and trash large enough to interfere with transplanting.

Most soils benefit from bedding. This is particularly true for slow draining soils in low-lying areas. Bedding improves water drainage away from plants and aeration. Bedding also accelerates soil warming in the spring. Use implements such as disk hillers, listers or bedders to pull the soil into a ridge. The ridge should then be shaped into a bed 30 to 36 inches wide and 4 inches to 6 inches high, with a slight crest in the middle. Equipment can be purchased or constructed to perform this function in one operation. The exact size and shape of the beds will vary with the situation.

Mulching

Black plastic mulch increases earliness and total yield of marketable tomatoes. The mulch helps warm spring soils, regulates soil moisture loss, prevents weed growth, (except nutsedge) and reduces the incidence of cull fruits. Most plastic mulch is 36 to 48 inches wide on rolls 2,000 feet to 2,400 feet long.

Many types and brands of mulch are available commercially. Do not sacrifice quality for cost. Mulch which does not last the season is a wasted expense. In most cases, 1 1/4 mil thick embossed or 3/4 mil linear low density mulch is adequate. Smooth plastics less than 1 1/4 mil thick may not be strong enough to resist wind and mechanical damage. Plastic mulch is most effective when used in conjunction with a drip irrigation system.

Mulch should be applied to a well prepared shaped bed with adequate moisture. Do not apply mulch if the bed is dry below a depth of 2 inches unless drip irrigation is used. Make sure your mulch application machine is adjusted to apply only enough soil to hold the edges of the plastic in place. Excess soil on the plastic restricts air movement beneath and complicates removal at the end of the season. Plastic mulch should be applied soon after the fertilizer has been placed in the row. This should be at least two weeks before planting to allow time for soil warming. Plastic mulch must be removed from the field at the end of the season.

Spacing and Transplanting

Transplants should be four to six weeks old, properly hardened off, but not stunted. They should be 8 inches to 10 inches tall with thick, stocky stems, dark green color and well developed root systems. Space transplants so indeterminate plants have 15 square feet (2.5 feet x 6 feet); vigorous determinate plants have 12 square feet (2 feet x 6 feet); and very determinate plants have 9 square feet (1.5 feet x 6 feet). For maximum season yields, transplants should not have any fruits, flowers, or flower buds present when set in the field. If fruit sets too early, it will stunt the plant and reduce its yield potential.

If the transplants were grown in peat pots, make sure that the top edges of the pot are buried completely when set in the ground. If the pot is exposed, it will act like a wick and dry the soil in the pot. Tear out the bottom of the peat pot before transplanting for earlier root development.

Tomatoes are highly susceptible to injury from frost and grow little or not at all when set in cold soils. Plants set before the last frost must be protected. The mean date of the last frost in the spring varies from about March 30 along the Red River to about April 24 in northwest Oklahoma. Ask your county Extension educator if you are not sure about the frost date in your area.

Where the price benefit from early harvest justifies, early planted tomatoes can be covered with row tunnels. The practice is expensive, but can allow planting as much as two weeks before the last frost with a corresponding acceleration of first harvest. The practice is probably most suited to small plantings for local sales. Many different materials and techniques are available. Ask your county Extension educator for information.

Weed Control

An adequate selection of herbicides is available for chemical weed control in tomatoes. Due to rapidly changing labels, they are not listed here. Refer to Extension Circular E-832 for a list of herbicides cleared for use on tomatoes. Follow label directions.

Irrigation

Tomatoes are a deep-rooted crop, with their roots reaching a depth of 5 feet or more in most soils. When irrigating tomatoes early in the season, it is best to give the plants infrequent, heavy applications of water rather than frequent light applications. This will encourage a deeper root system.

Tomatoes may be irrigated by three methods: Sprinkler, furrow, or trickle (drip) irrigation. Sprinkler irrigation of tomatoes wets the foliage and washes off spray residues. A spray program will need to be practiced more frequently throughout the season with sprinkler irrigation. For sprinkler irrigation, maintain the level of soil moisture in the top foot at about 70 percent of field capacity during the major portion of the growing season. Devices such as tensiometers will provide information on the soil moisture level. Wide fluctuations in soil moisture will increase tomato fruit cracking.

Furrow irrigation is preferred by some growers over sprinkler irrigation because less fruit cracking occurs. However, this is the least efficient irrigation method and it is becoming uncommon.

Trickle irrigation is excellent for tomato production and minimizes the amount of water used. It utilizes plastic pipe or tubing with emitters through which water is applied under low pressure at a very slow rate. The tubing is laid out next to the plants for entire row length up to 800 feet. The water is delivered in the row to the root zone of the plants, thereby being able to penetrate deeply without wetting the aisles between the plants. One can irrigate and spray or irrigate and harvest at the same time. Trickle irrigation will provide water to an acreage nearly twice as large as sprinkler or furrow irrigation with an equal water supply. Trickle irrigation requires less labor than other irrigation methods. Sidedress N can be uniformly applied through a trickle system. Refer to Extension Fact Sheet BAE-1511, “Drip (Trickle) Irrigation Systems” for additional information.

Low soil moisture early in the season results in retarded plant growth and excessive blossom-end rot of fruits. Excessive moisture, particularly early in the season results in poor root development with increased susceptibility to drought later. Excessive moisture late in the season causes increased fruit cracking, rots and poor color. Since the tomato is a deep-rooted crop, many soils will require at least 3 inches of water during dry periods to saturate the soil where most of the root system is located. During warm, dry weather, 2 inches to 3 inches of water are required each week by large tomato plants.

Pruning & Training

Tomatoes can be grown on various training systems ranging in increasing cost, from unsupported bare ground culture, unsupported on plastic mulch, staked, trellised, stake and weave systems or wire cages, or some combination of the above.

Sprawling ground culture is the least expensive method, but also offers the least potential for suitable marketable yields and premium quality fruit. Sprawling plants on plastic mulch is relatively inexpensive, but with the crop being close to the ground expect more disease pressure on the foliage and fruit. When used in conjunction with drip irrigation, high planting beds and determinate varieties, it may be practical. Incidence of cull fruit from plants grown by sprawling on plastic will be less than without mulch, but greater than with caged or staked production.

Confining each plant to a wire cage, e.g., 6×6-inch mesh concrete reinforcing wire, 2 1/2 ft. tall x 14 inches in diameter offers the greatest potential marketable yield. Startup cost for cages can be as high as $2,500 per acre about $0.70/cage, but that can be amortized over five or more years. Caging requires much less labor than staking or stake and weave and may be a good alternative for small plantings operated as part of a multi-crop market or truck garden.

The last and probably most utilized method is staking. The function of staking is to hold plants and fruit off the ground. The simplest trellis consists of stakes or small posts spaced at frequent intervals in the row with tightly stretched twine or small wires running horizontally alongside the plants. A satisfactory trellis may be constructed of stakes 1 inch by 4 feet driven 10 to 12 inches into the soil midway in the space after every second plant (approximately 2,420 stakes per acre) (Figure 1). Slightly larger and longer stakes should be used with the more vigorous varieties and the indeterminate cultivars. A simple, hand-operated stake driving tool consists of a 36-inch length of 21/2-inch galvanized pipe with a cap screwed or welded on one end. Slide the pipe down over the stake, striking down repeatedly with force (Figure 1a).

Figure 1. One method of trellising tomatoes using stakes and twine.

The first string should be about 10 inches above the soil and should be strung when the plants are 12 to 15 inches high. A “stringing tool” is used to pass the string along one side of the row, looping the string around each stake. It is important to keep the twine tight. Proceed to the end of the row and return on the opposite side passing the string along the other side of the plants, again looping each stake. It is helpful at the first stringing to cross the string between plants. Subsequent strings should be put up as the plants grow to maintain a well-trained system (Figure 1b). Three to four stringings are desirable, each about 6 to 10 inches higher than the preceding one. “Crossing-over” with twine between plants may not be practical, or helpful, after the first time.

The job of stringing tomatoes can be simplified through the use of a “stringing” tool (see Figure 1c). Such a tool can be made from a length of discarded broom handle or a piece of metal pipe (conduit) 24 to 30 inches long. The broom-handle stringing tool should have a small hole 2 inches to 3 inches from the bottom end of the handle and a similar hole through the handle near the top. Twine—from a ball in a pouch on the back or at the waist of the operator—is threaded through both holes and is guided by the tool alongside and under the leaves of the plants and around the stakes.

Some growers have successfully used other trellis systems for determinate varieties. One of these systems utilizes heavy 5-foot posts, driven every 10 feet to 12 feet in the row. As the plants grow, wire is stretched along both sides of the row and stapled or tacked on the posts at a height which will support the foliage. Usually, four levels of wire approximately 8 inches apart are adequate. The wire and posts can be reused another year.

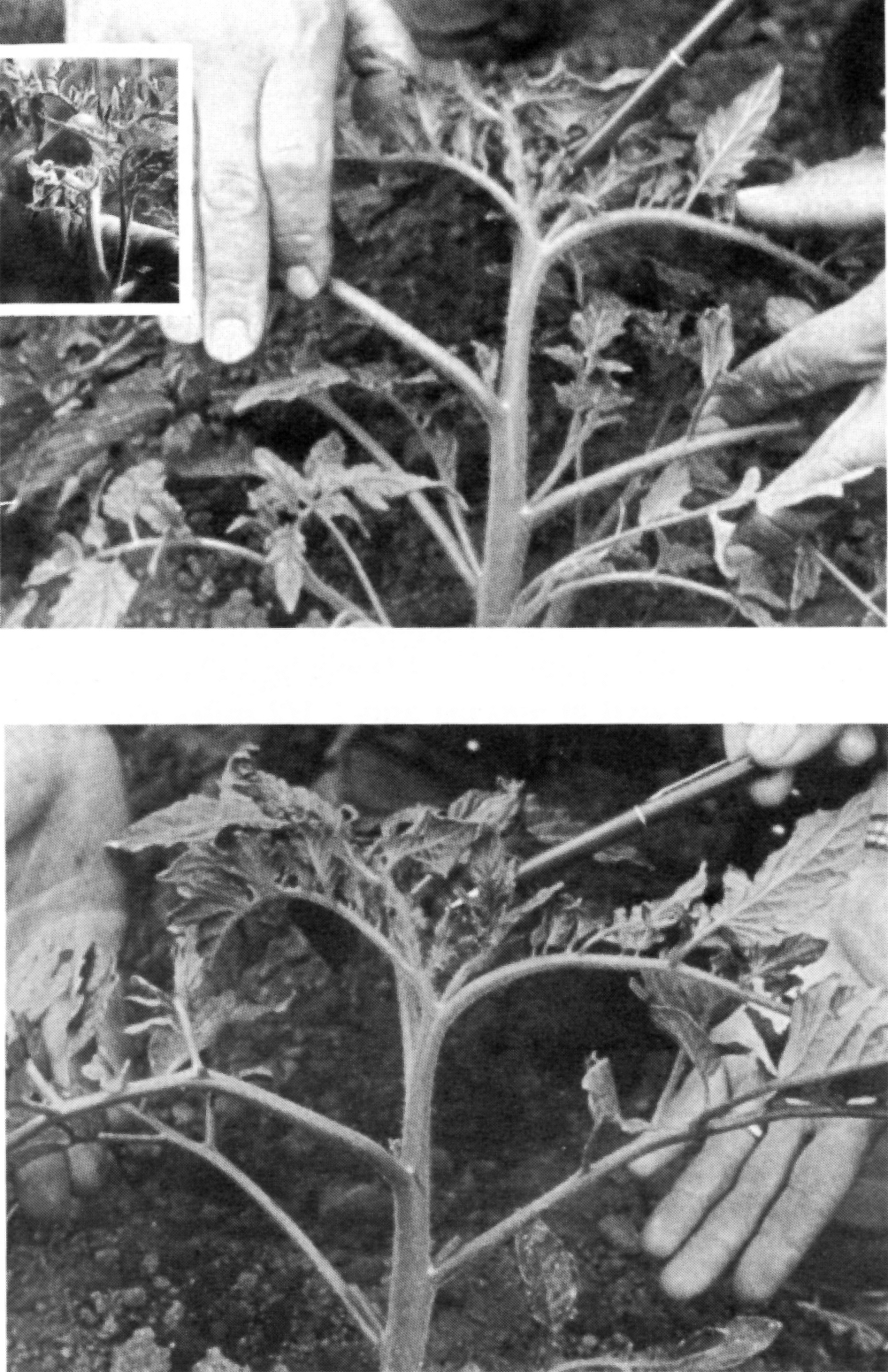

Pruning will help maintain the desired balance between vegetativeness and fruitfulness. Little or no pruning results in more vine growth with a heavy load of smaller fruit. Moderate pruning results in smaller vines and larger fruits which mature earlier. Remove by breaking all suckers up to the one immediately below the first flower cluster. Leave this lateral shoot to form a fork just below the first flower cluster (Figure 2). A single pruning when basal suckers are no longer than 3 inches or 4 inches will usually be adequate. Vigorously vegetative determinate and indeterminate varieties may need to be topped if vegetation exceeds the top of the stakes.

Figure 2. A method of pruning staked tomatoes.

Insect & Disease Control

Effective control of insects and diseases is imperative in commercial tomato production. Unless specialty varieties are being grown, look for varieties with resistance to Verticillium wilt and Fusarium wilt races 1 and 2 at a minimum. Seed catalogs often code these as VF1,2. Soil insecticide may be applied during soil preparation or in the transplant fertilizer solution to reduce cutworm damage. Scout for fruitworms beginning at the time of initial fruit set. Spray schedules must be developed and maintained. Spreader/sticker materials should be added to all spray solutions to improve leaf and fruit coverage and prevent spray wash off by rain or sprinkle irrigation. Refer to Extension Fact Sheets EPP-7625, EPP-7626, EPP-7627 and Circular E-832 for the most current information.

Sprayers—A good sprayer for disease and insect control is essential for growing quality tomatoes. Adequate coverage of the leaf surfaces requires high pressure and several nozzles or high speed air movement to break up the spray material into small particles.

The main components of a tractor sprayer for disease and insect control will include a PTO driven pump that can provide adequate pressure to spray nozzles to operate properly, a spray boom with multiple nozzles (select nozzles based on spray volumes and operating pressure) to provide adequate spray coverage to the crop, and a spray tank with enough capacity to allow the operator to efficiently apply sprays to the crop without too many refills.

Growers with larger acreages may want to consider using sprayer tanks with up to 500 gallons capacity. Booms can be specified, or built by the grower and added to the basic sprayer. If five acres or more of tomatoes are grown, a larger-capacity sprayer of this type is highly recommended to ensure timely applications of pesticides.

Harvesting

Proper harvest management makes it possible to have a higher per acre return. Deciding when to harvest tomatoes is connected to how the fruit will be marketed and what is desired by customers. The earliest fruit that should be harvested would be at the “breaker” stage of maturity if they will be shipped. The breaker stage is when pink color first shows at the blossom end. A tomato at this stage is mature and is already red inside. Such fruits can be handled and shipped better than those with more color. Tomatoes for local fresh markets can be harvested somewhere between the breaker and firm ripe stages of maturity. When 10 percent to 30 percent of the individual fruit is pink, it would be considered at the turning stage. Fruit could also be harvested up to and including the firm ripe stage where fruit are well colored, but still firm.

The grower should harvest often and thoroughly to avoid having too many overripe tomatoes. Harvesting every day may be desirable during the peak of the season.

Avoid picking fruit that have not reached the “breaker” stage of maturity. Less mature fruit will ripen with poor quality or may not ripen at all, and too many of this kind will affect the marketing of the vine ripe tomatoes. Green fruit should be harvested for market at the end of the season before frost.

Remove all diseased and cull tomatoes from the vines as soon as they are discovered. These should be removed from the field with cull piles well away from the production and packing sites.

At the peak of the season, the rate of production of marketable fruit may reach 100 to 150 field boxes (30 to 35 pounds each) per acre per day. Provide enough containers to handle the maximum harvest.

The labor required to harvest tomatoes is considerable. The distance traveled during a season of harvesting a typical tomato crop totally by hand is 120 man-miles per acre. Having a break across the middle of the field for loading containers on a truck or trailer would reduce this figure to about 90 miles. If no doubling back or wasted travel were spent, only about 50 miles would be required for the same field. Thus any arrangement for picking the full length of the field, as with a harvesting aid, would reduce considerably the distance traveled as well as the exertion spent and time required. For a hand-harvesting operation, following a few guidelines can minimize the distance traveled on foot while harvesting. For a given acreage:

- Use shorter rows and a wider field where possible.

- Provide drive-through alleys across the field for loading boxes on truck or trailer.

- Provide pick-up facilities at both ends of the field or at each harvest block.

- Use the largest feasible picking containers.

Individual farm conditions may preclude the employment of some of these guidelines.

Harvesting Aids—Mechanical harvesting aids reduce the amount of labor required for harvesting and make the work easier and more pleasant. Hand-operated carts or wheelbarrows to carry the tomatoes from the field are useful, but motorized 1-, 2-, or 3-row rigs, which transport the pickers as well as the picked tomatoes are more practical. Tractors that travel between rows can be used to transport a driver-picker, or to pull an over-the-row trailer on which additional pickers and box racks are carried. One picker per middle, picking the inside of 2 rows, or 2 pickers per middle can be used, depending on the speed of travel. A canvas or plastic cover over the rig protects riders from sun and rain. Some tomato harvesting equipment is available commercially. However, most growers have found it necessary to custom-build part or all of their rigs to meet their needs. Large “high-boy” self-propelled sprayers which have been equipped with seats and box racks work well for large growers as dual-purpose machines to harvest and spray without eliminating rows for a tractor spray rig. The cost of a harvesting aid will vary widely depending on capacity, number of functions to be performed, and how much of the equipment is “home-built” from scrap parts.

Cultural practices, accuracy and consistency of row spacing, uniformity of post placement and trellis construction, and careful pruning and tying become more important as production and harvesting of tomatoes are mechanized. Very steep slopes are not compatible with mechanization; thus site selection is more critical. Turn rows must be adequate, and length of rows should be consistent with the box-carrying capacity of the harvester.

Grading and Packing

Grading and packing requirements vary considerably with the type of market outlet chosen. In some cases, different buyers on the same market may request some variation in grade and/or pack. USDA grade standards are available for tomatoes. Market requirements, however, must take precedence.

Fresh tomatoes in general are sized in accordance with the number which can be packed per layer in a standard tomato box, e.g., 5 x 6’s pack five fruits the width of the box and six fruits the length of the box. Each carton will accommodate two or three layers, with a net weight of 25 to 35 Ibs.

Fruit must be graded to uniform size and maturity prior to packing. Machines are available to efficiently size grade tomatoes. Mixing sizes and maturities can result in a price reduction or, if supplies are plentiful, cause a load to be rejected by the buyer. A No. 1 quality tomato pack contains fruits of uniform size and maturity that are free from any blemishes, e.g., insect, disease or mechanical damage. Less than No. 1 fruits may be salable, but must be packed and priced accordingly. Mistakes in grading and packing are the most expensive mistakes a grower can make. They can result in loss of the product after all other expenses have been incurred.

In general, packing and grading requirements of the wholesale market are much more stringent than retail markets. Retail market requirements must be tailored to each customer group. Retail markets usually allow the grower to move a wider selection of tomato grades. Many growers find it profitable to service both wholesale and retail markets.

Post-Harvest Holding

Tomato fruit are sensitive to chilling injury. Temperature management is crucial to maintaining quality. Mature green tomatoes will begin to ripen for packing in 7 days to 14 days if held at 57 F to 61 F. They will not ripen normally at temperatures above 81 F. Temperatures between 57 F and 61 F are probably most desirable for slowing ripening without increasing decay.

Light red tomatoes with 60 percent to 90 percent red color can be held up to seven days at 50 F. If held longer, their life on the retail shelf will be shortened.

Costs & Returns

Production costs for tomatoes vary from farm to farm, since different input mixes are utilized by different growers. Soil conditions, weather, the grower’s experience, and his personal preference will alter cultural practices, chemical application rates, and the number of labor hours needed to produce the tomatoes. Thus, cost estimates reflect only one set of typical practices and procedures and should not be used as the principal production guide.

Machinery and equipment include the conventional set of soil preparation equipment, a transplanter, a good sprayer and perhaps some type of harvesting aid. Costs of owning and operating this machinery and equipment will depend on the amount it is used and the initial purchase prices. Although many areas of Oklahoma receive adequate annual rainfall to produce a tomato crop, distribution patterns make it much too risky to rely on rainfall only. The larger the acreage and the more money invested in the crop, the more necessary irrigation becomes. Water must be available when needed. Table 1 provides an estimate of total operating costs associated with producing staked tomatoes in Oklahoma for one possible input mix. Table 2 shows the effect of yield and price on the growers’ return above total operating costs. This return must cover overhead, risk, management and ownership costs of machinery, equipment and land.

Table 1. Estimate of operating costs associated with production of staked tomatoes in Oklahoma.

Staked tomatoes, Oklahoma

Sandy loam soils, irrigated, owned equipment with hand harvest 30 lb. lugs, FOB packing plant

| Operating Inputs: | Units | Price | Quantity | Value | Your Value |

|---|---|---|---|---|---|

| Herb. Treflan 4E | Acre | 5 | 1 | 5 | |

| 15-15-15 Fert | Cwt. | 33 | 3.35 | 110.55 | |

| Potash (K2O) | Lbs. | 0.41 | 100 | 41 | |

| RNTFertSPRD/Acre | Acre | 3 | 2 | 6 | |

| Transplants | Thpl | 100 | 5 | 500 | |

| Transplant Labor | Hr. | 10 | 16 | 160 | |

| Stakes 3 year | Each | 1 | 834 | 834 | |

| String | Lbs. | 2.5 | 30 | 75 | |

| Staking Labor | Hr. | 10 | 50 | 500 | |

| Pruning and Tying | Hr. | 10 | 180 | 1800 | |

| Hand Hoeing | Hr. | 10 | 9 | 90 | |

| Insecticide. Lannate | Acre | 17.3 | 10 | 173 | |

| Bact. Kocide 101 | Acre | 8.15 | 10 | 81.5 | |

| Fung.Dithane | Acre | 4.8 | 4 | 19.2 | |

| Nitrogen (N) | Lbs. | 0.52 | 50 | 26 | |

| Fungicide Bravo 6F | Acre | 14 | 6 | 84 | |

| Lugs | Lugs | 1 | 700 | 700 | |

| Hand Harvesting | Hr. | 10 | 200 | 2000 | |

| Grading Marketing | Lugs | 1.75 | 700 | 1225 | |

| Annual Operating Capital | Dol. | 0.06 | 786.09 | 50.31 | |

| Labor Charges | Hr. | 10 | 21.13 | 211.3 | |

| Machinery Fuel, Lube, Repairs | Acre | 100 | |||

| Irrigation Fuel, Lube, Repairs | Acre | 40 | |||

| Total Operating Cost | 8831.86 |

Table 2. Effects of Alternative yields and prices on per acre returns above total operating costs of staked tomatoes and the break-even prices and yields.

| Yield (30 pound lugs/acre) | ||||||

|---|---|---|---|---|---|---|

| Price $/lug | 420 | 525 | 630 | 700 | 770 | Breakeven |

| Returns above total operation costs ($/acre) Lugs/acre | ||||||

| 10 | -3061.86 | -2600.61 | -2139.36 | -1831.86 | -1131.86 | 1117 |

| 12.5 | -2011.86 | -1288.11 | -564.36 | -81.86 | 793.14 | 711.9 |

| 15 | -961.86 | 24.39 | 1010.64 | 1668.14 | 2718.14 | 522.4 |

| 17.5 | 88.14 | 1336.89 | 2585.64 | 3418.14 | 4643.14 | 412.6 |

| 20 | 1138.14 | 2649.39 | 4160.64 | 5168.14 | 6568.14 | 340.9 |

| dollars per lug | ||||||

| Break-even | 17.29 | 14.96 | 13.4 | 12.62 | 11.98 |

The Department of Agricultural Economics at Oklahoma State University has provided production budgets for staked tomatoes (Tables 1 and 2). Use these budgets as a guide and reference for lenders. Substitute various input items and prices that more directly relate to your operation.

Marketing

Your marketing program must be intact prior to planting, whether you plan to market wholesale or on the local retail market. If you do not have a market available when the tomatoes are ready for harvest, the crop can probably not be held until one is found.

The following fact sheets are referenced in this guide available at: osufacts.okstate.edu

HLA-6035 Commercial Vegetable Varieties for Oklahoma

HLA-6036 Soil Test Interpretations for Vegetable Crops

BAE-1511 Drip (Trickle) Irrigation Systems

EPP-7625 Common Diseases of Tomatoes Part I. Diseases Caused by Fungi

EPP-7626 Common Diseases of Tomatoes Part II. Diseases Caused by Bacteria, Viruses and Nematodes

EPP-7627 Common Diseases of Tomatoes Part III. Diseases Not Caused by Pathogens

E-832 OSU Extension Agents’ Handbook of Insect, Plant Disease, and Weed Control

PSS-2207 How to Get a Good Soil Sample

Lynn Brandenberger

Extension Vegetable Specialist

Brian A. Kahn

Vegetable Research Specialist

Raymond Joe Schatzer

Prof. Agricultural Economics