Understanding Cotton Irrigation Requirements in Oklahoma

Making the most of available water is critical in modern production agriculture. Crop physiologists and irrigation engineers use the term water use efficiency (WUE) to describe crop response to this critical resource. In its simplest form, cotton WUE is the amount of lint produced per quantity of water and is typically expressed as pounds of lint per inch of water available to the crop, including rainfall, irrigation and stored soil moisture. In contrast, irrigation water use efficiency refers to the lint produced per unit of irrigation water applied. Irrigation WUE can vary widely as function of rainfall, soil water-holding capacity and irrigation system efficiency. When salinity is not an issue, cotton responds well to moderate levels of deficit irrigation. This can be defined as irrigating less than the full crop need, typically based on evapotranspiration models. If a high efficiency delivery system is used, deficit irrigation can result in higher irrigation WUE with similar yields to those achieved when full evapotranspirational demand is met, if properly managed. It should be noted that cotton yields are sensitive to heat unit availability. Studies show that yield and WUE are negatively affected by reductions in heat units below the required thresholds.

Cotton Water Use Patterns

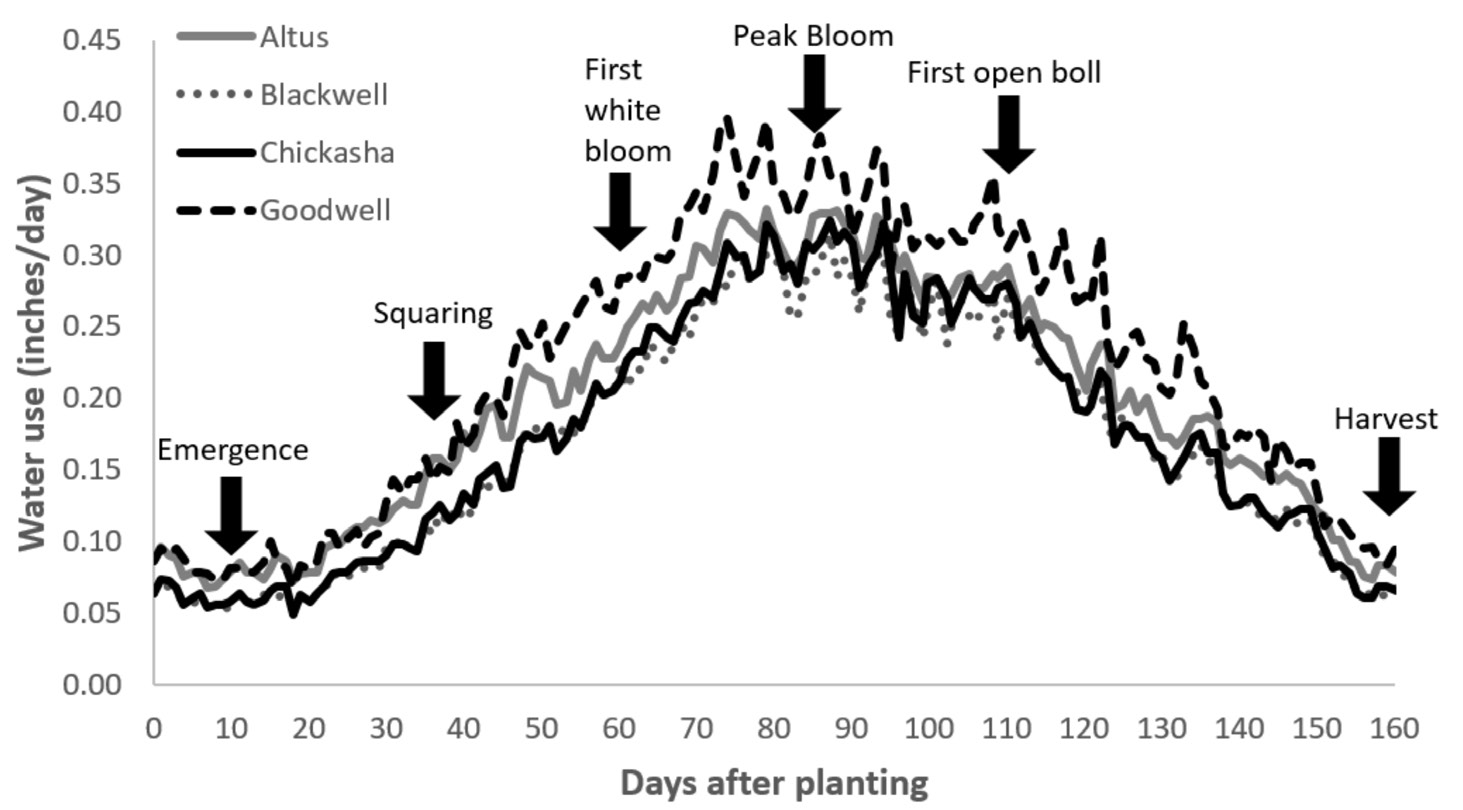

Based on long-term Mesonet data from Altus, seasonal water use for adequately watered and otherwise healthy cot- ton is approximately 30 inches in southwestern Oklahoma. Figure 1 illustrates the typical seasonal water use pattern for cotton produced for select locations in Oklahoma.

Cotton water use, also known as evapotranspiration (ET), can be defined as the sum of evaporation and transpiration, and is both crop-species and growth-stage dependent. Evaporation is water loss from plant and soil surfaces. Transpiration means water taken up by roots and is transpired through the stomata in leaves. From planting to square initiation (about 40 days), ET is generally less than 0.1 inch per day. Plant water requirements are low due to the limited leaf area. Most of the water used in transpiration is extracted from the top foot of soil. The transpired amount of water from planting to square initiation is fairly small and most water loss during this period is due to evaporation.

Figure 1. The 15-year (1997-2012) average rate of water use in relation to cotton development in Altus, Blackwell, Chickasha and Goodwell, based on long term data from the Mesonet Irrigation Planner.

ET increases to 0.1 to 0.3 inch per day during the square to early bloom stage (40 days to 75 days after planting). During this period, leaf canopy and roots develop rapidly, and transpiration exceeds evaporation. Moisture extraction occurs mainly from the top 2 feet of soil, although the taproot and some feeder roots extend to deeper depths if unrestricted by soil depth, hard pans, plow pans, etc.

From early bloom to the opening of the first bolls (usually 60 days to 120 days after planting), ET values of 0.25 to 0.35 inch per day are common. At this stage, plants have reached their maximum leaf canopies and root densities. Because the root system is fully developed, moisture can be extracted from deeper in the entire soil profile at this stage. ET values may exceed 0.4 inch per day during the peak bloom period. During extreme stress (such as 30 mph wind, 110 F), crop ET values can be as high as 0.55 inch per day.

Following the opening of the first bolls until crop termination, ET generally declines from about 0.25 inch per day to as little as 0.1 inch per day. Actual water use will vary with the condition of the plant, soil moisture status and general growing conditions.

Stress Sensitive Periods

Fruit production, retention and shedding are closely related to availability of soil moisture. Production is optimized with an available moisture status that allows uninterrupted development of fruiting positions while avoiding excessive vegetative development on the one hand, or fruit shedding on the other. Many producers believe it is appropriate to allow cotton to stress the plants before applying the first irrigation in order to slow vegetative growth, force root system expansion and enhance early fruit development. While it is true that excessive soil moisture during this time can cause excess vegetative growth and limit root expansion, it is important not to limit water to a point of excessive stress. In contrast, it is more accurate to say that it is best to challenge cotton to expand its root system, while providing adequate water under drought conditions to allow for adequate rates of growth and maturity development. Research has shown that excessive stress prior to the first irrigation may reduce main-stem node development and result in fewer nodes above white flower at first bloom, which can ultimately reduce yield potential (Cotton Physiology Today).

Severe moisture stress during the peak flowering period can have a pronounced negative effect on yield and fiber quality. However, stress either early or late in the blooming period results in significant yield reductions. Ideally, moisture stress should be avoided throughout the crop development period. Early irrigations may be justified to maintain adequate, but not excessive vegetative growth. Matching the lower water demand late in the season is key to achieve timely cutout and optimize fiber quality; i.e. minimize the number of immature bolls present that contribute to low micronaire. Micronaire is a measure of the air permeability of compressed cotton fibers. It is often used as an indication of fiber fineness and maturity.

Irrigation System Type

Irrigation application efficiency can be described as the amount, typically in percent, of water delivered by an irrigation system that contributes to transpiration of a crop. Application efficiency for furrow typically ranges from 40 percent to 80 percent, center pivot sprinkler/spray ranges from 65 percent to 90 percent, center pivot low energy precision application (LEPA) ranges from 85 percent to 95 percent and sub-surface drip ranges from 85 percent to 99 percent. The theoretical goal is to be 100 percent efficient.

If using a spray system, make sure to use nozzle applicators that generate large droplet sizes. This should help reduce evaporation losses during application. Apply at least 1 inch per application, if it can be done without causing runoff. Larger applications will increase the depth water infiltrates into the soil, which will decrease evaporation from the soil surface. Be thoughtful not to over-apply and cause drainage. The likelihood of drainage can be better estimated if an irrigation planner or soil moisture probes are used to estimate soil moisture status.

Evaporation replacement Tables 1 and 2 provide information concerning ET replacement for 60-acre and 120-acre center pivots with various pumping capacities and delivery efficiencies. This analysis shows that an ET of 0.35 inch per day (recall the Mesonet data graph on page 1. On average, this represents a maximum daily ET) will require 400 gallons per minute for a 60-acre pivot or 800 gallons per minute for a 120-acre pivot at 100 percent application efficiency. In contrast, if the application efficiency is 85 percent, then the capacity required for 0.35 inch per day increases to 500 and 1,000 gallons per minute for the 60- and 120-acre pivots. These irrigation pumping system capacities will ensure sufficient water is supplied to the crop to maximize water use efficiency, regardless of rainfall. However, these irrigation capacities assume that all of the water is supplied through irrigation. Rainfall in southwest Oklahoma will generally supplement these irrigation requirements and reduce the irrigation capacity requirements to 200 and 400 gallons per minute for the 60- and 120-acre pivots (Based on long-term rainfall and ET from Mesonet). During periods of limited rainfall, high temperatures and wind; irrigation capacity requirements can dramatically increase, as illustrated by the irrigation capacities required when the maximum daily ET is 0.55 inch. This was experienced in western Oklahoma in 2011. In fact, maximum daily ET values as high as 0.58 inch were experienced with no rainfall leading to reduced crop performance with irrigation capacities that were sufficient in other years.

Water Quality

Irrigation water quality should not be overlooked. High salinity water and/or saline soils can adversely affect crop performance. If high salinity water is the sole source of water input for the crop, there is a high risk the crop will ultimately suffer. These effects can vary with seasonal rainfall, soil type and soil salinity, however this discussion is beyond the scope of this fact sheet. OSU Extension Fact Sheet PSS-2401, Classification of Irrigation Water Quality provides classification of irrigation water quality, describes how irrigation water quality is determined and the conditional use of low-quality water for various crops including cotton. If you are concerned about water quality, contact the local county Extension office. Educators can send a water sample in for analysis at the OSU Soil, Water and Forage Analytical Laboratory.

Table 1. Amount of cotton evapotranspiration replacement for various 60-acre center pivot irrigation pumping capacities and delivery efficiencies.

| Pumping capacity delivered to center pivot | Acre-In/acre/day | In/acre/day delivered at Irrigation application efficiency (%) | ||||||

| 95 | 85 | 75 | ||||||

| GPM | GPM/acre | Gal/day | Acre-ft/day | Acre-in/day | at 100% efficiency | (LEPA, SDI) | (Low elevation spray) | (Poor spray) |

| 100 | 1.7 | 144,000 | 0.44 | 5.3 | 0.09 | 0.08 | 0.08 | 0.07 |

| 200 | 3.3 | 288,000 | 0.88 | 10.6 | 0.18 | 0.17 | 0.15 | 0.13 |

| 300 | 5.0 | 432,000 | 1.33 | 15.9 | 0.27 | 0.25 | 0.23 | 0.20 |

| 400 | 6.7 | 576,000 | 1.77 | 21.2 | 0.35 | 0.34 | 0.30 | 0.27 |

| 500 | 8.3 | 720,000 | 2.21 | 26.5 | 0.44 | 0.42 | 0.38 | 0.33 |

| 600 | 10.0 | 864,000 | 2.65 | 31.8 | 0.53 | 0.50 | 0.45 | 0.40 |

| 700 | 11.7 | 1,008,000 | 3.09 | 37.1 | 0.62 | 0.59 | 0.53 | 0.46 |

| 800 | 13.3 | 1,152,000 | 3.53 | 42.4 | 0.71 | 0.67 | 0.60 | 0.53 |

| 900 | 15.0 | 1,296,000 | 3.98 | 47.7 | 0.80 | 0.76 | 0.68 | 0.60 |

| 1000 | 16.7 | 1,440,000 | 4.42 | 53.0 | 0.88 | 0.84 | 0.75 | 0.66 |

Table 2. Amount of cotton evapotranspiration replacement for various 120-Acre center pivot irrigation pumping capacities and delivery efficiencies.

| Pumping capacity delivered to center pivot | Acre-In/acre/day | In/acre/day delivered at Irrigation application efficiency (%) | ||||||

| 95 | 85 | 75 | ||||||

| GPM | GPM/acre | Gal/day | Acre-ft/day | Acre-in/day | at 100% efficiency | (LEPA, SDI) | (Low elevation spray) | (Poor spray) |

| 100 | 0.8 | 144,000 | 0.44 | 5.3 | 0.04 | 0.04 | 0.04 | 0.03 |

| 200 | 1.7 | 288,000 | 0.88 | 10.6 | 0.09 | 0.08 | 0.08 | 0.07 |

| 300 | 2.5 | 432,000 | 1.33 | 15.9 | 0.13 | 0.13 | 0.11 | 0.10 |

| 400 | 3.3 | 576,000 | 1.77 | 21.2 | 0.18 | 0.17 | 0.15 | 0.13 |

| 500 | 4.2 | 720,000 | 2.21 | 26.5 | 0.22 | 0.21 | 0.19 | 0.17 |

| 600 | 5.0 | 864,000 | 2.65 | 31.8 | 0.27 | 0.25 | 0.23 | 0.20 |

| 700 | 5.8 | 1,008,000 | 3.09 | 37.1 | 0.31 | 0.29 | 0.26 | 0.23 |

| 800 | 6.7 | 1,152,000 | 3.53 | 42.4 | 0.35 | 0.34 | 0.30 | 0.27 |

| 900 | 7.5 | 1,296,000 | 3.98 | 47.7 | 0.40 | 0.38 | 0.34 | 0.30 |

| 1000 | 8.3 | 1,440,000 | 4.42 | 53.0 | 0.44 | 0.42 | 0.38 | 0.33 |