Steam Kettle Hookup

Steam-jacketed kettles (Figures 1 and 2) are often used to rapidly and uniformly heat food and agricultural products to processing temperatures. Steam is injected into a thin jacket that surrounds the bowl of the kettle (Figure 3). The steam condenses on the product-surface of the kettle jacket and transfers its latent heat of vaporization to the product. Condensed steam (condensate or water) is removed from the jacket of the kettle to allow more steam to enter and continue the heating process. The purpose of this fact sheet is to describe the hookup requirements for steam-jacketed kettles.

Figure 1. Tilting, siphon-drained kettle.

Figure 2. Tabletop, gravity-drained kettles.

Figure 3. Types of steam-jacketed kettles.

Table 1. Typical steam use for jacketed kettles.

| 12 psig (244°F) | 20 psig (259°F) | 30 psig (274°F) | 45 psig (292°F) | |||||

|---|---|---|---|---|---|---|---|---|

| Kettle size, gallons | lbs/hr avg. | Heating time, min | lbs/hr avg. | Heating time, min | lbs/hr avg. | Heating time, min | lbs/hr avg. | Heating time, min |

| 5 | 32 | 12.1 | 39 | 10 | 45 | 8.6 | 53 | 7.4 |

| 10 | 57 | 13.7 | 69 | 11.3 | 81 | 9.7 | 94 | 8.3 |

| 20 | 89 | 17.5 | 108 | 14.4 | 127 | 12.4 | 147 | 10.6 |

| 40 | 151 | 20.7 | 183 | 17.1 | 214 | 14.7 | 249 | 12.6 |

| 60 | 202 | 23.3 | 245 | 19.2 | 285 | 16.5 | 332 | 14.2 |

| 80 | 228 | 27.5 | 277 | 22.6 | 322 | 19.5 | 376 | 16.7 |

| 100 | 292 | 26.8 | 354 | 22.2 | 413 | 19.0 | 480 | 16.3 |

Steam Traps

A steam trap is a mechanical device that automatically traps steam in an enclosed space and simultaneously allows condensate to be drained away. Many configurations of steam traps exist. The type of trap recommended depends on the kettle configuration. See Figure 2 to determine the type of kettle to be trapped. The two main types of kettles are fixed, gravity drained and tilting, siphon drained. The recommended trap for gravity-drained kettles is the inverted bucket style with a large vent. The large vent allows excess air to quickly escape. Alternate choices for the gravity-drained kettle are the float and thermostatic or thermostatic style traps. Siphon-drained tanks are preferably trapped with a differential condensate controller or an inverted bucket trap with a large vent. Steam traps should be sized approximately two-to-three times larger than the estimated condensate flow to allow for a safety factor.

Air Removal

Air is present in equipment and pipelines before steam is turned on. Air can continue to enter the system with steam and mix with it. Stagnant air-steam mixtures tend to settle out in time, with air dropping to the bottom of an enclosure. The presence of air will inhibit steam condensation and reduce the effectiveness of a kettle. Air vents must be installed to remove trapped air. Air vents on steam kettles should be located at a point farthest from the steam entry. Also, a steam trap with air venting capabilities is necessary. Each installation should be reviewed carefully to determine where pockets of air would tend to collect with regard to gravity, steam flow and equipment geometry.

Condensate Return

Heat transfer efficiency is improved if condensate is trapped and returned to the boiler as make-up water or used to preheat boiler make-up water. Other uses for condensate may be possible, depending upon the process requirements and the ingenuity of the designer. Many steam equipment suppliers sell packaged condensate return systems. These systems can be purchased and plumbed directly into a system. The choice of motive force used to return the condensate to the boiler is important. Electric pumps or steam power are common. In the case of electric pumps, electricity powers pumps that force condensate back to the boiler. For steam-powered units, boiler steam is used to drive the condensate back to the boiler. Steam powered pumps are often selected since fewer mechanical components are involved compared to electrically driven pumps. However, if steam is in short supply, or relatively expensive, steam pumping may not be the best choice.

Hookup

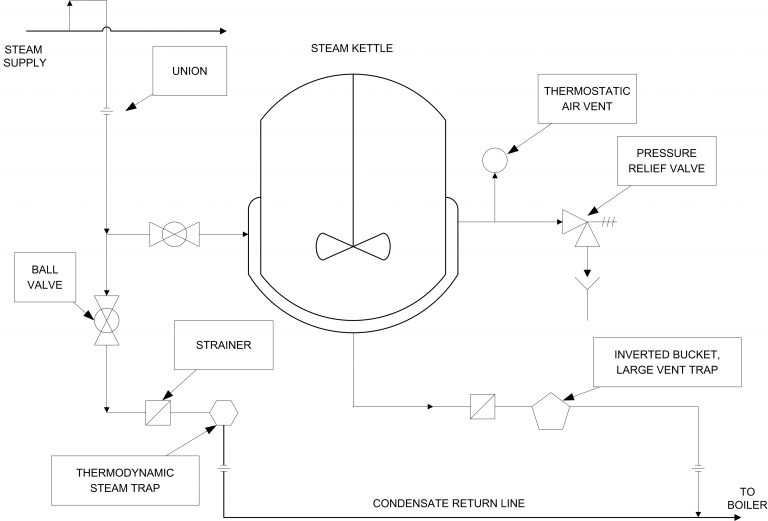

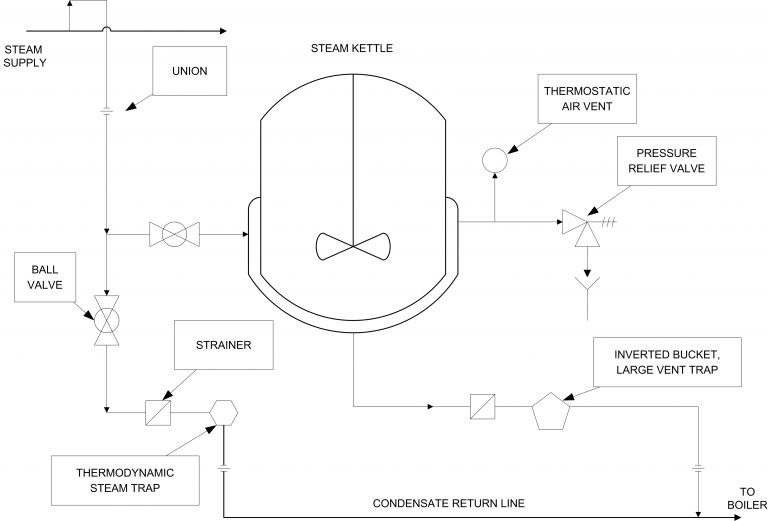

A typical, fixed, gravity-drained kettle hookup is shown in Figure 4. A licensed, professional engineer with expertise in steam utilization can properly design and specify a system or check your design. Some steam equipment suppliers offer advice and diagrams for equipment hookup. An experienced steam fitter or plumber should be contracted for installation. Some hookup tips follow:

- The team supply should be ample in size with the kettle inlet located high in the kettle jacket.

- Slot the steam inlet pipe at the kettle entrance to promote steam flow around the entire jacket area.

- Install traps close to the kettle.

- Never connect more than one kettle to the same trap to avoid short-circuits.

- Install unions and ball valves to facilitate installation and maintenance.

- Install filters and “dirt legs” to protect equipment from particles.

- Include one or more ball valves in the piping to facilitate system “blow-down” to

a drain. A blow-down valve is often installed on a strainer.

Figure 4. Suggested kettle hookup for gravity-drained kettle.

Safety

All installations should include a pressure relief valve at each pressure vessel (e.g. kettle jacket and boiler). The setting on the pressure relief valve should be equal to or preferably less than the labeled, maximum pressure rating for the vessel. Older equipment, or equipment with an unknown history, should be pressure tested with air or water before connecting steam to determine containment integrity. All steam lines and steam-heated equipment should be insulated or guarded to protect operators from burn injuries.

Conclusion

A well-installed steam kettle system will provide many hours of trouble-free operation, improve product quality and increase process performance. When principles of steam heating are understood and applied, installation is a straightforward matter that requires making the best and safest use of available components.

References

Armstrong International Inc., 2000. How to trap steam jacketed kettles (brochure), Stuart, FL.

Groen, Inc. (a division of Dover Industries), 2000. Steam jacketed kettles (brochure). Jackson, MS.

Spirax Sarco, Inc. 1986. Design of fluid systems; Hookups, 8th edition. Allentown, PA.

Tim Bowser

FAPC Food Processing Engineer