Steam Basics for Food Processors

Introduction

The purpose of this fact sheet is to provide an introduction to the basic terminologies and use of steam in food processing. The term “steam” applies to the vapor-phase of water when reached by boiling. The term vapor describes the gaseous state of many substances. Steam, or water vapor, is invisible. Only through partial condensation does it appear as a mist (Heald, 1988).

Steam is a convenient means to convey energy in food processing operations. It is produced from inexpensive and abundant water. Pressure control valves can be used to precisely regulate and maintain the temperature of steam. Large amounts of energy are contained in a relatively small mass of steam, so heat-transfer equipment can be compact. Steam is easily and inexpensively conveyed over fairly long distances and into remote locations of the process.

Steam used by food processors commonly falls into two broad categories. The first is the so-called “culinary,” “sanitary” or “clean” steam. This type of steam is used for direct injection into the product or to clean or sterilize product contact surfaces. We will refer to steam in this category as “culinary” steam. Any additives in culinary steam must meet all applicable FDA and USDA requirements for human consumption.

The second category of steam used by food processors is often referred to as “plant steam,” “utility steam” or just simply “steam.” This document will call steam in this category “plant” steam. Ordinary plant steam can be used in most applications that do not involve contact with food products or with surfaces that contact food products. An example of a non-contact use of plant steam is indirect heating. Most people are familiar with radiant heaters (a type of indirect steam heater) used in residential and commercial applications.*

Definitions

- Condensation – conversion of water from the vapor state to a liquid phase.

- Culinary steam – steam that is suitable for direct injection into food products or direct contact with food products or surfaces that contact foods. Culinary steam must meet all applicable codes of the appropriate regulatory agency (e.g. FDA and USDA) for the application.

- Heat transfer – energy in transit as the result of a temperature difference.

- Indirect heating – heat transfer from a warmer body to a cooler body through a physical barrier such as steel.

- Latent heat – heat given off or absorbed in a process (as fusion or vaporization) other than a change of temperature.

- Latent heat of vaporization – the heat added to water to make it vaporize without a change in temperature.

- Plant steam – steam that is not or cannot be classified as “culinary steam.” In general, steam is water vapor kept under pressure to supply energy for heating, cooking or mechanical work.

- Quality – property of steam determined by the amount of free moisture carried with the steam.

- Sensible heat – heat given off or absorbed in a process characterized by a change in temperature.

- Specific heat – a ratio of the amount of heat transferred to raise a unit mass of material one degree in temperature to that required to raise a unit mass of water one degree in temperature at some specified, initial temperature.

- Steam trap – mechanical device that automatically traps steam in an enclosed space and simultaneously allows condensate (and sometimes air) to be drained away.

Generation

Chemical energy contained in coal, gas oil or other boiler fuel is converted into heat energy when burned. This heat energy is transmitted through the wall of the boiler furnace to the water. The temperature of the water increases due to this added energy until it boils. The heat energy added that increases the water’s temperature is known as sensible heat.

Heat is continually being added to the water, so after reaching the boiling point, the water begins to evaporate. Heat added after the boiling point is reached is known as the latent heat of vaporization. At this point, the temperature of the water (and steam) remains constant. Since the boiler is a closed vessel, the steam becomes compressed as more steam is generated and the pressure in the boiler rises. As the pressure increases, so does the boiling point of water and the temperature. As steam pressure increases, the total heat increases slightly. The sensible heat of the steam increases with increasing pressure while the latent heat decreases slightly.

Effective Heat Transfer

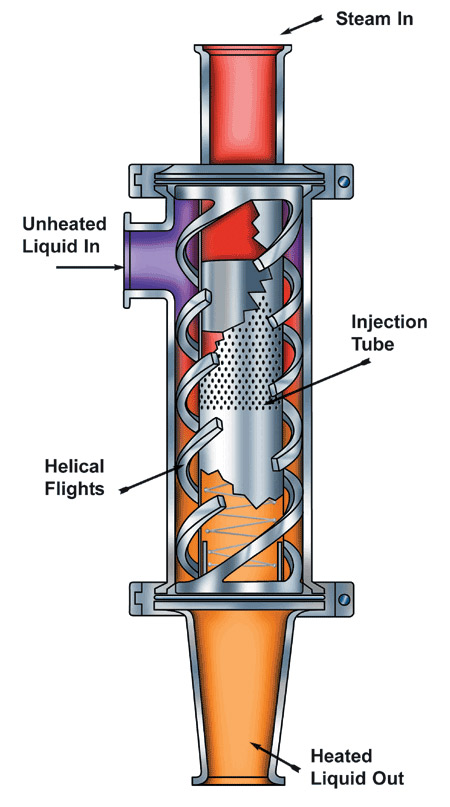

Steam is most effective at transferring heat when it condenses on a surface at a lower temperature. The latent heat of vaporization is given up by the steam as it condenses. Maximum heat transfer occurs when steam is allowed to condense on a heat transfer surface without restriction or obstruction. Realistically, there are obstacles that prevent perfect condensation by insulating heat transfer surfaces. Figure 1 shows examples of layers of films that can build up on the product and steam side of a heat transfer surface. Some of the most common examples of these films in food processing operations are: stagnant layers of product, burned-on product, rust, scale, water (condensate), layers of single-celled organisms, and air. These films must be eliminated or reduced to optimize heat transfer.

Figure 1. Films on heat transfer surfaces that slow heating.

Stagnant layers of product can be removed (or reduced) by agitation, especially surface-scraping agitation. Product burn-on can be minimized by surface-scraping agitation and regulation of the heat-transfer surface temperature. Rust, scale and organic films may be controlled by methods such as frequent cleaning of heat-transfer surfaces, specification of corrosion-resistant materials, and selection and maintenance of boiler-water additives.

Condensed water must be quickly and completely drained from the steam side of the process. This is accomplished by providing dry steam to the process and utilizing correctly specified and installed steam traps. Air can be removed from the steam side of the process by proper design and installation of equipment, following startup procedures designed to remove air, and installation of air vents.

Examples of Food Processing Equipment that use Steam

Examples of typical steam-using equipment in food processing plants are given in this section.

Shell and Tube Heater

Shell and tube heaters are commonly used to heat a flowing liquid by condensing plant steam or a pumped heat transfer media. A thin-tube wall separates the heating media from the product being heated. In the case of a pumped heat-transfer media (such as hot water), steam is often used to heat the media in a separate heat exchanger. Figure 2 shows a typical shell and tube heater.

Figure 2. Shell and tube heater.

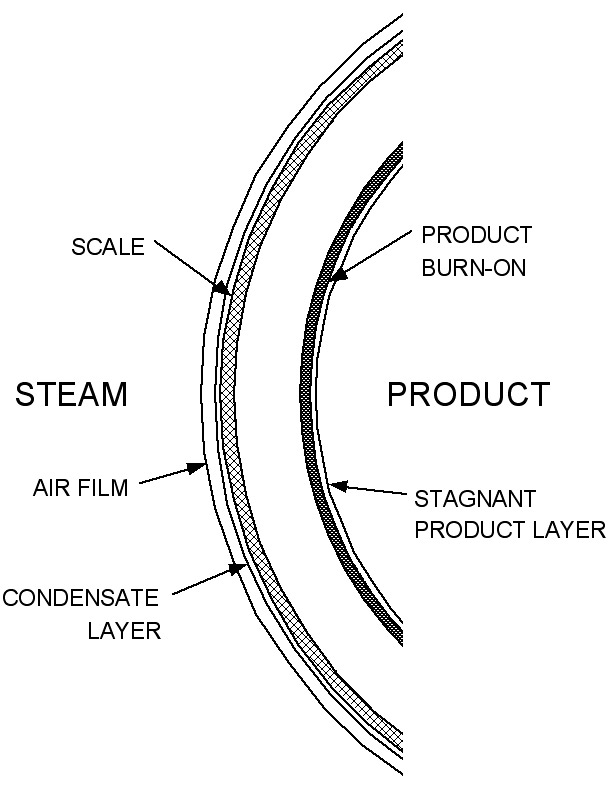

Steam Injection Heater

Steam injection heating for food products is a direct-contact process in which culinary steam is mixed with a pumpable food (or ingredient). Heating occurs when the steam transfers some of its internal energy to the food product. Steam gives up all of its latent heat of vaporization while condensing and, depending upon the system pressure, some of its sensible heat. Since the steam directly contacts the food product and the condensate becomes incorporated into it, the steam source must be culinary. Typical steam injection units are compact, inexpensive and simple to control. An example is provided in figure 3.

Figure 3. Steam injection heater (top) and section drawing (bottom).

Figure 3.

Steam Infusion

Steam infusion is another method of steam heating where the food product is heated by relatively low-pressure, culinary steam. A steam infusion device usually incorporates a chamber where the product is cascaded through a steam environment.

Steam Sparger

Steam sparging is common in open tanks or kettles containing liquid products or water. Culinary steam is bubbled into the liquid from nozzles located near the bottom of the tank.

Steam Jacketed Kettle

A jacket, used to distribute steam over a wide surface area, consists of a thin space formed between two, parallel, metallic surfaces. Steam jackets are typically used to heat bulk products held in tanks and kettles. An example of a steam-jacketed kettle is shown in figure 4. Condensing steam, held captive within the jacket, transfers heat to the product in the kettle. A layer of insulation over the jacket protects operators and conserves heat.

Figure 4. Steam-jacketed kettle.

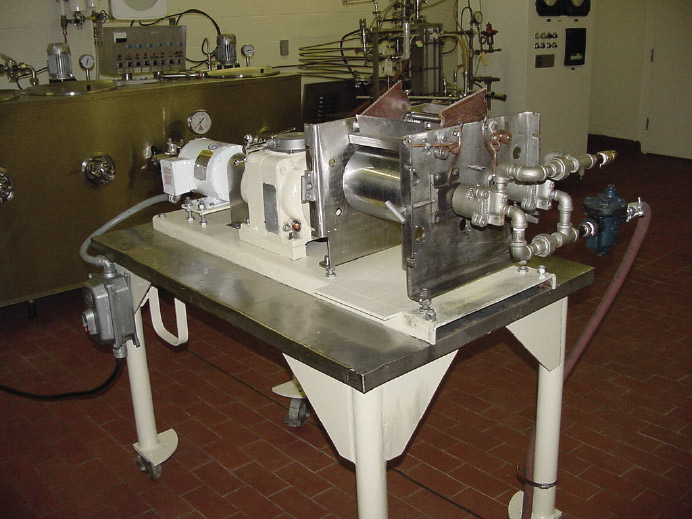

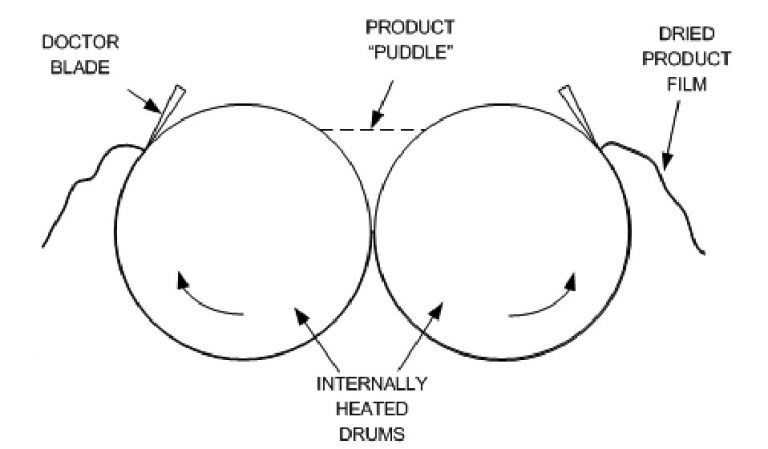

Drum Dryer

Drum dryers consist of one or more internally heated, metallic drums on which a thin, uniform layer of wet material is applied. In food processes, plant steam is often selected as the heat transfer media. An example of a drum dryer is shown in figure 5.

Figure 5. Pilot-plant drum dryer (top) and end-view drawing of drying drums (bottom).

Figure 5.

Humidifier

Certain drying and curing processes require humidification of the air surrounding the product to control the drying rate. Culinary steam can be injected directly into a drying chamber or into a ventilation air duct.

Space or Air Heater

Plant steam is contained in various enclosures (such as tube coils or radiators) and used to heat air.

Steam-In-Place (SIP)

Culinary steam is used to achieve high temperatures and moisture levels required to sterilize enclosed surfaces (such as closed tanks, pipes and valves) in food processing equipment.

Mixing Tee

Mixing Tees are typically found in a wash-down hose station. Culinary steam is mixed with potable water to produce hot water used in washing operations (see figure 6).

Figure 6. Hose station mixing tee.

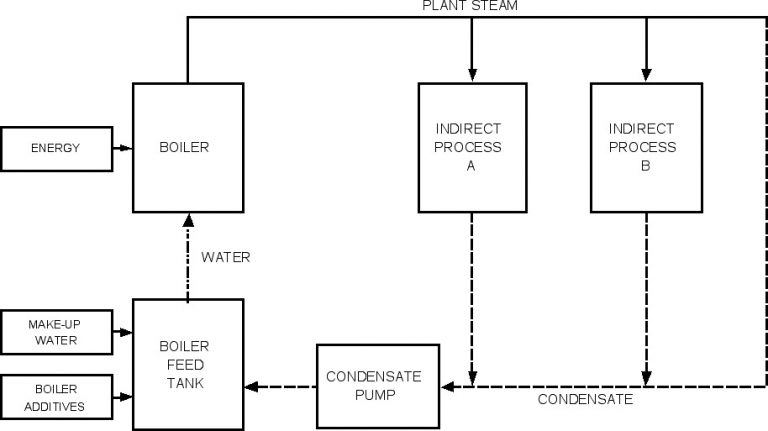

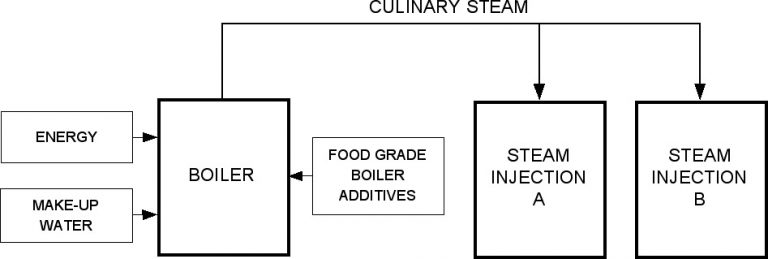

Steam Circuit

Figure 7 portrays simplified steam circuits typically found in a food processing plant. In diagram 7(a), condensate is recovered and returned to the boiler for reheating into plant steam. Diagram 7(b) shows a culinary steam injection system without condensate return.

Figure 7. Simplified steam circuit for indirect steam heating processes (above) and direct steam heating processes (below).

Figure 7. Simplified chart of direct steam heating process.

Steam Usage Estimation

Important information to identify when estimating steam usage for a food process is given in table 1. Rough steam usage calculations are simple to make, when certain assumptions are made and the English system of units is employed. Numbers obtained using rough estimates are valuable for sizing equipment, pipelines and estimating capacity. Key simplifying assumptions are:

- Only the latent heat of vaporization of steam is transferred to the product (ignore sensible heat) during processing. The latent heat of vaporization of steam “hg” is estimated as 1,000 BTU/(pound of steam). This number can assumed to be constant (within 10 percent) for most steam sources (zero to 60 psig).

- The specific heat of the product “cp” is estimated to be 1.0 BTU/(pound·°F), or about the same as water.

For more rigorous calculations of steam usage, see one of the many texts regarding this subject as applied to food processes (Singh and Heldman (1993), Henderson, Perry and Young (1997), or Toledo (1999))

Table 1. Information required to compute steam usage in food processes.

| Units | ||||

|---|---|---|---|---|

| Variable or unknown | Symbol | SI (metric) | English | Explanation |

| Heat energy required | Q | kJ | BTU | Energy needed to accomplish the desired process. |

| Mass of product to be heated | mp | kg | lb | Total amount of the product to be heated in a given amount of time. |

| Specific heat of product to be heated | cp | kJ/(kg•C) | BTU/(lb•°F) | Characteristic of product to be heated in a given amount of time. |

| Temperature differential of product heated | _T | °C | °F | Initial product temperature subtracted from final product (heated) temperature |

| Latent heat of evaporation of steam | hg | kJ/kg | BTU/lb | Energy required to evaporate a given quantity of pure water at given conditions |

| Mass of steam required to heat product | ms | kg | lb | Amount of steam required to accomplish the desired heating process |

| Efficiency of heating process | ef | Decimal % | Decimal % | Accounts for heat losses to the environment |

Key equations for heat energy and steam usage calculations are:

Q = (wp · cp · ΔT) / eff (1)

and

Q = hg · ws (2)

Where:

wp = weight of product being heated, lbs

ws = weight of steam, lbs

T = temperature change of product, F

eff = efficiency of heating process, decimal percent

Q = heat energy, BTU

Two examples follow considering the above assumptions:

- Estimate the amount of steam is required to heat 1,000 pounds of liquid product in

a steam-jacketed kettle from an initial temperature of 70°F to 160°F, assuming 75

percent efficiency.

-

The heat energy “Q” required is estimated by using equation (1).

Q = 1,000 lb · 1.0 BTU/(lb·°F) · (160 °F – 70 °F)/ 0.75

Q = 120,000 BTU

The amount of steam needed is estimated using equation (2).

120,000 BTU = 1,000 BTU/(lb of steam) · ws

ws = 120,000 BTU / 1,000 BTU/(lb of steam)

ws = 120 lb of steam

-

- How much water (condensed steam) is added to 600 pounds of liquid product when it

is heated from 65°F to 185°F by the direct injection of steam (efficiency is 100 percent)

and what size boiler is needed if this process is to take place in a five-minute period?

-

The heat energy “Q” required is determined using equation (1).

Q = 600 lb · 1.0 BTU/(lb·°F) · (185 °F – 65 °F)

Q = 72,000 BTU

The amount of water (or condensed steam) added to the product is estimated using equation (2).

72,000 BTU = 1,000 BTU/(lb of steam) · ws

ws = 72,000 BTU/1,000 BTU/(lb of steam)

ws = 72 lb of steam

Boiler capacity is generally given in BTU/hour or boiler horsepower (one boiler horsepower is equivalent to 33,475 BTU/hour).

Boiler capacity = 72,000 BTU/5 min · (60 min/hr)

Boiler capacity = 864,000 BTU/hr or 25.8 boiler horsepower

-

Piping

Generally, piping codes form the basis for many state and municipal safety laws. In Oklahoma the codes of the U.S. National Standards Institute have been adopted (Oklahoma Department of Labor, 2000). Some piping installations may not be within the scope of any mandatory code, but it is advisable to comply with the codes in the interests of safety and as a basis for negotiations with contractors (Thielsch, 1996). Seek the services of a qualified, licensed contractor and/or professional engineer for system design and installation.

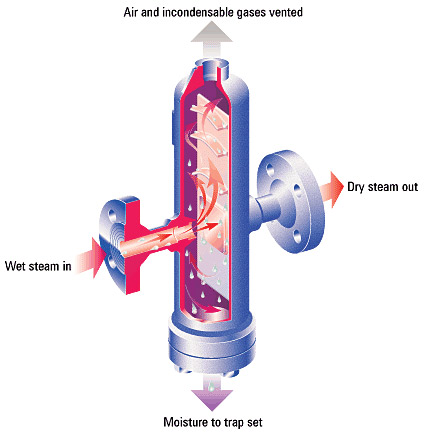

Condensate Handling

Condensate must be separated from steam in pipes. Since steam can travel very quickly in pipelines, it tends to carry droplets of condensate. One way to remove the water droplets is to install a condensate collection pocket in the pipeline. Steam separators (figure 8) are also used to remove condensate from steam. It is good practice to install steam separators in pipelines ahead of equipment or processes that require high-quality (low water content) steam.

Figure 8. Steam separator (image courtesy of Spirax Sarco).

Insulation

Insulation of steam pipes and equipment is useful to reduce energy losses and for safety reasons. Unfortunately in many food plants, insulation can become a harborage for pests and a clean-up and maintenance nightmare if not properly installed and maintained. In addition, certain types of insulation are susceptible to water absorption and loose their insulative properties when wet.

When designing steam systems, it is best to keep insulated lines high overhead where there is less chance for food products to contact insulation. Pipes that are frequently soiled by food products or require periodic disassembly may be left uninsulated, but should be guarded to prevent a burn hazard. For systems operating above 200°F, insulation contributes to worker safety. Outside surface temperatures must be limited to 125°F for highly conductive surfaces (metal) and 150°F for non-conductive surfaces (DOE, 1995). An insulation contractor or supplier can assist you in determining the required and most economical thickness of insulation.

Control

Steam is controlled using automated and manual valves. The major types of control valves found in food processing systems are pressure and temperature. Pressure control valves act to maintain a constant pipeline pressure downstream of the valve. Constant, regulated steam pressure is an important aspect for the reliable control of many steam processes. The temperature control valve uses input from a down-stream temperature sensor (placed in the product or steam line) to determine the action of the flow control valve. Figure 9 shows an example of a self-actuating temperature control valve.

Figure 9. Self-activating temperature control steam valve (image courtesy Armstrong International).

Steam Trapping and Condensate

Removal

A steam trap is an automatic valve that senses the difference between steam and condensate and acts to allow condensate to pass through the valve. Steam trap selection can be a complex task that should be left to the professional. Nevertheless, owners need to understand the need for steam trapping and some of the basics mechanics.

Condensate must be removed from heat transfer equipment immediately to optimize process efficiency. Improper trapping and condensate removal can lead to water-logging, steam or air locking that will result in process losses. Steam traps should be fitted to the low points of equipment and piping to make use of gravity to remove condensate.

Condensate contains valuable heat that can be conserved by returning it to the boiler. The condensate may be pumped directly into the boiler or used as a heat source (e.g. to preheat boiler makeup water).

Air Removal

Air is present in equipment and pipelines before steam is turned on. Air continues to enter the system with the steam and mixes with it. Stagnant air-steam mixtures tend to settle out in time, with air dropping to the bottom of an enclosure. From this information, it should be understood that air vents must be installed at the end, or remote point of steam lines, before the line connects with any equipment. This allows the steam to push the air toward the vent where it can be removed. The same idea follows for the equipment. Equipment air vents should be located at a point farthest from the steam entry at a low elevation. Steam traps have varying ability to remove air, depending upon trap design, condition and installation. Each situation must be reviewed carefully to determine where pockets of air would tend to collect with regard to gravity, steam flow and equipment geometry.

Conservation

A properly designed, installed, operated and maintained system will contribute immensely to steam conservation and efficiency. Operator training will ensure that operators do not contribute to steam wastage and will help them to identify and report potential problems. Maintenance technicians should be skilled in the trade of steam system upkeep and have sufficient diagnostic and repair tools available. A supply of spare parts should also be kept on hand to maintain important systems in peak running condition.

Conclusion

Steam provides a convenient means for transferring energy throughout a food processing plant. When properly engineered and installed, a steam system is reliable, safe and economical. A wide choice of fuel sources can be used to generate steam contributing to its flexibility as a heat transfer vehicle. Steam may be used for indirect heating of food products or may be directly incorporated in foods for heating using a wide array of commercially available equipment. In addition, steam can be used for non-food processing activities (e.g. space and surface heating) throughout the facility. Estimation of steam use is possible using simple mathematical equations. Finally, steam can be precisely controlled, helping to make processes consistent and repeatable.

References

U.S. Department of Energy. 1995. Industrial insulation for systems operating above ambient air temperature (ORNL/M-4678). Energy Efficiency and Renewable Energy Office of Industrial Technologies, Washington, D.C.

Spirax Sarco. 1985. Design of fluid systems steam utilization. Allentown, PA.

Heald, C.C. 1988. Cameron Hydraulic Data. 17th ed. Ingersoll Rand, Woodcliff Lake, NJ.

Henderson, S.M., R.L Perry and J.H. Young. 1997. Principles of process engineering, 4th edition. American Society of Agricultural Engineers. St. Joseph, MI.

Oklahoma Department of Labor. 2000. Welding law 59 O.S. 1624-1641, Administrative roles OAC 380:20. Oklahoma City, OK.

Rahman, S. 1995. Food properties handbook. CRC Press. New York.

Singh, R.P. and D.R. Heldman. 1993. Introduction to food engineering, 2nd edition. Academic Press, New York.

Thielsch, H. 1996. Pipe, pipe fittings and valves, in Mark’s Standard Handbook for Mechanical Engineers, tenth edition. E.A. Avallone and T. Baumeister (editors). McGraw-Hill. New York. [8-143]

Toledo, R.T. 1999. Fundamentals of food process engineering. Aspen Publishers, Inc. MD.

Tim Bowser

FAPC Food Process Engineer