Some Properties of Scrim Lumber Manufactured from Eastern Redcedar

- Jump To:

- Results and Conclusions

- References

Scrimming is a manufacturing process of value-added engineered lumber or panel products by converting 6-9 feet long small diameter logs into disintegrated long fiber bundles using compression. This process was developed in 1975 by CSIRO in Australia. In a typical process the scrim mat is dried and mixed with adhesive and various types of chemicals before being molded in a press converting it into a composite lumber or beam type of products.

In this experimental work some of the mechanical and physical properties of commercially manufactured scrim lumber from small eastern redcedar logs were evaluated. Modulus of elasticity (MOE), modulus of rupture (MOR), internal bond strength (IB), Janka hardness, thickness swelling and water absorption of small size samples were tested.

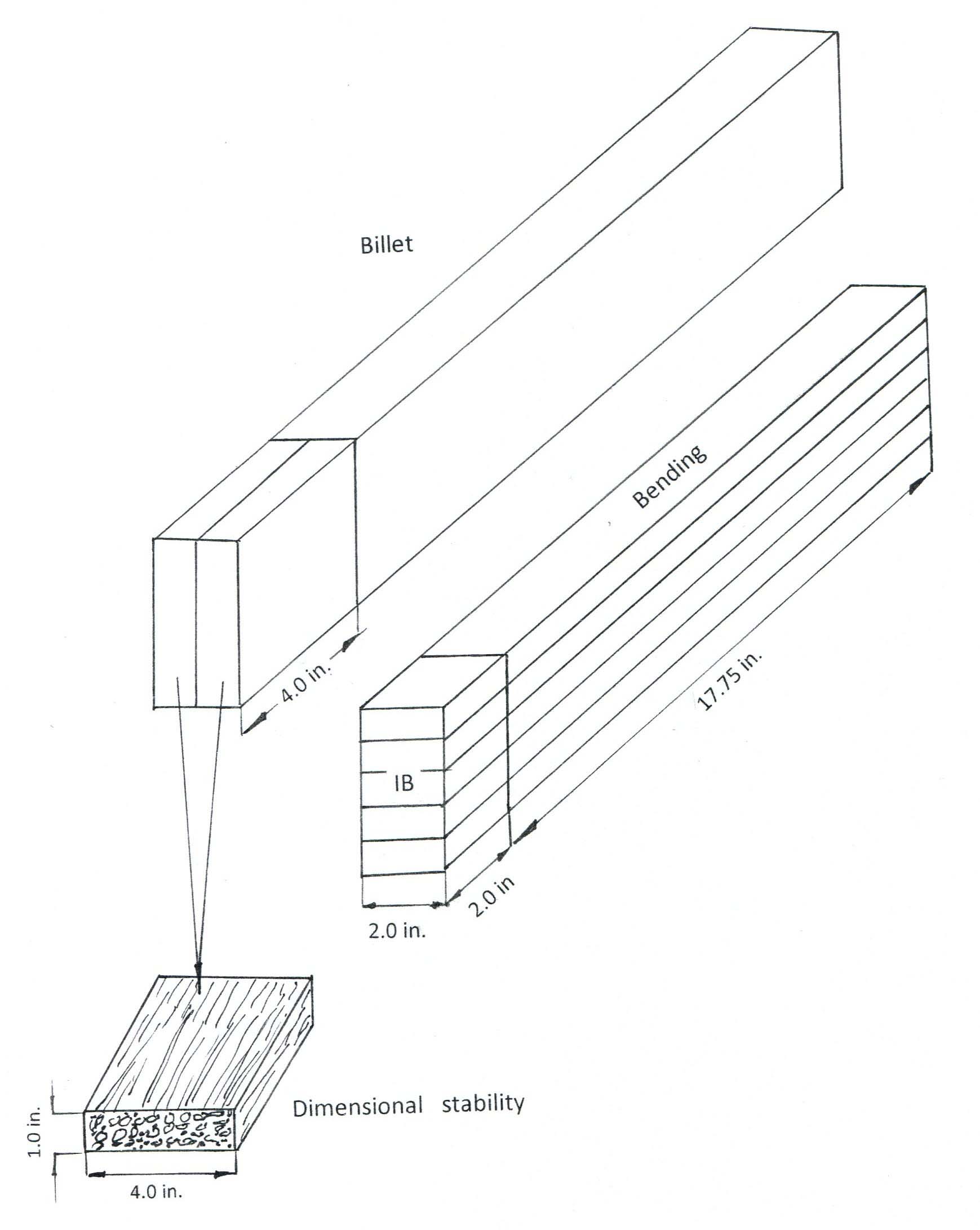

Nine scrim billets two feet long were supplied by the manufacturer as shown in Figure 1. Two dimensional stability samples, five bending samples resulting in MOE and MOR, and five IB samples were cut from each billet as illustrated in Figure 2. Comten Testing System equipped with 2,000 pounds load cell was employed for the mechanical tests. Figures 3 and 4 depict bending, IB and Janka hardness test set-ups, respectively.

Figure 1. Two feet long billets.

Figure 2. Cutting schematic of the lumber samples.

Figure 3. Bending (left) and internal bond strength (IB) (right) test set-ups.

Figure 4. Janka Hardness test set-up.

Results and Conclusions

Table 1 displays average values of both mechanical and physical properties of the specimens tested in this work. Samples had an average density of 0.706 g/cm3. Average values of MOE, MOR, IB and Janka hardness of the samples were determined as 1,167,154 psi, 9,637 psi, 265 psi and 1,219 pounds, respectively. Dimensional stability in the form of water absorption, thickness swelling of the samples also were determined as a result of 2- and 24-hour water soaking tests.

Table 1. Test results of the samples. (Numbers in parentheses are standard deviation values.)

| Density (g/cm3) |

MOE (psi) |

MOR (psi) |

IB (psi) |

Hardness (lbs) |

WA 2-h (%) |

WA 24-h (%) |

TS 2-h (%) (a) |

TS 24-h (%) (a) |

TS 2-h (%) (b) |

TS 24-h (%) (b) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.706 | 1,167,154 | 9,637 | 265 | 1,219 | 10.8 | 20.2 | 2.33 | 4.39 | 2.45 | 4.60 |

| (0.055) | (178,744) | (2,184) | (38) | (152) | (4.10) | (5.00) | (1.84) | (2.38) | (1.61) | (1.98) |

| N=50 | N=46 | N=46 | N=47 | N=40 | N=18 | N=18 | N=18 | N=18 | N=18 | N=18 |

Currently, there is no data on properties of scrim lumber manufactured from eastern redcedar, and there is little information on properties of scrim lumber manufactured from other types of lignocellulosic-raw materials including wood and non-wood species in the literature. It is a known fact properties of typical scrim lumber as a constructional product is relatively comparable to those of laminated veneer lumber (LVL) or parallel strand lumber (PSL). Both types of products are more homogeneous and have better glueline between the individual pieces as compared to scrim lumber. Modulus of elasticity of typical LVL ranges from 1.30 to 2.10 million psi listed in Wood Handbook General Technical report Forest Products Laboratory GTR 190, which is slightly higher than MOE values of the samples tested in this work. There have been several research projects carried out to evaluate mechanical characteristics of scrim lumber in the past, but all used chemically modified or steam treated raw material, which resulted higher mechanical properties than those found in this study. Samples in this work had relatively high IB strength and hardness values for a typical construction type of composite product. Although the type of the adhesive of the products is not known, the samples had low water absorption and thickness swelling, which makes them an excellent material for exterior applications. One important point, which should not be overlooked, is the tests in this work were carried out on small samples rather than full-size billets.

The non-homogeneous nature of scrim lumber would play more important role on mechanical properties of the small samples, specifically bending characteristics. Therefore, one would expect lower bending properties of the small size samples than those of large samples due to less homogeneous representation having more interrupted glueline between individual pieces.

Based on the findings in this brief experimental study, it seems all samples showed satisfactory properties as compared to those determined in previous studies using different types of wood species. It appears eastern redcedar has the potential for manufacture of scrim lumber type products, which may result in converting such invasive species in Oklahoma into a value-added structural composite material.

References

Leng, W. and Barnes, H.M. 2017. Properties of pine scrim lumber made from modified scrim. Wood and Fiber Sci. 49(2)158-167.

Kitchen, S, Amburgey, T, Barnes, M, and Seale, R. 2016. Mechanical and durability properties of steam pressed scrim lumber. Bioresources. 11(12) 5343-5357.

General Technical Report -190, Forest Products Lab. Page 12-2. Madison, WI.

Sam Hiziroglu

FAPC Value-Added Wood Processing Specialist