Preparation of Biochar for Use as a Soil Amendment

Introduction

Biochar is a carbon rich organic matter that remains after heating of organic material in the absence of oxygen, a process called pyrolysis. The International Biochar Initiative standards for biochar defines biochar as the solid byproduct of a thermochemical conversion process containing greater than 10% organic carbon. Carbon in biochar is extremely stable which takes more than 100 years to break down, so amending soils with biochar is an effective way to sequester carbon. Biochar is used as a substrate for soilless media and soil amendments to improve soil quality. The high surface area of biochar contributes to the soil's ability to hold water and reduces nitrogen leaching and dissolved organic carbon. Application of organic matter along with biochar reduces nutrient leaching, thus enhancing nutrient use efficiency of the crop instead of organic matter alone.

Pros and Cons of Using Biochar:

Benefits:

Biochar helps to improve the soil quality by restoring the degraded soil by removal of heavy metal contaminants. Greater surface area and porosity of biochar increases water holding capacity, which lowers water and nutrient leaching/loss. Therefore, applying biochar to soil increases nutrient availability and nitrogen retention, boosting crop yield. Application of biochar at the root zone (15-20 cm) is beneficial.

Since biochar is high in carbon, burying it as a soil enhancement also helps lower atmospheric carbon dioxide through carbon sequestration. Farmers can get carbon credit and certificates for sequestering carbon dioxide in the form of biochar. Farmers can sell their carbon credits in the carbon credit market, which can be an additional source of income. In addition, use of biochar as a partial peat moss substitute at 5-30% of soilless media also help to reduce sustainability concerns of peat moss, which is a major substrate component in soilless media mixes.

Disadvantages:

Biochar on a soil surface can lead to soil loss due to wind erosion as it loosens the compacted soil layer. Biochar applied at high rates may negatively affect earthworm and other beneficial worm survival rates in the soil. Application rate will also depend upon soil type, texture, and fertility condition. Biochar must be carefully balanced with plant nutrients, as an imbalance can lead to the absorption and unavailability of applied nutrients. When feedstock used to produce biochar contains high levels of heavy metals, soil health and productivity may be affected. High absorption of pesticides by biochar may lead to pesticide accumulation in the soil. This accumulation of pesticides could act as another pollution source for agricultural land.

Methods of Biochar Production

The production process, including temperature and duration, significantly affects the quality and properties of the biochar produced. There are different methods to produce biochar. Among all the methods, pyrolysis is the most common method used to produce biochar.

- Pyrolysis: The process of pyrolysis involves heating biomass in the absence of oxygen to produce

biochar as the primary byproduct. It is the most common method used. There are two

types of pyrolysis which are slow pyrolysis and fast pyrolysis.

- Slow pyrolysis is the process in which biomass un-dergoes decomposition at a low heating rate (0.1°C-0.8°C/s) with sufficient residence time (>30 min).

- In fast pyrolysis, biomass is heated at a higher rate (1000°C/s) with residence time

< 2 seconds and is used to produce bio-oil and syngas as the main products.

- Gasification: (700°C-1000°C) is a partial oxidation of biomass. The process yields byproducts such

as biochar (mixed with tar and ashes) and syngas.

- Torrefaction: (200°C-300°C) converts biomass in the absence of oxygen at a low heating rate (50°C/min)

to produce bio-oils, or biochar.

- Flash carbonization: is a process that transforms bio-mass mostly into gaseous and solid products by igniting

a flash fire under a packed bed of biomass at higher pressures (1 to 2 MPa) for less

than half an hour.

Feedstock Biomass includes Animal, Plant and Waste Products:

Plant sources: straw and crop residues, wood chips and barks, twigs, leaf litter, forest debris, rice husk and bagasse, rice and wheat straw, corn stalk.

Animal sources: poultry manure, pig manure, cattle and dairy manure.

Waste source: sewage sludge and municipal solid waste. Source of feedstock used determines the quality of biochar produced. Biochar produced from poultry litter have higher pH and extractable phosphorus and sodium. Wood-based biochars have higher carbon content and surface area compared to animal sources.

Biochar Production

Biochar can also be purchased from select manufactures, but large volumes are generally sold to cover production and shipping costs. There are several commercially available systems on the market for biochar production but are costly and require additional site modification to run the equipment. In this factsheet, we will discuss a biochar production system suitable for small scale production.

Making Biochar with a Double Barrel Retort:

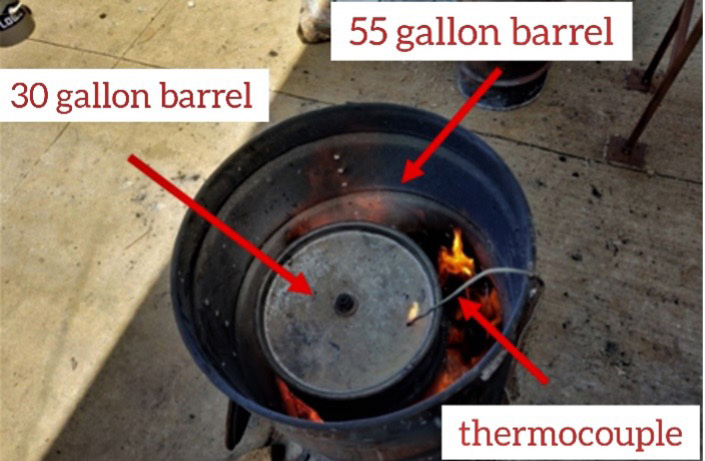

A double barrel retort system can be used to produce biochar locally through pyrolysis with minimal costs and can yield 10-15 pounds of biochar at a time. A double barrel retort is a system where one small barrel is used inside a large barrel to produce biochar (Figure 1 and 2). With the system demonstrated at Oklahoma State University, Stillwater, the small or inner barrel was 30 gallons and the larger outer one is 55 gallons. The smaller barrel is also called the carbonization (converting organic matter to carbon) barrel which is filled with biomass and the outer barrel acts as the burning barrel.

Materials Required:

- 55-gallon metal barrel

- 30-gallon metal barrel

- Biomass

- Fan/blower (high pressure blower, radial base of 12-1/4 in wheel diameter, 230/460 voltage)

- Aluminum vent pipe (3.5-inch diameter, 3 meter long)

- Drill

- Various metal drill bits• 1/2 inch for hole in big barrel• 5/16 inch for thermocouple hole• 3/8 inch for base of small barrel

- Duct tape

- Proportional Integral Derivative (PID) controller

- Thermocouples (uxcell 6.5 ft long K type 50 x 5 mm 0-800°C thermocouple probe sensors)

- 1/2" Heat resistant nonmetallic conduit pipe

- Metal block or stand

- Plastic junction box for PID controller

- Wire cables

- Wood

- Heat resistant gloves

- Lab glasses

- Fire starter (fuel) and lighter

- Water

- Electricity/outdoor grounded extension cord

Figure 1: Double barrel retort system used at OSU.

Figure 2: Eastern red cedar mulch biochar prepared from double barrel system.

Constructing Double Barrel System:

- Take a 55 gallon barrel and a 30 gallon barrel along with their lids. Clean the barrels and let them dry. Then, drill (16) ½ inch holes on the top and bottom outer edge of large barrel and (8) 3/8 inch holes in the bottom of the small barrel (See Figure 3).

- Drill a 5/16-inch hole in the lid of the small barrel for the thermocouple (See Figure

1). The thermocouple will measure the temperature inside the small barrel.

Figure 3: Drilling a hole in the lid for thermocouple. - Make a square shape cut on one side of the junction box where the PID will be fitted

and on the

opposite side of it make hole to be able to pass the thermo-couple and power cable wire out of the box.

Figure 4: PID connection. - Connect the thermocouple to the PID controller and the PID controller to a power supply cable. Pass the thermocouple from the large barrel to the small barrel.

- Use a piece of round aluminum vent pipe to pass air from the fan to the barrel (Figure

5). The diameter of pipe should be fitted with the opening pipe of the fan. To double

production, connect the pipes between the fan and two barrels by a three-way system

(See Figure 6). Use the duct tape to keep pipe in a position without moving. Maintain

at least 10 feet distance between the two barrels for safety and easy of handling.

Figure 5: Fan used to increase air flow. - The system should be done outside and the power supply should be at least 10 meters

away from any structure.

Figure 6: Biochar production on two double barrel system or single barrel in background. - An iron sheet stand is needed beneath the large barrel if concrete flooring (Figure 7). Without the stand, continuous heating at the same place will cause the concrete to crack. This can be done on flat ground as well as long as any vegetation has been removed.

- Put a metal box or stand in the center of the large barrel and put the small barrel

on the middle of the box, allowing syngas (smoke and fumes) to pass through holes

at the bottom of small barrel. Then fill the small barrel with pieces of biomass (~20

pounds of biomass will fit in the small barrel).

Figure 7: Metal box used as a stand for the small barrel (18 cm X 7.5 cm X 7.5 cm).

Constructing Double Barrel System:

- It is easier to convert smaller pieces of biomass into biochar compared to large pieces because the heat transfer is more efficient with small pieces compared to larger ones.

- Do not fill the small barrel up to the top. Leave 4.5-inch space from the top for the thermocouple.

- Connect the PID controller to the power supply to record the temperature inside the barrel.

- After filling the smaller barrel, cover it with the lid.

- Fill the larger barrel by placing pieces of smaller seasoned wood between the two barrels all the way around to about 1/3 of the height of the small barrel.

- Ignite seasoned wood in larger barrel with the help of starter fuel and a lighter. Once the fire is started add larger wood pieces until the optimal temperature (See Table 1) is reached for 3 hours. It is important to have flaming wood and not smoking wood to increase temperature. Adding the wood equally on all side is necessary to completely turn biomass to biochar as one side of the barrel may contain partial converted biomass (Figure 8).

- For cedar mulch (biochar source), after 3 hours of burning, let the barrels cool down until you can easily lift out the smaller barrel. Use heat resistant gloves and glasses for safety. Duration for pyrolysis will depend upon the size of barrel, biomass and moisture content of biomass.

- When the biomass is converted to biochar completely, there will be reduced volume of material and the syngas (smoke) coming out of small barrel will stop.

- Once the small barrel is taken out, remove the lid and the biochar. Splash sufficient water (average: 3 gallons for a batch) over it to prevent combusting and catching fire.

- After cooling down, remove any pieces not fully converted. These pieces can be used in the next batch. High quality biochar sounds like broken glass when mixed together.

- Keep the biochar in a shady dry location for 3 days then store in a drum/container.

- It is best to grind the biochar down to a smaller size before utilization. This will allow for uniform distribution of biochar in the soil media.

Figure 8: Partially converted biomass.

Table 1: Wood requirement as a source of heat for 3 hours pyroly-sis for different temperatures for a single double barrel system.

| Temperature range (°C) | Approximate wood re-quirement (pounds) | |

|---|---|---|

| 300-350 | 85 | |

| 400-450 | 107 | |

| 500-550 | 130 |

Regulating Temperature

- Keep adding the wood and increase air supply from the fan by increasing fan speed till you reach the desired temperature. Closing the lid of the large barrel will help in increasing temperature as it traps the heat inside.

- To lower temperature, remove the closed lid, reduce the air supply from the fan and splash a small amount of water around the fire.

Safety Precautions:

- Do not go near the burning barrel without wearing heat resistant gloves and glasses.

- Have a source of water or a fire extinguisher available.

- Once you start the fire, do not leave unattended.

- Put out the fire and cool down the barrel with water before leaving.

- If burning on concrete, place large barrel on a metal stand or concrete can crack due to high temperature.

- Do not burn near combustible fuel like gases.

- Avoid burning if wind is over 10 miles per hour.

- Do not burn alone and have access to a phone for emergency.

- Follow all fire and lab safety rules.

Summary:

Biochar, a carbon rich matter which is beneficial for agricultural land and crops can be produce through various methods. Producing biochar by pyrolysis using a double barrel system is easy and a cost-effective method for small batch production. However, you need to be careful in constructing the system and follow safety precautions properly.