Oil and Oilseed Processing II

Oil Extraction Techniques

Oilseed processing and oil extraction processes are designed to obtain high quality oil with minimal undesirable components, achieve high extraction yields and produce high value meal. There are several techniques for extracting oil from oilseeds. Two common oilseed extraction processes are solvent extraction and mechanical extraction using a screw press. Today in the United States, mechanical oil expression is not widely used due to low oil recovery. However, the use of screw press is preferred by small processors because of its low capital cost. Solvent extraction with hexane is the standard practice in today’s modern oilseed-processing facilities. Solvent-extraction plant capacities range from 100 to 9000 metric tons per day. Supercritical fluid, water and enzyme-aided water extraction processes are of interest for specialty and gourmet oils production.

Solvent Extraction

Solvent extraction refers to preferential dissolution of oil by contacting oilseeds

with a liquid solvent. This is the most efficient technique to recover oil from oilseeds.

The efficiency depends on the oilseed preparation prior to extraction, temperature,

mode of operation (batch vs. continuous and co-current vs. counter current operations)

and equipment design. It is expected that residual oil in the meal to be less than

1 percent after commercial solvent extraction.

The choice of solvent type is based on solubility of oil in the selected solvent,

cost and safety. Light paraffinic petroleum fractions, pentane (boiling point 88-97°F),

hexane (boiling point 146-156°F), heptanes (boiling point 194-210°F) and octane (boiling

point 215-264°C) can be used for oil extraction. Currently hexane is widely used for

commodity vegetable oil extraction. The major disadvantage of these solvents is their

flammability. Strict precautions have to be taken to avoid fires and minimize explosion

risk in the extraction plants. The 1990 Clean Air Act listed hexane as a hazardous

air pollutant. The oilseed processing industry is under pressure to switch to solvents

that are considered benign such as alcohol or water. Low oil solubility and higher

energy requirement for solvent recovery and meal drying are major disadvantages for

using alcohols and water for oil extraction. Furthermore, alcohols lower functionality

of soybean proteins.

Oil solubility in solvent increases with extraction temperature. High temperature

also has a positive effect on viscosity and diffusivity of oil. Viscosity decreases

while diffusivity increases as the extraction temperature increases, resulting in

shorter extraction times. Energy required for solvent recovery decreases when higher

operating temperature is used for extraction. However, high temperatures may cause

deterioration and denaturation of some oil and meal components. Hence, temperature

selection is based on type of oil and required specifications of the final product.

There are three major steps in traditional solvent extraction (Figure 1): oil extraction,

meal and oil desolventizing, and meal toasting.

Figure 1: Simplified flow diagram of a hexane extraction process

In the 1800s, small batch type oil extraction systems were common in Europe. The same

vessel was used for both extraction and meal desolventizing. Today, extraction of

specialty and high value oils and recovery of oil from spent bleaching clay are carried

out in batch extractors. A rotating drum and a vertical cylindrical kettle equipped

with a vapor tight cover and a low speed agitator are two popular batch type extractor

designs.

Use of large-scale continuous processes began in the early 1920s. Today, immersion

and percolation type continuous extractors are used for commercial solvent extraction

of oilseeds. In immersion-type extractors, flaked oilseeds are completely submerged

in solvent. For such a system to be efficient, particle size should be as small as

possible to achieve maximum contact between seed and solvent. The main disadvantage

of this design is that solid and miscella (oil + solvent mixture) separation is difficult.

Thus, immersion-type extractors are suitable for small-scale production facilities.

In percolation-type extractors, flaked seeds are formed into a fixed bed over which solvent is sprayed. Solvent drains through the bed and washes oil out. The particle size of the seeds needs to be large enough to allow a good solvent flow rate through the seed bed. Fine particles in the bed block the solvent flow causing flooding of the bed and, consequently, lowering extraction efficiency. Early designs based on percolation were basket-type extractors in which flaked seeds were placed in baskets with perforated bottoms. These systems look like an enclosed bucket elevator. The baskets are supported by endless chains in a sealed housing and continuously raised and lowered at a slow rate (1 revolution per hour). Each basket is filled with flaked seeds by an automatic feed hopper at the top. As the basket starts descending, solvent is sprayed over the baskets. The spent flakes in baskets ascend to the top of the housing on the opposite side of the feed hopper. At the top, baskets are automatically inverted and spent seeds are discharged into a hopper from which they are transferred to a meal desolventizer on a conveyor belt. Basket-type extractors are bulky and hard to maintain. The newer extractor designs are horizontal and rotary type. The design principle for horizontal extractors is similar to the basket-type extractors, but the baskets rotate in a single horizontal plane rather than vertically. A popular rotary-type design, Rotocel® Extractor, holds the flaked seeds in cells, which rotate in a horizontal plane around a vertical axis. The extractor has four countercurrent extraction stages. The latest rotary extractor design, Reflex®, has a fixed slotted floor and bevel gear drive. A Reflex® extractor, which has a capacity of 9000 metric tons of soybeans per day, is currently in operation in Argentina. Information on various solvent extractor designs can be found on the following web site:

http://www.fao.org/docrep/t0532e/t0532e04.htm#3.2.

Meal and Oil Desolventizing

After oil extraction, residual solvent in meal (spent seeds) is removed in a desolventizer-toaster

(DT), which may have three sections for predesolventizing, desolventizing and toasting.

Meal is heated high enough to evaporate solvent, but not deteriorate nutritional value.

DT consists of trays mounted on top of each other along a vertical shaft with sweep

arms attached to move the meal around (http://www.crowniron.com/userImages/Crown_DT_Brochure.pdf,

http://www.desmetgroup.com/desmet04/extraction.html#Anchor-De-44591). Meal from DT

may still contain some moisture, which has to be removed. In some cases desolventizing

and drying is done in the same equipment referred to as a desolventizer-toaster-dryer-cooler.

Solvent recovery from miscella (oil + solvent) is carried out in distillation columns.

An additional stripping column, which is heated indirectly with steam, removes residual

solvent and moisture in the oil. Solvent vapors from distillation and stripping columns

are condensed and recycled to the extractor. After stripping, oil goes through a refining

process, which removes undesirable components in the oil.

Mechanical Oil Extraction

Lever and wedge presses were the early mechanical oil expression equipment used for

oilseed processing. The first cottonseed oil mill constructed in the United States

in the 1920s utilized a hydraulic press. Seeds in filter bags were manually loaded

into perforated, horizontal boxes between the head block and the ram of the press.

Boxes were pressed together by applying hydraulic pressure on the ram. Oil was pressed

out through the filter bag. Then the filter bag containing spent cake was manually

removed from the hydraulic press. Later versions of the hydraulic presses used cages

instead of filter bags. Hydraulic presses were in use until the 1950s. They are replaced

with continuous screw presses and continuous solvent extraction plants, which are

less labor intensive. The olive oil industry still utilizes hydraulic press today.

The mechanical screw press consists of a vertical feeder and a horizontal screw with

increasing body diameter to exert pressure on the oilseeds as it advances along the

length of the press. The barrel surrounding the screw has slots along its length,

allowing the increasing internal pressure to first expel air and then drain the oil

through the barrel. Oil is collected in a trough under the screw and the de-oiled

cake is discharged at the end of the screw. The main advantage of the screw press

is that large quantities of oilseeds can be processed with minimal labor, and it allows

continuous oil extraction. The maintenance of screw presses is challenging. The moving

parts and high pressure and temperature generated in the press increase wear. The

primary improvement in mechanical screw press design has been developing materials

of construction that extend life of the parts that wear the most. Equipment parts

that used to last three months before requiring replacement may now last up to two

years. Today, much larger screw presses have been built. Former capacities of 5 tons

per day are now more than 100 tons per day for full pressing and more than 800 tons

per day for pre-pressing applications.

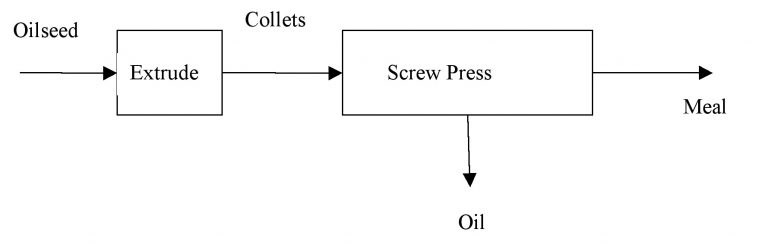

A growing number of mini crushing mills, which employ extruding-expelling (E-E) technology have been built as farmer-owned cooperatives or as on-farm operations to process locally produced soybeans or other oilseeds (http://www.insta-pro.com/products_services.htm) (Figure 2). E-E uses a dry extruder in which heat is generated by friction prior to screw pressing, replacing more capital intensive use of steam-heated dryers and cookers and associated steam generation equipment. The partially defatted meal, typically with 6-7 percent residual oil content, is used in livestock rations.

Figure 2: Flow diagram of an Extrusion-Expelling (E-E) process

Expanders can be used to form oilseeds into porous pellets, which are commonly known as collets. Conversion of flaked seeds into extruded collets improves solvent extraction efficiency. Collets are larger and stronger and have larger bulk density than flakes. Better solvent flow and micelle (oil + solvent) drainage are achieved in the solvent extractor when collects are used for solvent extraction. Because of the larger bulk density of collets, less space is required for the same weight oilseed in the extractor. Production capacity in a plant is increased when collets, rather than flaked seeds, are used for solvent extraction. High oil content seeds such as sunflower, safflower, peanut canola and rapeseed have too much oil to produce good flakes and collets. Hence, they are pre-pressed to reduce meal oil content to 16-18 percent before solvent extraction. Soybean does not require pre-pressing because of its relatively lower oil content, 18-20 percent. A new screw press design, Hivex, combines pre-pressing and extruded collets formation into a single processing unit (http://www.andersonintl.net/VO%20Expander%20Page.htm). A drainage cage and a pressing screw are included into the barrel of an expander, so there is no need for purchasing a separate extruder and pre-press.

Aqueous Extraction

Aqueous extraction (AE) is traditionally used in many developing countries. The process called water-flotation has been used for extracting coconut and palm oil. It involves heating oily material, grinding with or without water, and boiling with water to liberate the oil. The oil, which appears on the surface, is collected and heated to remove moisture. Oil extraction yields of around 50 percent are generally considered to be satisfactory for traditional non-commercial processes. This process can be used to extract oil as well as high quality proteins. In order to improve oil and protein extraction yields and to undertake extraction under milder processing conditions, some enzymes or surfactants have been added to the extraction medium; however, there are certain limitations. Finely ground seeds, which cause dusting, may lead to an explosion if the processing area is not ventilated well. Other key disadvantages for aqueous oilseed extraction include lower efficiency of oil extraction, provision for breaking emulsion (that might form during the process) to separate oil and water phases, enzyme and surfactant costs and the treatment of aqueous effluents.

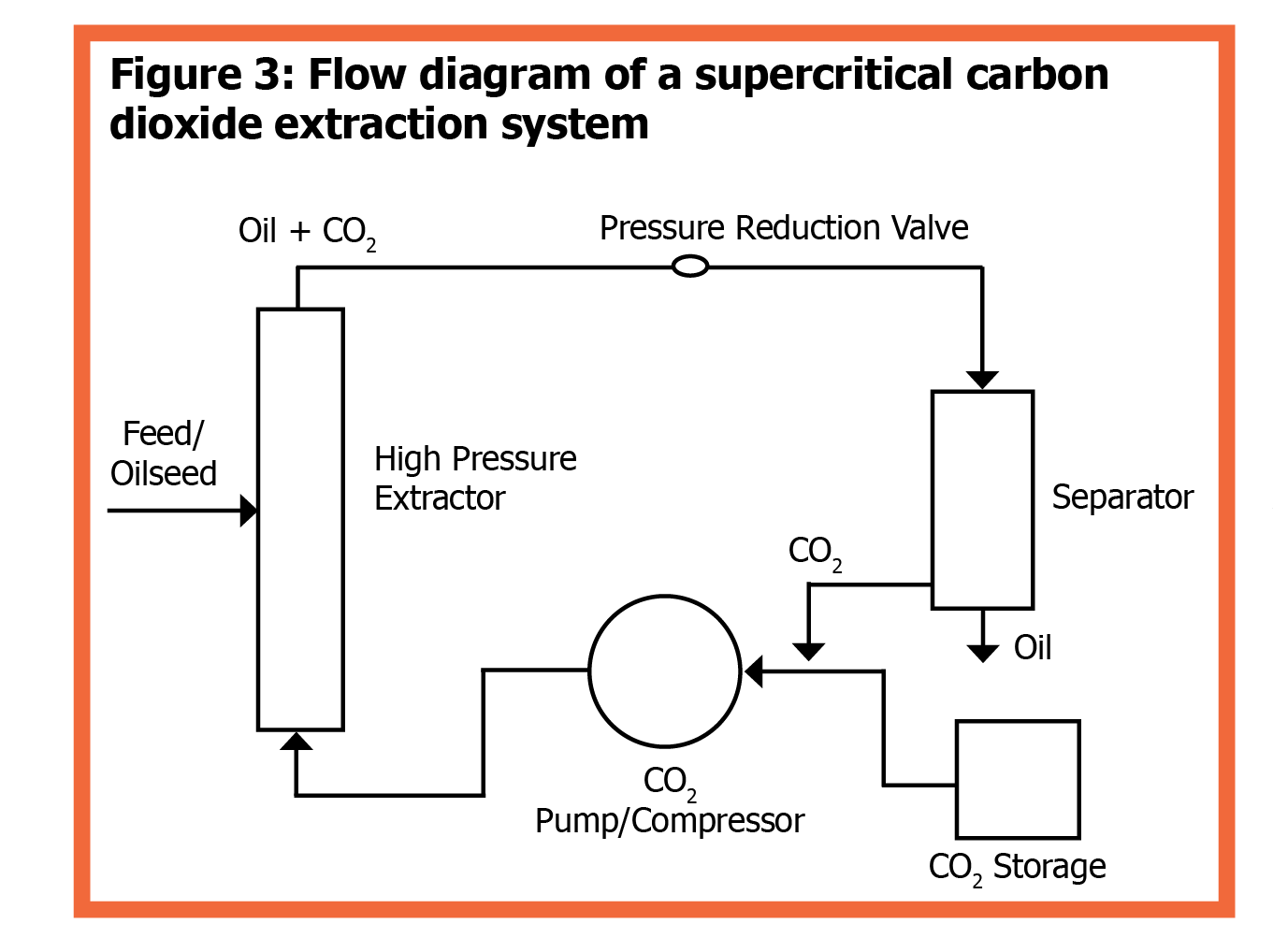

Supercritical Fluid Technology

Public concerns and government scrutiny about the environmental and human health hazards of organic solvents and residues in oil/oilseed-derived products have catalyzed the search for alternative solvents for edible oil processing. Ethanol, isopropyl alcohol, acetone, iso-hexane and supercritical fluids (SCF) have been studied as alternative solvents. SCF technology has been examined as an alternative technique for the conventional oil and oilseed processing methods for more than two decades. The supercritical carbon dioxide (SC-CO2) technique, which utilizes carbon dioxide above its critical pressure (7.3 MPa) and temperature (31°C) as solvent, has been the choice for the majority of edible applications. The unique advantage of SC-CO2 is the easy removal of solvent from the extract. When pressure is released from the system, carbon dioxide returns to the gas phase and oil precipitates out from CO2-oil mixture. Carbon dioxide is recycled; hence, CO2 released from the system is not an environmental issue. Although industrial applications of SC-CO2 technology have been growing steadily, currently most of the applications involve high-value products. The economic feasibility of SC-CO2 based processes is still hampered by the capital cost of high pressure vessels. However, cost saving can be realized from simplified separations and the lower solvent cost of supercritical fluids. The nontoxicity of SC-CO2 and significantly reduced waste streams from the process makes this technology unique in terms of meeting increasingly stringent health and environmental regulations.

Figure 3: Flow diagram of a supercritical carbon dioxide extraction system.

Nurhan Dunford

FAPC Oil/Oilseed Specialist