Oil and Oilseed Processing I

Oilseed Handling, Storage and Pre-treatment

Oils are essential components of all plants. However, commercial oil production facilities

only utilize plants that accumulate large amounts of oil and are readily available.

Currently, the largest source of commercial oils is oilseeds: the seeds of annual

plants such as soybean, canola, rapeseed, cottonseed, sunflower, peanut, castor and

flax. The second largest source of plant oils includes coconut, palm, olive and tung

oil.

Handling and Storage

In the United States, oilseeds are shipped like any other grain, either in railroad

cars or trucks, and received at elevators. Physical properties of the seeds, such

as size, shape, bulk density and flowability affect the design of oilseed handling

facilities. For example, canola, rapeseed, delinted cottonseed, soybean and sunflower

have very good flowability. They are usually stored in vertical cell-like storage

bins. Copra (dried meat or kernel of the coconut) and undelinted cottonseed do not

flow well. Hence, vertical bins are not suitable for this type of seeds. Copra is

stored in large flat warehouses. Storage bins can be built of stainless steel, concrete,

tile or other material. Vertical bins are preferred where ambient temperature is low.

Concrete bins are used at places where average outside temperature is relatively high

(95-113 degrees Fahrenheit).

Proper handling and storage of oil-containing materials are very important to minimize

deterioration and maintain good quality of both contained oil and meal. Whole, intact,

low-moisture oilseeds (about 8-10 percent moisture) may be stored for an extended

time under suitable conditions. Deterioration of oilseeds is accompanied by respiration

or carbon dioxide evolution and heat generation by oxidation reactions. Sound, intact

seeds may release less than 10 cubic centimeters of carbon dioxide per gram of seed

per day, while damaged, high moisture seeds may release 50 cubic centimeters or more

of carbon dioxide per gram of seed per day. Furthermore, heat generation by oxidation

reactions may increase the temperature of stored seed, accelerating deterioration

even to the point of charring the seeds.

Activity of native enzymes present in oilseeds, infestation by insects and mites along

with microbial activity during storage also are important factors affecting oil and

meal quality. In general, high moisture content (above 14-15 percent moisture) in

seeds has an adverse effect on oil and meal quality. Oil splitting, or acid generation,

may be accelerated by microbial growth (mold and/or bacterial growth) and enzyme activity

in high-moisture seeds. Oil in mature seeds may contain about 0.5 percent free fatty

acids. However, if seeds are damaged mechanically or by frost or become wet during

harvest, handling and storage, then the acidity of oil can be much higher.

Sprouting, considered a damage factor, is another important issue during storage of

high-moisture seeds. Sprouted seeds may have lower oil and higher free fatty acid

content as compared to sound seeds. Today, air dryers are essential components of

modern storage facilities to maintain oilseed quality. Most oilseed storage bins are

equipped with aeration ducts and ventilation blowers to cool the seeds. Since oxidation

reactions are aerobic processes, a low oxygen atmosphere in storage bins helps to

slow down oxidation and quality deterioration. Mature seeds can be stored longer than

immature seeds because of the lower activity of oil-splitting enzymes in mature seed.

Proper storage of harvested oilseeds also may contribute to desirable changes. For

example, oil extraction yields from fresh soybeans can be lower than for soybeans

stored more than five months. The storage of soybeans also decreases the chlorophyll

content of green beans. Chlorophyll is not desirable in edible oils and needs to be

removed during the oil refining process.

Preparation of Seeds for Oil Extraction

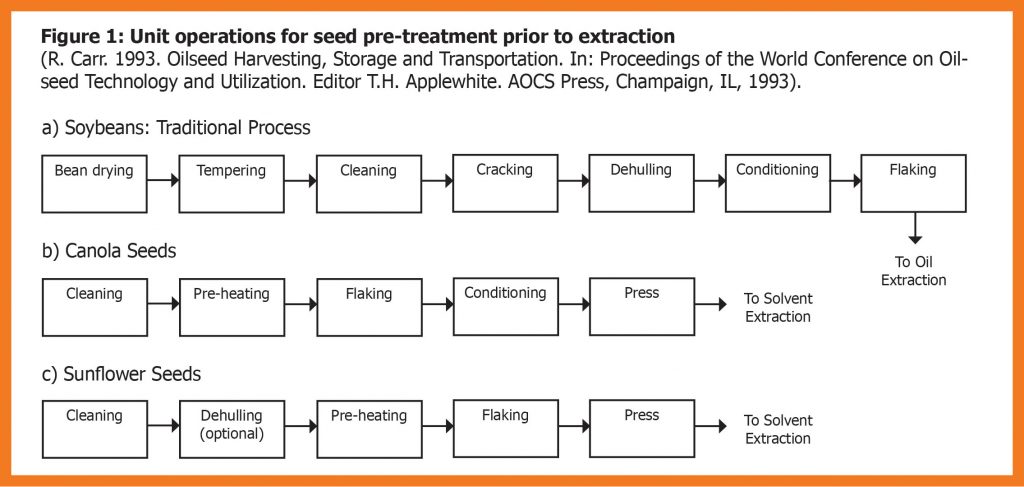

Unit operations for preparation of seeds for oil extraction vary slightly depending on the physical properties and oil content (Figure 1). However, most oilseeds go through the process of cleaning, drying dehulling, size reduction, flaking cooking and tempering.

Cleaning

Oilseeds need to be cleaned to remove plant stems, sticks, leaves and foreign material before storage. Such material may decompose and cause heating in stored seed mass diminishing oil and meal quality. Foreign materials in seeds are typically separated out by a combination of rotating or vibrating coarse screens, reels and aspiration. This process is commonly referred to as scalping. Buhler, Carter-Day, and Kice Metal Products are some of the suppliers of scalping equipment.

Sand and dirt also are removed by fine screening. Rotex and Buhler are well known suppliers of such screens. Magnetic devices remove metal contaminants from seeds. Plate magnets, drum magnets or electromagnets installed over conveyor belts are commonly used. Some oilseeds such as peanuts may contain stones which are similar in size to the seeds. Hence, they cannot be separated by screening. Seeds need to be separated from stones by gravity. Special “destoners” are available to remove stones and mud balls. Companies such as Buhler and Triple S Dynamics are popular suppliers of such equipment.

Seed Drying

The moisture content of oilseeds often needs to be reduced to minimize degradation in storage and to improve the effectiveness of downstream processing. For example, soybeans are often received at 13 percent moisture and need to be dried to 10 percent moisture to facilitate efficient hull removal. Large, vertical, open-flame grain dryers can be used for oilseeds as well. These dryers have multiple columns of oilseeds which slowly migrate downward. The upper portion of the column is used for drying and lower section is for cooling.

Dehulling

The amount of hull on oilseeds varies significantly. The percentage of hulls for cotton

seed, sunflower seeds and soybean are 45, 25 and 7 percent, respectively. Hulls and

shells of oilseeds do not contain a significant amount of oil (less than 1 percent).

Most oilseeds need to be separated from their outer husk or shell prior to oil extraction.

Dehulling also is referred to as shelling or decorticating. Dehulling increases oil

production efficiency, capacity of the extraction equipment and reduces wear in the

expeller as the husks are abrasive. If not removed, hulls reduce the total oil yield

by absorbing or retaining oil in the pressed cake. Furthermore, wax and color compounds

present in the hulls end up in the extracted oil. These compounds are not desirable

in edible oils and need to be removed during the refining process. Dehulling reduces

fiber and increases protein content of the meal.

There are numerous dehuller designs to choose from depending upon the types of seeds. Knife, disk and impact type dehullers are widely used. For example an impact dehuller, which is commonly used for sunflower seeds, consists of a rotating blade that drives seeds into a hard material outside the diameter of the blades. The force of impact causes the hulls to break. Then, seeds are separated by using shaking conveyor belts, multiple sifting screens or vacuum. Dehulling efficiency of a system often is measured by the residual fiber content in the meal and the residual oil content in the hulls. The industry standards for soybeans are less than 3.5 percent fiber content remaining in the meal and less than 1.5 percent oil content remaining in the hull. Suppliers of dehulling equipment include Buhler, Crown Iron Works, De Smet, Kice Industries, Inc., Rotex and Carter Day.

Size Reduction and Flaking

Most oilseeds are reduced in size to facilitate hull removal, heating, drying and

flaking prior to oil extraction. Canola, rapeseed and corn germ do not require size

reduction as they are already sufficiently small. Cracking mills are used for seed

size reduction. A cracking mill consists of two sets of cylindrical corrugated rolls

in series. The rolls rotate at differential speeds to break apart seed cells containing

oil. High capacity cracking mills can process up to 1,000 tons per day of oilseeds.

Buhler and CPM Roskamp are the primary suppliers of cracking mills.

Oilseeds also can be flaked prior to solvent extraction. Flaking ruptures seed cellular structure and reduces the distance that solvent has to travel to reach the oil in the cells. A flaking mill has two large diameter rolls turning in opposite direction and forced together by hydraulic cylinders. As the seeds are pulled through the flaking mill, they are stretched and flattened. Typical flake thickness is in the range of 0.01-0.015 inch or 0.25-0.37 mm. Flaking of oilseeds also increases surface area for increased contact between solvent and seed during the solvent extraction process. Oil from the cracked or flaked seeds should be extracted as quickly as possible (within 24 hours) to minimize meal and oil quality deterioration. Flaking mills, which can process 300 to 500 tons of seeds per day, are available. Buhler and CPM Roskamp are the major suppliers of flaking mills.

Cooking/Tempering

Oilseeds are cooked or tempered to denature proteins, release oil from the cells and inactivate enzymes. For example, rapeseed contains the enzyme myrosinase. This enzyme catalyzes hydrolysis of glucosinolates which are naturally present in rapeseed. During the hydrolysis process, undesirable compounds such as isothiocyanates and nitriles form. These compounds are soluble in oil and lower the quality of oil. Rapeseed is cooked in multistage cookers to keep the glucosinolates intact and inactivate the myrosinase. Rapeseed is preheated to 68-122 degrees Fahrenheit in less than 5 minutes and contacted with live steam at 248 degrees Fahrenheit. Since canola has much lower levels of glucosinolates than that of conventional rapeseed varieties the cooking temperature for canola is lower (less than 212 degrees Fahrenheit). Cooked seeds are immediately pressed to separate oil. Cooking also gives seeds proper elasticity for efficient pressing. Cooking at high temperature is not necessary for sunflower seeds. Cracked and dehulled soybeans are conditioned/tempered by increasing the temperature to 149 degrees Fahrenheit and adjusting the moisture by using live steam. Conditioning is done in rotating drums with an internal steam coil. Tempering improves flaking performance and extraction efficiency.

Resources

Buhler Group

Carter-Day

CPM Roskamp

Crown Iron Works

De Smet Group

Kice Industries, Inc.

Kice Metal Products

Rotex

Soyatech

Triple S Dynamics