Managing Bermudagrass Pasture to Reduce Winter Hay Feeding in Beef Cattle Operations

A large proportion of cow-calf enterprise costs are associated with feeding harvested forages from November through April. By extending grazing through late fall and early winter, producers can reduce the amount of harvested forage that is needed to maintain beef cows. One management practice that can be utilized to achieve this goal is late-summer fertilization of bermudagrass forage with the intent of stockpiling the forage regrowth for fall or winter grazing. Bermudagrass is highly responsive to late summer precipitation. Figure 1 shows the 30-year average monthly precipitation for Okmulgee County, which is located in East Central Oklahoma. This bimodal pattern of rainfall is ideal to enhance late summer and fall bermudagrass forage growth.

The OSU Cattle and Forages Initiative Team and specialists at the Noble Foundation, have conducted research to investigate various management aspects of stockpiling and grazing bermudagrass pastures. In this bulletin, results from two series of experiments will be summarized. The first series of experiments were focused on the use of managed stockpiled bermudagrass forage in beef cow enterprises; the second series addressed the use of stockpiled bermudagrass forage in stocker cattle enterprises. Results of additional field trials conducted throughout Oklahoma will also be summarized.

Figure 1. Mean monthly precipitation for Okmulgee County, OK.

Series 1: Beef Cows

Pasture Preparation and Fertility

For this discussion, the concept of stockpiling does NOT include stockpiling forage before the month of August for winter grazing. When forage is stockpiled earlier in the spring or summer and grazing is delayed until the winter, forage quality is extremely low, resulting in poor animal performance or excessive feed costs. Therefore, pastures should be managed to remove (graze, clip, or hay) existing forage by mid to late August.

Depending on N available in the soil, producers commonly apply 50 to 100 pounds of actual N per acre during late August. Grazing should be deferred until sometime in October or early November. Grazing initiation will need to be flexible depending on timing of fall precipitation, fall temperatures and the first killing frost.

Forage Production

Early fall-forage accumulation has been variable, with an average of 2,750 pounds per acre (see Table 1). For example, forage production in 1999, was low with an average of just over 1,600 pounds. Low forage production was due to cool weather during September and lack of moisture during October. During the fall of 1998, forage production was 1,881 pounds in Stillwater when the first substantial rainfall was delayed until late September. Maximum forage production was 4,058 pounds at the Eastern Research Station in Haskell where greater rainfall was available in early September.

During the fall of 1998, Noble Foundation forage specialists recorded 4,261 pounds of forage accumulation at the Noble Foundation’s Red River Farm, south of Burneyville, OK. In this work, 60 pounds of N was applied in early August. During that year, 100 pounds of N was applied in the spring and, undoubtedly, some of this carried over to the fall due to low spring and summer forage production.

Nitrogen response is better on sites that have a history of nitrogen applications and good fertility management. Numerous research and demonstration projects have been conducted throughout Northeast Oklahoma. In this work, we have found that 50 to 100 pounds of fall nitrogen produces anywhere from 1,500 to 2,500 pounds of forage, depending on time of application, as well as timing and amount of precipitation. This work was conducted primarily on sites that had not historically been fertilized with nitrogen.

Figure 2. Effect of late summer N fertilization on fall forage accumulation.

Table 1. Forage production and harvest efficiency.

| Location | Year | N application rate, lbs/acre | Fall forage accumulation lbs/acre | Harvest efficiency, % |

|---|---|---|---|---|

| Haskell | 1997 | 50 | 3324 | 60.4 |

| Stillwater | 1997 | 50 | 2722 | 61.2 |

| Haskell | 1998 | 50 | 4058 | 62 |

| Stillwater | 1998 | 50 | 1881 | 64.8 |

| Burneyville | 1998 | 60 | 4261 | - |

| Haskell | 1999 | 50 | 1745 | - |

| Stillwater | 1999 | 50 | 1522 | - |

Grazing Management

It is recommended that access to forage be controlled with rotational or strip-grazing as much as possible. These grazing practices will reduce waste and further extend the grazing period. Greater grazing intensity, coupled with faster cattle movement, should result in improved harvest efficiency, although this issue has not yet been studied in the context of stockpiled bermudagrass forage. Forage allowance can be controlled with a “rotational” system, using permanent fence, or by utilizing temporary electrical fencing to “strip-graze” the pastures. In either case, a high stocking density should be used. Allowing access to the entire pasture will result in wasted forage. Continuous grazing will result in excellent cattle performance early, followed by weight loss by the end of the period. Cattle consume the high-quality leafy material at the top of the plant first, resulting in low-quality stems available at the end of the period.

Recommended harvest efficiency is around 60 percent, plus or minus 5 percent. For example if grazing is managed to utilize 60 percent of the 3,000 pounds of available forage, the cows would be allowed to harvest 1,800 pounds of forage per acre. Greater harvest efficiency should result in lower animal performance. On average, one acre should provide around 60 days of grazing for a moderately-sized cow.

If cool-season pasture is available for winter grazing, utilize stockpiled bermudagrass first, preferably by the end of December. If native pasture is available for winter grazing, plan on spending no more than 100 days utilizing the stockpiled bermudagrass, unless the winter is exceptionally mild. These rules of thumb should be adjusted based on location in the state, (shorter grazing window in the southeast due to greater precipitation and thus, forage deterioration).

For several years, Noble Foundation Specialists wintered cows with stockpiled bermudagrass through March at the Noble Foundation’s pasture demonstration farm. In this case, recognize that greater protein and energy supplementation may be required compared to shorter grazing programs.

Forage Quality and Supplementation

If the stockpiled forage is grown during late August, September, and October, forage quality; especially protein content, is usually adequate for gestating beef cows through November. Table 2 includes chemical composition of forage samples that were collected from grazing animals fitted with esophageal cannulas. This data suggests that fall fertilized bermudagrass may contain adequate protein through February to meet the needs of a gestating cow. It was apparent that during both of these studies, cool season annual grasses began to make up a small percentage of the grazed forage during the month of February. Consequently, some of the higher protein concentration represents the growth of those cool-season annual grasses.

In the grazing trials conducted at OSU, supplementation during November gave no advantage over non-supplemented animals (Table 3). After November, it appeared that there was little difference in animal performance when cows were supplemented with 2 pounds per day of 12.5, 25, or 37.5 percent protein feed. Based on this data, we suggest beginning supplementing two pounds of 14 percent to 25 percent protein feed in early December, and continuing through the program. The 25 percent protein feed is recommended if the stockpiling period begins earlier in August and/or during winters when forage rapidly deteriorates due to high precipitation. Feed can be delivered on a 3- or 4-days-per-week basis.

Table 2. Chemical composition of grazed forage samples at Stillwater, percent of dry mattera.

| Sample Date | Protein | ADIN | NDF | ADF | TDN |

|---|---|---|---|---|---|

| ‘97-98 | |||||

| Nov. | 13.1 | 1.4 | 56.4 | 30.3 | 54 |

| Dec. | 12.5 | 1.4 | 66.6 | 33.8 | 53.5 |

| Jan. | 10.9 | 2.3 | 68 | 38 | 48.9 |

| Feb. | 12.7 | 1.5 | 63.3 | 32.9 | 47.9 |

| ’98-99 | |||||

| Nov. | 15.2 | 1.8 | 60.6 | 30.5 | 48.4 |

| Dec. | 14.7 | 1.9 | 57 | 32.1 | 47.9 |

| Jan. | 11.6 | 1.8 | 64.6 | 38.9 | 43.3 |

| Feb. | 13.2 | 1.4 | 62 | 33.4 | 46.3 |

aADIN = acid detergent insoluble nitrogen, NDF = neutral detergent fiber, ADF = acid detergent fiber, TDN = total digestible nutrients.

Table 3. Cow weight change (pounds) by year and supplement type.a

| Supplement Treatment | ||||

|---|---|---|---|---|

| Year and Period | Control | 12.5% CP | 25% CP | 37.5% CP |

| ’97-98 | ||||

| Day 1-30 | 39 | 46 | 46 | 44 |

| Day 1-79 | -45 | 13 | 26 | 25 |

| ’98-99 | ||||

| Day 1-30 | 55 | 57 | 57 | 54 |

| Day 1-90 | 61 | 91 | 97 | 84 |

aPooled data from Stillwater and Haskell.

Economics

A logical and very important question is: “How does the stockpiling system compare to feeding hay or utilizing some other standing forage resource during the same period?” To address this question, during both years of the experiment described above, a group of 20 cows grazed stockpiled native tallgrass prairie (SNP) at a stocking rate of 1 cow to 3 acres. The native pastures had not been grazed through the spring or summer. Cows in this group were supplemented with 2 pounds per day of 38 percent protein feed, consisting primarily of cottonseed meal. Initial and final weights and condition scores were recorded for each group of cows for a total of 79 days in year 1 and 90 days in year 2. Averaged across both years, there was no difference in cow weight or condition score change during this period.

An economic analysis was conducted to compare costs for 5 different systems for a 100-day period:

- Stockpiled native pasture and 38 percent protein supplement (NP).

- Stockpiled native pasture providing 75 percent forage dry matter, 38 percent protein, and hay supplement providing 25 percent forage dry matter (75/25).

- Stockpiled native pasture providing 50 percent forage dry matter, 38 percent protein supplement, and hay providing 50 percent forage dry matter (50/50).

- Hay feeding alone (no supplement required).

- Stockpiled bermudagrass pasture and 25 percent protein supplement.

In each of these comparisons, it was assumed that cow weight and body condition change would not be significantly different. Additional assumptions and costs were as follows:

Bermudagrass pasture rental rate was $18 annually and rental costs were allocated to 120 days of summer grazing and 90 days of fall/winter grazing (Oct. 24 through Jan. 22). Fall forage accumulation was 2,755 pounds per acre, stocking rate was 1.42 acres per cow, and harvest efficiency was 60 percent. Fall nitrogen fertilizer application was 50 pounds per acre with a cost of $28.50 per acre. Total cost for the stockpiled bermudagrass pasture was $36.21 per acre for the 90-day period. Medium protein range cubes (25 percent crude protein) were priced at $270 per ton and fed for the last 70 days of the 90-day period.

Native pasture rent was $13 per acre with an annual stocking rate of 10 acres per cow. High protein range cubes were priced at $350 per ton and were fed the duration of the 90-day period. Harvest efficiency of the native pasture was assumed to be 30 percent and initial availability of native forage was assumed to be 3,250 lb per acre.

Grass hay used in the comparisons contained 9 percent protein and 54 percent TDN, and would be adequate to meet a gestating cow’s protein and energy needs when fed alone. Hay feeding waste was calculated as 15 percent above total pounds of hay fed. Hay was priced at $60 per ton.

When hay replaced native pasture forage intake, the amount of supplement fed was prorated accordingly. For example, when hay was “supplemented” at 25 percent total forage intake, total pounds of protein supplement was also reduced by 25 percent. In the native pasture and hay feeding scenario, hay replaced 50 percent native pasture forage intake and 50 percent of the protein supplement.

Costs were also calculated assuming that some producers might want to consider utilizing all of the stockpiled bermudagrass pasture in a shorter time period using a heavier stocking rate. For this scenario, a 60-day grazing period was used with a stocking rate of .94 acres per cow and 2 pounds of 25 percent protein feed during the last 50 days. Total period and daily cost comparisons are given in Table 4.

Obviously, costs of each of these systems will be sensitive to forage availability at the beginning of the fall/winter grazing period, pasture rental cost, feed prices, fertilizer, hay price, and quality, as well as various other factors. It is interesting to note that the native pasture with supplement and no hay fed is still the lowest cost wintering system for the 100-day period. However, given the values used in this example, it does appear that grazing fertilized, stockpiled bermudagrass is a viable and economical alternative to feeding hay. Said another way, grazing stockpiled, fertilized bermudagrass pasture can reduce the length of the expensive hay feeding season and thereby, reduce costs of wintering beef cows.

Table 4. Estimated cost of different feeding systems.

| System | Cost per day | Total cost |

|---|---|---|

| 90 daysa | ||

| Native pasture and 38% protein supplement | 0.58 | 52.3 |

| Native pasture, 38% protein and hay supplement (75/25) | 0.66 | 59.41 |

| Native pasture, 38% protein supplement and hay feeding (50/50) | 0.74 | 66.52 |

| Hay feeding alone | 0.93 | 80.73 |

| Stockpiled bermudagrass and 25% protein supplement | 0.78 | 70.17 |

| 60 days | ||

| Short term grazing of stockpiled | ||

| Short term grazing of stockpiled bermudagrass (60 days) | 0.77 | 46.06 |

aOctober 24 through January 22.

Series 2: Stocker Cattle

Many producers wean calves or purchase weaned calves during the fall months of the year. Stockpiled, fertilized bermudagrass pasture could provide an alternative grazing system or growing program for beef calves. Therefore, this experiment was conducted to determine a) if producers could expect performance of growing cattle to be different when allowed to graze stockpiled bermudagrass pasture, as compared to being fed hay during the same period, and 2) to determine if supplementation of growing cattle receiving either type of forage is necessary and (or) economical.

Methods

This experiment was conducted over a three year period at the Noble Foundation’s Pasture Demonstration Farm, located west of Ardmore, OK. Approximately 200 steers were purchased during August each year. Processing upon arrival included mass medication, individual identification, weighing, castration, dehorning, branding, deworming, vaccination for clostridial and bovine respiratory diseases, and implanting. The cattle were fed hay and 2 pounds per head per day of a 14 percent CP supplement during the 30-day receiving period.

Steers were randomly allotted to twelve experimental groups (four treatment groups with three replications each). Treatments included the main effects of supplement and forage source. Levels of supplement included no supplement (NS) or 4 lb per day of a commercial pelleted feed (14 percent CP) (SUP). Forage sources included bermudagrass hay (HAY) or fall fertilized bermudagrass pasture (PAS). Treatments were initiated on September 16, September 17, and September 19 and terminated on December 2, December 15, and December 2 in 2002, 2003, and 2004, resulting in experimental periods of 77, 89, and 74 days, respectively.

Pastures were grazed during May, June, July, and August each year to insure a maximum of approximately 3,000 lb per acre of residual forage was available at the time of late-summer fertilization. During mid-August each year, pastures were fertilized with 50 lb of actual N per acre.

Six groups of HAY-fed cattle were randomly assigned to six drylot pens with three receiving SUP and three receiving NS. Hay was sampled prior to feeding and samples were composited before being submitted to a commercial laboratory for determination of crude protein (CP) and acid detergent fiber (ADF) concentrations. Acid detergent fiber concentration has been shown to be negatively correlated to digestibility of forage in ruminant animals.

The PAS groups were turned out to graze in six pastures with three receiving NS and three receiving SUP. The PAS groups were rotated through the six pastures on a weekly basis to minimize the possibility of pasture effects on performance. Clip samples were collected weekly to determine forage availability and subsamples of the clipped forage were dried, ground and submitted to the commercial laboratory for chemical analysis. Average forage availability and chemical composition within each month are presented.

Results and Discussion

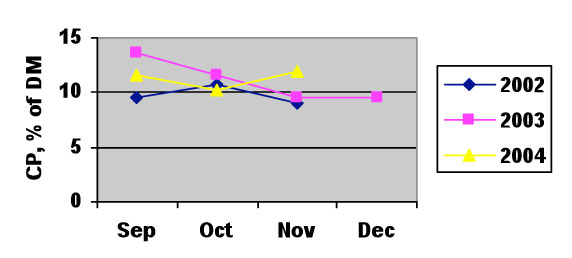

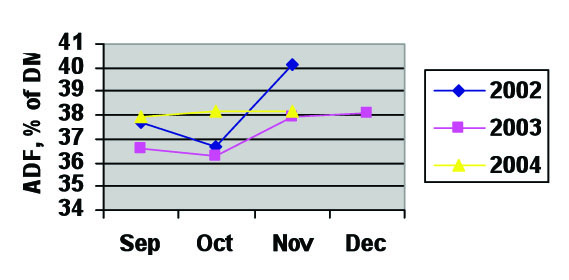

Average CP and ADF concentration of hay fed is shown in Table 5 and fertilized, stockpiled bermudagrass forage CP and ADF concentrations are shown in Figures 3 and 4, respectively. Hay nutritive value was similar during each year of the experiment and did not differ substantially from the CP concentration of the grazed forage. Protein concentration of the stockpiled forage, averaged within one month, ranged from 13.6 to 9 percent. A 500- to 600-pound steer gaining 2 pounds per day has a dietary CP requirement of 12 to 13 percent. Consequently, at times, the stockpiled, fertilized forage would have had adequate protein to meet the dietary requirement, while weight gain would have been limited by forage protein concentration at other times. In general, ADF concentration in the stockpiled forage increased over time, suggesting that forage digestibility would have limited steers’ growth rate to a greater extent later in the experiment.

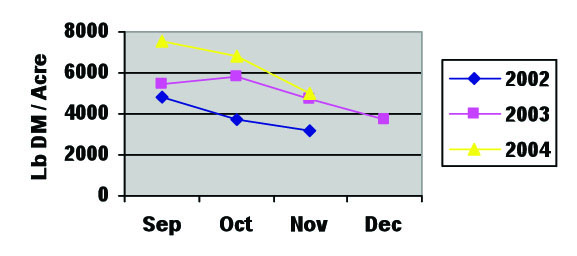

Average initial forage availability was greater than that of the experiments presented in the previous section and was quite variable, ranging from 7,555 to 4,850 pounds per acre (Figure 5). There could be several reasons for higher forage availability in these experiments, although the most likely difference is that less of the summer-grown forage was removed by grazing before late-summer fertilization.

Forage availability declined over time, as would be expected (Figure 5).

Table 6 shows the effects of fall backgrounding forage source and supplementation on the performance of stocker steers. There was no forage source by supplement treatment interaction. In other words, steers responded the same to supplementation, regardless of the type of forage they were grazing. During the initial 28-day period, the PAS steers gained at a faster rate compared to the HAY steers. However, performance during the subsequent periods was similar between the two forage sources. As a result, final weight and cumulative ADG was similar among the two forage sources.

Steers receiving SUP outperformed NS steers during each weigh period. In fact, both forage sources provided only a maintenance level of nutrient intake in the absence of supplement during the latter two weigh periods. Supplement efficiency (pound of supplement per pound of additional weight gain) was 5.4. Consequently, if value of additional weight gain was $.60, $.80, or $1.00 per pound, the breakeven value of the supplement would be $222.40, $296.29, and $370.37, respectively. When cost of similar feed supplements is less expensive than these values, the supplementation program would be profitable. However, additional research is necessary to determine whether additional weight gain due to supplementation during the backgrounding period is lost during the winter grazing period.

In conclusion, with the possible exception of extreme environmental conditions, producers should expect similar performance of growing cattle grazing fertilized, stockpiled bermudagrass pasture compared to cattle consuming bermudagrass hay. Therefore, fertilizer, labor, and hay purchase price or hay harvesting costs are the primary considerations when evaluating this management option. As shown in the first series of experiments, the cost of fertilized, stockpiled bermudagrass forage should be less than that of harvested forage in most years. However, this will not always be the case as forage production (and therefore cost per unit of forage produced) is highly variable and highly dependent on late-summer and fall precipitation.

Table 5. Average crude protein and acid detergent fiber concentration of bermudagrass hay by year, DM basis.

| Year | Crude Protein, % | ADF, % |

|---|---|---|

| 2002 | 11.5 | 39.2 |

| 2003 | 12.3 | 39.8 |

| 2004 | 11.9 | 38.6 |

Figure 3. Stockpiled bermudagrass protein concentration.

Figure 4. Stockpiled bermudagrass ADF concentration.

Figure 5. Stockpiled bermudagrass forage availability, lb/acre.

Table 6. Effects of fall backgrounding forage source and supplementation on performance of stocker steers during backgrounding and wheat pasture grazing.

| Item | Stockpiled Bermudagrass | Hay | Not Supplemented | Supplemented | SE |

|---|---|---|---|---|---|

| No. of steers | 310 | 309 | 309 | 310 | |

| No. of pasture groups (3 yr) | 18 | 18 | 18 | 18 | |

| Weight, lb | |||||

| Mid-Sep | 468 | 462 | 466 | 464 | 3 |

| Mid-Oct | 521a | 506b | 507a | 520b | 3 |

| Mid-Nov | 544 | 528 | 516a | 555b | 7 |

| Dec | 554 | 543 | 520a | 577b | 7 |

| ADG, lb | |||||

| Pd1 | 1.8a | 1.51b | 1.4a | 1.9b | 0.1 |

| Pd2 | 0.76 | 0.69 | .30a | 1.12b | 0.19 |

| Pd3 | 0.34 | 0.71 | .15a | .90b | 0.2 |

| Cumulative | 1.05 | 1.01 | .66a | 1.40b | 0.07 |

a,b Means within a treatment with uncommon superscripts are different (P<.05).

David Lalman

Extension Beef Cattle Specialist, Animal Science

Bob Woods

Former NE District Area Agronomist

Kent Barnes

Former NE District Area Livestock Specialist

Daren Redfearn

Former Extension Forage and Pasture Management Specialist, Plant and Soil Sciences

Chuck Coffey

Noble Foundation Senior Pasture and Range Consultant