How Storage Time and Harvest Season Impact the Success of Planting Bermudagrass and Zoysiagrass Sod

Introduction

Turfgrass sodding provides a fast and efficient method for establishing turfgrass in residential, commercial, recreational and golf course settings. However, the success of sodding is highly influenced by post-harvest sod handling practices, storage duration and storage conditions. Extended storage duration, especially in warmer months, can compromise sod quality and reduce transplant success. After sod harvest and stacking, limited air circulation and light initiate internal respiration, generating and building up heat inside the sod pile. Additionally, microbial activity also speeds up the breakdown of organic material, causing more heat to build up and further contributing to sod deterioration. The longer the sod is stored, the worse the problem gets, with extreme heat forming in the center and the edges drying out, ultimately lowering its quality.

While installing sod immediately after harvest gives the best results, it’s often not possible due to transportation delays and retail distribution. That’s why it’s important to understand how storage time affects sod quality, including its appearance and ability to establish after planting. This study examined how storage duration and harvest season impacted the sodding success of Tahoma 31® hybrid bermudagrass (Cynodon dactylon x C. transvaalensis) and ‘Meyer’ zoysiagrass (Zoysia japonica). It explored how these grasses responded to varying storage times and temperatures, providing valuable insights for sod producers, installers and end users to enhance storage practices and improve transplant success.

Materials and Methods

This study tested hybrid bermudagrass harvested as big sod rolls and zoysiagrass harvested as slabs. Sod was harvested in early June and late July 2023 and subject to storage durations of 0, 24, 48, 72, and 96 hours in shaded areas before planting at the Cimarron Valley Research Station in Perkins, Oklahoma. After planting the sod, we watered the plots thoroughly a couple of times per day, as needed, to prevent drought stress and support root growth. Internal temperature was measured by placing the thermistor between the soil of one sod pad and the grass canopy of another. We also monitored sod handling quality and green cover to assess recovery and establishment after sodding.

Findings

Internal Temperatures

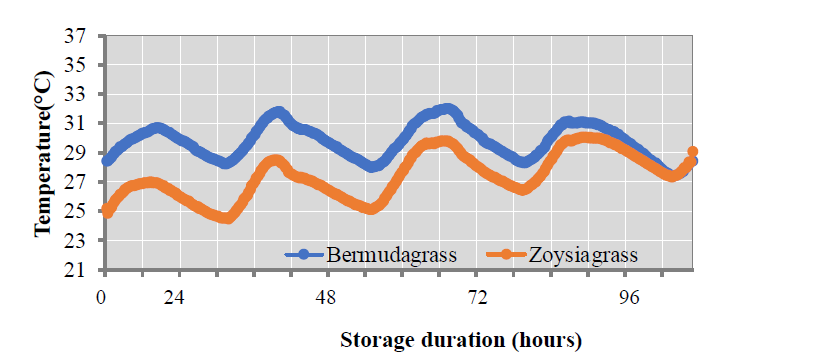

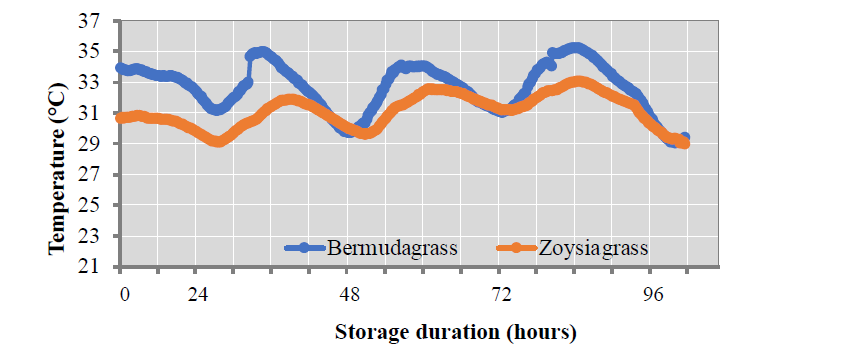

Although the internal temperature of zoysiagrass pallets increased with longer storage times, bermudagrass sod rolls consistently exhibited higher internal temperatures than zoysiagrass throughout the study (Figures 1 and 2). Additionally, sod harvested during the hotter conditions in July showed higher internal temperatures upon receiving the pallet (Figure 2). This is likely due to the warmer soil temperatures at the time of harvest.

Figure 1. Internal temperatures of bermudagrass sod rolls and zoysiagrass sod pallets harvested in early June 2023.

Figure 2. Internal temperatures of bermudagrass sod rolls and zoysiagrass sod pallets harvested in late July 2023.

Handling Quality

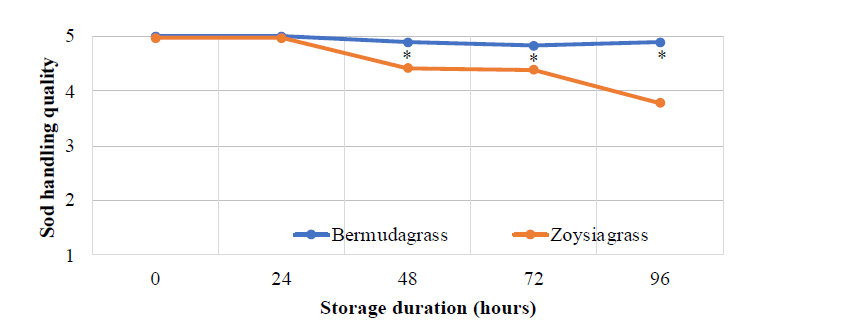

Sod handling quality at installation was rated on a scale from 1 to 5, with 1 meaning poor quality where the sod completely fell apart during handling, and 5 meaning excellent quality with no cracking and well-formed rolls or pads. In both months, bermudagrass sod showed little change in handling quality with longer storage, while zoysiagrass sod slabs became a little harder to handle as storage time increased (Figure 3).

Figure 3. Sod handling quality as a function of sod storage time on the pallet. Quality was measured at the time of sod installation. A quality rating of 1 = poor quality, complete breakage during handling; whereas 5 = excellent, very tight, no cracking during handling. Asterisk (*) indicates statistically significant differences between the two species at the 95% certainty level.

Post-Installation Recovery

Prolonged sod storage times generally reduced live green coverage following installation, especially in bermudagrass. After 96 hours of storage in both months, bermudagrass had complete leaf and shoot discoloration (Figure 4.1 and 5.1). However, with proper irrigation and care, bermudagrass sod resumed growth within two weeks of installation, even after 96 hours of storage (Figures 4.2 and 5.2). In contrast, zoysiagrass was less affected by prolonged storage, showing minimal changes in leaf and shoot color (i.e. green coverage) (Figure 4.1) and achieving full recovery within one week (Figure 4.2).

Figure 4.1. Sod appearance across different storage durations from harvest to planting, arranged from left to right: 0 hours (A), 24 hours (B), 48 hours (C), 72 hours (D) and 96 hours (E). Within each image, Tahoma 31® bermudagrass (larger sod rolls) is shown on the left, while Meyer zoysiagrass (smaller sod slabs) is on the right. The photo was taken on June 9, 2023, immediately after the 96-hour stored sod was installed.

Figure 4.2. Sod appearance across different storage durations from harvest to planting, arranged from left to right: 0 hours (A), 24 hours (B), 48 hours (C), 72 hours (D) and 96 hours (E). Within each image, Tahoma 31® bermudagrass (larger sod rolls) is shown on the left, while Meyer zoysiagrass (smaller sod slabs) is on the right. The photo was taken one week after planting the 96-hour stored sod.

Figure 5.1. Close-up images of Tahoma 31® bermudagrass sod (outlined in black) following 96 hours of storage. The photo highlights leaf and shoot discoloration following extended storage.

Figure 5.2. Close-up images of Tahoma 31® bermudagrass sod (outlined in black) following 96 hours of storage. The photo highlights the sod’s remarkable recovery just one week after installation, showcasing its resilience and rapid regrowth.

Discussion

This study showed that storage time greatly affects sod quality. Bermudagrass, harvested in rolls, was more sensitive to long storage because of higher internal heat buildup. However, it showed strong recovery, fully bouncing back even after 96 hours of storage during peak summer heat. On the other hand, zoysiagrass, harvested in slabs, had less heat buildup and only slight canopy discoloration, though its handling quality decreased a bit. This suggests zoysiagrass may be a better option for longer storage or delayed installation. However, differences in harvest methods - whether sod is cut in rolls or slabs - and the thickness of each type can also impact how well the sod performs under these conditions.

General Practical Recommendations for Sod Producers and Consumers

- Reduce Internal Heating and Desiccation: Store sod pallets in shaded or covered areas, and lightly moisten the outer surfaces to reduce desiccation.

- Adjust for Seasonal Variations: Exercise extra caution during hotter months to minimize the risk of internal heating. Harvest sod in the early morning when temperatures are cooler, and ensure it is transported promptly to reduce quality degradation.

- Ensure Prompt Irrigation: Thoroughly water the sod immediately after installation and continue regular irrigation until rooting is established. This promotes rapid recovery and successful establishment.

- Use of Refrigerated Transportation When Feasible: Although not a part of this trial, many sod producers/shippers offer the use of refrigeration during shipping of sod product to reduce post-harvest decline in turfgrass quality.

- Minimize Storage Time on Pallet: Effective planning and communication regarding delivery scheduling, installation timing and ensuring adequate equipment and staffing are crucial to minimize the time sod spends on the pallet before being installed at the end-use site.

Conclusion

This report highlights the strong recovery potential of both bermudagrass and zoysiagrass after up to 96 hours of storage, as long as they receive proper post-installation care, especially timely irrigation to support rooting before full establishment. Zoysiagrass slabs handled extended storage better, showing little impact on appearance, though their handling quality decreased over time. In contrast, bermudagrass sod suffered more leaf and shoot discoloration with longer storage but recovered fully without complications. Using effective post-harvest practices, like optimizing storage conditions and ensuring proper irrigation after installation, can greatly improve transplant success, even when sod is stored for extended periods.

Acknowledgments

This study was funded by the Specialty Crop Block Grant from the Oklahoma Department of Agriculture and Forestry (USDA AMS award number: 21SCBPOK1005) and Southern Extension Risk Management Education Center (USDA award number: 2024-70027-40446). Special thanks to Tulsa Grass & Sod Farms Inc and Riverview Sod Ranch for their generous donation of sod materials.