Grain Drill Fertilizer Calibration

- Jump To:

- Introduction

- Grain Drill Calibration

Introduction

While urea is a safe and easily handled form of nitrogen, it does present challenges when surface applied without incorporation through tillage, rainfall or irrigation. Urea is converted to ammonia (NH3) by the enzyme urease. The NH3 is immediately converted to ammonium (NH4) in the presence of water and the NH4 will bind with soil particles as soon as it is formed. However, if this process occurs outside the soil system, such as on residue, when the environment dries the NH4 will be driven back to NH3, which will be gassed off and lost to the atmosphere. This loss can even occur on bare soil if the prill is not fully melted and solubilized urea is moved into the soil.

One way to minimize losses of nitrogen is via drilling fertilizer into the soil, therefore

preventing any volatization to occur. This report aims to provide producers with two

methods that can be used to either estimate or accurately calibrate application rate

when applying topdress nitrogen fertilizer using seed boxes of a grain drill.

An important consideration when using a grain drill to deliver fertilizer: Most fertilizers

are corrosive and some fertilizers, such urea, will attract moisture. Therefore, it

is not advisable to leave the fertilizer in the drill for extended periods of time,

and it is a best practice to thoroughly clean the drill, box, tubes and disks.

The estimation method was developed for five different grain drills, chosen based

on their popularity with producers and availability to researchers (Table 1). Drills

were calibrated for two fertilizers: urea (46-0-0) and diammonium phosphate (DAP;

18-46-0), due to their common usage in Oklahoma. The estimation method, as the name

implies, is the approximation of actual fertilizer delivery and should only be used

as a guide. Just like seed, differences in fertilizer density, prill size and uniformity

can greatly impact the actual amount of fertilizer delivered as compared to the estimated

amount stated on a calibration chart. Calibration of the specific drill that will

be used as described in the next section is the most accurate and reliable method.

The grain drill can be set up to apply in furrow top-dress fertilizer in one of two

ways. For quick results, producers can use the percentage chart in Table 2.

Table 1. Make, model, width and row spacing of the grain drills used in the study.

| Grain Drill | Width (ft) Row | Spacing (in) |

|---|---|---|

| Landoll 5211 | 10 | 7.5 |

| Great Plains 1006 NT | 10 | 7.5 |

| John Deere 450 | 8 | 6 |

| International 5100 | 15 | 7 |

| John Deere 1560 | 10 | 7.5 |

Using Table 2

- Find the desired amount of fertilizer output in column 1.

- Find the name of the grain drill to be used.

- Set up the grain drill to deliver the pounds per wheat ac-1 that corresponds to the drill and desired fertilizer rate.

For example, for a targeted rate of 60 pounds per acre urea, using a Landoll 5211, the drill should be set to deliver 79 pounds per acre of wheat.

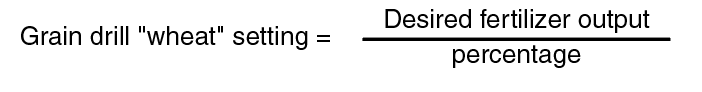

If the grain drill is not available in the chart, one of the following options can be used.

- Use the calibration method described in the next section

- Use the average column to set up your grain drill

- Use formula:

For example, for a targeted rate of 150 pounds per acre of urea, divide 150 by 0.73, to yield 205 pounds per acre of wheat. This can be thought of as the amount of urea to be applied is 73 percent of the amount of wheat at that same setting.

Grain Drill Calibration

For the most accurate results on individual grain drills, calibration can be done using the following steps:

- Setting up the drill for calibration

- Inside of the wheat grain bin, clean out all grain cups; make sure that no grain has been left behind. Not all grains cups have to be used, but it is recommended that a minimum of three cups are evaluated. If only a few of the cups are caught, then the width of the drill should be adjusted to effective width of cups measured.

- Remove the tube down to the grain drill coulters and set a small container underneath the opening (a small wallpaper tray works well for this if only catching a few cups)

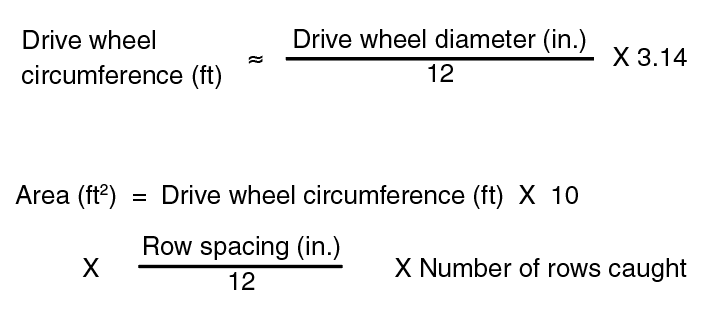

- Determine the drive wheel circumference by using a flexible tape or by calculation

from the wheel diameter (inches). Calculate the circumference of the wheel and the

area covered by the grain drill in 10 revolutions using the following formulas:

- Calibration

- Lift driving wheel off the ground.

- To begin calibration, start with a wheat setting (pounds). Drill settings can be chosen based on the wheat chart inside the grain bin of each drill.

- Pour 1 to 2 pounds of fertilizer into the empty grain cups. Rotate the tire the once (one revolution) to prime the drill. Then, rotate the tire again 10 times (10 revolutions) and collect all fertilizer that comes out underneath the dispensing orifice of the drill. Duct tape or chalk works well to label starting point on the tire.

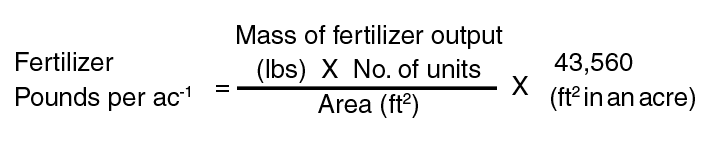

- Weigh collected fertilizer.

- Repeat steps 2b to 2d at least three times, to get a representative amount of fertilizer dispensed. Make sure to dump all fertilizer out of the container each time.

- Use the formula below to calculate output of fertilizer per acre:

- To be as accurate as possible, this should be done at multiple settings to develop the expected range from fertilizer application rates. As seen in Table 2, the higher the rate, the closer the fertilizer rate is to the seeding rate.

- Consider writing actual calibration settings in the lid of the drill with a marker. This will allow you to quickly approximate settings in the future.

Table 2. Targeted fertilizer rates to grain drill wheat settings.

| Desired Fertilizer Output | Landoll 5211 | Great Plains 1006NT | International 1500 | John Deere 450 |

|---|---|---|---|---|

| Lbs DAP ac-1 | Lbs Wheat ac-1 | |||

| 30 | 28 | 27 | 56 | 27 |

| 60 | 63 | 58 | 85 | 67 |

| 90 | 97 | 89 | 114 | 106 |

| 120 | 132 | 121 | 144 | 145 |

| 150 | 167 | 152 | 173 | 184 |

| 180 | 201 | 183 | 202 | 223 |

| Urea 46-0-0 | Lbs Wheat ac-1 | |||

| 30 | 40 | 37 | 60 | 44 |

| 60 | 79 | 74 | 94 | 86 |

| 90 | 119 | 112 | 129 | 128 |

| 120 | 159 | 149 | 164 | 169 |

| 150 | 198 | 186 | 198 | 211 |

| 180 | 238 | 224 | 233 | 253 |

| Desired Fertilizer Output | John Deere 1560 | Average* | Percent Wheat§ |

|---|---|---|---|

| Lbs DAP ac-1 | |||

| 30 | 38 | 35 | 85 |

| 60 | 73 | 69 | 87 |

| 90 | 108 | 103 | 87 |

| 120 | 143 | 137 | 88 |

| 150 | 178 | 171 | 88 |

| 180 | 213 | 204 | 88 |

| Urea 46-0-0 | |||

| 30 | 46 | 45 | 66 |

| 60 | 92 | 85 | 70 |

| 90 | 139 | 125 | 72 |

| 120 | 185 | 165 | 73 |

| 150 | 232 | 205 | 73 |

| 180 | 278 | 245 | 74 |

* The average column shows the average wheat setting to dispense targeted fertilizer

output.

§ The % wheat column shows the ratio of fertilizer output to the wheat grain drill

setting (by weight).

Applying dry fertilizer with a grain drill can help producers place nutrients below the soil surface without purchasing specialized equipment and improve fertilizer use efficiency while keeping application costs low. Each grain drill is different, and variation should be expected, even between the same brand and model. This report is intended to be used as a general guide, and is not a replacement for calibration of the specific drill that will be used.

Vaughn Reed

Graduate Research Assistant

Bryan Rutter

Graduate Research Assistant

Joy Abit

Post-Doctoral Fellow

Reece Harvey

Undergraduate Assistant

Raedan Sharry

Undergraduate Assistant

Dr. Brian Arnall

Precision Nutrient Management Specialist