Grain Bin Entrapment: Don’t Let It Happen To You!

How It Happens

People may be trapped or caught in grain in a matter of seconds. There are three ways this can happen: entrapment in flowing grain, collapse of a grain bridge and collapse of a vertical wall of grain. All three involve moving or flowing grain. Anyone working in the grain industry must know how these incidents happen and be prepared to prevent or respond to the situation. Keeping grain in good condition also plays a significant role in preventing these catastrophic incidents. When grain flows freely through unloading systems, workers have little need to enter bins.

EXTRA PRECAUTION: Never allow children to play in or around grain bins or gravity wagons!

Entrapment in Flowing Grain

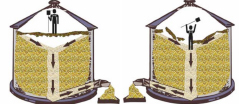

During unloading, the grain in a bin flows downward from the top center of the bin, creating a “funnel” effect that draws material and objects down to the conveyor at the bottom of the bin (Figure 1). An unloading auger at the bottom of the bin transports the grain outside. It only takes two to three seconds to become helpless in flowing grain. With the trend toward moving grain faster, entrapment happens much faster than a victim can react. Flowing grain acts like quick sand and can pull a worker under, causing suffocation. This can also happen inside a gravity wagon.

Figure 1. Entrapment can occur quickly while an unloading auger draws grain from the center of the bin, forming a surface cone as the bin is emptied.

Prevention

- Warn family, employees and visitors of dangers in flowing grain.

- Place warning decals on all bin entrances and gravity wagons.

- Turn off and lock out power controls to unloading conveyors before entering a bin, using “lock out/tag out” procedures.

- Always use a safety harness, safety line and at least two observers during bin entry.

- Tie a permanent lifeline in the bin for a person trapped in grain flow to grab (i.e., a rope hanging down from the center with knots tied every few feet).

- Secure grain storage areas to prevent unauthorized entry.

Collapse of a Grain Bridge

A grain bridge can form when grain on the surface is moldy or frozen together to form a hard, thick crust. When grain is unloaded from a bin with a surface crust, a hollow cavity forms underneath the grain bridge (Figure 2). If an individual enters the bin and attempts to walk on the crusted surface, the additional weight will cause the crust to collapse and the individual could be partially or completely submerged instantly. The shifting grain can move the victim four to five feet from the point of entry where the victim was last seen, making it difficult to determine exactly where the victim is located.

Figure 2. Grain can form a hard crust, which appears to be firm enough to walk on. However, the crust can break and instantly bury an individual in the hollow cavity that formed underneath the bridge.

Prevention

- To detect whether a grain bridge exists, always look for an inverted cone after unloading grain from a bin. The newly exposed grain surface should look shiny. If it does not, a bridge may have formed.

- Use a pole or other object to free the bridge. Do this from the bin roof hatch or from the inside ladder while tied to the ladder securely. Do not stand on the grain surface.

- Carry a long pole when entering bins to probe grain for cavities and stabilize the worker in case of grain flow.

- Manage grain to avoid conditions that cause spoilage and bridging.

Avalanche of a Vertical Grain Wall

Grain in bad condition can cake in large vertical columns against the bin wall. Workers may try to dislodge the grain by poking it with a stick or shovel (Figure 3). This can cause the grain wall to break free, resulting in an avalanche that can completely bury workers inside the bin. Vibration from trucks outside the bin, running machinery or passing trains can cause the grain wall to release as well.

Figure 3. If broken up from below, a steep wall of grain can break free, causing an avalanche that could bury workers inside the bin.

Prevention

- Use a body harness and safety rope that is securely tied off (Figure 4).

- Work from top to bottom of a vertical grain wall, staying above the highest part of the wall.

- Be prepared for the entire grain wall to break free and fall at any time.

- Manage grain to avoid conditions that cause spoilage and formation of vertical grain walls.

Grain Bin Rescue Procedures

For the farmer or workers present at the time of the entrapment or discovery of the entrapment:

- Be sure the auger or unloading equipment is shut off and locked out.

- Contact an emergency rescue team or fire department.

- Ventilate the bin with an aeration system, if one is present. Do not activate a heat source (in the case of dryers or heated air).

For the emergency responders and rescuers:

- Protect rescuers.

- Check to be sure the auger or unloading equipment is locked out.

- Attach safety lines to rescuers (Figure 4).

- Check air quality before entering the bin.

- Use respiratory protection as required; i.e., dust filter masks, filter respirators or SCBA.

- Avoid putting additional pressure on the victim.

- Stay away from the area immediately around the victim.

- Use a ladder, plywood, soft drink crates or other material to distribute weight.

- Keep unnecessary personnel out of the grain bin.

- Do NOT try to pull the victim out! Forces required to pull an entrapped victim can cause serious damage to the body or, in some cases, death.

- Construct a retaining wall if the surrounding grain slope is above victim’s head.

- Use plywood, sheet metal, large trash cans with the bottoms removed or heavy cardboard cylinders to keep grain from the victim’s chest area or higher. Some emergency responders may have rescue tubes designed specifically for grain entrapment rescue.

- Build a self-supporting box or brace walls to prevent collapse.

- A series of retaining walls may be needed.

- Remove grain from around the victim.

- Attach a harness to the victim to prevent further submersion in the grain, but don’t try to pull the victim with a line and harness before removing the grain (hoist or block and tackle removal can cause serious injury).

- Use a vacuum conveyor or scoop to remove grain from around victim.

- Be careful when parts of the victim are not visible to avoid further injury.

- Cut a hole in the bin and drain.

- Do this immediately if the victim is completely submersed.

- Cut at least two holes on opposite sides; three to four holes symmetrically spaced are recommended. More holes can be cut for large bins.

- Use a U-shaped or V-shaped cut.

- Make a cut about 30 to 40 inches across between the bolt lines of a single sheet (do not cut across vertical or horizontal bin sheet joints).

- Locate holes just below the feet of a partially submerged victim or as low as possible if victim is not visible.

- An air chisel, power saw, tractor loader or cutting torch can be used.

- Drain the grain uniformly from two, three or four holes around the bin. Provide room for grain to drain outside of the bin and arrange for equipment to remove the grain from the area around the bin. An area of about four times the height of the grain column should be allowed for the drainage of the grain on the ground. Spectators and workers should be kept away from this area.

- Provide care for the victim.

- Assist the victim’s breathing by using oxygen or SCBA.

- Maintain body temperature with saline plasma I.V. or other means.

- Communicate with the patient about his/her condition and the rescue activities taking place.

- Plan ahead for removal of the patient from the bin.

- Be patient and don’t give up (victims have survived complete burial in grain for two or more hours). Sometimes victims can still breathe while buried.

References

J. Allen and R. Noyes (1994). CR-1726, Grain Bin Entrapment: What If It Happens To You? Oklahoma Cooperative Extension Service, Oklahoma State University.

C.V. Schwab, I.J. Ross, L.R. Piercy, B.A. McKenzie (1985). Vertical Pull and Immersion

Velocity of Mannequins Trapped in Enveloping Grain Flow. Transactions of the ASAE

Vol. 28(6).

Grain Handling Safety Coalition: www.grainsafety.org.

Carol L Jones, PhD, PE

Stored Product Engineer