Food Emulsifiers

The terms emulsifier, emulsifying agent, surfactant, and surface-active agent are synonymous and used interchangeably. They are chemical compounds that promote formation and/or stabilization of emulsions by their effect on interfacial tension. Food emulsions are produced from two immiscible liquids, usually oil and water, in the presence of anemulsifier and by applying an emulsification method, usually vigorous mixing and homogenization. Emulsifiers adsorbed on the oil-water interfaces decrease the interfacial tension between two immiscible phases, prevent droplet formation and aggregation creating one smooth phase. They enhance emulsion stability by generating strong repulsive interactions and facilitating dispersion of immiscible particles into another.

The food industry uses emulsifiers in food formulations for several reasons: a) counteract

variations in raw materials, b) ensure consistent quality, c) produce alternative

products, d) preserve freshness and organoleptic properties and, e) facilitate processing.

For example, sodium stearoyl lactylate is used as an emulsifier in bread because it

forms a complex with starch, preventing retrogradation (staling) of bread. Addition

of lecithin to chocolate reduces its viscosity. Separation of peanut oil from peanut

butter may be averted by addition of a small amount of monoglycerides.

Types of Emulsions

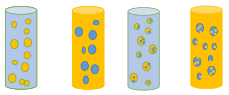

Emulsions can be classified based on the relative distribution of the immiscible phases, i.e., oil (lipophilic phase) and water (hydrophilic phase), and arrangement of the emulsified components (Figure 1). Oil-in-water (O/W) and water-in-oil (W/O) are simple emulsions. Double emulsions are oil-in water-in-oil (O/W/O), and water-in-oil-in-water (W/O/W). Milk, sauces, beverages, yogurts, ice-creams, and mayonnaise are a few examples of O/W emulsions. Butter and margarineare W/O emulsions. W/O/W emulsion systems are frequently used to produce reduced-fat products. Water soluble flavors and bioactive ingredients can be encapsulated using W/O/Wemulsion systems to control their release as needed.

Hydrophilic-lipophilicbalance(HLB), which is the balance of the size and strength

of the hydrophilic (water loving) and lipophilic (lipid loving) moieties of an emulsifier,

is commonly used for selection of a suitable emulsifier for a given application. The

HLB scale ranges from 0 to 20. Emulsifiers having HLB values between 3.5-6.0 (i.e.,

glycerol esters, propylene glycol fatty acid esters, polyglycerol esters, and sorbitol

fatty acid esters) are more suitable for use in W/O emulsions whileemulsifiers with

HLB values in the 8 to 18 range (proteins, phospholipids, potassium and sodium salts,

and alginates) are most commonly used in O/W emulsions.

Pickering emulsions are stabilized by solid colloidal particles. These solid particles (i.e., starch, protein, chitin, sugar particles and cocoa powder) are partly wetted by oil and water and act as emulsifiers. Pickering emulsions are highly resistant to coalescence due to the tight attachment of the particles to the surface of the droplets. One example of a Pickering-stabilized emulsion is homogenized milk in which the milk protein casein is adsorbed on the surface of the milk fat globules and act as surfactants.

Types of Emulsifiers

Food emulsifiers are regulated as food additives in most countries. US Food and Drug Administration (Federal Register 2013) regulates the composition of foods (Title 21 of the Code of Federal Regulations). The sections 182 and 184 list“Generally Recognized as Safe (GRAS)” and the additives “Affirmed as GRAS”, respectively. Diacetyltartaric ester of monoglycerides (DATEM), lecithin, mono-and diglycerides, monosodium phosphate derivatives of mono and diglycerides are GRAS emulsifiers widely used in food preparations.These substances have long histories of use and clean safety records.

Conventional food emulsifiers are categorized in two groups: a) Low Molecular Weight

Emulsifiers (i.e., monoacylglycerols and polysorbates) and b) amphiphilic [a molecule

having both hydrophobic (fat loving-nonpolar) and hydrophilic (water-loving-polar)

regions] biopolymers (i.e., dairy proteins caseins and β-lactoglobulin).

Synthetic emulsifiers such as Tweens and Spans form very stable emulsions. Yet, increasing consumer demand for healthy, sustainable, and natural products is forcing the food industry to use natural emulsifiers to replace synthetic ones.Proteins, polysaccharides, phospholipids and saponins from natural sources have good emulsifying properties in food formulations.

Figure 1: Classification of emulsions.

Phospholipids obtained from milk, vegetable oils (such as soybean, rapeseed or sunflower), egg yolk, meat and fish are the most common emulsifiers used in food formulations. For example, lecithin, a mixture of phospholipids, is used in mayonnaise, creams, and sauces.

Saponins are a group of complex compounds (triterpenes or steroid aglycones linked to glycosyl

derived sugar structures)extracted from plants. They produce very stable emulsions

having very small size droplets (nanoscale) at relatively low surfactant contents.

The emulsions prepared with saponins are stable at a broad range of pH, ionic strength,

and temperature conditions. Food-grade saponins are utilized in beverages containing

added flavors or bioactive compounds such as vitamins.

Proteins contain both hydrophobic (fatloving) and hydrophilic (water loving) amino acids that

allow them to be absorbed at oil/water interfaces leading to stabilization of an emulsion.

Proteins from whey, soy, fava beans and casein have been tested for controlled release

of health beneficial compounds including lutein, omega-3 oil, fish oil and β-carotene

in food applications. However, protein-based emulsions tend to be highly susceptible

to the pH, temperature and ionic strength in the final product limiting their broad

use. Chemical modification of proteins with compounds like polyphenols and formulating

protein and polysaccharides mixtures for specific

applications help to overcome some of the issues encountered when using only proteins

in an emulsion. The most common protein-based natural emulsifiers are from animal

sourcese.g., whey proteins, caseins, egg protein, and gelatin. Plant-based alternatives

such as pea and soy proteins are commonly used in products designed for people with

dietary restrictions e.g., lactose-free and in vegetarian and vegan foods.

Emulsifier selection tips

Although HLB of an emulsifier is helpful for selecting a suitable emulsifier for a given food formulation, the following factors should also be considered; final product characteristics, emulsion preparation methodology, amount of emulsifier added, chemical and physical characteristics of each phase,and presence of other functional components in the emulsion will affect the emulsion stability. Here are a few steps helpful in the decision-making process:

- Determine type of emulsion required, i.e., W/O, or O/W.

- Consider compatibility with other ingredients in the formulation.

- Look for an emulsifier that provides long-term stability to the emulsion, preventing phase separation or changes in texture over time (shelf stability).

- Consider the pH and temperature conditions of your food product. Some emulsifiers may break down or lose effectiveness under extreme pH or temperature conditions.

- Determine the required concentration of the emulsifier for effective emulsification without negatively affecting taste, texture, or appearance.

- Consider the processing methods used in food production. Certain emulsifiers may be more suitable for specific processing techniques like high shear mixing, homogenization, or low-temperature processing.

- Ensure that the selected emulsifier complies with regulatory standards for food safety and labeling requirements in the target market.

- Evaluate the emulsifier’s ability to provide the desired texture, mouth feel, and appearance in the final product.

- Be mindful of potential allergens. Some emulsifiers may contain allergenic components, so choose an emulsifier that aligns with your product’s allergen labeling requirements.

- Consider the cost-effectiveness and availability of the emulsifier for your production scale and market demands.

In the US, many emulsifier manufacturers and suppliers provide technical support to their clients. The best way to start the decision-making process would be to talk to a few suppliers first and narrow down your options to a few products.Several small-scale trial runs might be required before the pilot runs and scale up to a commercial scale production.