Fertilizer Nutrients in Animal Manure

In addition to meat, livestock and poultry operations produce another valuable commodity—manure. Manure is a by-product containing many plant nutrients and organic matter. Animal manure can be an asset rather than a liability for producers when effectively managed and properly used on field crops. Besides providing valuable macro- and micronutrients to the soil, manure supplies organic matter to improve the soil’s physical and chemical properties. It also increases infiltration of water and enhances retention of nutrients, reduces wind and water erosion, and promotes growth of beneficial organisms.

Each year in Oklahoma, an estimated 10 million tons of manure produced by animals in confinement is available for use as fertilizer. This translates into tens of millions of pounds of plant nutrients and organic matter available to enrich our soil. The key to capturing the benefits of this resource is good nutrient management.

Nutrient Contents in Manure

The actual nutrient value of manure from a particular operation will differ considerably with the method of collection, storage facilities, and species of animal. The approximate fertilizer nutrient content for various manures is shown in Table 1. These are average values, and a chemical analysis on each sample should be obtained before applying manure to a field.

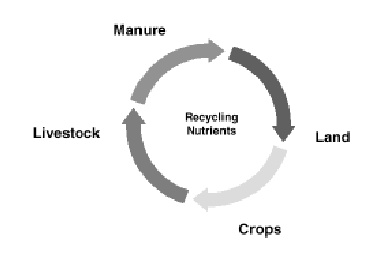

Figure 1. Land application of animal manure recycles nutrients back to the land. It is the most economical and environmentally sound method to handle by-products in livestock and poultry operation.

Table 1. Average Nutrient Analyses (as is)* of Major Types of Manure in Oklahoma

*P2O5 and K2O are commonly used for fertilizer ingredients instead of P and K. Some laboratories may still report in elemental P and K content. To convert, use the following equations: K2O = K x 1.2 or P2O5 = P x 2.29

Factors Affecting Nutrient Composition in Manure

Nutrients in animal manure may be lost or converted to other forms during treatment or storage and handling, affecting their availability for use by growing plants. The type of animal housing system and/or waste handling method is known to affect the final nutrient composition of the manure.

Bedding and water have a diluting effect on the final nutrient concentration of manure and result in less nutrient value per ton. In addition, the type of housing and waste handling system can decrease the final nutrient composition of manure materials. For instance, there can be considerable loss of nitrogen (N) to the air, and there is a potential for runoff and leeching when animal manure is exposed to weather conditions in an open lot system. In contrast, there is considerably less N loss from a completely covered feedlot with manure pack or a liquid lagoon.

Only about 5 percent to 15 percent of the phosphorus (P) or potassium (K) is lost with various waste handling methods, with the exception of the open lot and lagoon systems. Up to 80 percent of the P in manure can settle in lagoons, making it low in the liquid used for spray irrigation of cropland.

Difference Between Nutrients in Manure and Commercial Fertilizers

Plant nutrients in commercial fertilizers are mostly water soluble and readily available for plant uptake. Not all the nutrients in manure are available to crops during the year of application because some are in their organic form, while others can be lost during application. Therefore, an availability factor (percent of nutrients available) is used for rate calculations based on the amount of nutrients available during the first year. The N availability can vary from 30 to 80 percent depending on the type of manure and application method.

Most nitrogen in lagoon effluent is in the ammonium form and is more subject to volatilization loss during storage and land application. The average N available in the first year of application and in subsequent years is listed in Table 2. The greatest response from animal manure application can be obtained by promptly incorporating the waste into the soil either by injection or cultivation. The practice of injecting, chiseling, or knifing liquid animal manure beneath the soil surface minimizes N loss to air or runoff. Therefore, use a lower availability factor if manure is surface applied and not incorporated within two days. Otherwise, a higher factor can be used. The time of manure application also affects the amount of nutrient available to a crop. Higher availability is expected when manure application matches the crop nutrient uptake.

The availability of P and K in manure is considered similar to that in commercial fertilizer. For all manure types, 90% of P and K is considered to be available during the first year of application and 10% for future years.

Table 2. Estimated Ranges of Nitrogen Availability in Animal Manure.

| Manure Type | 1st Year Availability | Future Availability |

|---|---|---|

| Feedlot Manure | 50%-70% | 10%-20% |

| Poultry Litter | 50%-70% | 10%-15% |

| Dairy Manure | 50%-70% | 10%-20% |

| Swine Lagoon Effluent | 30%-50% | 5%-10% |

Taking Credits From Manure

Nutrients in animal manure are as effective as commercial fertilizers for improving crop production if used properly. Producers should subtract the available nutrients in the manure from their regular fertilizer program so they can reduce fertilizer cost and avoid nutrient buildup in soils. Follow these steps to take credits from manure:

- Test soils: Know what nutrients the soil already contains, including residual N, available P and K, as well as soil pH. Take soil samples before land application. A soil test report indicates the amount of nutrients that the soil can supply and recommends the amount needed from other sources.

- Analyze manure: Take samples before spreading manure. Results should include dry matter contents as well as N, P, and K contents.

- Determine when to apply: Applying manure just before planting or at peak growing stages gives plants the best chance to use the nutrients. It also reduces the chance of nutrient runoff.

- Determine how much to apply: To best calculate application rates, balance the nutrient levels in the soil and manure with the needs of the crop. This will ensure you apply enough nutrients for your yield goal but not more nutrients than the crop needs.

- Calibrate manure spreader: By calibrating the equipment, you can guard against applying too much or too little manure per acre. Too much manure may be harmful to the water supply, and too little could hurt crop yields.

- Use supplemental fertilizer as needed: Extra N may be needed if application rates are based on P. Phosphorus can build up in the soil if manure is used to meet the N needs of a crop.

- Consider conservation measures: Maintaining grass waterways, buffer strips, and other water quality practices will help prevent nutrients from reaching nearby water supplies.

- Review nutrient management plan frequently: As the operation changes, so will your nutrient needs. Changes in land use, numbers of livestock, feeding programs, and application methods all affect the amount of nutrients available for crop use.

Other Related Extension Publications

BAE-1734 – What is a Waste Management System?

BAE-1736 – Lagoons for Livestock Waste Treatment

BAE-1739 – Movement of Odors Off-Farm

BAE-1740 – Measuring Farmstead Odors

PSS-2207 – How to Get a Good Soil Sample

PSS-2225 – OSU Soil Test Interpretations

PSS-2245 – Using Lagoon Effluent as Fertilizer

PSS-2246 – Using Poultry Litter as Fertilizer

PSS-2248 – Sampling Animal Manure

PSS-2249 – Managing Phosphorus From Animal Manure

PSS-2250 – Using Stockpiled Feedlot Manure as Fertilizer

PSS-2251 – Selecting Forages for Nutrient Removal from Animal Manure

Hailin Zhang

Waste Nutrient Management Specialist

Department of Plant and Soil Sciences