Efficient Use of Bandsaws in Lumber Manufacturing

Bandsaws are the most widely used cutting tool in the primary breakdown of logs. The board foot yield from a typical bandsaw mill will be greater than that of a typical circular mill. Bandsaws result in less sawdust and more lumber due to a smaller kerf. However, the lack of understanding in bandsaw operation and maintenance cause major problems that affect the overall lumber manufacturing process. This fact sheet deals with bandsaw blade geometry, and some of the basic concepts for efficient primary breakdown of logs.

Bandsaw Blade Geometry

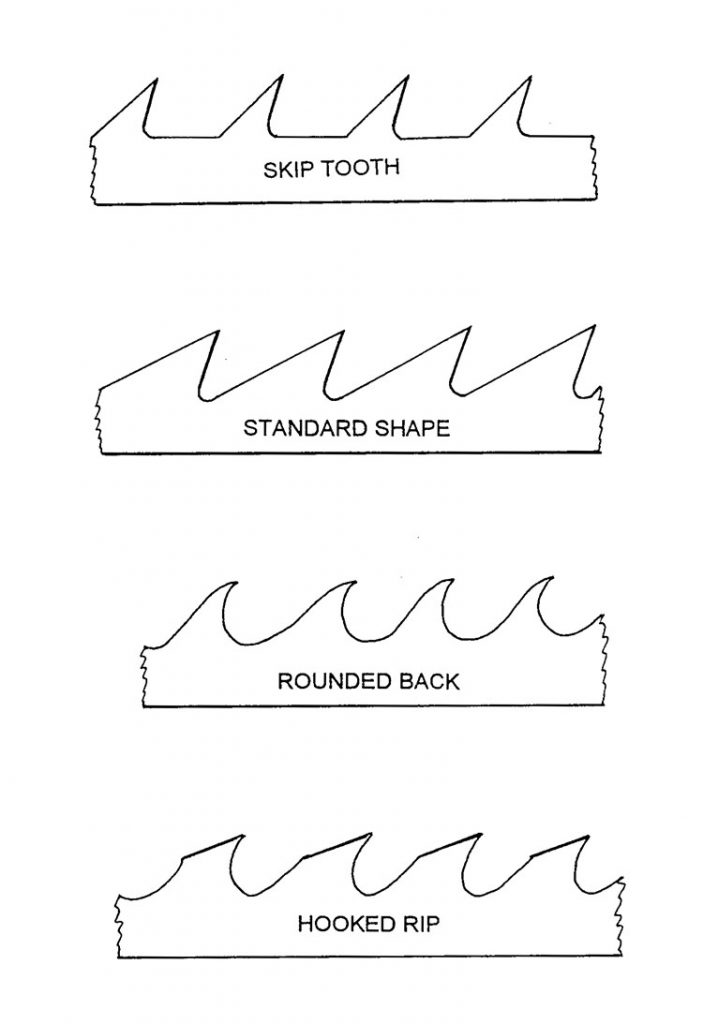

There are many types of bandsaw blades based on tooth design, blade thickness, and width. Log size, species, and grain orientation are some of the main parameters to be considered when selecting the correct bandsaw blade. Tooth design is probably the most important element affecting cutting quality. In general, there are four types of tooth design: standard shape, hooked rip, rounded back, and skip tooth. The standard shape design is widely used for narrow bandsaw blades. Since the gullet area is small, the tooth strength is greater in standard shape blades.

A rounded back pattern is generally used for wide bandsaw blades. The curved back gives a small clearance angle resulting in greater strength at the tooth point.

The tooth strength is less on a skip tooth blade, which is used for resawing and rough cross sawing. The flat gullet area of skip tooth blades is designed to reduce gullet cracks.

Hooked rip blades have a lengthened gullet and positive tooth shape used for sawing large sections of high density wood. Figure 1 illustrates the four basic bandsaw tooth configurations.

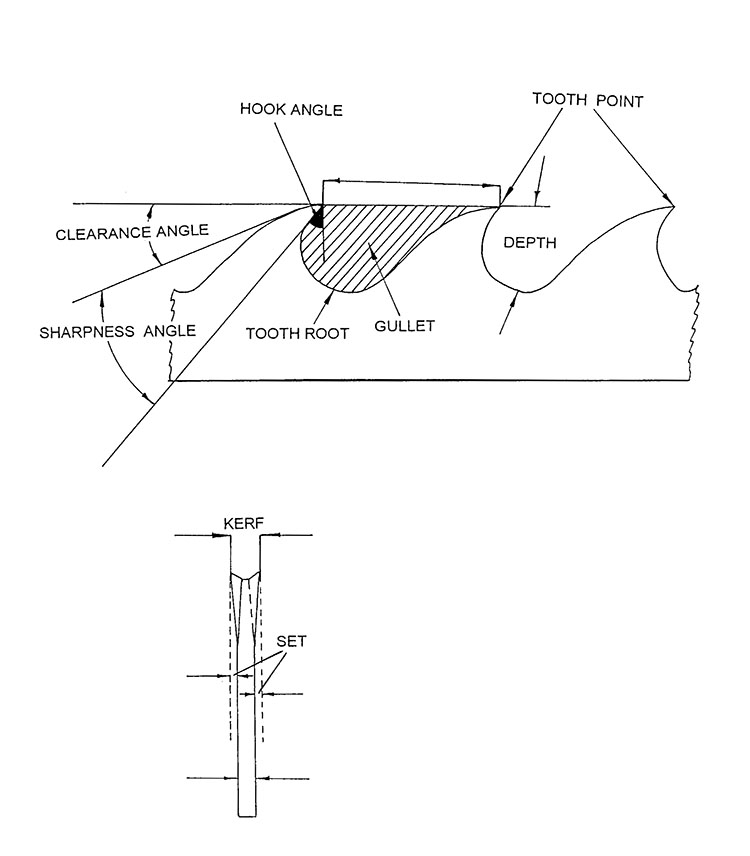

Proper sawing and production capacity are affected by clearance angle, sharpness angle, and hook angle. Clearance angle determines if the saw will run freely, while the sharpness angle gives the tooth strength. Stiffness of the tooth is determined by sharpness angle and usually ranges from 40 to 60 degrees. Hook angle is the most important among the three blade angles, since the bandsaw cuts the wood in a way similar to that of a wood chisel, if the hook angle is too small the chip will not be chiseled out of the wood. On the other hand, a large hook angle will result in rubbing the wood surface rather than cutting it.

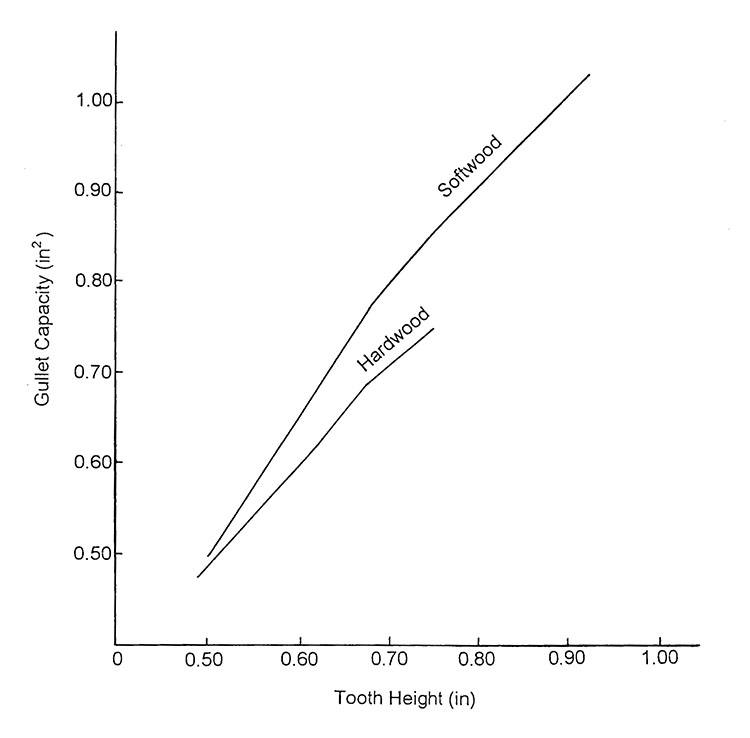

The gullet is the part of the tooth where the chip is collected and carried during the sawing. Tooth pitch can be defined as the distance between two points of the tooth and it is a function of blade size and saw speed. Longer pitch is used for larger blades that are run at a higher speed. Both gullet and pitch are important parameters of blade geometry that influence sawing quality. Typical bandsaw blade geometry is shown in Figure 2. Determining the gullet area is also important for an efficient sawing and it can be calculated by the following formula:

Gullet area = (Pitch × Tooth Height) ÷ 1.75

If the pitch and the tooth height are 2.5 inch and 7/16 inch, respectively the gullet area for this blade will be

(2.5 × 7/16) ÷ 1.75 = 0.625 inch 2

Relationships between blade width, pitch, tooth height, and gullet capacity for softwoods and hardwoods are shown in Table 1 and Figure 3.

Selection of incorrect blade geometry during the sawing based on above angles can result in various problems reducing productivity of the sawing process. Some of these problems and their possible causes are summarized in Table 2.

Table 1. Relationships between blade width and pitch, tooth height, and gullet capacity for softwoods and hardwoods.

| Pitch (in) | Tooth height (in) | Gullet (in2) | ||||

|---|---|---|---|---|---|---|

| Blade width (in) | Softwood | Hardwood | Softwood | Hardwood | Softwood | Hardwood |

| 5 | 1.75 | 1.5 | 0.5 | 0.43 | 0.5 | 0.36 |

| 6 | 2 | 1.75 | 0.68 | 0.62 | 0.77 | 0.62 |

| 7 | 2 | 1.75 | 0.75 | 0.68 | 0.85 | 0.68 |

| 8 | 2.25 | 1.75 | 0.93 | 0.75 | 1.19 | 0.75 |

Table 2. Bandsawing problems and their possible causes.

| Problems | Possible Causes |

|---|---|

| Cracks in the saw | Too narrow gullet |

| Overloading the gullet capacity | |

| Too high feed speed | |

| Inappropriate tension in the blade | |

| Dull saw teeth | |

| Worn wheel bearing | |

| Excessive strain due to non-aligned wheels | |

| Vibrating saw | Out of balance wheel |

| Improper tensino on the wheel | |

| Improper adjustment of saw guide | |

| Saw runs forward when entering the cut and deviates constantly | Too slow feed speed |

| Excessive hook angle | |

| Unequal side clearance | |

| Improper tension | |

| Blade overheating | Too high feeding speed |

| Too high saw guide | |

| High density species | |

| Uneven side clearance | |

| Saw snakes in cut | Dull teeth |

| Overloaded wheel | |

| Misaligned wheel | |

| Non-rigid held lumber | |

| Uneven blade tension |

Figure 1. Bandsaw blade tooth configurations.

Figure 2. Typical bandsaw blade geometry.

Figure 3. Relationship between gullet capacity and tooth height.

Bandsaw Power Requirement

Saw speed is the distance the wood advances for each revolution of the saw. If the blade is fed too fast into the log, the gullet becomes overloaded and the blade can easily be overheated resulting in not only damage to the blade in the form of cracks, but also reducing overall sawing quality. Therefore, saw feed speed should be selected so that an efficient sawing of the log can be achieved. Feed speed can be calculated based on following formula:

F = (B × V) ÷ T

where, F, B, V, and T are feed speed (ft/min), bite per tooth (in), saw velocity (ft/min), and tooth pitch (in), respectively.

If a saw has bite per tooth of 0.050 inch, with a velocity of 10,000 ft/min, and having 2 inch pitch, proper feed speed for this blade is:

F = (0.050 × 10,000) ÷ 2 = 250 ft/min

Specific cutting energy (SCE) and cutting horsepower (CHP) are two important concepts for efficient sawing. SCE is the amount of energy required to saw and remove wood in a certain given length of time. If a specific cutting energy is 40 hp/ft3/min, 40 hp is required to saw 1 foot3 of wood in 1 minute.

Cutting horsepower (CHP) is a function of depth of cut, kerf, feed speed, and the specific cutting energy of the wood and it can be calculated by the following equation

CHP = (D × K × F × SCE) ÷ 144

where, D is depth of cut (in), K is kerf (width of the sawtooth, in), F is feed speed (ft/min), and SCE is the specific cutting energy (hp/ft3/min).

If a saw blade with 0.10 inch kerf requires 60 hp/ft3/min cutting energy to cut an 18 inch thick piece of wood at 126 ft/min of feed speed the required horse power will be

CHP=(18in × 0.10in × 126ft/min × 60hp/ft3/min) ÷ 144 = 94.5hp

Based on above calculations, the right feed speed and power consumption for the saw can easily be selected without any energy waste or improper cutting.

Basics of Bandsaw Blade Maintenance

Proper maintenance of the bandsaw blade is very important to efficient sawing of lumber products. Punching, tensioning, straightening, leveling, swaging, setting, and sharpening are major processes should be carried out in a typical bandsaw blade maintenance.

The purpose of punching is to have uniform shape and spacing of saw teeth. A machine, with an automatic feed mechanism, usually performs punching. Selection of proper guide, die, and punch is important to have good quality punching. For example, if there is insufficient clearance or slippage between punch and die, high machine wear and high power consumption are inevitable results.

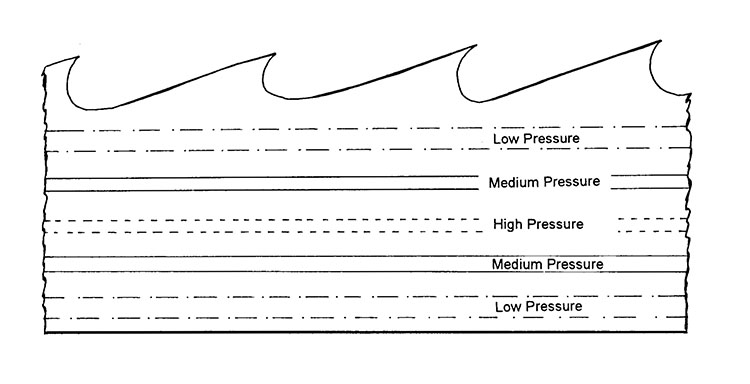

The objective of tensioning is to eliminate unbalanced force distribution on the blade. It is a method of stretching the sawblade body in the inner area of the blade to compensate for expansion of the bandsaw edges due to heat built up during sawing. This tensioning process eliminates the unbalanced force distribution on the blade. A bandsaw blade is tensioned between the rollers of a stretching machine. The amount of tension depends on thickness and width of the blade, diameter of the wheel, and feed rate. For example, thick blades are not tensioned as much as thin blades. Also slow feed blades require less tensioning than that of high feed blades. Figure 4 illustrates several levels of tensioning passes on a bandsaw blade. Tensioning is checked at intervals throughout the stretching process using a straight edge or a convex template. In the case of insufficient tensioning of a blade, the cutting edge will snake so that accurate cutting cannot be done. Insufficient tensioning of the blade can also cause fluttering and pushing the sawblade off the wheel. On the other hand, over tensioning of the cutting edge will result in cracks at the blade root.

Straightening and leveling are the acts of bringing a saw to an even surface and making it flat to eliminate cutting problems. Cross-face and twist-face hammers are commonly used for leveling to eliminate bumps and irregularities on the surface of the blade. Automatic leveling machines are also used for straightening the blade.

Swaging or spring setting makes the tip of the tooth wider than the thickness of the blade. The objective of this process is to prevent the heating up of the blade during the cut. As a rule of thumb, the blade is swaged to twice the plate thickness or two times the thickness of the saw plus one gauge more when cutting green lumber. Spring setting is bending alternate teeth in the opposite direction at an equal amount. If the teeth are overset excessive power is required during the cutting and the teeth will be overloaded resulting in rough-cut lumber.

Bandsaws are sharpened by grinding after they have been swaged. Aluminum oxide grinding stones are widely used in the industry. The stone should be run at the recommended speed. If sharpening stone pressure is too high or uneven the blade can be damaged. Correct stone thickness is also an important factor for proper sharpening. It should be around one-half the length of the tooth pitch for ideal sharpening of the blade.

Figure 4. Tensioning passes on a bandsaw blade.

Conclusion

The concepts described in this fact sheet are important elements influencing overall efficiency of a bandsaw in any application. Detailed information about these elements can also be found in the following literature.

Brown, T 1982. Quality Control in Lumber Manufacturing. Miller Freeman Inc. San Francisco.

Denig, J. 1993. Small Sawmill Handbook. Doing Right It and Making Money. Miller Freeman Inc. San Francisco.

Tooch, D.E. 1992. Managing Successful Sawmill Management. The Northern Loggers’ Association Inc. Old Forge, NY 13420.

Williston, E.D. 1990. Lumber Manufacturing. The Design and Operation of Sawmill and Planer Mills. Miller Freeman Inc. San Francisco.

Williston, E.D. 1989. Saws. Design, Selection, Operation, and Maintenance. Miller Freeman Inc. San Francisco.

Williston, E.D. 1981. Small Log Sawmills. Miller Freeman Inc. San Francisco.

Salim Hiziroglu

Assistant Professor, Forestry

Win Adams

Application Engineer, Biosystems and Agricultural Engineering