Determining Winter Canola Maturity for Harvest

- Jump To:

- Managing Harvest Activities

Harvest timing is one of the most critical steps during the production season of canola. Not only does it determine the total tonnage collected from that field, it also plays a significant role in the overall quality of the harvested seed. This very critical decision also is one of the most difficult decisions growers can make. This is partially due to the variable environmental conditions experienced in any given year.

Producers within the state have two viable options of direct harvest or swathing for harvesting canola. The third option of pushing exists and may be suited for certain areas in the region, but information is relatively limited. Therefore, the focus of this Fact Sheet will be on swathing and direct harvesting.

Choosing to swath or direct harvest comes down to several decisions producers must make at a farm level, as well as on a field-to-field basis. Overall, optimum yields are achieved in best-case scenarios from direct harvesting the crop. This allows the crop to dry-down in a more traditional manner. However optimum conditions rarely exist. In addition to yield, direct harvesting has the potential to produce the highest quality seed with better protein and oil content. Furthermore, permitting the crop to stand in the field allows the quality to be maintained through a wide-range of environmental conditions, such as hot weather at harvesting and poor moisture conditions after swathing. This method also has the best resilience to harvest in heavily tangled and extremely thick stands. However, direct harvesting has the highest potential of yield loss when dry-down and harvest conditions are not optimum. This point is emphasized during severe storms. Hail as small as pea sized can dramatically reduce crop productivity, especially later into maturity. This would make direct harvesting a higher risk, higher reward option.

While swathing does not have the overall yield potential that direct harvesting does, it offers flexibility to the grower. Swathing canola gives the grower some control over when the canola matures and at what rate. It also can offer the grower the opportunity to harvest up to 10 days prior to direct harvesting, allowing for more acres to be harvested in a timely fashion or allowing for harvest of canola prior to moving on to wheat. Besides flexibility, two of the biggest advantages swathing provides are decreased shattering potential and widened windrows to allow for a more uniform crop maturity and moisture. The one major limitation to swathing is the potential for decreased yield and quality, which can be as high as 30 percent, but typically ranges from 0 to 10 percent yield loss. Other issues exist for swathed canola, but they can be surmounted by optimizing the harvest/swathing activities.

Figure 1. Identify the main raceme of an individual plant. This will be used to determine maturity of the crop.

Managing Harvest Activities

Direct harvest

The biggest management decision for direct harvesting comes with when to harvest and setting up a combine. Producers should allow the crop to dry to 8 to 10 percent moisture before it is harvested. Harvesting with higher moisture and drying by forced air can be successful; however, results have been varied. It is best to wait for the crop to dry down and use combine management to minimize shattering.

If growers want to compare combine setup to wheat, the general rule is to slow to about 3/4 of the speed typically done for wheat harvest. This will include ground speed, reel speed and cylinder speed. In addition to speed, the reel should be set high and moved back over the grain table as far as allowed. Fan speed can be set similar to wheat, with no major advantage to slowing the fan speed. Canola is pretty easy to thresh, so opening concave up until whole dry pods are not threshed is better than too narrow and grinding stems, which can increase overall seed moisture. Lastly, make sure the sickle is sharp. A dull sickle can lead to increased shatter loss in front of the combine. If the harvester believes the combine is set properly, drive a test cut then get out and look behind the combine. Approximately 115 seeds per square foot is equal to one bushel yield loss per acre.

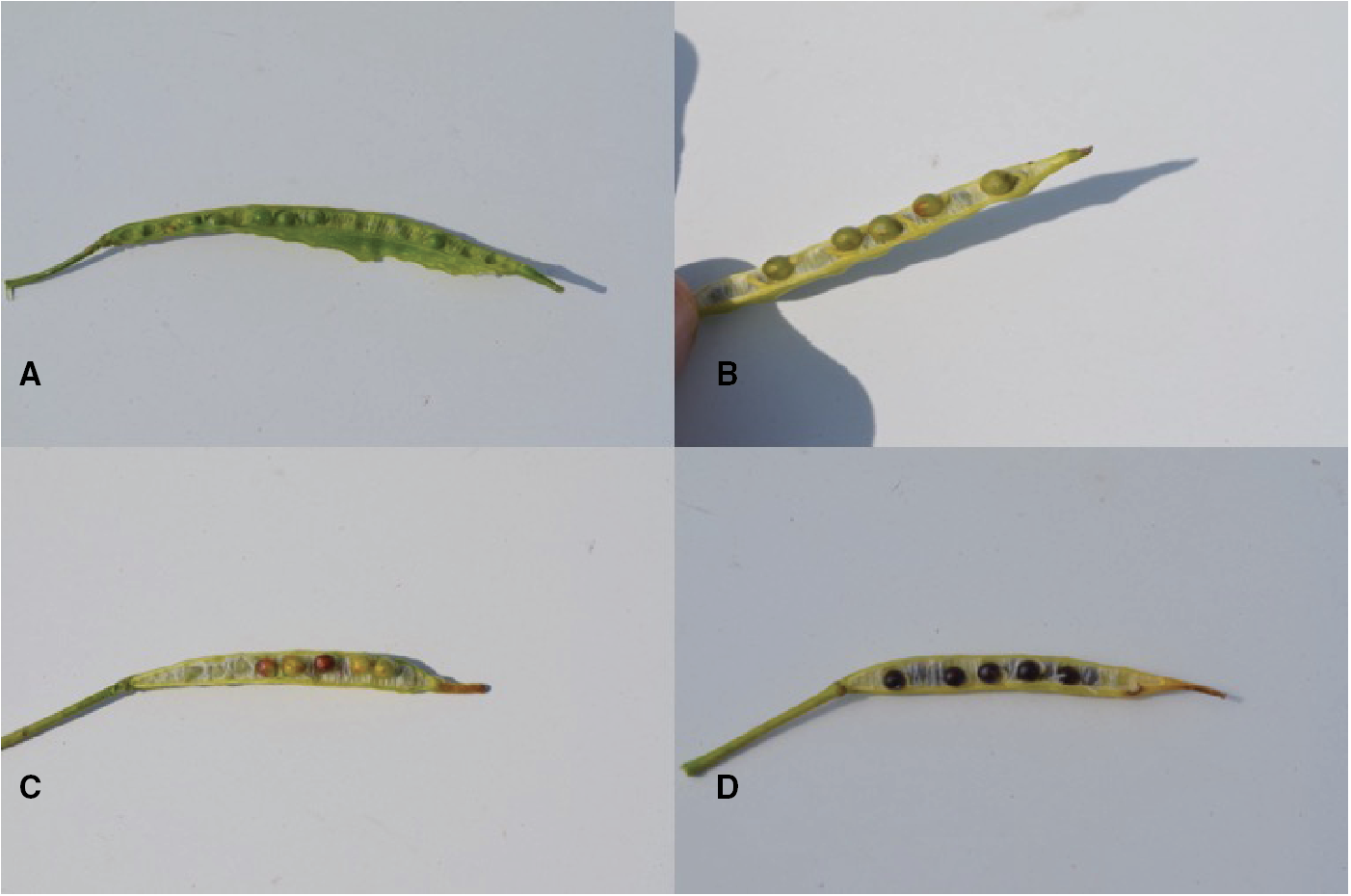

Figure 2. Progression of color change for winter canola at maturity. (A) No color change throughout the pod and some soft seeds. (B) Spotty color change throughout the pod, seeds firm with limited translucent seeds throughout the plant. (C) Color change throughout the pods with spotting on some less mature seeds. (D) Full mature seed color. Swathing can begin when at least 30 percent of pods exhibit pod color change (B and C), swathing at D may result in increased shattering during swathing.

Swathing

One of the most important decisions is determining when to actively swath the canola. Maturity is determined primarily from the main stem of the canola plant. Once the main stem is identified, it should be broken up into sections. When determining maturity, look at color change. Seed color should possess small patches of brown to black color (spotting) when ready.

Swathing can begin when at least 30 percent seed color change has occurred (color change of a majority of the seed within the pod in at least 30 percent of the main stem); however, lower yield and quality loss are typically seen when the grower can delay swathing until 50 to 70 percent seed color change. The risks associated with higher color change when swathing is both increased shatter due to swathing or rapid drying. Once it is determined that the plant has sufficient color change, producers need to ensure there are no translucent or water seeds within the branching racemes. If canola is swathed with higher amounts of these seeds, a good fraction of yield loss can be experienced, especially if side branches make up a large fraction of the overall plant. Once it is determined that the crop can be swathed, producers need to make sure the environmental conditions over the next several days are conducive for quick, but quality dry-down. If soil moisture has been limited and hot, dry conditions are in the forecast, swathed canola can dry-down too quick and not allow for the crop to successfully cure. This will result in increased seed shrinkage and potentially higher percentage of green seed.

Caution should be placed on ensuring minimum loss occurs in the windrow or as the canola is being picked up. Canola should be ready to harvest in seven to 14 days after swathing, but if the crop contains high amounts of immature seed or seed moisture, then it is better to let the crop sit in the windrow longer to minimize green seeds in the load. Only a few of these can result in high grade loss. Windrows are best picked up using a rubberized draper belt. These belt types have rubber or synthetic fingers and are preferred when harvesting canola because the gentle action helps reduce shattering losses. The aluminum pick up is more suited for bunched windrows. Crop lifter attachments that are the width of the windrow will lift it into the header in most cases. The rest of the cutter bar may be covered to prevent or reduce the amount of second-cut stubble entering the combine.

Overall, canola harvest can be a very challenging task. Growers should select which method they would like to harvest canola, then start planning several weeks prior in managing the crop to optimize the intended technique.

Figure 3. Determine color change as the percentage of main stem. Use the length of the stem to help estimate maturity.

Figure 4. Shattered canola. This is possibly due to late- swathed canola or late-harvested standing canola. Appropriate timing on swathing can minimize this issue.

Josh Lofton

Cropping Systems Specialist