Dehydrator Exhaust Recirculation for Energy Savings

Dehydration is an important process that can be extremely profitable for food processors. Large-volume processors typically use continuous dehydration systems, while smaller volumes are processed batch-wise. Energy costs are frequently an issue in food processing operations, but particularly for those operating dehydrators. Over the years, many researchers have reported significant energy savings by recirculating dehydrator exhaust air. Recirculation is the practice of mixing dehydrator exhaust air with incoming fresh air. Five main advantages of exhaust recirculation were cited by Weigand (1923):

- Heat and fuel savings.

- Moisture addition to air.

- Decreased drying time.

- Lower drying cost.

- Increased product quality.

These advantages remain true today, but within limits that vary according to products and equipment. The purpose of this fact sheet is to discuss exhaust recirculation for batch dehydration processes and how it may be used for energy savings and to improve product quality.

Advantages of Exhaust Recirculation

Each of the five advantages of dryer exhaust air recirculation (listed above) are discussed in this section.

Heat and Fuel Savings

Substantial heat savings can be gained from recirculating exhaust air. This seems counter-intuitive, since exhaust air is laden with moisture, which can slow dehydration. Temperature of the exhaust air is the key factor to consider. When warm, moist exhaust air is mixed with fresh air, the temperature of the mixture is higher than the temperature of fresh air alone. This means that less energy will be needed to heat the mixture to the dryer’s set point. The evaporative capacity of the air mixture is less after exhaust air is added, but the decrease is only moderate.

One study (Walker and Wilhelm, 1995) suggested recirculation rates of up to 75% that resulted in energy savings ranging from 45 to 50%. Another study (Van Leersum, 1987) recommended recirculation rates from 60 to 85% with energy savings from 30 to 60%.

Both studies considered fruit in their drying processes. Walker and Wilhelm dried fruit between 24 to 27% moisture content and found that recirculation did not affect drying time.

Achieving lower moisture content in the final product (e.g. 10 to 15% range) may require reduced rates of exhaust recirculation. Reported studies experimented with fixed recirculation rates; variable rates may be required to achieve optimum results.

Moisture Addition to the Air

For most dehydration processes, low humidity air will dry foods rapidly and completely. Some foods however, exhibit “case hardening” from low-humidity drying, normally at the beginning of the process. Case hardening results from a too-rapid drying of the food, which forms a hard layer at the surface. The hard layer slows moisture loss and the tension between the hard outer layer and moist interior may distort the shape of the food and cause cracks to open (United States Bureau of Agricultural and Industrial Chemistry, 1944). Case hardening can be avoided by recirculating exhaust air to moderate the drying rate.

Decreased Drying Time

Case hardening (described in the previous paragraph) can cause increased drying time as the hard outer layer, or “case,” formed around the food product slows moisture loss. The addition of moisture to the air in the dehydrator (recycling exhaust air) helps to prevent the occurrence of case hardening. For products with case hardening issues, exhaust gas recirculation reduces overall drying time.

Lower Drying Cost

Researchers have reported energy savings from 30 to 60% for dehydration processes with exhaust recirculation. The savings will be offset by a partial reduction in drying capacity.

Increased Product Quality

If products are subject to case hardening, then exhaust recirculation will resolve the problem. When case hardening is not an issue, researchers have found little difference in the quality of products processed in the same dehydrator with and without exhaust recirculation.

Practical Application

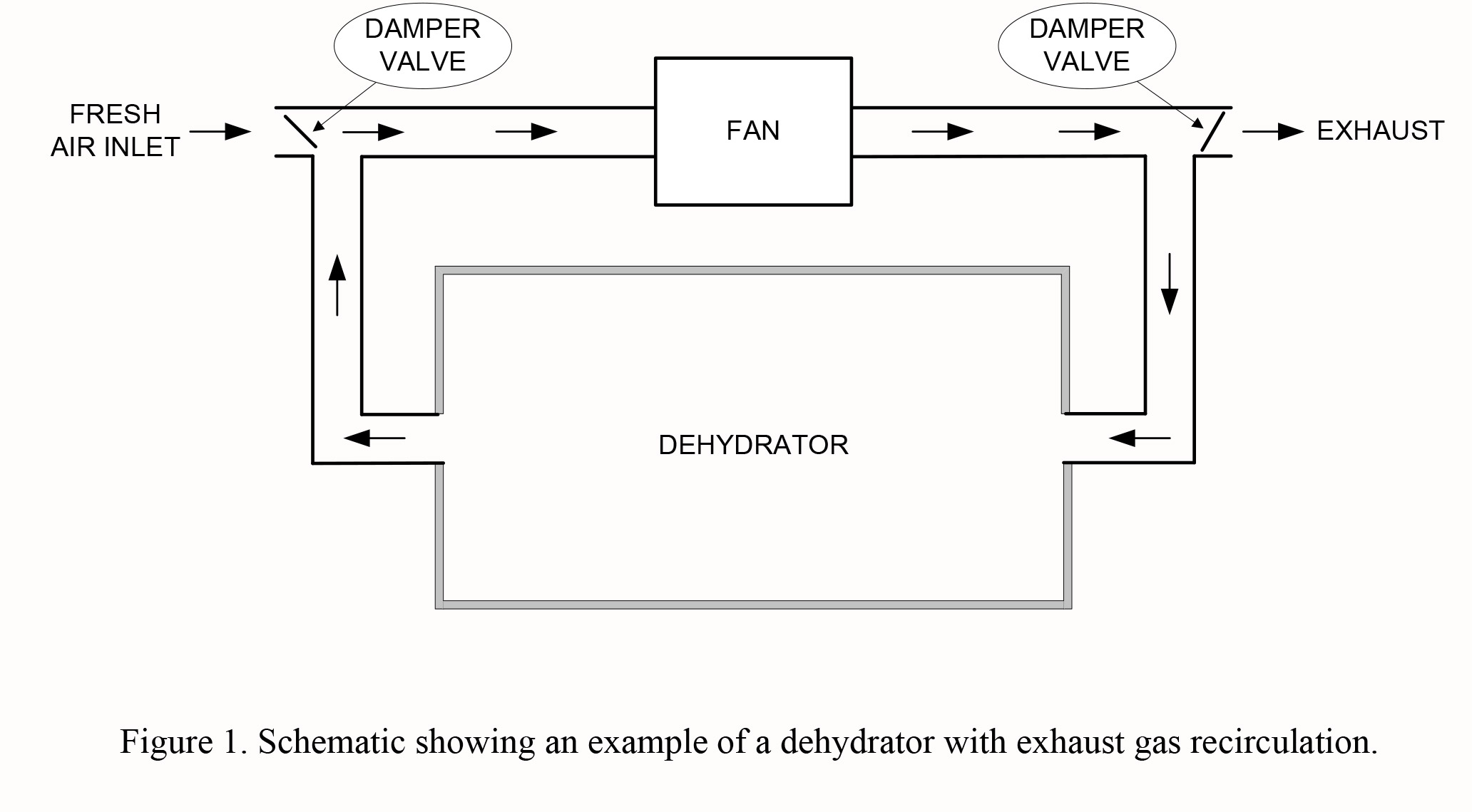

Figure 1 shows a schematic of a dehydrator equipped to recirculate exhaust gases. The fresh air inlet is located on the suction side of the fan, and the exhaust outlet is located on the pressure side of the fan. Two flow control (damper) valves are used to adjust air flow rates. Butterfly-style dampers tend to be difficult to control, since airflow is not linear with respect to valve position. Louver or knife-style dampers are a good alternative with a more linear airflow response to valve position.

Figure 1. Schematic showing of a dehydrator with exhaust gas recirculation.

Flow control valves can be hand-operated or automatic. Automatic and manual control may be based on properties measured in the dehydrator. Examples of control variables include humidity, wet bulb temperature and dry bulb temperature. Additional studies need to be completed to determine the best control scheme for exhaust recirculation. According to Walker and Wilhelm (1995), the exit air temperature of their test dehydrator increased with increasing amounts of air recirculation, but may have reached a maximum temperature at equilibrium conditions. Based on this information, one possible control strategy might be to regulate damper position (exhaust gas recirculation percentage) to achieve maximum exhaust air temperature. Practically, a maximum initial recirculation rate could be set, then reduced over time until a reduction in exhaust temperature was observed.

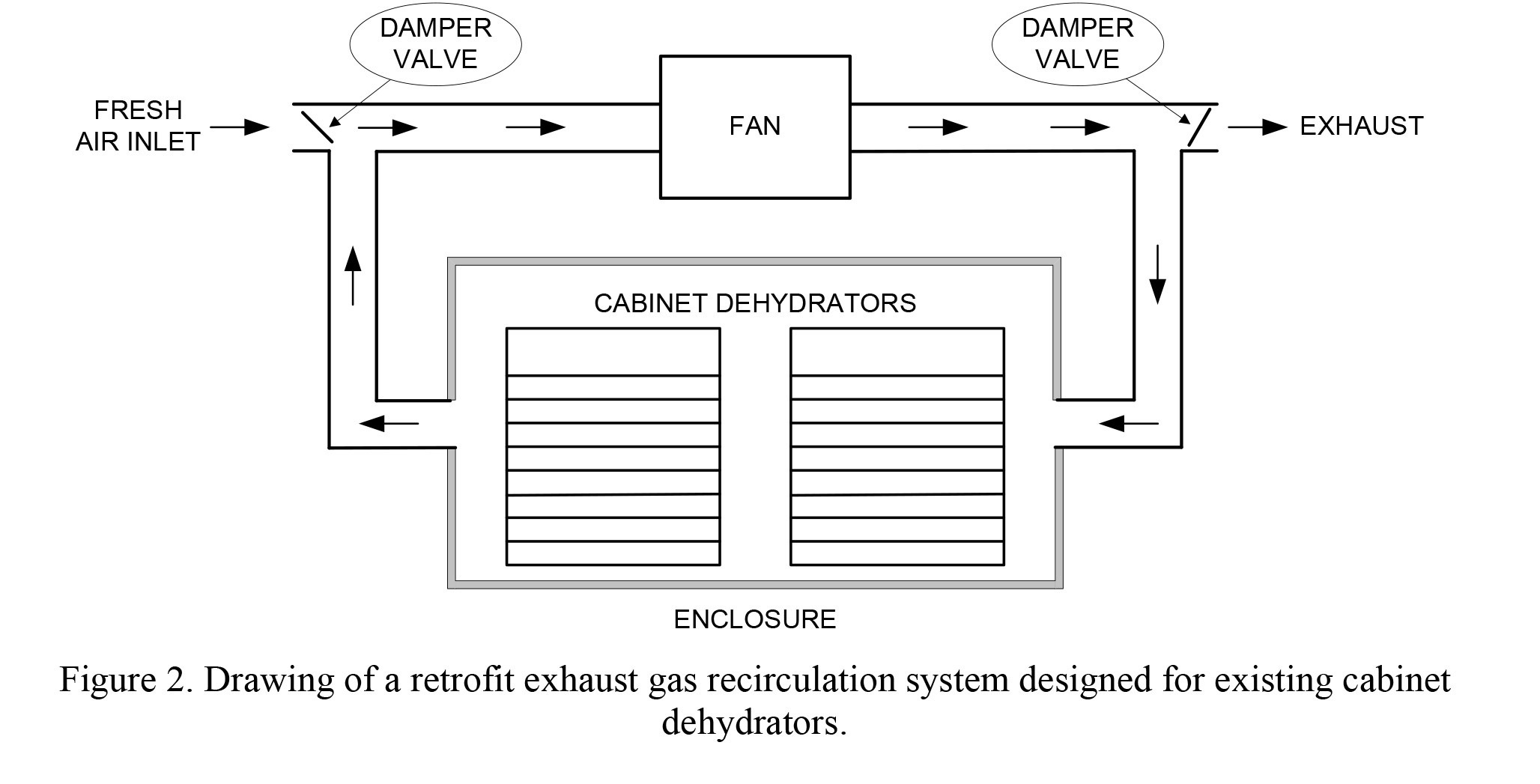

Dehydrators can be retrofitted for exhaust gas recirculation. All dehydrators have one or more fresh air inlet and exhaust air locations. Ductwork and valves, as shown in figure 1, can be added to enable recirculation. Figure 2 shows an enclosure built around an existing dehydrator to facilitate exhaust recirculation.

Figure 2. Drawing of a retrofit exhaust gas recirculation system designed for existing cabinet dehydrators.

Food Safety

Dehydrated foods are generally considered safe, but studies have shown that pathogens can survive the moderate drying conditions of some processes (Allen et al., 2007). Processors can improve food quality and safety by using good manufacturing practices (GMPs) and effective cleaning and sanitation procedures. Understanding and minimizing temperature variation in a dehydrator and establishing a lethality process to minimize the likelihood of under-processed products is another important food safety measure. See Fact Sheets FAPC-121 and 165 for more information on sanitation and lethality treatment, respectively.

Conclusion

Dehydrated products are popular in today’s food market and are likely to remain so indefinitely. Operation and maintenance of dehydrators to save energy is an essential procedure that can increase profits and have a positive impact on the environment. Dehydrator exhaust recirculation is a simple and important tool for energy savings.

References

Allen, K.D., D. Cornforth, D. Whittier, M. Vasavada, and B. Nummer. 2007. Evaluation of high humidity and wet marinade methods for pasteurization of jerky. Journal of Food Science; (72)7: 351-355.

Bowser, T.J. 2007. Construction and operation manual for: Low-cost, safe dehydrator for small and very small meat processors. Oklahoma State University, Robert M. Kerr Food & Agricultural Products Center. Internet: http://www.fapc.biz/files/DehydratorManualV1.pdf (accessed May 23, 2008).

United States Bureau of Agricultural and Industrial Chemistry. Vegetable and Fruit Dehydration: a Manual for Plant Operators. 1944. Washington, D.C.: U.S. Dept. of Agriculture.

Van Leersum, J.G. 1987. The use of rotary heat regenerators in fruit dehydration systems. Journal of Agricultural Engineering Research; 37: 117-128.

Walker, T.H. and L.R. Wilhelm. 1995. Drying fruit with recirculated air for energy savings. Applied Engineering in Agriculture; (11)6: 861-867.

Weigand, E.H. 1923. Recirculation driers. Circular 40. Corvallis: Oregon Agricultural Experiment Station.

Tim Bowser

FAPC Food Process Engineer

R. Scott Frazier

Biosystems and Agricultural Engineering Associate Professor