Defining Cutout in Cotton

- Jump To:

- References

The timing of cotton reaching cutout can be a critical factor for decisions regarding inputs and crop management, although this growth stage is often misunderstood or misidentified. Cutout and the term “blooming out the top” often are used interchangeably to describe cotton near the end of the blooming period. However, these are two distinctly different growth stages in regard to the timing of their occurrence and crop status.

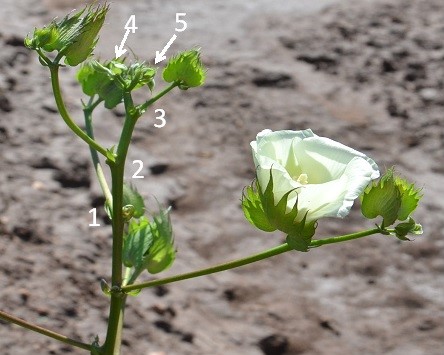

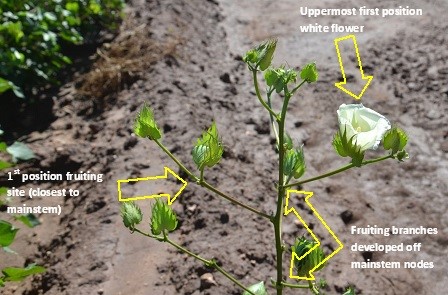

Cutout is the point when the terminal is five nodes above the uppermost first position white flower, or there are five nodes counting down from the terminal to the uppermost first position white flower (5 NAWF; Figure 1). First position refers to the fruiting site closest to the mainstem on the fruiting branch, with node referring to the point where a fruiting branch connects to the mainstem (Figure 2). In general, when the cotton plant is cutout, it has reached its capacity for supporting fruiting positions and likely will not development any additional fruiting sites resulting in harvestable bolls. In other words, at cutout there may be up to seven or more fruiting sites (squares), in addition to the uppermost white flower and these can develop into harvestable bolls as long as adequate water and heat are available. Eventually, the white flower will reach the terminal signaling the end of the flowering period. At this point the crop is “blooming out the top” and white flowers are present at the very top of the plant (0 – 1 NAWF; Figure 3). When cotton has reached this stage, there are no further nodes available to support fruiting sites and the plant is solely focused on developing and maturing the young bolls and few remaining flowers into harvestable bolls.

Figure 1. Plant that has reached cutout, five nodes from the uppermost white flower to the terminal node.

Figure 2. Location of fruiting branches on mainstem nodes, 1st position fruiting site, and uppermost 1st position white flower.

Figure 3. Cotton field at cutout or around five NAWF (top) vs. a field “blooming out the top” (bottom), with white flowers on the uppermost fruiting branches (0 – 1 NAWF).

What does cutout mean from the plant’s perspective? The plant is supporting a developing fruit load and is supplying the squares, blooms and bolls with the resources needed to develop a mature, harvestable boll. Although the demand for water will start declining after peak bloom and as bolls mature (Wrona et al., 1999), the plant will still require enough water to avoid stress. It also needs enough heat units to ensure the full maturation of all the fruiting sites. Even though the crop is finished developing fruiting sites, proper management of both the crop and inputs are still necessary to optimize yield. In cases where the water supply is adequate, or if a fruiting gap (due to aborted squares or bolls lower on the plant) exists, the crop can stay at 5 NAWF for an extended period of time before the white flower reaches the terminal. On the other hand, dryland cotton that has experienced early season water stress begin the flowering period at or close to 5 NAWF. In these situations, it is difficult to extend the fruiting period as the crop has likely already experienced some sort of stress. Attempting to extend the flowering period through irrigation or fertility applications will not likely succeed, particularly if the early season leaf, shoot and root growth, which supports fruit development, was inhibited by stress. The flowering period will likely be abbreviated and fruit retention will be key to optimize yield in these challenging conditions. A more detailed description of cutout and scenarios where the cutout period can be abbreviated or extended is provided by Guthrie et al. (1993).

References

Guthrie, D., F. Bourland, P. Tugwell, and K. Hake. 1993. Charting a Course to Cutout. Cotton Physiology Today 4(6), 1-4. Available online at http://www.cotton.org/tech/physiology/cpt/upload/CPT-July93-v4-6.pdf

Wrona, A.F., D.R. Krieg, D. Baker, C. Bednarz, and R. Hutmacher. 1999. Cotton Water Use. Cotton Physiology Today 10(2), 9-16. Available online at http://www.cotton.org/tech/physiology/cpt/plantphysiology/upload/CPT-v10No2-99-REPOP.pdf

Seth Byrd

Extension Cotton Specialist