Cross Laminated Timber (CLT) as a Value-Added Product

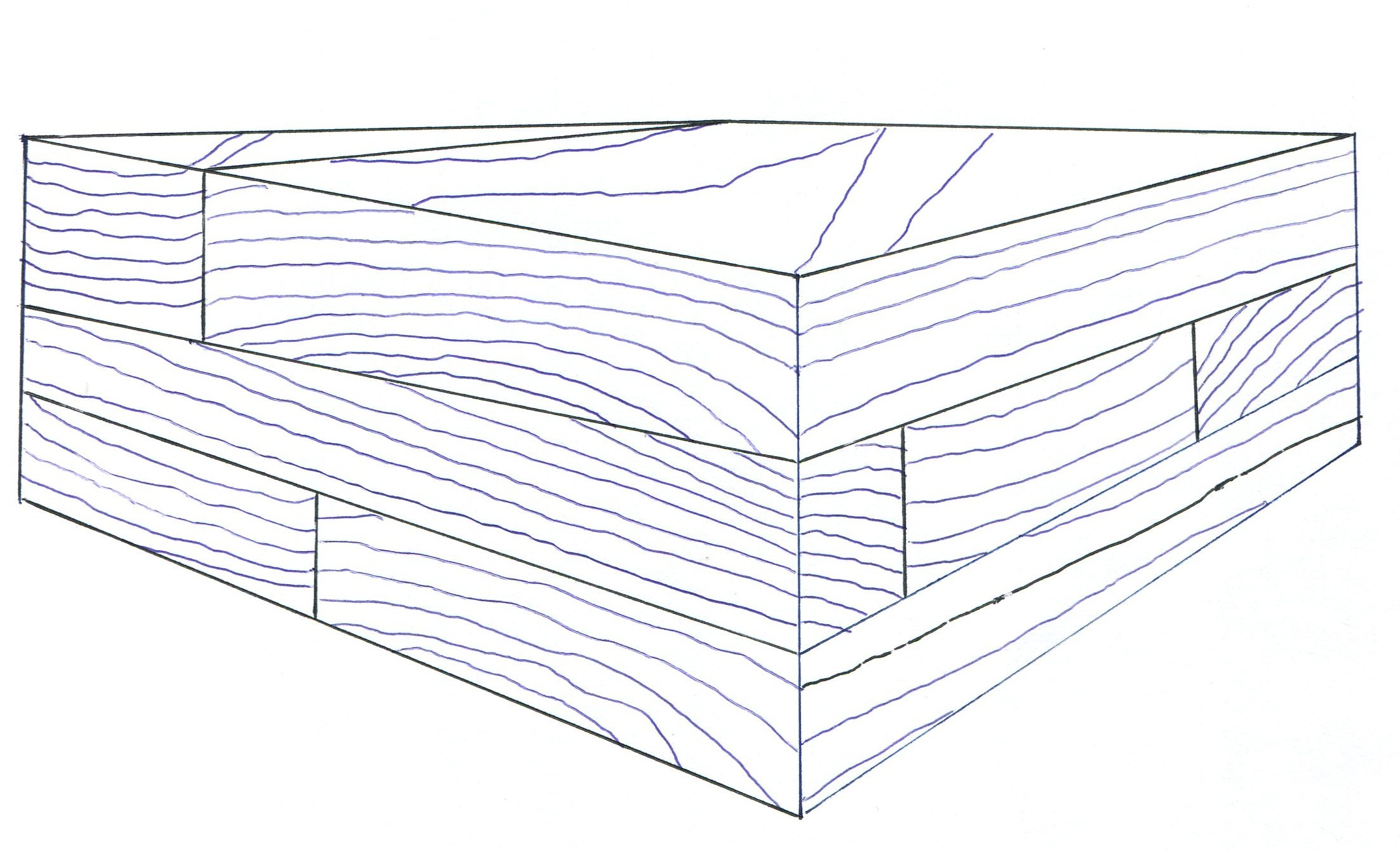

Cross laminated timber (CLT) is a relatively new generation of engineered timber product, which has been developed in Europe and is gaining in popularity for both residential and non-residential constructions in many countries. Currently, there are more than 100 CLT projects in Europe. The main driving force behind CLT production in the USA and Canada is to provide alternative value-added wood based product with more flexible applications. CLT is being increasingly adopted for structural purposes in several seven or eight-story buildings in the USA, as illustrated in Figure 1. This engineered panel product is simply another form of glue laminated timber, so-called glulam. It is generally manufactured from any softwood species having a minimum density of 0.35g/cm3. A typical CLT is produced with several layers of structural lumber stacked across the grain orientation similar to plywood configuration, which makes it different than glulam. Usually CLT is manufactured with three to seven layers of the lumber although more layers also can be used for special applications. Overall thickness of the individual lumber ranges from 15 mm (0.59 in) to 50 mm (1.96 in) of kiln dried softwood species including pine, spruce, larch and Douglas fir, which are the most widely used raw materials for CLT manufacture. Pieces of lumber having moisture content of around 12% are glued together using a polyurethane and melamine based adhesives followed by assembling and compressing process in a hot press yielding a mass lumber. Finger joint timber without having any defects also are commonly used in CLT production to have a great accuracy to determine overall dimensions and structural properties of the final unit. Assembly of the lumber could take from 20 minutes to 1 hour depending on type and size of CLT. Press operation is one of the most important processes determining target strength of CLT. Prior to compression of mass timber, computer numerical control (CNC) type equipment is employed for necessary drilling or cutting of the individual pieces. Figure 2 illustrates a typical CLT configuration. Size of CLT is determined by available equipment in manufacturing site. In general 10-11 feet width and 40-45 feet length is typical size of CLT panel.

Figure 1. An example use of CLT in a seven stories tall building (source: www.bing.com).

Figure 2. Typical cross laminated timber and structure.

CLT is known to be environmentally friendly since lumber from short rotation trees are used for its production. Compared to concrete and steel, construction time of CLT is much shorter. Due to the lightweight of CLT, requirement of small size foundation is also another major advantage of such engineered product. Also, carbon sequestration of CLT is substantially lower as compared to those of other traditional construction materials making CLT sustainable and environmentally friendly.

Some of the major concerns of CLT includes its fire performance and creep, which is time dependent deformation. Based on various studies it was found that generally CLT units have a good fire resistance comparable to massive non-combustible construction materials. It is a known fact wood develops charring as a result of fire exposure extending its structural resistance. A CLT massive wood structure would have slow charring maintaining significant structural capacity. Creep would play a more important role on structural behavior of CLT than any other characteristics during its service life. Special attention should still be paid during the design of CLT so effect of creep can be minimized.

Moisture durability of CLT is also important issue, which needs to be evaluated. Based on American Plywood Association (APA) APA PRG 320 moisture durability of CLT is tested employing an accelerated aging method by exposing CLT samples to vacuum pressure and water soaking cycles.

CLT is not inexpensive material, but its cost is competitive with other structural panel materials. However, it has certain benefits such as the reduced installation cost, lighter weight and enhanced job site safety making it a sustainable value-added panel product. As mentioned CLT is still a new product, and there are certain challenges that need to be addressed. It is clear however, such a product has a bright future as a value-added panel to be used in construction industry.

Further information can be obtained from the literature below.

www.apawood.org/cross-laminated-timber

Brandner, R. G. Flatscher, A. Ringhofer, G. Schickhofer, A. Thiel. 2016. Cross laminated timber (CLT): Overview and development. 2016. European Journal of Wood Products. 74:331-351.

Frangi, A, M. Fontana, E. Hugi, R. Jubstl. 2009. Experimental analysis of cross-laminated timber panels in fire. Fire Safety Journal. 44(8), p. 1078.

Salim Hiziroglu

FAPC Value-Added Wood Processing Specialist