Corn Kernel Damage

Principal Corn Kernel Damage

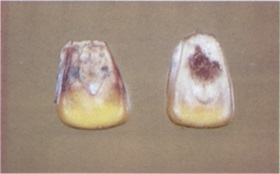

Blue-Eye Mold Damage

A germ affected with blue-eye mold, regardless of amount, shall be considered damaged.

Purple Plumule (Not Damage)

The outward appearance is similar to blue-eye mold, but the coloring is due to genetic

or varietal characteristics and is not damage.

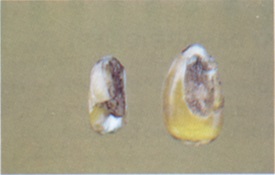

Cob-Rot Damage

The presence of a distinct discoloration or rotting caused by a fungus that attacks

ears of weakened plants. A kernel containing cob-rot shall be considered damaged without

opening the kernel.

Mold Damage

When a kernel of corn has been chipped or broken exposing the starch, it becomes susceptible

to mold. Kernels which have mold on the exposed part of the kernel shall be considered

damaged.

Dirt (Not Damage)

Whole or broken kernels which have dirt on the exposed part of the kernel. Do not

confuse dirt with mold.

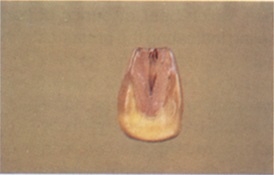

Germ Damage

Kernels of corn which are slightly discolored by respiration or heat shall be considered

damaged but not heat damaged.

Heat Damage

Kernels of corn which are materially discolored by excessive respiration, with the

dark discoloration extending out of the germ through the sides and into the back of

the kernel, shall be considered heat damaged.

Drier Damage

Kernels which have a discolored, wrinkled, and blistered appearance; or which are

puffed or swollen and slightly discolored and which often have damaged germs; or whose

seed coats are peeling off or have already peeled off; or which have a cracked or

checked appearance resulting from external heat caused by artificial drying methods

Heat Damage (Drier)

Kernels of corn which are puffed and swollen and materially discolored by external

heat caused by artificial drying methods shall be considered heat damaged.

Insect Damage

Kernels which bear evidence of boring or tunneling indicating the presence within

the kernels of insects and kernels in which noticeable weevil-bored holes have been

eaten shall be considered damaged. Kernels which have been partially eaten by insects

or rodents but which are entirely free from refuse, webbing, insects, or other forms

of damage shall be considered sound kernels.

Surface Mold (Blight)

Kernels of corn which have mold caused by corn leaf blight on them shall be considered

damaged.

Sprout

Kernels of corn which are sprouted shall be considered damaged.

Mold Damage (Pink Epicoccum)

A germ affected with mold caused by a fungus regardless of amount, shall be considered

damaged.

Special Grades

Infested corn

Corn that is infested with live weevils or other live insects injurious to stored

grain. Corn will be considered infested if the representative sample, or lot as a

whole (stationary), or component sample (continuous loading/unloading of ships and

barges) contains two or more live weevils, or one live weevil and five or more other

live insects injurious to stored grain, or ten or more other live insects injurious

to stored grain.

Other grading factors

Distinctly low quality. Corn which is obviously of inferior quality because it contains foreign substances, or because it is in an unusual state or condition, and which cannot be graded properly by use of other grading factors. Distinctly low quality shall include any object too large to enter the sampling device; i.e., large stones, wreckage, etc. Corn which is distinctly low quality shall be graded U.S. sample grade.

The factor distinctly low quality is by nature not susceptible to measurement by weight or count. However, the following guidelines are prescribed:

- Large stones, etc. Corn containing two or more stones, pieces of glass, pieces of concrete or other pieces of wreckage or debris which are visible to the sampler and are too large to enter the sampling devise shall be considered distinctly low quality.

- Diatomaceous earth. Corn which contains diatomaceous earth shall be considered distinctly low quality.

Broken corn. All matter that passes readily through a 12/64 round-hold sieve and over a 6/64 round-hole sieve.

Foreign material. All matter that passes readily through a 6/64 round-hole sieve and all matter other than corn that remains on top of the 12/64 sieve.

Grade Requirements for Corn

Table 1. Grade Requirements for Corn

| Grade | Minimum weight per bushel (pounds) | Maximum limits of damaged kernels - Heat damaged kernels (percent) | Maximum limits of damaged kernels - Total (percent | Maximum limits of broken corn and foreign material (percent) | |

|---|---|---|---|---|---|

| U.S. No. 1 | 56 | 0.1 | 3 | 2 | |

| U.S. No. 2 | 54 | 0.2 | 5 | 3 | |

| U.S. No. 3 | 52 | 0.5 | 7 | 4 | |

| U.S. No. 4 | 49 | 1 | 10 | 5 | |

| U.S. No. 5 | 46 | 3 | 15 | 7 |

U.S. Sample grade-

U.S. Sample grade is corn that:

- Does not meet the requirements for the grades U.S. Numbers 1, 2, 3, 4, or 5; or

- Contains stones which have an aggregate weight in excess of 0.10 percent of the sample weight, 2 or more pieces of glass, 3 or more crotalaria seeds (Crotalaria spp.), 2 or more castor beans (Ricinus communis L.), 4 or more particles of an unknown foreign substance(s) or a commonly recognized harmful or toxic substance(s), 8 or more cockleburs (Xanthium spp.) or similar seeds singly or in combination, or animal filth in excess of 0.20 percent in 1,000 grams; or

- Has a musty, sour, or commercially objectionable foreign odor; or

- Is heating or otherwise of distinctly low quality.

Corn

Grain that consists of 50 percent or more of whole kernels of shelled dent corn and/or shelled flint corn (Zea Mays L.) and not more than 10.0 percent of other grains for which standards have been established under the Untied States Grain Standards Act.

Yellow Corn - Corn that is yellow kerneled and contains not more than 5.0 percent of corn of other colors. Yellow kernels of corn with a slight tinge of red are considered yellow corn.

White Corn - Corn that is white kerneled and contains not more than 2.0 percent of corn of other colors. White kernels of corn with a slight tinge of light straw or pink color are considered white corn.

Mixed Corn - Corn that does not meet the color requirements for either of the classes yellow corn or white corn and includes white-capped yellow corn.

Acknowledgments

We wish to express sincere appreciation to representatives of the Wichita Field Office of the Federal Grain Inspection Service for their assistance in revising this publication. Appreciation is also extended to the Oklahoma Grain & Feed Association, 2309 N. 10th, Suite B, P.O. Box 1747, Enid, Oklahoma 73702.

The photographs appearing in this publication are printed by permission from S J Systems, 645 West Virginia, Milwaukee, Wisconsin 53204, (414) 271-7112. The photographs are reproductions of the line slides used by the Federal Grain Inspection Service and are intended for illustration only. Since the intensity of the reproductions may not precisely duplicate the originals, we do not recommend that they be used for grading purposes.

Authors

Dr. Kim Anderson and Dr. Phil Kenkel

Department of Agricultural Economics

Cooperative Extension Service

Oklahoma State University.

Gail Calkins

USDA, GIPSA, FGIS, Wichita, KS.

For additional copies contact:

Kim Anderson

513 Ag Hall

Oklahoma State University

Stillwater, OK 74078-0505

(405) 744-6082