Bunker Silo Sizing and Management

Silage is the end product of the fermentation of a high moisture crop (40 to 80% water). The first record of a containment structure or “silo” in the U.S. is during the late 1800s. Ensiling gained slow acceptance until today when silage contributes over 50 percent of the nutrients for beef and dairy cattle production in the U.S.

Regardless of whether you harvest hay or silage, producing high quality forage requires sound management practices.

The more common advantages of harvesting forage as silage compared to hay are as follows:

- More nutrients are preserved per acre primarily due to lower field losses.

- There is reduced risk of weather damage because there is less time between cutting and harvesting.

- A wider selection of crops can be harvested as silage.

- Silage is better suited as an ingredient in total mixed rations.

The more common disadvantages of silage compared to hay are as follows:

- Losses during storage can be excessively high with poor management.

- If feedout is too slow, substantial spoilage losses can occur.

- There is high investment in facilities and equipment.

- There is limited alternative use for silage facilities and equipment.

- Marketing silage is limited due to high transportation costs and susceptibility to spoilage.

This fact sheet provides management tips for properly locating, constructing and managing a bunker silo to obtain the maximum benefit in both feed quality and quantity.

Site Selection

Drainage

Select an elevated location that allows rain and snow melt to drain from the site rather than toward the bunker. Do not locate the bunker in a low area that may become inaccessible due to mud or standing water.

Ground Water

Locate the bunker at least 150 feet away and down slope from existing wells to minimize possible contamination from seepage. In highly permeable soils or locations with shallow wells, increase this distance to at least 300 feet.

Feeding

Locate the bunker as close to the feeding system as possible. Consider how you will move the silage to the cattle. You must also consider what, if any, modifications are needed to the feed bunk or feeding system. One of the more common problems in locating a bunker is under estimating the space required to efficiently move equipment in and around the bunker.

Site Preparation

Because equipment traffic is often heavy during feedout, all-weather access to the bunker is essential. Without an improved vehicle surface, precipitation and silage seepage can make access to the bunker difficult. In addition, equipment can create ruts and mud holes. Concrete makes the best all-weather traffic surface while asphalt is the next best alternative.

Slope concrete floors one inch per eight feet to drain precipitation and silage leachate out of and away from the bunker. Use a two to five percent surface slope to drain runoff away from bunkers, preferably into a grassed waterway for infiltration. For high moisture silage where large quantities of seepage could cause an environmental concern, collect runoff in a storage basin for later disposal.

Design Criteria

Certain design criteria must be met to minimize spoilage and to maximize the effective use of bunker silos. These criteria include silage removal rate and bunker width, height and length.

Face Removal Rate

In Oklahoma, a minimum of six inches of silage must be removed from the silo face each day to keep ahead of spoilage in warm weather. Design the bunk to remove at least eight inches per day. In larger operations or when haylage is stored, consider designing for a 12-inch removal per day to minimize spoilage.

Bunker Width

The minimum width is determined by the packing-tractor width. To determine the minimum bunker width, simply multiply the packing tractor width by 2. If using an 8-foot wide tractor, the minimum bunker width is 16 feet for full coverage of the silage while packing. The maximum bunker width is limited by the amount of silage removed each day which is influenced by bunker height, face removal rate and silage density.

Bunker Height

The maximum height is usually limited by cost. In some cases, it can be limited by the maximum safe vertical reach of the silage unloading equipment.

Bunker length: Length is primarily determined by the total quantity of forage that must be stored.

Design Procedure

To calculate the silo size, you first must determine the amount of dry matter (DM) that will be fed each day from the bunker. Naturally, the amount of dry matter fed will depend on the particular ration for each group of cattle. To determine the amount of silage needed per day, use the following equation:

Total Dry Matter (lbs/day) = Dry Matter (lbs DM/head-day) x Number of head

The volume of silage needed per day can be estimated knowing the silage density. Typical densities are listed in Table 1. Density is highly influenced by harvest moisture content, packing tractor weight and packing time. The higher packing densities are achieved using higher moisture content forage that is packed with a heavy tractor for an extended time, usually greater than 30 minutes per load.

Table 1. Dry matter density based on wet bulk density and moisture content.

| Wet Bulk | Moisture Content, % | ||||

|---|---|---|---|---|---|

| lb/ft3 | - - - - - - - - - - - lb/ft3 - - - - - - - | ||||

| Note: Typical range of silage dry matter densities are: | |||||

| 20 | 9 | 8 | 7 | 6 | 6 |

| 25 | 11.3 | 10 | 8.8 | 7.5 | 6.3 |

| 30 | 13.5 | 12 | 10.5 | 9 | 7.5 |

| 35 | 15.8 | 14 | 12.3 | 10.5 | 8.8 |

| 40 | 18 | 16 | 14 | 12 | 10 |

| 45 | 20.3 | 18 | 15.8 | 13.5 | 11.3 |

| 50 | 22.5 | 20 | 17.5 | 15 | 12.5 |

| alfalfa: 12.3-14.0 lb/ft3, | |||||

| corn: 14.0-17.3 lb/ft3 and | |||||

| sorghum: 13.0-16.5 lb/ft3. |

To determine the daily volume, divide the amount fed by the approximate density:

Volume (ft3/day) = Total Dry Matter (lbs DM/day) ÷ Dry Matter Density (lbs DM/ft3)

For example, assume you are planning to feed 18 lbs of dry matter per head per day of corn silage to 120 cows and the density of corn silage is 16 lbs/ft3. The total dry matter

fed daily is:

Total Dry Matter = 18 lbs/head-day x 120 head = 2160 lbs/day

The volume to be removed from the bunker is:

Volume = 2,160 lbs/day ÷ 16 lbs/ft3 = 135 ft3/day

Next, consider silo height and estimate the settled depth. Bunker silo walls are often available from 8 to 16 feet tall in two-foot increments. To estimate the settled depth of silage, multiply the selected wall height by 0.85.

Settled Depth (ft) = Wall Height (ft) x 0.85

If the bunker wall height in our example is 10 feet, the settled depth is:

Settled Depth = 10 x 0.85 = 8.5 ft

Finally, decide what the face removal rate will be.

Remember, you should remove at least six inches per day.

For our example, use eight inches or 0.67 feet.

You can now calculate bunker width (BW):

BW (ft) = Volume Removed (ft3/day) ÷ Face Removal Rate (ft/day) x Settled Depth (ft)

For our example, bunker width is:

Bunker Width = 135 ft3/day ÷ 0.67 ft/day x 8.5 ft = 23.7 ft (Use 24 ft.)

Bunker width must be at least twice the width of your packing tractor to make sure the middle can be packed. Since 24 feet is over twice the width of a 10-foot wide tractor, this width is acceptable. If the calculated bunker width is less than twice the packing tractor width, you must change some of your assumptions such as face removal rate or bunker height. If you have a small herd, a reasonable combination of dimensions may not be possible. If so, you may have to abandon using a bunker silo. Consider using a bag silo as an alternative storage.

The bunker length can be calculated once you have finalized the face removal rate and when the feeding period is known.

Length (ft) = Face Removal Rate (ft/day) x Feeding Period (days)

For our example, assume a 360-day feeding period and using the above equation, the silo length is:

Length = 0.67 ft/day x 360 days = 240 ft

Consider limiting bunker length to about 120 feet, because very long silos require excessive driving to remove feed when the bunker silo is less than half full. One method to improve the convenience of silo emptying and flexibility of use is to make several shorter bunkers. In our example, two 120-foot silos could be constructed instead of one at 240 feet. Another alternative is three 80-foot silos for added flexibility. The total volume or capacity would be the same. Flexibility is especially important if you harvest hay silage in several cuttings. Each silo could be sized to store each separate cutting. A multiple silo arrangement allows you more flexibility to store other forages and different forage qualities.

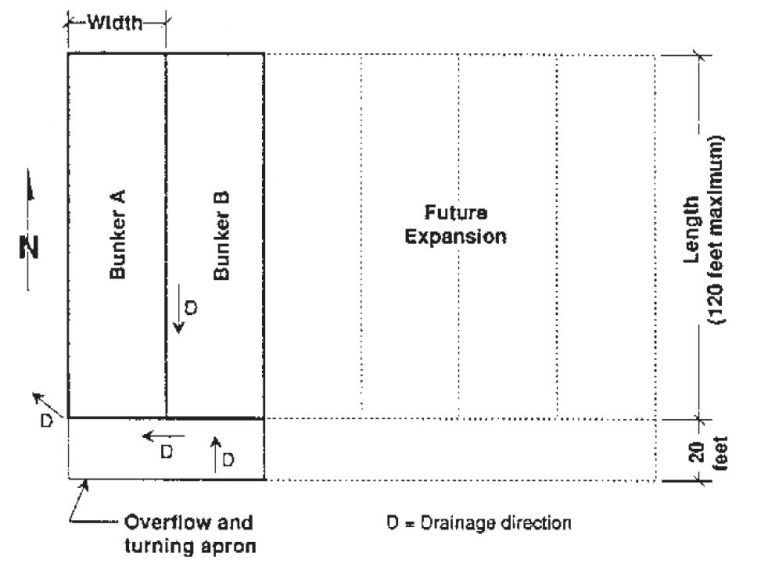

The bunker silos selected may be configured as shown in Figure 1. The common walls used between silos are less costly than two walls loaded from only one side. Selecting a common wall height for all silos helps make multiple silo design more manageable. Table 2 gives approximate bunker silo capacities for alfalfa, corn and sorghum silage.

Figure 1. Common bunker silo arrangement.

Table 2. Approximate bunker silo capacities.

| Width | Height | Length | Volume | Alfalfa | Sorghum |

|---|---|---|---|---|---|

| - - - - ft - - - - | - - - - ft - - - - | - - - - ft - - - - | ft3 | - - -Tons DM - - - | - - -Tons DM - - - |

| 20 | 8 | 40 | 5760 | 37 | 46 |

| 80 | 12160 | 79 | 97 | ||

| 120 | 18560 | 121 | 148 | ||

| 20 | 12 | 40 | 8160 | 53 | 65 |

| 80 | 17760 | 115 | 142 | ||

| 120 | 27360 | 178 | 219 | ||

| 20 | 16 | 40 | 10240 | 67 | 82 |

| 80 | 23040 | 150 | 184 | ||

| 120 | 38540 | 233 | 287 | ||

| 20 | 20 | 40 | 12000 | 78 | 96 |

| 80 | 28000 | 182 | 224 | ||

| 120 | 44000 | 289 | 352 | ||

| 30 | 8 | 40 | 8640 | 56 | 69 |

| 80 | 18240 | 119 | 146 | ||

| 120 | 27840 | 181 | 223 | ||

| 30 | 12 | 40 | 12240 | 80 | 98 |

| 80 | 26640 | 173 | 213 | ||

| 120 | 41040 | 267 | 328 | ||

| 30 | 16 | 40 | 15360 | 100 | 123 |

| 80 | 34560 | 225 | 276 | ||

| 120 | 53760 | 349 | 430 | ||

| 30 | 20 | 40 | 18000 | 117 | 144 |

| 80 | 42000 | 273 | 336 | ||

| 120 | 66000 | 429 | 528 | ||

| 40 | 8 | 40 | 11520 | 75 | 92 |

| 80 | 24320 | 158 | 195 | ||

| 120 | 37120 | 241 | 297 | ||

| 40 | 12 | 40 | 16320 | 106 | 131 |

| 80 | 35520 | 231 | 284 | ||

| 120 | 54720 | 356 | 438 | ||

| 40 | 16 | 40 | 20480 | 133 | 164 |

| 80 | 46080 | 300 | 369 | ||

| 120 | 71680 | 466 | 573 | ||

| 40 | 20 | 40 | 24000 | 156 | 192 |

| 80 | 56000 | 364 | 448 | ||

| 120 | 88000 | 572 | 704 | ||

| 50 | 8 | 40 | 14400 | 94 | 115 |

| 80 | 30400 | 198 | 243 | ||

| 120 | 46400 | 302 | 371 | ||

| 50 | 12 | 40 | 20400 | 133 | 163 |

| 80 | 44400 | 289 | 355 | ||

| 120 | 68400 | 445 | 547 | ||

| 50 | 16 | 40 | 25600 | 166 | 205 |

| 80 | 57600 | 374 | 461 | ||

| 120 | 86900 | 582 | 717 | ||

| 50 | 20 | 40 | 30000 | 195 | 240 |

| 80 | 70000 | 455 | 560 | ||

| 120 | 110000 | 715 | 880 |

Assumptions

- Vertical side walls.

- Entire volume can not be filled and front surface is at a 45 degree slope.

- Silage dry matter densities are 12.5 lb/ft3 for alfalfa and 16.0 lb/ft3 for corn and sorghum.

Silo Management

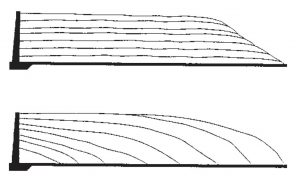

Bunker silo management begins at harvest. For best results, chop corn and sorghum silage at 1/4 inch and hay silage at 3/8 inch theoretical length of cut. The moisture content should be between 55 and 70 percent. Higher moisture contents give better packing and preservation. Several methods of distributing the forage in the bunker are possible. A self-unloading wagon can be drawn through the bunker distributing its load along the way. Below ground bunkers can be filled by discharging a self-unloading wagon over the side as it drives by. The most common method is to dump the forage at the face of the pile and push it up with a front-end loader or blade. Figure 2 is a cross section of a typical bunker silo filled by layers. Cornell research shows that a progressive wedge-filling method provides better carbohydrate digestibility than other methods.

Figure 2. Bunker silo filling methods (full-length layers, top; progressive wedge, bottom).

Whatever method is used for filling, the silage should be distributed in thin layers. The tractor should then be driven over the whole surface as many times as possible before the next load arrives. To obtain the best packing, the tractor should be heavy with single instead of dual wheels. Four-wheel drive tractors provide the best control and traction on moist and loose forage. An industrial loader with a heavy duty transmission is often the loader of choice for larger feeding operations.

The bunker should be filled as quickly as possible. This is why it is desirable for hay silage bunkers to hold a single cutting. This bunker can be filled and covered without having to be uncovered when the harvest progresses quickly.

Oxygen causes silage spoilage. Practices which exclude oxygen from the silage maximize the feed recovery from a bunker silo. Oxygen from the atmosphere is minimized by tightly packing the silage during filling and by covering the top surface with polyethylene. Weighting the polyethylene cover heavily and uniformly prevents the wind from billowing the polyethylene and sucking air into the space between the silage and polyethylene. Tires are the most popular items used to weight the polyethylene. Place the tires so they touch each other to minimize cover movement. Other weighting materials that have been used include soil and lime. Water that enters the silage carries oxygen that will enhance silage spoilage. Mound the silage surface before covering with polyethylene to ensure water will drain from the surface. Divert this water along the length of the bunker so the water does not flow between the bunker wall and the silage.

Proper silage removal techniques minimize face surface exposure to oxygen spoilage. Remove only as much polyethylene from the top surface exposing silage that will be needed during the next few days. The front-end loader should be used to shave the silage face from the top down. Forage accumulating on the bunker floor is then scooped up with the front-end loader. This procedure keeps a smooth, tight face with minimal exposure to oxygen. It is tempting to stab the front-end loader bucket into the face and lift. This opens fissures and allows large amounts of silage to loosen. However, these fissures allow oxygen to penetrate deep into the silage face exposing more silage to spoilage.

Silage made in bunker silos using good management practices (including a polyethylene cover) can be expected to produce storage losses of 10 to 15 percent of the original dry matter. Poor management practices (without a cover) might yield losses as high as 30 to 40 percent. Consider an example where one of the 24 feet by 120 feet corn silage bunkers (each holding 196 tons dry matter) designed earlier is not covered. The value of the silage is assumed to be $40/ton dry matter. Also assume, for this example, the dry matter loss is 15 percent higher for the uncovered compared to a covered bunker. The feed value lost as a result of not covering the silage can be estimated by the following equation:

Feed Value Lost ($) = Bunker Capacity (total ton DM) x Difference in Estimated Losses (fraction of % loss) x Value of Silage ($/ton DM)

For the above example:

Feed Value Lost = 196 tons DM x 0.15 fraction loss x $40/ton DM = $1176

Assuming a polyethylene cover costs $200, the return is $976 ($1176 minus $200) not including tires or labor. The total time to cover and uncover a bunker this size will be about 16 man-hours. If tires are at no cost and labor is $10/man-hour, the return to management for covering the bunker is $816 ($976 minus $10/man-hour x 16 man-hours). Naturally, the return when using a cover on higher valued forage such as alfalfa would be much greater.

Note: Material adopted from information by B.J. Holmes and D.W. Kammel, University of Wisconsin, Madison, and J.P. Chastain, University of Minnesota, St. Paul.

Raymond L. Huhnke

Professor and Extension Agricultural Engineer