Basics of Paper Manufacturing

Paper is a thin sheet usually manufactured from cellulose pulp derived from wood and other lignocellulosic materials such as cotton, rice or wheat straw for writing, printing and packaging purposes. Some of the important production processes and properties of different kind of papers will be reviewed in this fact sheet.

It is believed that paper originated in China in the 2nd century as alternative writing material to silk. Production of paper was introduced to Europe in the 12th century. Almost 200 years of mechanized production of paper resulted in significant changes in information networking all over the world.

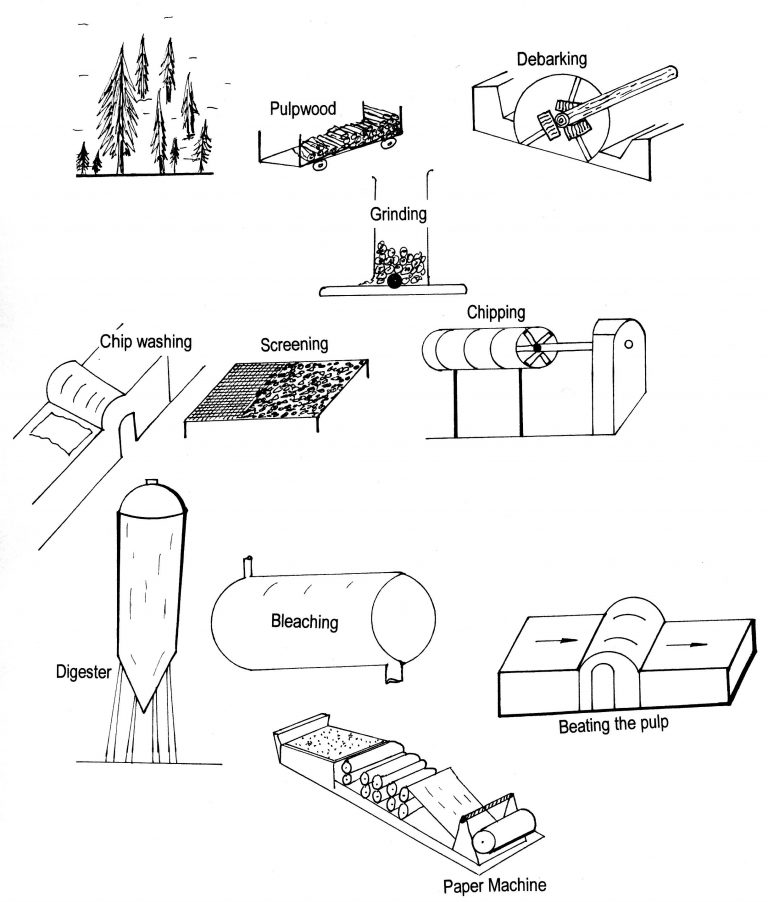

The first step in a typical paper manufacturing process is to produce pulp from wood chip. Softwoods, such as spruce and pine with slender, strong and elastic fibers, are most commonly used species in North America. In general, pulp, which is the raw material of paper, can be manufactured using two methods: chemical pulping or mechanical pulping.

The first one involves breaking down the chemical structure of lignin into a liquid using different chemicals, including sodium hydroxide and sodium sulfide. Cooking liquor is a by-product of the production, which is washed from cellulose fibers to produce pulp. Chemical pulping is used to produce higher quality paper with more expensive production cost than that of mechanical pulping.

Mechanical pulping can further be classified into two subgroups, namely ground pulping and thermo-mechanical pulp (TMP) that does not remove lignin from the fibers in contrast to chemical pulping. In both methods chips are simply fed into a refiner to disintegrate and to convert the material into fiber bundles. The refiners are consisted of steam-heated rotating steel discs having different types of profiles. The final product of TMP is unbleached, dark pulp with short-length fibers. The main advantage of this kind of pulp is it has a higher yield than that of chemical pulping. The second one is a more commonly used method to produce paper with low strength properties.

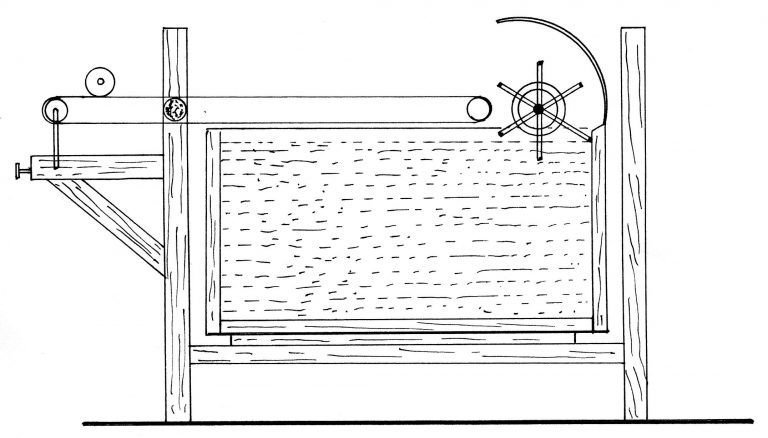

Initially, paper was made manually as single sheets until the invention of paper machine by Louis Robert in France in 1799. Figure 1 illustrates schematics of the first paper machine of Louis Robert.

Figure 1. Schematics of the first paper machine of Louis Robert.

Today, the Fourdrinier paper machine is extensively used to form the fiber mat for production of various types of papers, such as writing and drawing papers, printing and newspaper, wrapping and tissue paper, and other special papers. Typical mechanized paper production involves two main processes: the treatment of raw material, which includes converting chip into pulp, washing and bleaching, refining, beating, sizing, coloring of the fibers, and later to form paper sheet in a Fourdrinier machine.

For writing purposes whiteness of paper is important, therefore, pulp is bleached using mostly oxygen bleaching techniques rather than chlorine bleaching due to its high environmental pollution problem. Dark color lignin is removed during the bleaching process. Most of the strength of paper comes from hydrogen bond between fibers. Beating and refining of the pulp increase surface area of fibers so that better contact between fibers will result in higher mechanical properties of the paper.

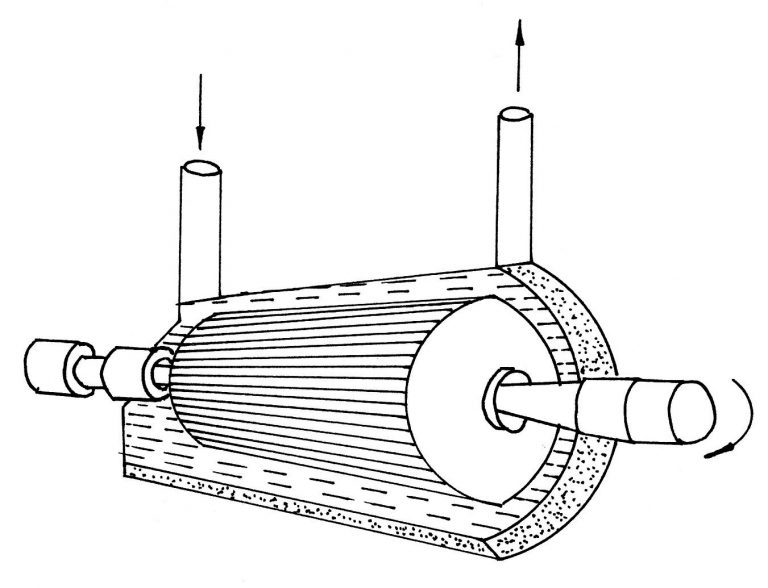

A conical refiner is a widely used machine to improve pulp quality, as shown in Figure 2. Pulp flows on the screen of the Fourdrinier, and water is drained away with the help of a series of vacuum boxes and other equipment before a thin sheet of fiber mat is formed. Speed of the sheet in the machine ranges from 1,200 fpm (13.6 mph) to 5,000 fpm (56.7 mph). Once the paper web is formed in a sheet, its moisture content is reduced first using suction units, called the wet press area, and later by drum type dryers. Paper sheet continuously runs through a series of stainless steel drums heated up to 200oF (93oC) to ensure the sheet has an approximate 4-5% moisture content.

Figure 2. A conical refiner machine to improve pulp quality.

Calendering is a process to enhance both physical and mechanical properties of paper as it passes through a specially designed series of drum type rolls as a result of friction. For example, surface finish of newsprint is mainly due to calendering process. Depending on the type of paper, further finishing processes are needed. Application of coats of various types of chemicals applied to the surface of the paper make it extra shiny for special applications, such as art papers. In general, coated papers are classified into three groups: matte, semi matte and glossy.

Finally, the paper sheet is wound into large rolls, and then, they become ready to be shipped. Figure 3 shows the main steps of typical paper manufacturing.

Figure 3. The main steps of typical paper manufacturing.

Evaluation of Some of the Properties of Paper

Physical and mechanical properties are very important in determining overall quality of the final sheet. Tensile strength, compression strength, bending stiffness, tear and burst resistance are some of the mechanical properties of paper. Measure of the force perpendicular to the plane of the paper required to tear several pieces is used to evaluate tearing resistance. Burst strength is determined by applying pressurized air to the surface of the sheet. Stiffness is determined by bending a small sample in both directions in specially designed equipment, such as a Taber Instrument.

Opacity, the measurement of light passing through a sheet of paper and brightness and the percentage of light reflected from the surface of paper are two physical characteristics influencing overall printing quality. Also, texture of paper, including smoothness and finish quality, is important for many applications.

A sufficiently smooth surface is a basic requirement for most printing papers for proper transfer of ink. Surface smoothness of paper is well known to correlate with printability. Efforts to measure the surface smoothness can be classified into two groups: simulating the printing process by pressure on the surface and determining an original surface profile.

The Sheffield smoothnesstester, which measures the air leak in contact with paper under the condition of a fixed weight of measuring head, is a typical example of the first group. The stylus profilometer that falls in the second group presents an original surface profile of the paper as accurately as possible.

Information about Pulp and Paper Manufacturing

The Technical association of the Pulp and Paper Industry

Patrick, K., 1998 Primer of Pulp and Paper Making: Technologies and Production Practices.

Smith, M. 1997. The U.S. Paper Industry and Sustainable Production.

Macdonald, R.G. Ed. 1970. The Pulp and Paper Manufacture. TAPPI.

Volume 1. The Pulping of Wood.

Volume 2. Control, secondary fiber, structural board, coating.

Volume 3. Papermaking and Paperboard Making.

Salim Hiziroglu

FAPC Value-added Wood Products Specialist