Are You “Sweeping” Your Grain Bin Safely?

Introduction

The Occupational Safety and Health Administration (OSHA) has been concerned about the safety surrounding sweep augers since 2009. The OSHA Grain Handling Standard 29 CFR 1910.272 was interpreted by OSHA to mean that an employee could not enter a grain bin while the sweep auger was engaged. About four years later, and after much discussion with industry, OSHA backed off its ruling to a certain extent. In a memorandum issued in May 2013, OSHA agreed that workers could be allowed into a bin with the sweep auger engaged if certain conditions were met. These conditions are listed below. The OSHA standards listed in this fact sheet are available at the www.osha.gov website by searching for the number of the standard.

While not all farms are under the jurisdiction of OSHA, the same safety guidelines

are good “best practices” to follow to keep workers and family members safe while

working around grain bins. If a farm bin has a sweep auger, efforts to meet the conditions

below will certainly help to provide a safer working environment and could potentially

save a life or a limb from entanglement.

Reducing Danger when Operating Sweep Augers

These 10 steps are required by OSHA and go a long way in keeping workers safe when entering and working around grain bins.

1. Workers must obtain a bin entry permit certifying that the precautions contained in 1910.272(g) have been implemented, unless the employer or the employer’s representative who would issue the permit is present during the entire operation. (An example of a bin entry permit is given at the end of this fact sheet.)

2. The grain entry points and the subfloor auger must be de-energized and locked out/tagged out before anyone enters the bin. Figure 1 demonstrates locking out/tagging out of an energy source.

Figure 1. Lock out/tag out of electrical equipment.

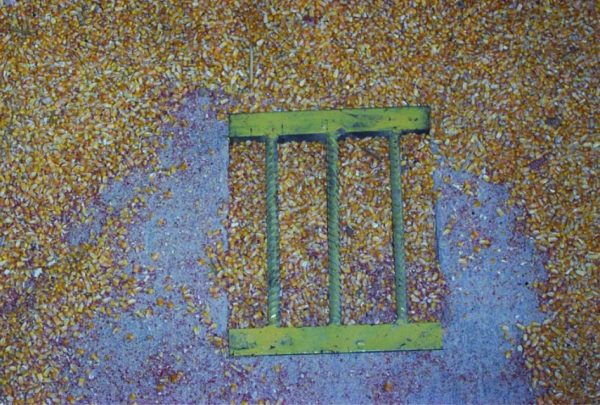

3. Grates/guards must be in place and SECURED on the subfloor auger sumps before the sweep auger is operated. The grates must be secured against all forces that could act on the guard in such a way that it might be displaced. Figures 2 and 3 show an unguarded sump opening and the same sump opening with a guard imposed on the figure. The unguarded sump opening is a safety hazard because workers could step into the sump. Many limbs have been lost and deaths have occurred in unguarded sump openings with the subfloor auger in operation. Figure 4 shows a guard in place but not properly secured. Figure 5 shows a guard that can be securely attached. The space between the bars on the grates is determined by the distance between the bin floor and the auger flights or paddles (Figure 6).

Figure 2. Unguarded bin sump.

Figure 3. Guarded bin sump.

Figure 4. Improperly secured grate.

Figure 5. Grate with proper secure mounting modifications.

Figure 6. Sump opening guard design requirements.

4. Walking on the grain where the depth of the grain presents an engulfment hazard is forbidden.

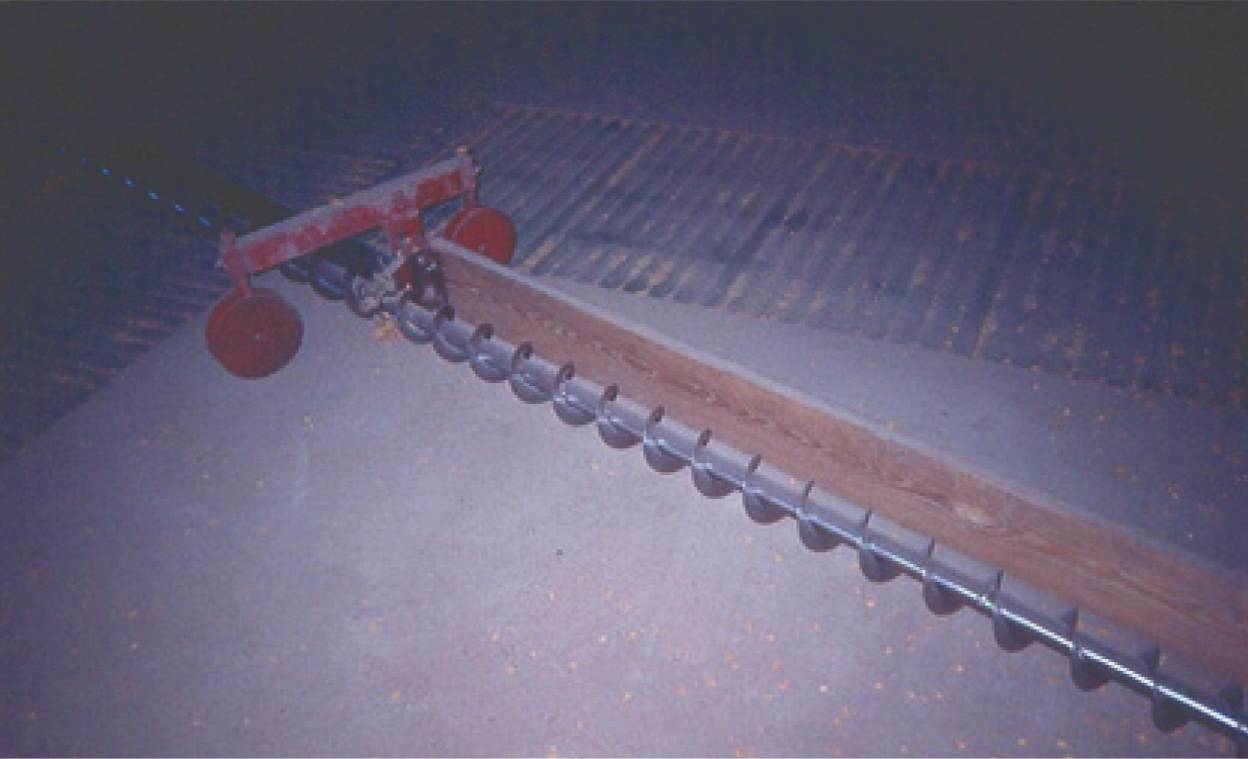

5. Sweep augers, including portable sweep augers, must have guards that protect against

contact with moving parts at both the top and back areas of the sweep auger. The only

unguarded portion of the sweep auger should be the front point of operation. Figures

7 and 8 show an auger with no acceptable guarding and an auger with an acceptable

guard system.

Figure 7. Unguarded sweep auger.

Figure 8. Sweep auger with acceptable guarding.

6. An observer must be positioned outside the storage structure and have contact with the person working in the bin either through sight, radio or voice. This observer must be trained in emergency procedures and rescue, and know who to contact in case of an emergency.

7. When the sweep auger is energized, a worker may enter the bin if grates are secured

over the sumps (see step 3) and the worker must use engineering controls within the

bin to prevent the worker from coming in contact with the operating sweep auger.

These engineering controls may include:

a. Sweep auger equipped with an attached guard preventing contact with the worker

on the unguarded portion of the auger (29CFR1910 Subpart O, machinery and machine

guarding).

b. Sweep auger equipped with a dead man switch or similar device that allows operation

only when the operator is in contact with the device (Figures 9 and 10). The worker

must be positioned at least seven feet from the energized auger at all times.

Figure 9. Sweep auger “dead man” handle that energizes the sweep auger only when the worker grips the handle.

Figure 10. “Dead man” control handle for sweep auger.

c. Workers in the bin other than the person operating the sweep auger must also be protected in such a manner that they are kept out of the danger zone of the auger. This may be achieved by catwalks or guardrails. All devices should meet 29CFR1910 Subpart O (Figures 11 and 12).

Figure 11. Sweep auger worker protection fencing.

Figure 12. Worker protection caging and sweep auger controls.

8. The auger has a positive speed control mechanism or bin stop (Figure 13) device that prevents uncontrolled rotation around the bin. These bin stops are for direct drive sweep augers. Hydraulically driven sweep augers are positive speed control augers.

Figure 13. Bin stop for limiting sweep auger travel.

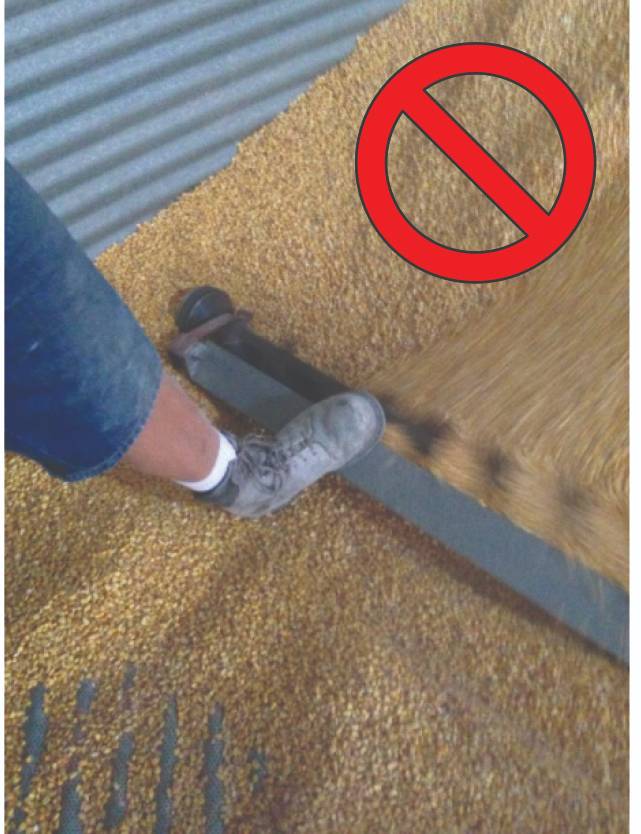

9. Workers may not use their hands, legs or similar methods to directly manipulate (dislodge) the sweep auger while it is energized (Figures 14 and 15).

Figure 14. Unsafe handling of a sweep auger with foot.

Figure 15. Moving grain around the sweep auger with a foot is an unsafe practice.

10. The sweep auger must be de-energized and unplugged during maintenance and adjustments. The person doing the maintenance must maintain control of the lock out/tag out equipment or the plug (see Figure 1).

Zero-Entry Sweep Augers

Clearly, the safest place to be when unloading or working around a grain bin is outside the bin. If workers do not need to enter the bin to dislodge out-of-condition grain clumps and bridges, entrapment and engulfment do not occur. There are two factors that help to keep workers out of bins: keeping grain in good condition, so clumping and bridging do not occur and using zero-entry sweep augers. In the past decade, bin sweep manufacturers have made great advances in sweep design. Zero-entry sweep augers are controlled from outside of the bin and are robust enough to handle out-of-condition grain without help from workers entering the bin.

When purchasing a zero-entry sweep auger, consideration for the types of grain and

how often the bin is swept is important. Different types of grain and higher moisture

content grain require greater horsepower and larger clearances. Emptying bins completely

to the floor more frequently makes it easier for bin sweeps to move the remaining

product to the sump openings. Upgrading an existing sweep auger to “zero-entry” is

something to consider in some situations. Be sure to work with a reputable dealer

of zero-entry bin sweeps when making the decision to retrofit existing equipment or

purchase new equipment. If a current sweep auger requires a cord to be run into the

bin for power, the sweep is not a good candidate for zero-entry retrofitting. A person

must enter the bin to plug the cord into the sweep or retrieve the cord to plug in

to power outside of the bin, thus “zero-entry” is not possible.

Grain facility managers report great benefits from installing and using zero-entry

sweep augers. These benefits include:

- Reduced time to sweep out bins. Therefore, bins get swept out more often and out-of-condition grain does not develop when old grain is left repeatedly in the bottom of bins.

- Temporary help may be used with reduced training requirements because workers do not have to enter the bin.

- Bins can be used for multiple commodities because of the ease and completeness of bin clean out.

- Added efficiency in unloading a bin. The sweep can work 24/7 while workers may not be available for continuous work assignments. This reduces an otherwise two- or three-day task to a task that takes just a few hours.

- Significant reduction in risk because workers do not enter the bin until it is completely empty.

Sweep Auger Policies

Commercial grain facilities and facilities that must meet OSHA standards should have a sweep auger use and maintenance policy. The National Grain and Feed Association has produced an excellent resource that gives an example of just such a policy. This information may be accessed at: Guidance for Sweep Auger Operations in Grain Bins

The policy is based on the 10 steps reported in this fact sheet. It also provides definitions of terms used in the OSHA policy as well as in the 10 steps. Training is addressed along with safety steps, preparation for sweep-cleaning operations and disciplinary action for employees not willing to follow the requirements set forth in the operating guidelines.

Summary

With planning, training and coordination, the risks that are inherent in working inside grain bins can be reduced. Equipping with safety features and having management policies in place certainly help workers stay safe. Grain bin sweeps are an important part of the unloading process of grain bins. Guidelines for safe working conditions are in place and must be followed. When the 10 steps listed above are followed, incidents involving injury and death are greatly reduced, and in most cases, eliminated. When these methods become habit in a facility, the safety culture of the facility is greatly reinforced.

CONFINED SPACE ENTRY PERMIT

Example (Other examples are available on the Internet) (click link below)

References and other information sources

Grain and Feed Association of Illinois Safety, Health and Environmental Services Update newsletter, Vol. 25, No. 7, October 2, 2013.

Grain Journal. 2017. Sweep Auger Safety. September/October Issue, pps. 38 – 48.

National Grain and Feed Association. 2013. Guidance for Sweep Auger Operations in

Grain Bins.

Occupational Safety and Health Administration 29CFR1910. 272 Grain Handling Standard.

Carol L. Jones, PhD, PE

Professor and Orville L. and Helen L. Buchanan Chair

Stored Products Engineering