Anaerobic Digestion of Animal Manures: Understanding the Basic Processes

Producing methane from manure is fairly straightforward. Seal manure in an airtight container and it forms biogas: a mixture of methane (CH4), carbon dioxide (CO2), and trace amounts of other gases. The process is so automatic, before Pasteur, anaerobic digestion was considered a prime example of spontaneous generation. The organisms producing biogas were believed to spawn directly from manure. Now that the germ theory is widely accepted, we know it takes two elements to start biogas production: organic matter and a seed community of microorganisms. Fortunately manure contains both. Fresh manure is 80 percent to 90 percent organic matter, and most domestic animals continuously excrete live cultures of biogas producing organisms from their colons.

Anaerobic Digestion is the Work of Microbial Communities

Behind anaerobic digestion’s apparent simplicity are complicated interactions involving several microbial communities. Each community completes a separate step in digestion. Each community produces its own waste, and the waste of one is the food of another.

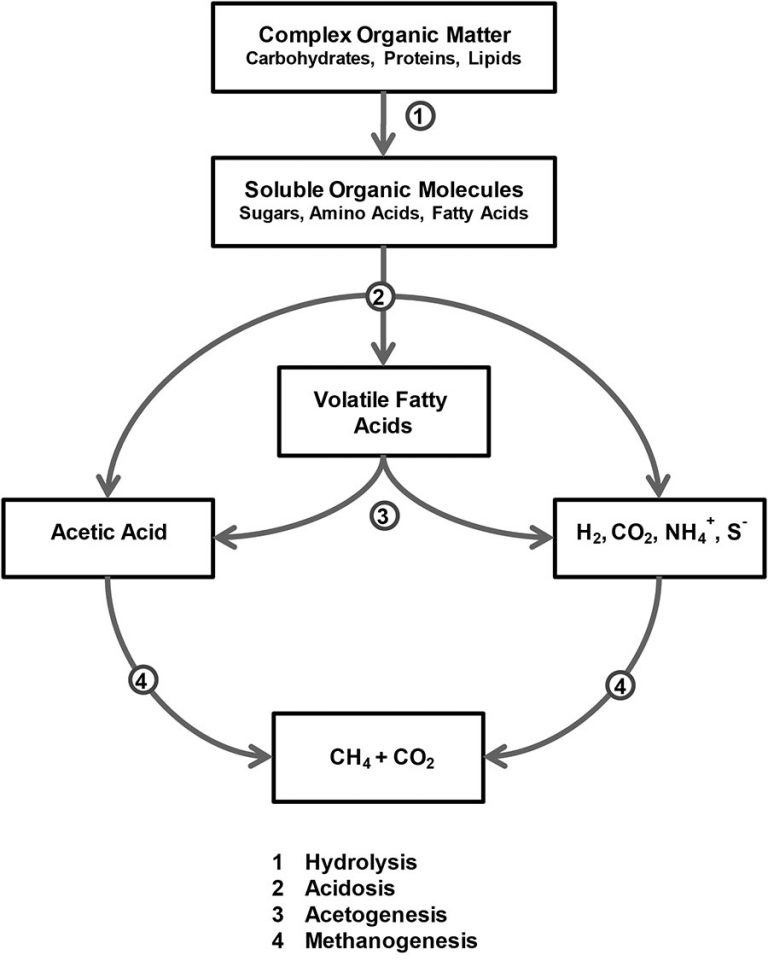

Anaerobic digestion involves two to four steps, depending on where you draw lines in the process (Figure 1). Communities of hydrolytic bacteria (sometimes called liquefiers) break complex organic matter down into simpler compounds. Acid forming bacteria (acidifiers) convert the simple compounds to volatile fatty acids – principally acetic acid (vinegar). Hydrolysis (liquid formation) and acidosis (acid formation) are commonly lumped together and called anaerobic fermentation. Some microbiologists also distinguish between formation of mixed volatile fatty acids (acidosis) and the creation of acetic acid from the mixture (acetogenesis).

Figure 1. Steps in Anaerobic Digestion.

Methanogens are methane forming microorganisms belonging to the Archaea domain — very simple, single cell organisms similar to bacteria. Methanogens take the end products of fermentation – volatile fatty acids, hydrogen gas (H2), CO2, and water (H2O) – and use them to form methane. Methanogens fall into two camps depending on the pathway they use to produce methane (Figure 2). All methanogens reduce CO2 and H2 into CH4 and H2O. Those that use this pathway exclusively are called hydrotropic methanogens. Methanogens that cleave acetic acid to CH4 and CO2 are called acetotrophic methanogens.

Figure 2. Major Pathways of Methane Formation.

Carbon dioxide reduction: CO2 + 4H2 -> CH4 + 2H2O

Acetic acid cleavage: CH3COOH -> CH4 + CO2

Growth of Biological Communities

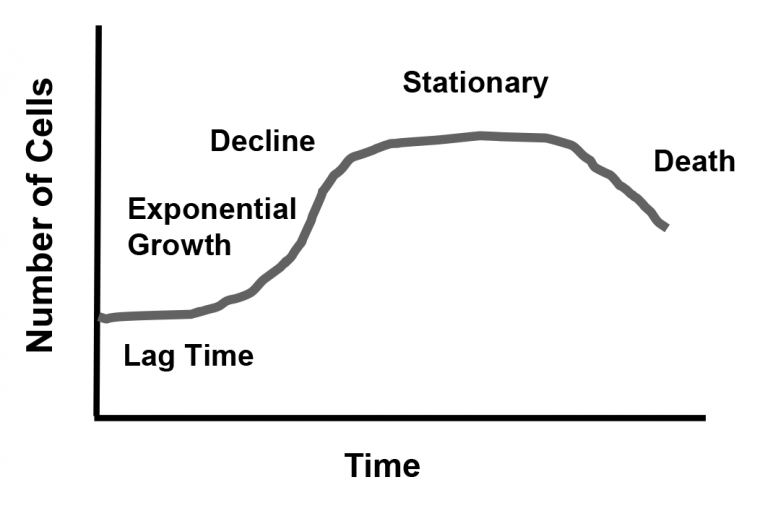

Given a limited food supply and no restriction on growth, all biological communities, whether microbial or human, follow the predictable pattern of growth and decline shown in Figure 3.

The lag time occurs as organisms acclimate to their environment. During the exponential growth phase, food is not limiting and population expands rapidly. It is called exponential growth because the growth pattern follows an exponential curve. Another term for the exponential growth phase is log growth, because growth increases by a factor of ten. Growth slows as the community begins to meet the limit of its food supply in the decline phase. The food is all but exhausted during the stationary phase. Reproduction does not stop during the decline and stationary phases. Individual organisms continue to live, reproduce, and die. The death rate equals the reproduction rate during the stationary phase. The death rate exceeds the reproduction rate during the death phase.

In sewage treatment, the death phase is sometimes called endogenous respiration, and it is used to reduce the mass of organisms in aerobic processes. The communities are so starved during endogenous respiration the living survive by devouring the bodies of the dead.

Many anaerobic organisms, including methanogens, have the ability to go dormant during periods of food shortage. The two coping mechanisms are spore formation and a kind of suspended animation. Dormancy begins during the stationary phase. This dormancy of anaerobic microorganism means an anaerobic digester can be easily restarted after long periods of inactivity.

Continuous Growth in Reactors

An important concept to grasp is the doubling rate or the reproduction time of an organism. This is the time needed for a population to double in size during exponential growth. In other words, it is the time required for the community to replace itself. Anaerobic digesters are biological reactors. They are designed to keep microbial communities in exponential growth. Three control parameters: Hydraulic Retention Time (HRT), Solids Retention Time (SRT), and Organic Loading Rate (OLR) are used to make sure individual organisms remain in the reactor longer than their reproduction time.

Hydraulic Retention Time (HRT)

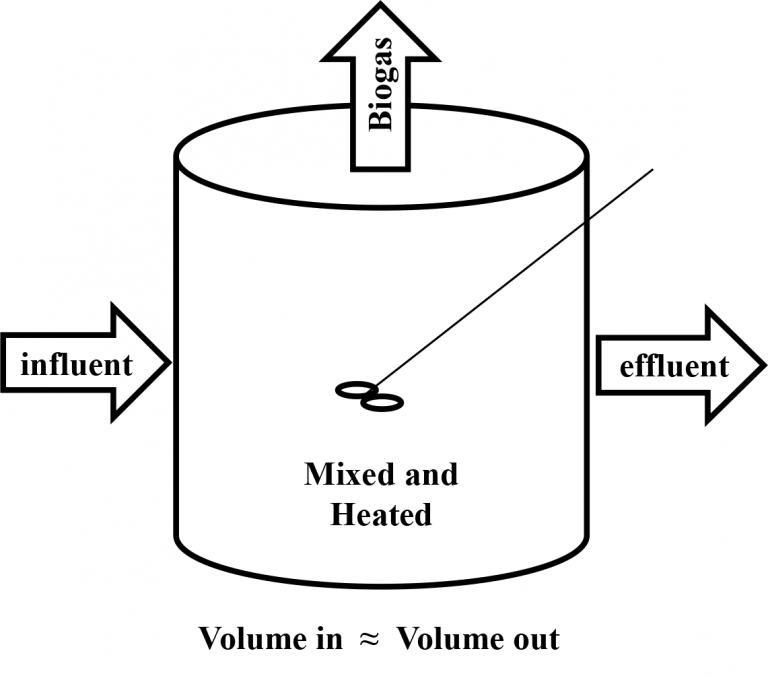

Anaerobic digestion commonly takes place in a liquid, continuous flow reactor (Figure 4). If the working volume of the reactor does not change, the volume entering the reactor (influent) equals the volume leaving (effluent). The time liquid remains in the reactor is calculated by dividing the reactor working volume by the effluent flow rate. This time is called the hydraulic retention time of the reactor, abbreviated as HRT.

If the reactor is completely mixed and microorganisms are completely suspended in the reactor, the time the microorganisms remain in the reactor equals the HRT. If the HRT equals the reproduction time, a new cell is formed to replace each cell leaving the reactor, and the population within the reactor remains stable. If the HRT is shorter than the reproduction time, a new cell will not replace the one leaving, and the population declines, or “washes out.”

Figure 4. Completely Mixed Anaerobic Digester.

Solids Retention Time (SRT)

Reducing HRT decreases reactor size, and small digesters cost less than big digesters. Therefore, high rate digesters are designed to keep microorganisms in a reactor longer than the reactor’s HRT. Cell retention time is calculated by dividing the mass of microorganisms trapped in the reactor by the mass of organisms leaving the reactor with effluent. If cell retention time equals reproduction time, the microbial population remains stable.

It is easier to measure the total mass of solid particles suspended in liquid than the mass of living organisms. Cell retention time is approximated by Solids Retention Time (SRT), or the mass of solids in the reactor divided by the mass of solids leaving the reactor.

Organic Loading Rate (OLR)

The growth stages of Figure 3 are determined by the relationship between the population of a community and its food supply. This relationship is summed up as the Food to Mass Ratio (F:M) of a reactor, or the mass of organic matter available per mass of microorganisms living in the reactor. A simpler method of describing this relationship, one that does not depend on knowing the mass of organisms, is the Organic Loading Rate, abbreviated OLR. Organic loading rate is the mass of organic matter entering a digester every day divided by the working volume of the reactor. It is also equivalent to the concentration of organic matter flowing into the digester divided by HRT.

“The higher the OLR of a digester, the higher the biogas production” is true up to a point. It is possible to overfeed a digester. One community may process food faster than the next one can remove its waste. The presence of waste products in the digester may inhibit the growth of a microbial community. It is also best to keep OLR fairly constant. Sudden increases in feeding can cause bursts of gas production, which leads to foaming and scum formation in the digester.

Conditions for Optimal Digestion

Temperature

Methanogens thrive in two temperature ranges: thermophilic and mesophilic. Thermophilic (heat loving) methanogens are fast growing (reproduction time 10 to 15 days), but they operate in a fairly narrow band of temperature centered on 55 C. Mesophilic methanogens are slower growing (reproduction time up to 30 days), but they tolerate a wider range of temperatures. 35 C is optimal for mesophyllic methanogens, but they can tolerate much lower temperatures. Provided they have sufficiently long SRT, digesters operated at 20 C do not show substantial loses in gas production when compared to those operated at 35 C.

pH and Alkalinity

The optimum pH range for anaerobic digestion is neutral to slightly basic (pH 6.6 to 7.6). The ability of a reactor to resist changes in pH is called alkalinity. A complex set of naturally occurring buffers control pH within anaerobic digesters, with organic acid-ammonia and carbonate-bicarbonate being the most important buffers.

Inhibitory Materials

Methanogens are strict anaerobes, meaning the least amount of oxygen is poison to them. Acid forming bacteria are more tolerant of oxygen. So, if oxygen gets into an anaerobic digester, methane concentration will drop and carbon dioxide concentration will increase in the biogas.

Identification and control of inhibitory substances is the subject of another Fact Sheet in this series, BAE 1763, Anaerobic Digestion of Animal Manures: Inhibitory and Toxic Materials. The most common on-farm materials that inhibit methane formation are antibiotics, cleaners, sanitizers, disinfectants, ammonia, sulfate and sulfide, heavy metals and salt.

Upset or Pickled Digesters

Fermentative bacteria are generally more robust and faster growing than methanogens. The first indication that something is wrong with a digester occurs when the acid formers start to overpower the methane formers. The volatile fatty acid concentration of the reactor liquid increases, reactor pH drops, methane concentration in biogas decreases, and eventually biogas production declines. Upset conditions are monitored by measuring pH and the ratio between volatile fatty acid concentration and bicarbonate alkalinity. The relationship between fermentative and methanogenic communities can become so unbalanced that even the acid formers can no longer tolerate the low pH. At this point we say the digester is “stuck,” has “soured” or it has “pickled.” Basic steps to follow for digester upset are:

- Reduce OLR.

- Stabilize pH by adding a source of alkalinity

- Determine and correct the cause of the imbalance.

- Slowly increase OLR while maintaining neutral pH.

Summary

Anaerobic digestion is a naturally occurring and nearly spontaneous process. Digesters have the undeserved reputation of being finicky and easy to upset. By gaining a basic understanding of the biology going on in the digester and following a few simple steps to correct upset conditions, a digester can steadily produce biogas for years on end without special treatment.

References

Cundiff, J.S., and K.R. Mankin. 2003. Dynamics of Biological Systems. St Joseph, MI: ASABE.

Darling, D. 2009. The Internet Encyclopedia of Science. www.daviddarling.info/encyclopedia.html. Accessed May 16, 2009

McCarty, M.L. 1964. Anaerobic waste treatment fundamentals. Public Works, Sept-Dec. 1964.