An Introduction to the Land Application of Drilling Mud in Oklahoma

With the recent boom in oil and gas exploration there also is an increase in waste produced from the drilling process. Many agricultural producers have opportunities to provide their property as disposal sites for drilling “mud” applications and receive payment in return. Most producers will have the material applied to pasture or rangeland that has a relatively low production capability. Depending on many factors, the land application of drilling mud may or may not inhibit future production. There has been little research conducted about potential impacts of drilling mud application on land quality. This Fact Sheet aims to provide some of the basic information to help producers make an informed decision.

What is Drilling Mud?

Drilling mud is the material created for the purpose of drilling oil and natural gas wells; the “mud” is pumped into the hole during the drilling process to help cool and lubricate the bit, suspend cuttings, seal the formation, and control well bore pressure. During this process, the mud is continuously recycled to remove solids until it can no longer be utilized for drilling. Options for disposal include injection wells, pits, and land application. The terms “land farming” and “soil farming” are often used synonymously with land application, although the former terms are technically reserved for remediation of contaminated materials and soils, while the purpose of land application is to prevent the contamination of soils.

The initial mud (prior to use in drilling) contains several chemical additives. These may include bentonite clay (soil mineral), sodium carbonate, lime, barium sulfate, lignite, and “loss circulation materials” such as ground peanut shells, mica, cellophane, walnut shells, plant fibers and cottonseed hulls.

Figure 1. Field application of drilling mud.

Types of Mud

There are two main types of drilling mud that are produced and land applied: water-based mud (WBM) and oil-based mud (OBM). The main difference between WBM and OBM is the solvent (liquid) used as the “base.” For WBM, the solvent is water and for OBM it is diesel. WBM is more common and is typically utilized in the shallow (0 to 3,000 feet) vertical portion of the well drilling and OBM is used in the deeper and horizontal portions.

Water-based Mud (WBM)

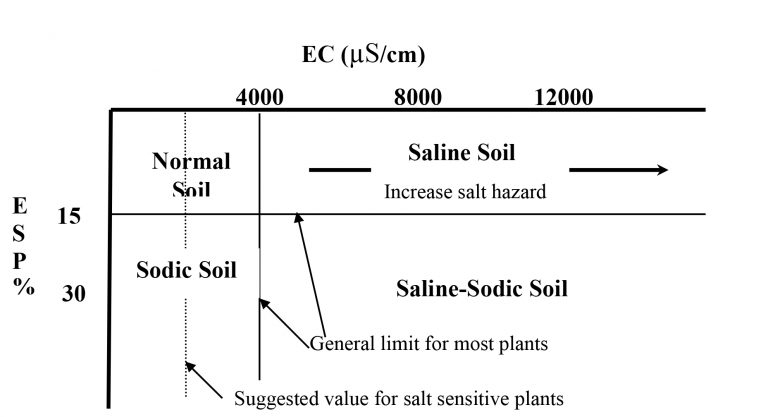

WBM consists mostly of water; the solids content will vary but is often around 8 percent. As a result, WBM is usually applied as a fluid suspension. The pH of WBM is often alkaline (pH > 10). The biggest concern with land application of WBM is salinization, or high salt content; WBM may also contain high concentrations of sodium salt in addition to high total salt content. Electrical conductivity (EC) is an indicator of salt content. If a soil becomes saline (>4,000 µS/cm or 2,600 ppm) with non-sodium salts resulting from WMB application, plants may have difficulty obtaining water due to excessive osmotic potential even if there is plenty of water available for them, depending on how sensitive different plants are to salts. However, with added rainfall or good quality irrigation, the salts may be leached out of the root zone. If a soil becomes high in sodium, or “sodic” (>15 percent exchangeable sodium; ESP) due to excessive WBM application, then there will be further problems with poor soil structure, decreased drainage, and accelerated erosion. Such a situation requires the application of gypsum to displace the sodium, allowing it to leach out of the root zone with rainfall or irrigation. The OSU Soil, Water, and Forage Analytical Laboratory can determine if a soil is saline or sodic based on the results of the “comprehensive salinity” test as illustrated in Figure 2.

Figure 2. Salinity and sodicity thresholds in soil electrical conductivity (EC) and exchangeable sodium percentage (ESP).

Oil-based Mud (OBM)

The solids content in OBM varies between 50 percent and 85 percent, and is therefore applied as a solid. The material usually smells like diesel fuel and is black in color. It is the diesel used as the solvent for the mud that contains “petroleum based hydrocarbons,” often analyzed and referred to as “total petroleum hydrocarbons” (TPH). The TPH can be toxic to plants at high concentrations. Immediately after application of OBM, soil TPH levels may be high; however, the goal of land application is fast degradation of TPH to non-toxic levels. Native soil microorganisms will consume and metabolize the TPH converting it into water and carbon dioxide. Conditions that favor the growth of microorganisms such as nutrients (N, P, K), adequate aeration (oxygen), suitable temperature, moisture and pH, therefore favor TPH degradation.

Threshold levels of soil TPH vary depending on the source of information and the context.

The OK Guardian (produced by the Oklahoma Corporation Commission; OnePetro has set a level of 10,000 mg TPH kg-1 (20,000 lbs acre-1) soil as the limit for plant

protection; and 2,600 mg kg-1 (5200 lbs acre-1) for residential areas. The Oklahoma

(OK) Department of Environmental Quality (DEQ) defines the “tier 1 generic cleanup

level” for residential soil as 50 mg TPH kg-1 (100 lbs acre-1) and 500 mg kg-1 (1000

lbs acre-1) for industrial sites (DEQ). The OSU Soil, Water, and Forage Analytical Laboratory can measure TPH in solid/soil

samples and liquid samples. Please contact your local county Extension office for

more information on soil salinity and TPH testing.

Within the category of TPH chemicals, those of most concern are “BTEX,” or benzene,

toluene, ethylbenzene, and xylene. Of those, benzene is the most important, since

it is the most leachable. According to the OK Guardian, threshold soil benzene levels

are 44 mg kg-1 (88 lbs acre-1) for residential soils, 190 mg kg-1 (380 lb acre-1)

for non-residential soil. In regard to risk of groundwater leaching, the threshold

is 3 mg kg-1 if the receptor well is located directly beneath the benzene source.

The Guardian also lists residential or “sensitive” thresholds for toluene, ethylbenzene,

and xylenes at 6,700; 5,400 and 21,000 mg kg-1 soil, respectively (13,400; 10,800;

and 42,000 lbs acre-1). The OK DEQ lists 0.03 mg kg-1 (0.06 lbs acre-1) benzene as

the threshold soil level for “acceptable cleanup levels;” however, concentrations

beyond this level may not necessarily be a problem. Fortunately, relatively small

amounts of benzene are applied to soils through OBM application and the half-life

of benzene is fairly short; researchers have indicated a half-life (time required

for half of it to degrade) from 5 days to 30 days, depending on soil conditions. Others

have shown that 70 percent to 97 percent of benzene degrades in 25 days. Although

there is little information with regard to benzene uptake by plants, the few studies

conducted on this indicate that benzene is metabolized into non harmful compounds

by the plant.

Depending on the geology of the site where the well was drilled, constituents of OBM will vary. This is because the majority of the OBM is simply ground-up bedrock (i.e. drill cuttings) that result from drilling the hole. Some geologic materials will contain appreciable levels of calcium carbonate equivalent, and the resulting OBM could provide a natural liming effect to soils. Similarly, some OBM could also contain nutrients such as Mg, Ca, and K depending on the local geology, in addition to original mud additives such as lime.

With regard to variations in geology and potential contaminants, it is unlikely but possible that some OBM samples could contain elevated levels of trace metals such as copper, zinc, lead, arsenic, chromium and molybdenum. The source of metals would not be from a mud additive, but from bedrock naturally elevated in metals. Therefore, potential metals content would vary spatially throughout the state with regard to the contents of naturally occurring geological formations. Trace metals in WBM are highly unlikely, since the material is mostly made up of water, and trace metals are extremely insoluble at the pH levels observed in WBM. Another public concern is radiation in OBM, also known as NORM (naturally occurring radioactive material). It is possible, but unlikely for geologic materials (i.e. ground up bedrock in OBM) to be elevated in NORM beyond safe levels. The NORM of topsoil generally ranges from 0.2 to 4.2 pCi/g and the threshold for safe land application is 30 pCi/g. NORM is typically expressed as the sum of radium-226 plus radium-228. Little to no data is available on the metals and NORM content of drilling mud.

Regulations Concerning Land Application of Drilling Mud

Drilling waste is categorized by USEPA as a “special waste,” and is exempt from federal hazardous waste regulations under subtitle C of the Resource Conservation and Recovery Act (RCRA). Land application of drilling mud is regulated and permitted by the Oklahoma Corporation Commission (OCC). The rules are specifically stated in the Oklahoma administrative code and register (www.oar.state.ok.us), Title 165. Rules for land application of WBM and OBM are found in 165:10-7-19 and 165:10-7-26, respectively.

Some of the rules can be summarized as follows:

- Maximum of 8 percent slopes of the fields eligible to receive mud.

- At least 12 inches of "suitable" texture.

- Certain buffer zones must be observed (i.e. property boundaries, ponds, wells, etc.).

- EC less than 4000 µS/cm and ESP less than 10 percent in receiving soil.

- Minimum 20-inch depth to bedrock for WBM and 40 inches for OBM.

- No water table within top 6 feet of soil profile.

- WBM may be re-spread after three years has passed, and if soil requirements are met.

- OBM applied sites may not be re-applied with OBM or receive WBM.

The application rate of drilling mud is limited based on the following requirements, which must not be exceeded:

- 6,000 lbs/acre total dissolved solids (TDS) including soluble salts in the soil. TDS is often converted to EC by the equation: TDS (mg/L) = EC (mS/cm) X 640.

- 3,500 lbs/acre chloride.

- 40,000 lbs/acre TPH.

- 200,000 lbs/acre dry weight (i.e. solids).

Although not a rule, the OCC recommends that OBM be mixed with a bulking agent (usually

lime or gypsum) at a 3:1 ratio of bulking agent:OBM. In some cases, the addition of

the lime or gypsum bulking agent could be beneficial to production.

It is extremely important that the land applicator obtains a permit from the OCC and

follows these rules, as they are designed to protect the landowner and the environment.

Landowners should expect a temporary decrease in productivity; however, some landowners

may experience no decrease in yield. The purpose of payments made to the landowner

is compensation for potential losses. Some of the problems associated with land application

that has previously occurred are likely due to improper application by the spreading

company. For this reason, it is recommended the landowner research the reputation

of the application company prior to receiving drilling mud. Also contact the OCC for an open records request to find out if the company in question has received many

fines in the past.

Overall Recommendations

With regard to OBM, the main concern is total petroleum based hydrocarbons (TPH), but this should not be a problem if OCC rules are followed. Also, TPH will eventually degrade into carbon dioxide and water. Excess application of salts from WBM could present some long-term problems if WBM is not properly applied, since salts are removed from the system by leaching, which can be a slow process. Heavy soils (i.e. high clay content) and poorly drained soils are more likely to suffer from salt problems compared to sandy, well drained soils. Low rainfall will worsen salt problems. Applications of WBM during dry periods are more likely to result in problems compared to wet periods.

Figure 3. Application of a simulated WBM to research plots in Lahoma

Current State of Research and Gaps in Knowledge

Little research has been conducted on the land application of drilling mud. Oklahoma State University is in the early stages of conducting research on this. Current investigations include TPH degradation rates and forage yield from land applied with OBM, and variation in bulking agent mixtures. There is some interest in the impact of different bulking agents and rainfall timing on TPH degradation rates. Oklahoma State University has initiated simulated WBM-applied field plots for research and demonstration at the Lahoma field day (scheduled in 2013). Ultimately, the long-term goal, which may require several years and increased research funding, is to produce a site-specific tool for landowners to assess risk, potential yield reduction, time required for salt leaching, or alternatively estimate the maximum WBM application in which little to no yield reduction will occur. Updates in research findings will be posted as developed.