Alfalfa Stand Establishment

The objective of alfalfa stand establishment is to obtain about 25 to 30 vigorously growing seedlings per square foot before extreme weather conditions prevail. Proper planning, along with some good management practices, is essential to successful establishment. Although the exact steps required for successful stand establishment vary from farm to farm and from year to year, the principle practices for successful alfalfa establishment are described below.

Site Selection

Alfalfa will be most productive in deep, well-drained soils. In Oklahoma, the ideal soil for alfalfa is a sandy, silt, or clay loam greater than 25 inches deep with a slope less than 2 percent. Alfalfa needs soils capable of supplying 6 inches of available water for each ton of hay produced. Soils deeper than 25 inches are preferable, as alfalfa develops a long taproot that allows plants to scavenge the soil layers for water and nutrients. Even though deep soils are preferred for alfalfa production, good alfalfa production is still attainable in shallower soils (5 to 20 inches deep), if properly irrigated.

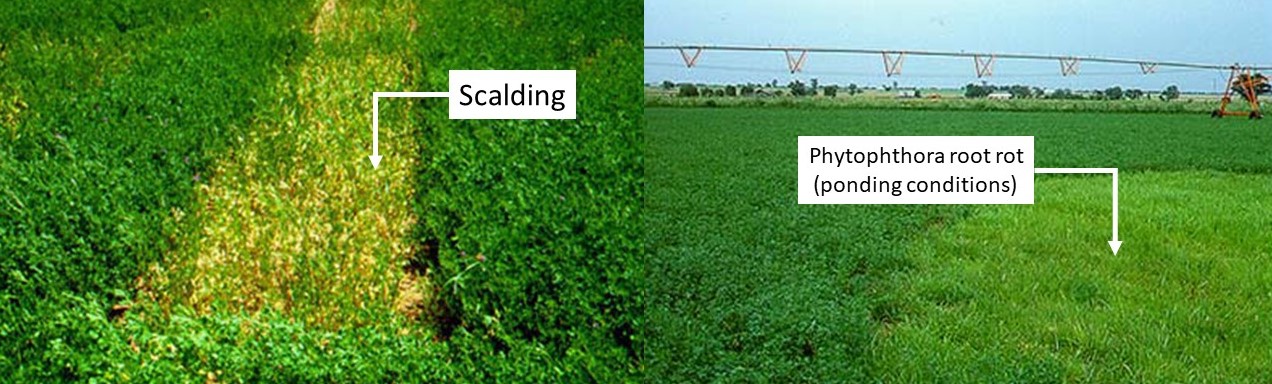

Alfalfa does not tolerate water-logging, and well-drained soils are required for optimum production. During summer, water logged soils combined with high temperatures can be lethal for alfalfa. This phenomenon is called alfalfa “scald,” which usually occurs in thin stands or just after harvest when foliage does not shade the soil on hot days. Alfalfa scald is sometimes mistakenly identified as a phytopthora root rot, but differs from root rot in that there is no pathogen involvement and no genetic resistance is available. Water-logged soil conditions during the winter result in ice sheeting, leading to plant root suffocation, toxic soil carbon oxide levels, crown injury and susceptibility to diseases. If soils with poor drainage cannot be avoided, select varieties with high resistance to root rot and apply fungicides for establishment.

Topography is another critical consideration when selecting a field for alfalfa production. Sloping fields are prone to erosion and require erosion control practices to keep soil and seed in place. Fields with less than 2 percent slope are ideal, but if not leveled properly, these fields are prone to water logging in lower areas, which can lead to irregular alfalfa establishment across the field.

Herbicide residues from previous crops can be harmful to alfalfa seedlings. Alfalfa is sensitive to picloram (sold as Grazon™ P+D and Tordon™ 22K) and to sulfonylurea herbicides such as Ally® and Finesse®. If any of these herbicides were used, wait 22 to 36 months before planting alfalfa. Always check the rotational crop restrictions section on the labels of all herbicides applied before seeding alfalfa. If rotating to alfalfa at an interval shorter than specified by the herbicide label, a field bioassay must be successfully completed.

Finally, make sure the site is absent of alfalfa autotoxicity. Residues present in the soil from a previous alfalfa crop may inhibit new alfalfa seedling root development. To avoid autotoxicity, it is recommended at least a one-year interval occurs between terminating an old alfalfa stand and re-seeding a new stand. Some locations may require longer intervals. To learn more about alfalfa autotoxicity, see Fact Sheet: PSS-2601 Alfalfa Autotoxicity: A Good Reason to Rotate Alfalfa Fields.

Figure 1. Alfalfa scalding (left) and phytophthora root rot disease (right) due to water logging conditions.

Soil Testing and Fertilization

A routine soil test will show soil pH, plant available phosporus and potassium. Obtaining a representative sample is critical to obtaining an accurate estimate of fertility needs. To do this, take 15 to 20 soil cores 6 inches deep following a W-sampling pattern. Avoid non-representative areas such as wet spots. Put the core samples in a clean bucket, mix thoroughly, remove rocks and plant material, place the soil mix in a soil sample bag, properly label the bag and send it for analysis. See fact sheet PSS-2207 How to Get a Good Soil Sample for more information on collecting soil samples. Fact sheet PSS-2225 OSU Soil Test Interpretations provides the soil test recommendations for the majority of crops grown in Oklahoma.

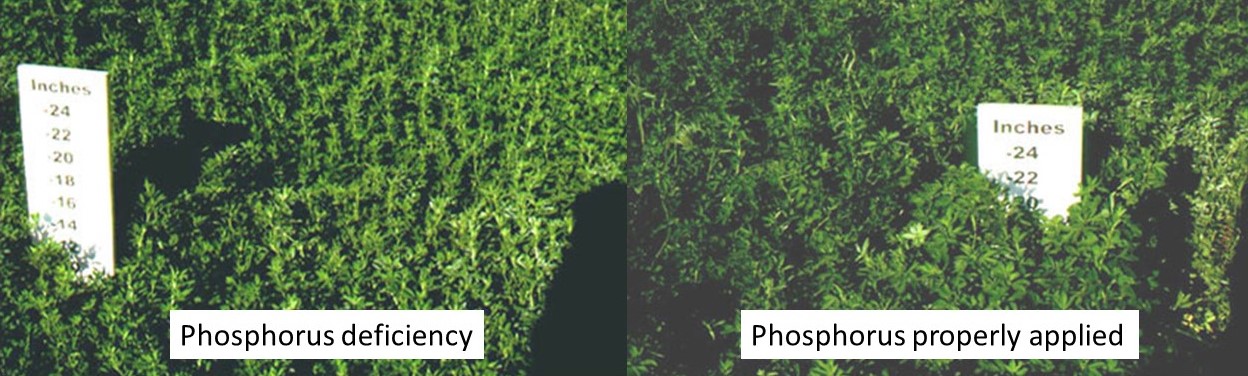

Soil nutrient deficiencies and low soil pH (acidity) should be corrected before seeding alfalfa. Proper soil pH is a critical factor for alfalfa. While most forages will grow well in soil pH 5.8 to 6.0, alfalfa requires pH of 6.3 to 6.9 for optimal growth. The process of raising soil pH through application of agricultural lime takes time. Soil sampling and analysis should occur six to 12 months before sowing to allow time for lime application and to increase the soil pH. For best results, lime, phosphate and potash should be incorporated into the upper 6 inches of soil during seedbed preparation.

Alfalfa symbiosis with nitrogen-fixing bacteria guarantee enough nitrogen supply in established stands, but research has shown that 25 to 30 pounds per acre of nitrogen when alfalfa is direct seeded may enhance establishment in coarse-textured soils. Finally, soil tests for secondary and micronutrients are not required before establishment. However, sub-surface samples (6 to 18 inches deep) are recommended when diagnosing nutrient deficiency symptoms in established stands. In these scenarios, both sulfur and boron levels will be of interest.

For more details on collecting soil samples or nutrient management refer to the Oklahoma Forage and Pasture Fertility Guide E-1021 or Oklahoma Soil Fertility Handbook (E-1039).

Figure 2. Alfalfa growth response to phosphorus fertilization.

Seedbed Preparation

Ensuring good surface drainage is critical before establishing alfalfa. General leveling to remove improperly placed dead-furrows and back-furrows should be done several months to one year before sowing alfalfa. Development of a well-drained field frequently requires several attempts. Observing where water stands between rains is one of the best indicators of drainage problems.

Seedbed preparation begins with the removal of the previous crop and involves many combinations of farming equipment. Generally, the normal steps include primary tillage, disking, leveling and smoothing. Primary tillage consists of moldboard plowing, chisel plowing or deep disking. Many producers believe that plowing at least 8 inches deep is essential to bury crop residue and control weeds by burying growing plants and ungerminated seeds. However, OSU researchers have found that a deep disking can be used as a substitute for moldboard or chisel plowing. In soils that develop hardpans, a chisel plow is commonly used to rip through existing hardpan layers. Shallow disking normally follows primary tillage. Disking breaks up clods and incorporates residue, lime, phosphate and potash. Soil conditions may require several diskings.

An ideal seedbed is firm on the surface, but loose enough in the root zone to allow rapid root penetration. Disking is often followed by spring-tooth and spike-tooth harrowing to break clods further and to help smooth the field. The final operation may be a corrugated roller or cultipacker to crush the remaining clods and finish firming the area. Preparing the seedbed should be done when the soil contains sufficient moisture so it crumbles when worked. There is usually a short time after each rain when soil moisture is just right. On certain sites, it may be desirable to maintain a significant amount of crop stubble and debris on the surface. This is especially important with sandy soils that are highly susceptible to wind and water erosion.

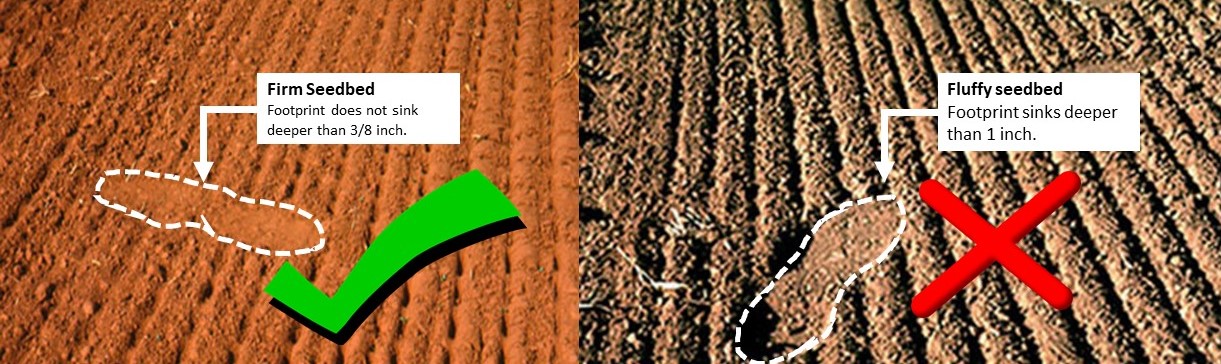

If preplant herbicides are used, they must be applied when the seedbed is fairly fine (no clods greater than 1/2 inch) and incorporated about 4 inches deep. At this depth, the herbicide is uniformly distributed in the top 2 inches. If using PTO-driven equipment (tillers, cultivators, hoes), only one incorporation pass is necessary. If using a tandem disk, two incorporation passes in different directions is recommended. On the surface of the final seedbed, clods should be no larger than 1/2 inch in diameter, yet should not be powdery. A seedbed is sufficiently firm when an entire footprint is visible but sinks no deeper than 3/8 inch (Figure 3) or if the impression of a tractor tire sinks no deeper than the tread bar.

Variety Choice

The choice of alfalfa variety is one of the few irreversible management decisions in stand establishment. That choice has a significant effect on hay yield, degree of insect and disease resistance and stand longevity, all of which affect profits. However, once the seeds are sown, the variety cannot be improved. In a nutshell, these are the main considerations when selecting alfalfa varieties:

- Select varieties with appropriate winter hardiness (3 to 4) and fall dormancy (4 to 6) ratings for our Oklahoma.

- Choose varieties that are resistant to the common diseases in your area to increase stand persistence.

- Look at the university variety trials nearest your location to select a high-yielding varieties for your soil and weather conditions.

For more details on how to select an appropriate alfalfa variety to your location, refer to Fact Sheet PSS-2602 Selecting Alfalfa Varieties.

Planting dates

Fall Sowing: Alfalfa is traditionally planted in late August and early September in Oklahoma. Fall plantings can be extended into early October in central and southern Oklahoma, if the field can be irrigated immediately after sowing to obtain emergence. Plants coming up after early October may not have adequate root development to survive the winter. A good rule of thumb is alfalfa plants need five leaves before the first hard freeze (20 F). Expect 4 to 5 tons per acre of weed-free hay in the first season from alfalfa planted in early September that is kept pest free.

Spring Planting: Spring-sown alfalfa in Oklahoma is more risky than fall plantings. This is primarily due to more problems with drying winds, insects, weeds and intense rains that tend to crust the soil. Planting between mid-March and mid-April is critical for success with spring-sown alfalfa. This allows seedlings enough time to develop good root systems before the onset of high temperatures (above 90 F). The use of multiple-pest resistant varieties, excellent seedbeds and preplant incorporated herbicides is even more important with spring plantings. Spring sowing is more likely to be successful in the eastern half of the state where rainfall is higher, but can be successful statewide if irrigation is used.

Normally only one or two cuttings are possible during the first summer for spring-sown alfalfa. Even in subsequent years, yields for spring-sown stands tend to be less than those produced by fall-sown crops. Ultimately, it is advisable to consider an annual forage crop to sow in spring and then harvest it in time to plant alfalfa in the fall.

Planting

Having soil moisture 1 to 3 inches below the surface at planting is important; however, moisture at the surface is not important. Most successful alfalfa plantings are made when the seed is planted into dry surface soil. Moisture required for germination and initial seedling growth comes from rain or irrigation after planting. If the soil is dry to a depth of 4 to 6 inches, it may take over 1 inch of rain to wet the soil enough for germination of the alfalfa.

Seed depth and rate

Alfalfa seeds are very small and correct seeding depth is crucial for establishment. The soil covering the seed needs to be thick enough to provide moisture for germination, but thin enough to allow the small shoot to reach the surface. The ideal seeding depth varies according to soil types. Place seeds ¼ to ½ inch deep in heavy texture soils, and ½ to 1 inch deep in sandy soils.

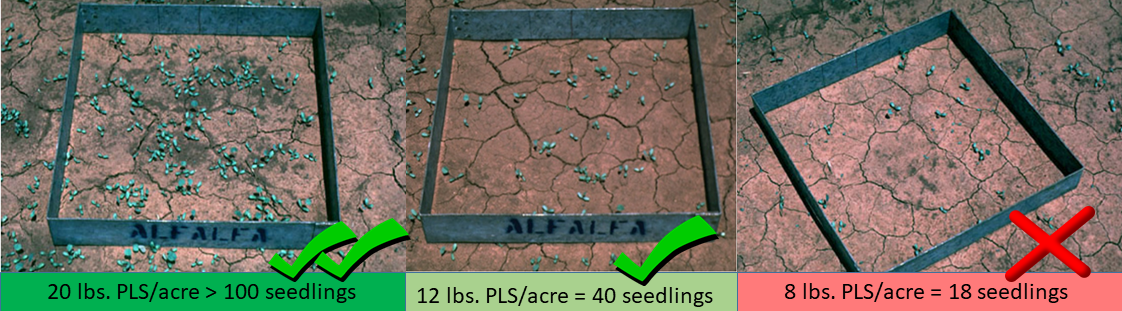

To attain 25 to 30 vigorous plants per square foot before first winter onset, alfalfa should be seeded at approximately 80 pure live seeds (PLS) per square foot. This requires 12 to 15 pounds of PLS per acre (approximately 250,000 seeds in 1 pound) In a seed bag, there is more than PLS. Check the label for percentage of pure seed, percentage of germination, and percentage of hard seed. Hard seed are seeds that will geminate within 30 days of seeding; therefore, percent viable seeds is the sum of percentage of germination and percentage of hard seed. Use the following formula to calculate or proper seeding rate:

Table 1. Formula's to calculate proper seeding rate.

| From bag seed tag | 9% light-coated seed | 34% light-coated seed |

|---|---|---|

| % germination | 66 percent | 56 percent |

| % hard seed | 24 percent | 14 percent |

| % pure seed | 90 percent | 70 percent |

| % PLS | 81 percent | 63 percent |

| Seed rate (for 15 lbs. PLS/acre) | 18.5 lbs/acre | 23.8 lbs/acre |

Figure 4. Different seed rates and their respective number of emerged seedlings. Thicker than necessary (left), thick enough (center), not thick enough (right) for good establishment (25 to 30 plants per square foot must be attained before first winter onset).

Planting Equipment

The following common types of equipment are used for successful alfalfa establishment:

Specialized drills have a box for small seeds and disk openers with depth bands to accurately place the seed 1/4 to 1 inch deep. Packer wheels firm soil over and around seeds. This type of drill is especially good on very firm seedbeds.

Double corrugated roller seeders drop the seed between the corrugated rollers. The first roller breaks small clods and firms the seedbed. The second roller splits the ridges made by the first roller, covers the seed and provides additional firming of the soil. While these are considered the best alfalfa seeders for most conditions, they may leave sandy soils very vulnerable to wind erosion.

Grain drills, equipped with small-seed attachments, can accurately meter alfalfa seed. The major problem in using grain drills is controlling seed placement depth. If the furrow created by the drill is too deep, rain can wash soil into the furrow and cover alfalfa seeds too much. Allowing seed drop tubes to wave from side to side leaves many seeds on the soil surface. Very few seeds left on top of the soil develop into vigorous plants even under ideal conditions. Tubes can be tied so seeds fall in front of press wheels; otherwise, rolling after the planter in a separate operation helps improve emergence percentages.

Pneumatic seeders, mounted on flotation-wheeled vehicles, can sow alfalfa fields rapidly and accurately. Seed is metered from a hopper and carried through tubes along booms (20 to 50 feet long) with air. These machines work well on fluffy, dry, sandy soils that cannot be firmed by rolling. Seed is blown onto the soil from delivery tubes spaced 6 to 12 inches along the booms. Lightly packing, dragging a chain or harrowing covers seed. The main advantage to this type seeder is the rapid speed they travel. Producers can sow several acres per hour, which may be important, just before a predicted rain.

Aerial sowing onto freshly prepared seedbeds is another method used to sow alfalfa with good success, especially in fluffy seedbeds. Use an aerial applicator experienced in sowing alfalfa. With broadcast planting, two passes in a crossing pattern may be necessary for uniform coverage. Rolling the fields after aerial sowing is advisable.

No-till or minimum-tillage drills can do a good job of placing alfalfa seed at the correct depth. When establishing alfalfa on steep slopes or erosive or shallow soils, this type of drill is best.

Dusting-in the seed is an alternative when it is impossible to prepare a firm seedbed due to excessively dry conditions. The bottom ends of the flexible seed tubes are removed from the drill shanks or disk openers, and the seed drops on the surface of the shallow furrow. A drag chain may be used to cover the seed with soil. Rainfall then firms the soil.

Seed Inoculation

Rhizobium bacteria infects alfalfa roots, creating nodules where atmospheric nitrogen is fixed. This symbiotic relationship allows alfalfa to produce great quantities of quality forage without nitrogen application if roots develop enough nodulation. Effective nodules on alfalfa are generally pink to deep red when split open and can fix several hundred pounds of nitrogen per acre each season. Most soils contain Rhizobium bacteria, but not in enough quantity for optimal nodulation. To guarantee enough nodulation, purchase seed pre-inoculated or treat the seed with commercial inoculum. Most commercial seeds sold today are pre-inoculated with Rhizobium and often include a fungicide that protects seedlings against Pythium spp. and Phytophthora spp. diseases. An additional fungicide seed treatment may be required if the area had aphanomyces issues (a type of water mold) in the past. Consult your local Extension office for trade names and fungicide treatments that might be most appropriate for your situation.

Inoculation is easy and cheap. It is probably the best insurance an alfalfa farmer can buy. A sticker (additive that helps inoculum adhere to seed) helps nodule-forming bacteria adhere to seed. Commercial preparations of stickers and rhizobium are available from inoculant manufacturers and do an excellent job. Closely following manufacturer’s instructions normally produces the best results. An alternative to commercial stickers is to use milk or a water-based solution containing 10 to 20 percent table syrup or sugar. One pint is sufficient sticker for a bushel of seed. Moisten all seeds with the sticker (in a cement mixer, if possible) then add the inoculant. If the mixture is still too moist, add more inoculant, finely ground limestone, or powdery, dry soil.

Heat, direct sunlight and drying are all detrimental to the survival of rhizobia. For this reason, it is important to store inoculant packets in a cool place. Expiration dates are printed on inoculant packets and pre-inoculated seed bags. The date indicates when most of the bacteria will have died under normal storage conditions. If there are questions about the viability of bacteria on inoculated seed due to the length of storage and storage conditions, seed should be re-inoculated. Use mineral oil as sticker to re-inoculate lime-coated seed rather than water-based solutions. In this case, 1/2 ounce of mineral oil per pound of seed is recommended.

Weed Control

Weed control should begin with site selection. A suitable site is one that is not severely infested with weeds (even in the fence rows). Perennials should be controlled one or two years before planting alfalfa. Also, annual weeds should not be allowed to produce seed in crops preceding alfalfa.

Preplant incorporated herbicides are a must for spring-sown alfalfa, but a postemergent treatment is a better option for fall-sown alfalfa. This difference in herbicide approach relates to variation in weed species competitiveness as well as differences in environmental conditions in the spring vs. fall. Preplant herbicides control most summer annual weeds but are not as effective on many of the cool-season weeds.

A disadvantage of preplant treatments is that the loosening and drying associated with the incorporation may result in a marginal seedbed, especially in the fall when soil moisture is limiting.

Most weeds in fall-sown alfalfa emerge at the same time as alfalfa (late September).

They remain small and inconspicuous until late winter or spring. Postemergent control

is most effective when applied to actively growing weeds in October or November.

Herbicides should be applied if weed populations warrant. Producers should be sure

that costs for chemical weed control will be recouped by increased forage quality

and yield at first harvest.

Insect and Disease Control

Insects begin attacking alfalfa plants at emergence. Frequent scouting of new stands is essential to good insect control. Grasshoppers, armyworms, cutworms and other general feeders can infest a new stand quickly. Timely application of insecticides is the only reliable method of control. With no-till alfalfa, it is critical that insects, such as grasshoppers, be controlled before planting.

Spotted alfalfa aphids, and occasionally pea aphids, build up during the fall on seedling alfalfa. Blue alfalfa aphids are present nearly every winter and spring. Using adapted, resistant varieties and good cultural practices that encourage rapid growth provide the best control for aphid infestations. Early detection is an important factor because it allows timely insecticide application.

Diseases, such as damping off and root rots, are sometimes problems with alfalfa stand establishment. Fungicidal treatments, applied to seed or sprayed on seedlings, are effective for a short time and may make the difference between successful stand establishment and failure. Genetic resistance in conjunction with crop rotation, good land preparation practices and good seedbed preparation are more long-lasting control measures. Root rots are most commonly found in soils that are wet for a prolonged period; therefore, providing drainage before sowing is an excellent disease prevention measure.